Alkali-activated binder with no cement, method for fabricating mortar using it, and method for fabricating alkali-activated reinforcement mortar with no cement

A cement-free, alkali-active technology that is used in cement production, climate sustainability, sustainable waste treatment, etc. to achieve high resistance to freezing and melting, low heat of hydration reaction, high initial strength and long-term strength development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0047]In the first embodiment of the present invention, the cement-free deactivated adhesive is formed by mixing Source material and Alkali mineral material.

[0048] At this time, the above-mentioned source materials include more than one of blast furnace slag (Blast-Furnace Slag), fly ash (FlyAsh) and metakaolin (Mata-Kaolin), and the above-mentioned basic inorganic materials include sodium silicate, powdered hydrogen More than one of sodium oxide, liquid water glass and liquid sodium hydroxide.

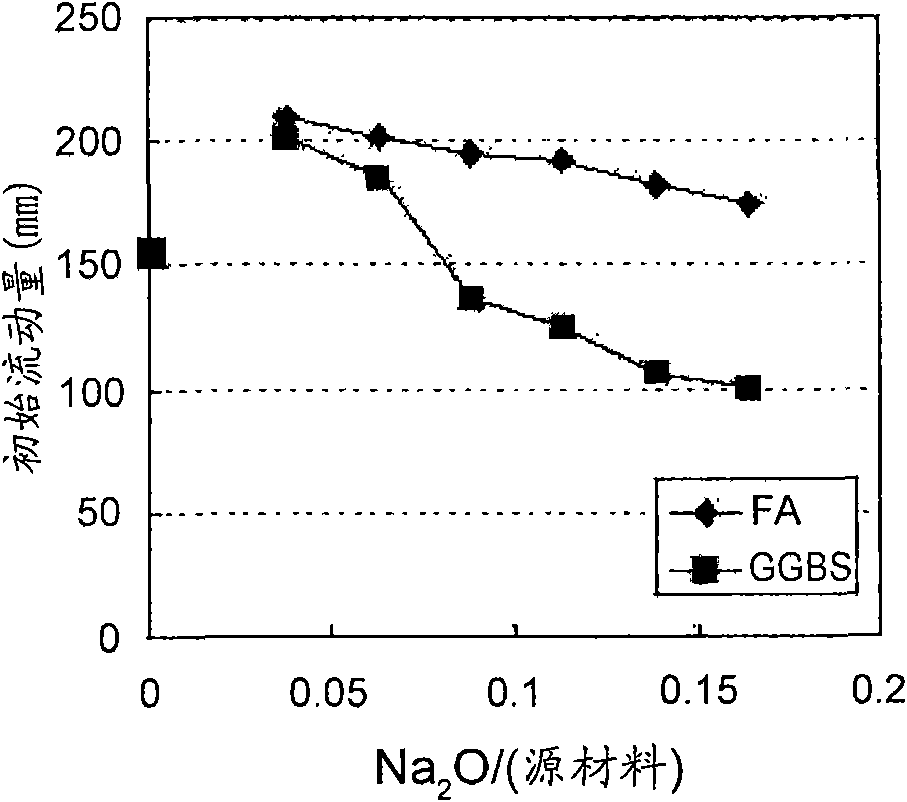

[0049] At this time, in the cement-free deactivated adhesive of the present invention, in the components constituting the above-mentioned basic inorganic materials, the weight ratio of the sodium material to the source material is 0.038 to 0.14, and the weight ratio of the above-mentioned sodium material to the source material determines the present invention. Invented the mechanical properties of cement-free deactivated adhesives such as fluidity, strength and drying shrinkage.

...

no. 2 example

[0086] The second embodiment of the present invention is a method for preparing cement-free alkali active mortar, mixing more than one of industrial wastes such as blast furnace slag (Blast-furnace slag), fly ash (Fly ash) and metakaolin (Mata-kaolin) The cement-free alkali-activated mortar is prepared from source materials, alkali-activated binders of alkaline inorganic materials including sodium materials, water and sand.

[0087] In this case, the alkaline inorganic material including sodium material includes one or more of sodium silicate, powdery sodium hydroxide, liquid water glass and liquid sodium hydroxide.

[0088] In this case, the basic inorganic material may include more than one of potassium silicate, calcium sulfur and dicalcium silicate. And when preparing deactivation mortar later on, also in order to improve fluidity, suppress drying shrinkage and include above-mentioned potassium silicate, calcium sulfate and dicalcium silicate.

[0089] In the above-mentio...

no. 3 example

[0132] The third embodiment of the present invention is a method for preparing cement-free reinforced alkali-active mortar, in a cement-free alkali-active binder including blast furnace slag, alkaline inorganic materials including sodium materials, calcium hydroxide, melamine water reducer and borate , mix dry sand and water.

[0133] In addition, the above-mentioned dry sand is selected to have a maximum diameter of 5 mm, and the mixing ratio is 2.5 relative to the above-mentioned cement-free deactivating binder.

[0134] In addition, the above-mentioned water was mixed in a weight ratio of 0.55 with respect to the above-mentioned cement-free deactivating binder.

[0135] The above-mentioned blast furnace slag is the main raw material used as the above-mentioned cement-free deactivating binder, and is slag produced when pig iron is extracted from iron ore.

[0136] That is, the cement-free reinforced deactivated mortar according to the third embodiment of the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com