Urethanated unsaturated water-soluble vinyl multipolymer and preparation method thereof

A multi-copolymer, unsaturated technology, applied in the field of printing, can solve the problems of many side reactions and by-products, the influence of printing resistance, and the poor stability of emulsified emulsions, and achieve good compatibility, good drug resistance, and good film-forming properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

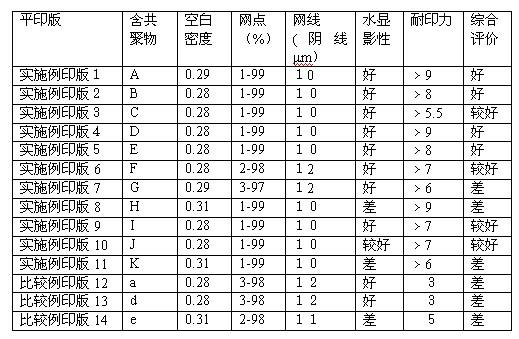

Examples

Embodiment 1

[0063] Example 1 (copolymer A)

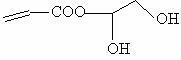

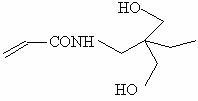

[0064] Add 500 g of DMF (N, N-dimethylformamide) and 120.0 g (60 % by weight) SM (styrene), 40.0 g (20 % by weight) AN (acrylonitrile), 20.0 g (10 % by weight) HEMA (hydroxyethyl methacrylate), 20.0 g (10 % by weight) AMPS (2- Acrylamide-2-methylpropene sulfonic acid), heated and stirred under nitrogen protection until the solid dissolved, then added 1.0g AIBN (azobisisobutyronitrile), reacted at 70°C for 3 hours, added 0.5g AIBN, and added di Dibutyltin laurate 0.1g, 23.8g MOI (X2 exemplary compound), ZJ-701 (nitroxyl piperidinol) 0.1g, and the reaction ended after 1 hour.

[0065] The solid content is 30.9% by weight, the GPC weight average molecular weight Mw=57900, and the iodine value Iv=17.4gI2 / 100g resin.

Embodiment 2

[0066] Example 2 (Copolymer B)

[0067] Add 500 g of dioxane and 110.0 g (55% by weight) of SM (styrene) dried over anhydrous sodium sulfate to a 1000 ml four-necked flask with temperature-controlled heating, mechanical stirring, reflux and nitrogen protection device , 30.0g (15% by weight) MAN (methacrylonitrile), 30.0g (15% by weight) hydroxyethyl acrylate, 30.0g (15% by weight) acryloylmorpholine, heated and stirred until the solid was dissolved under nitrogen protection, and then added 1.0 gAIBN (azobisisobutyronitrile), add 0.5gAIBN after reacting at 90°C for 3 hours, add 0.1g of dibutyltin dilaurate after reacting for 4 hours, 40.1gMOI (X2 example compound), ZJ-701 (nitrogen free Base piperidinol) 0.1g, after 1 hour, the reaction was finished.

[0068] The solid content is 32.4% by weight, the GPC weight average molecular weight Mw=63400, and the iodine value Iv=22.3gI2 / 100g resin.

Embodiment 3

[0069] Example 3 (copolymer C)

[0070] Add 500 g of ethyl acetate and 120.0 g (60% by weight) of SM (styrene), 40.0 g (20% by weight) AN (methyl cyanoacrylate), 20.0 g (10% by weight) hydroxypropyl methacrylate, 20.0 g (10% by weight) PEGMA (methoxypolyethylene glycol methacrylate, Mn=2040) Nitrogen protection, heating and stirring evenly, add 1.0g AIBN (azobisisobutyronitrile), add 0.5g AIBN after reacting at 40°C for 3 hours, add 0.1g lead octanoate after reacting for 4 hours, 21.5gMOI (X2 exemplary compound ), ZJ-701 (nitroxyl piperidinol) 0.1g, the reaction ended after 1 hour.

[0071] The solid content is 30.7% by weight, the GPC weight average molecular weight Mw=31300, and the iodine value Iv=16.4gI2 / 100g resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com