Producing method of environment protection cup and structure thereof

An environmentally friendly cup and a manufacturing method technology, which is applied to the manufacturing method and the structure field of the environmentally friendly cup, can solve the problems of insufficient heat resistance, slight softening of the foam, and unreliable connection of the cup structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

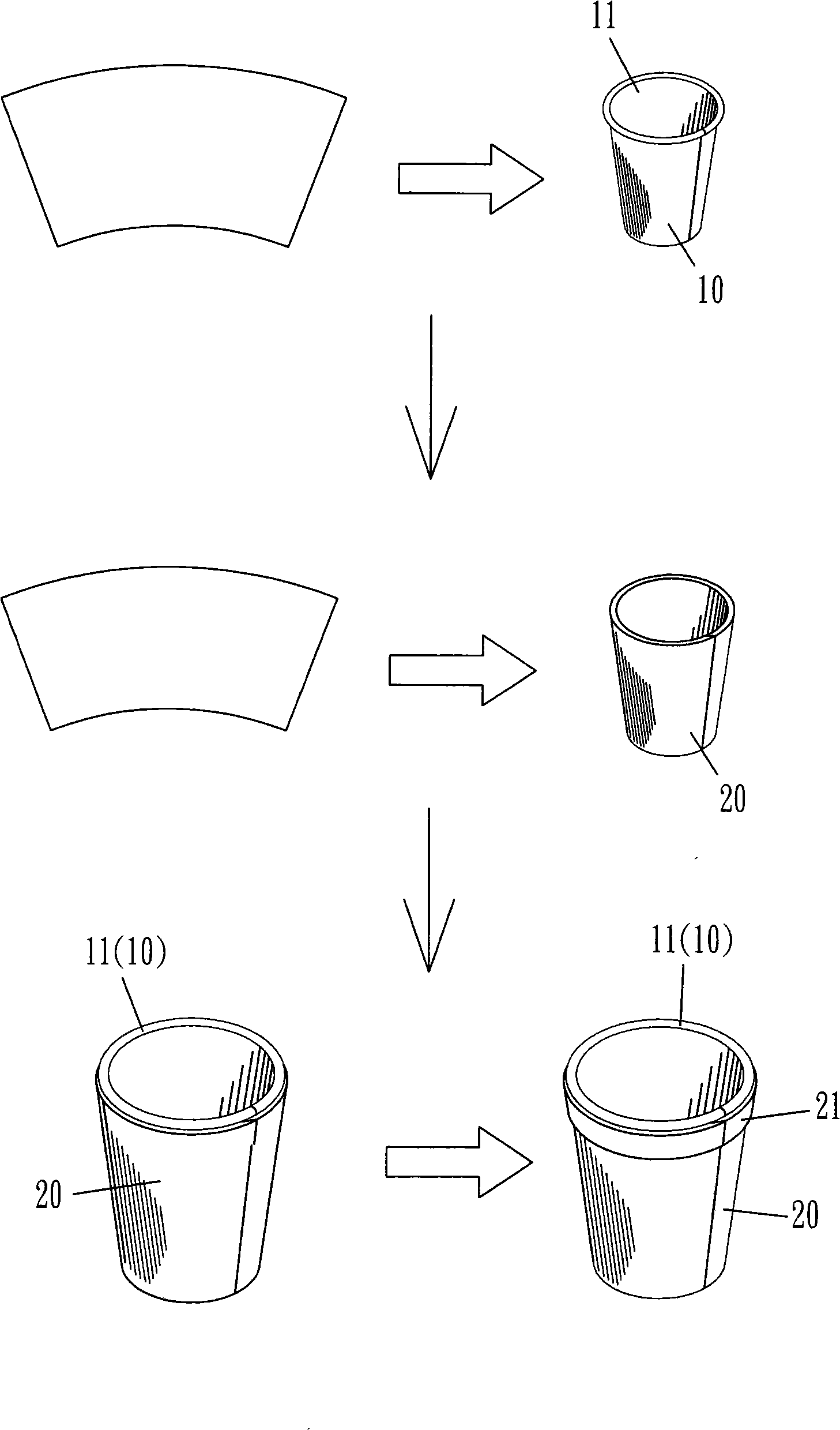

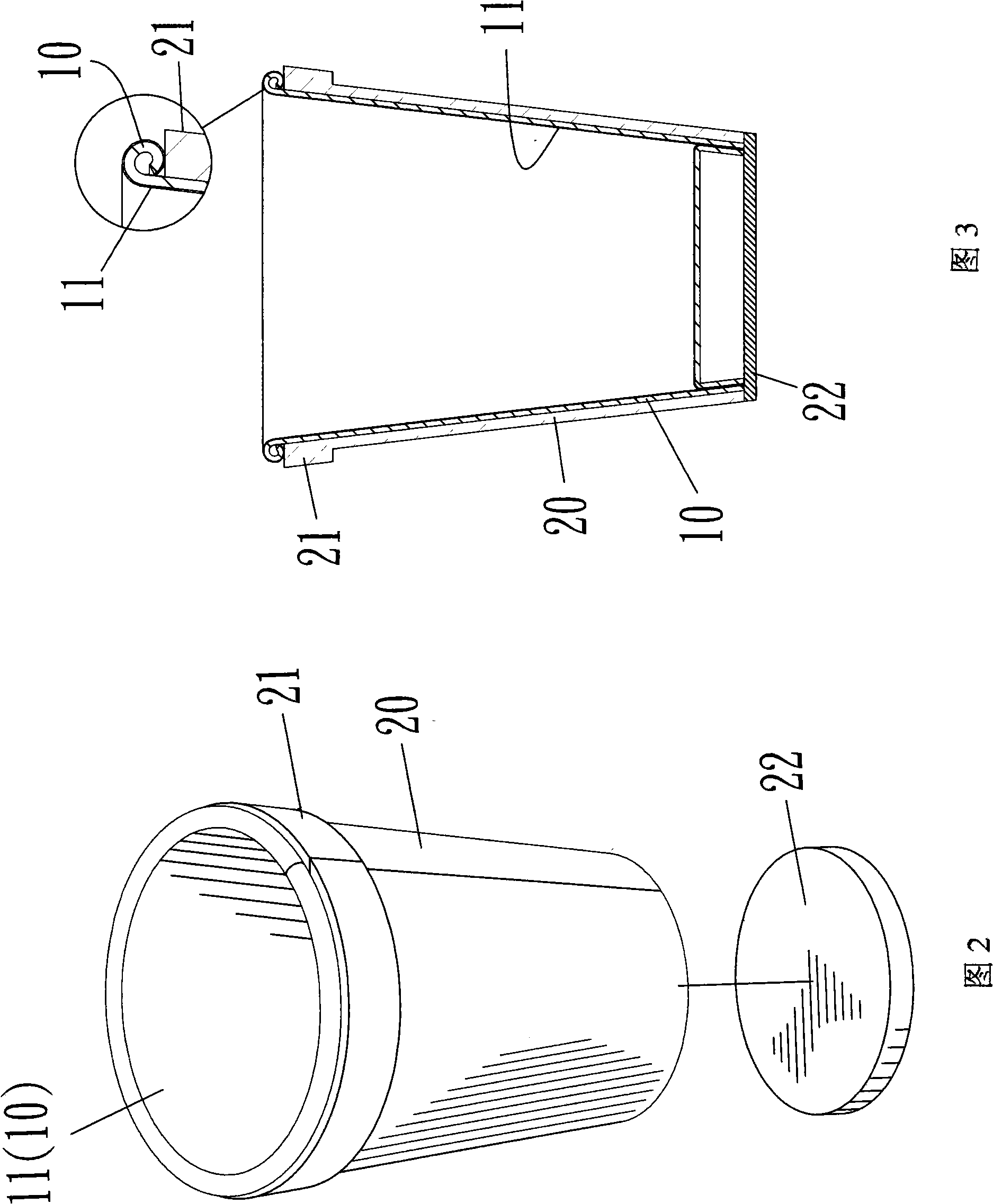

[0031] as attached figure 1 Shown in accompanying drawing 3, the method for making of environmental protection cup of the present invention mainly comprises:

[0032] At least one or both surfaces of a paper / board are covered with a fully biodegradable film layer 11, and then cut and pressed into various paper cups 10, so that they can be directly decomposed into carbon dioxide and water by composting , to achieve the benefits of no burden on the environment and no pollution;

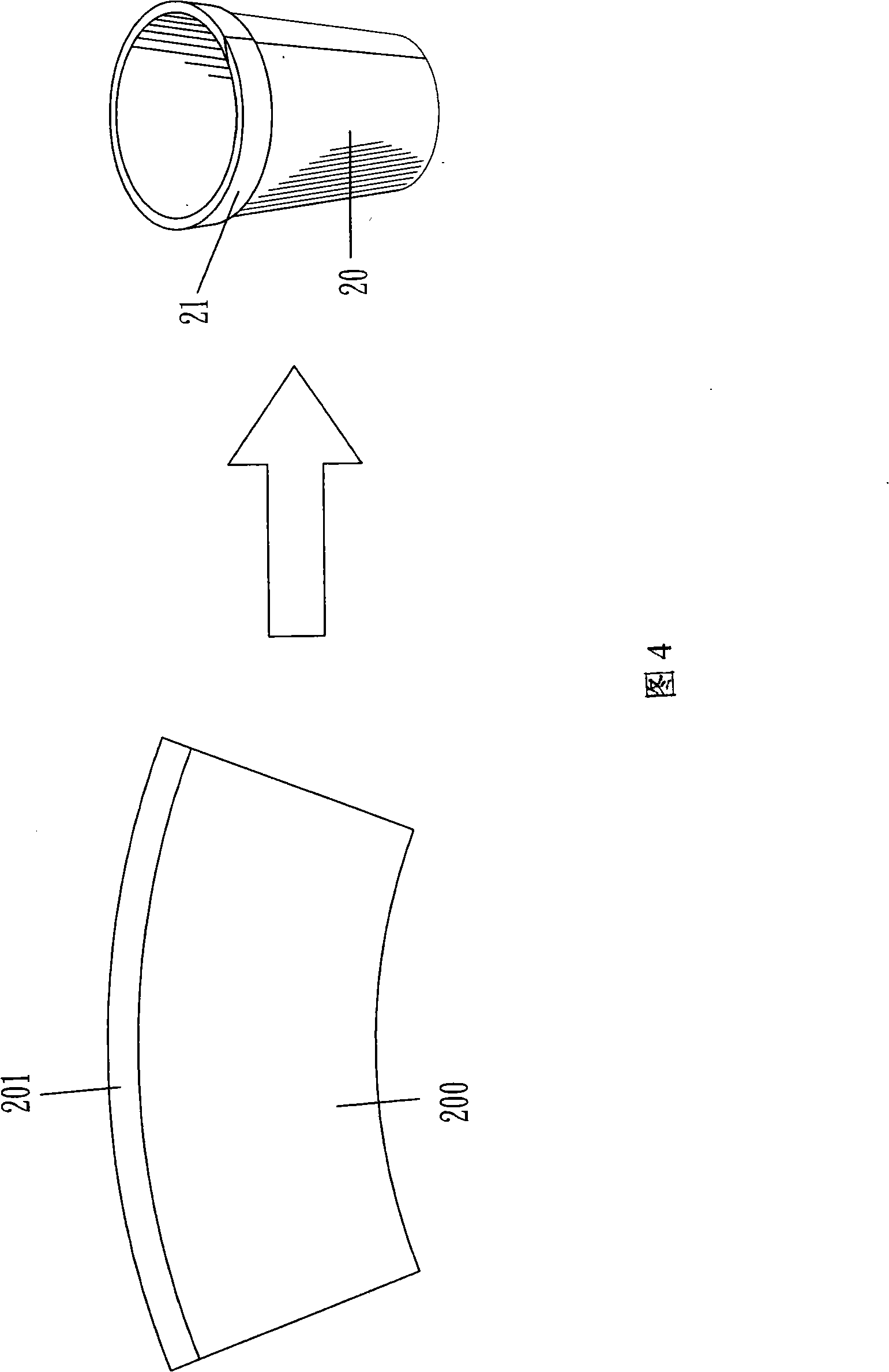

[0033] A foaming cup body 20, made entirely of biodegradable plastics, using supercritical carbon dioxide micro-extrusion foaming technology to make a rolled or flat plate body 200, and then printing, cutting, and folding the pattern or characters of the plate body 200 The second half of the pattern is processed into a fan-shaped semi-finished product, and then the board body 200 is glued into a cup-shaped foam body by means of ultrasonic heat pressing, electric heat pressing, hot air pressing or high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com