Method for making container cup and structure thereof

A technology for container cups and manufacturing methods, which is applied in the field of container cup manufacturing methods and structures, and can solve problems such as inaccurate bonding, difficulty in coating the entire circumference, and uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

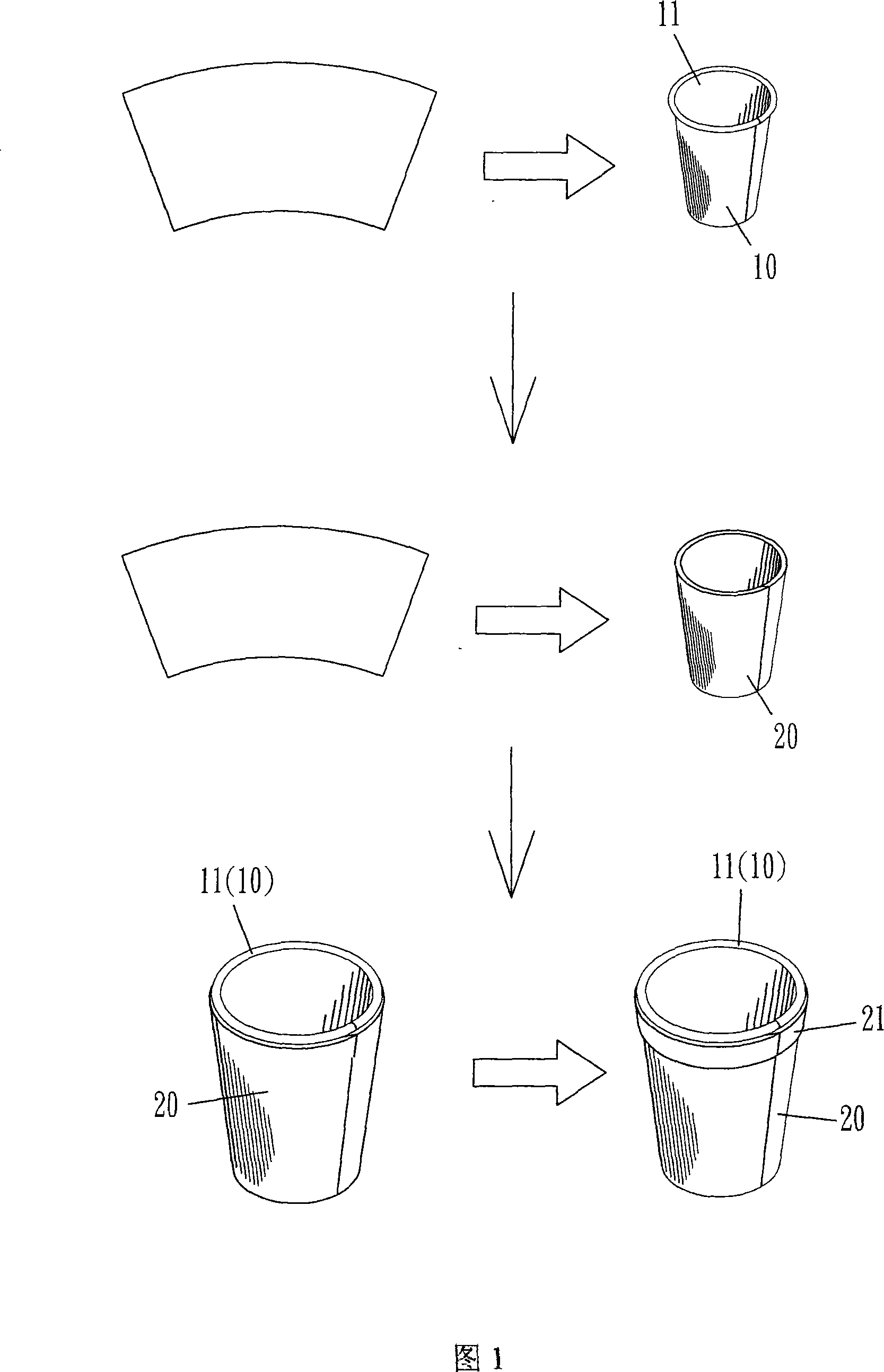

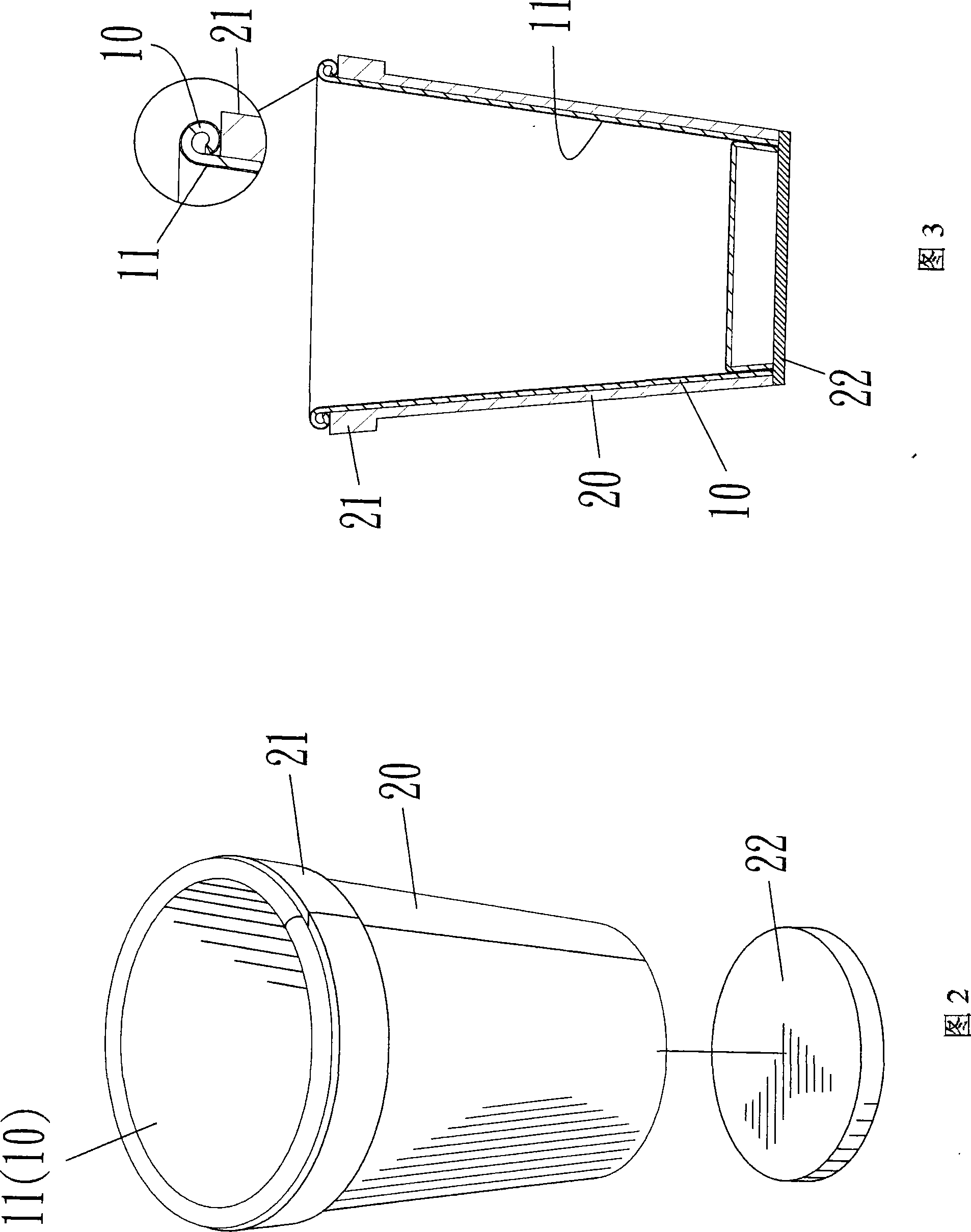

[0026] As shown in accompanying drawing 1 to accompanying drawing 3, the preparation method of container cup of the present invention comprises:

[0027] At least one or both surfaces of a paper / board are covered with a biodegradable film layer 11, and then cut and pressed into a paper cup 10, wherein the film layer 11 can be a polylactic acid (PLA) film layer extracted from natural plants, Any biodegradable polymer material, polyethylene (PE) film layer extracted from petroleum, polyethylene terephthalate (PET) film layer, polypropylene (PP) film layer and other non-biodegradable materials coating made;

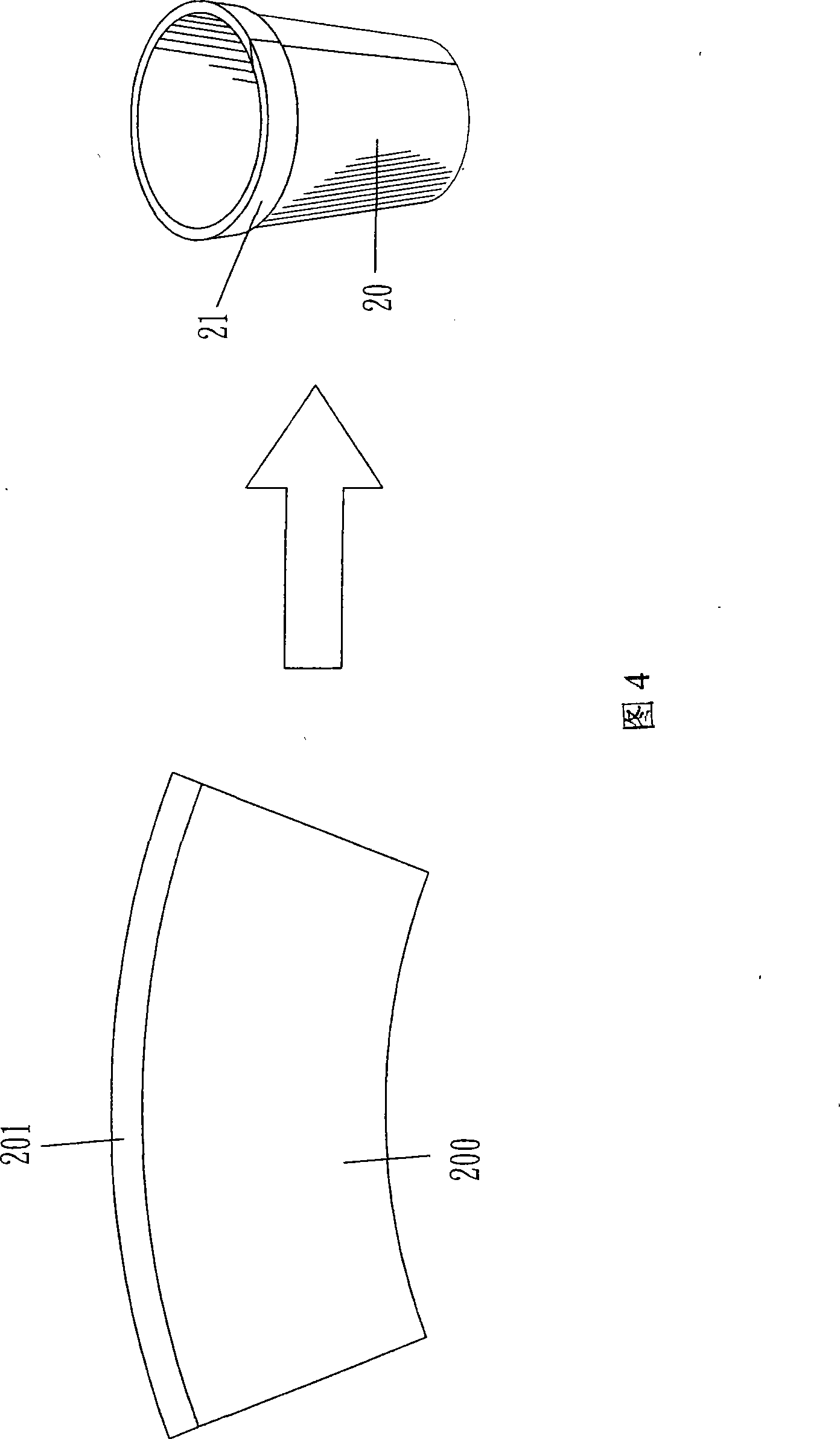

[0028] A cup-shaped electronic bridging foam cup body 20, its foam material can be biodegradable polylactic acid (PLA), polyhydroxycarboxylate (PHA), Biomax PET, Fepol, Piomax, Ecoflex, Mater-Be or Non-biodegradable polyethylene terephthalate (PET), polyethylene (PE) or polypropylene (PP), any of which is made into electronic bridging foam board, after printing, type cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com