Rice straw reinforced foam concrete and method for preparing same

A foamed concrete, straw and straw technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of poor working performance, material precipitation, low strength, etc., and achieve obvious later strength growth, long-term strength stability, and initial strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

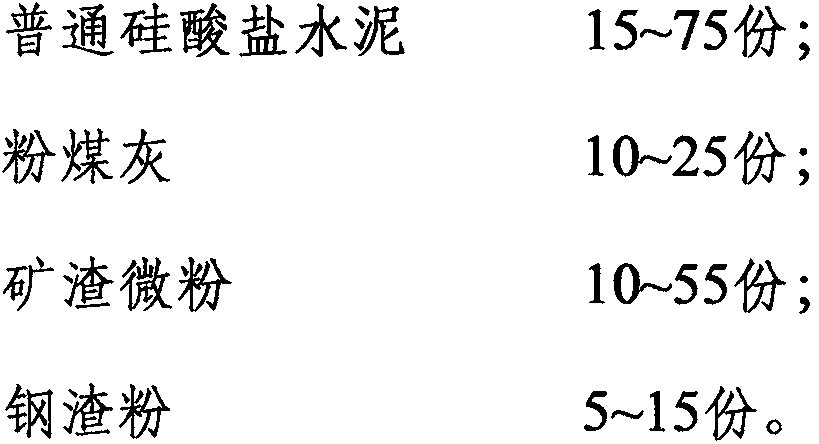

[0030] Mix 32.5 ordinary Portland cement, fly ash, slag powder, and steel slag powder according to the following mass percentages:

[0031]

[0032] Mix the above materials evenly and grind them until the specific surface area is 400m 2 / kg. The modified rice straw fiber is wetted with 5% water of fiber mass. Pre-wet the mixing tank of the mixer to ensure that there is no clear water in the mixer. Add 32.5 parts of ordinary Portland cement, fly ash, slag powder and steel slag powder to the mixer, add 40.5 parts of tap water, and start the mixer. Stir for 300s to obtain foam concrete slurry; add animal protein foaming agent 1.2 times the volume of the foam concrete slurry to the above foam concrete slurry and continue stirring for 30 seconds, and then modify the rice straw fiber per cubic meter of foam concrete slurry The modified rice straw fiber was added in a proportion of 3kg, stirred for 30 seconds, molded, formed, and naturally cured for 28 days to obtain a foam concr...

Embodiment 2

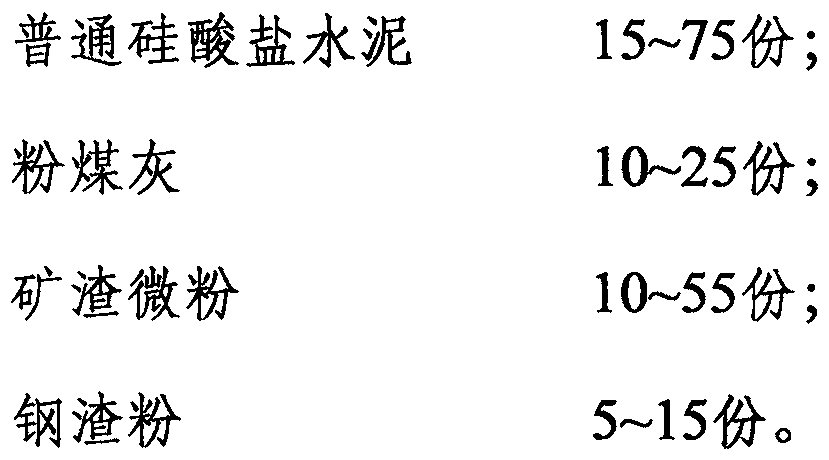

[0035] Mix 42.5 ordinary Portland cement, fly ash, slag powder, and steel slag powder according to the following mass percentages:

[0036]

[0037] Mix the above materials evenly and grind them until the specific surface area is 380m 2 / kg. The modified rice straw fiber is wetted with 10% water of fiber mass. Pre-wet the mixing tank of the mixer to ensure that there is no clear water in the mixer. Add 42.5 parts of ordinary Portland cement, fly ash, slag powder and steel slag powder to the mixer, add 51.0 parts of tap water, and start the mixer. Stir for 280s to obtain foamed concrete slurry; add rosin foaming agent 1.4 times the volume of the foamed concrete slurry to the above foamed concrete slurry and continue stirring for 90s, and then mix the modified rice straw fibers in each cubic meter of foamed concrete slurry The modified rice straw fibers were added in a proportion of 6kg, stirred for 90 seconds, molded, formed, and naturally cured for 28 days to obtain foame...

Embodiment 3

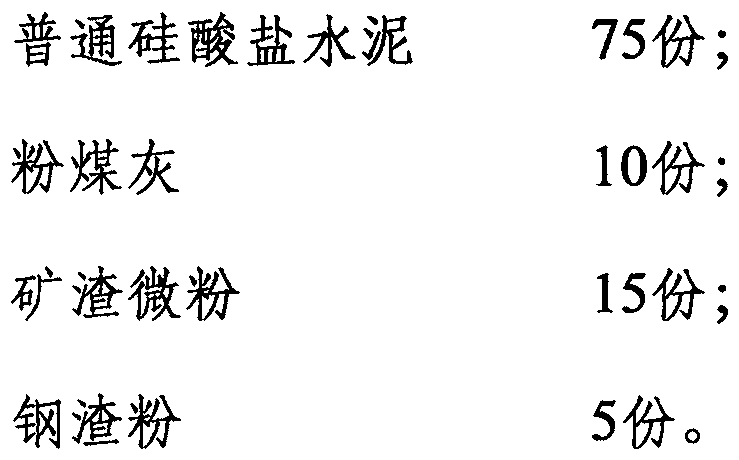

[0040] Mix 42.5 ordinary Portland cement, fly ash, slag powder, and steel slag powder according to the following mass percentages:

[0041]

[0042] Mix the above materials evenly and grind them until the specific surface area is 450m 2 / kg. The modified rice straw fiber is wetted with 8% water of fiber mass. Pre-wet the mixing tank of the mixer to ensure that there is no clear water in the mixer. Add 42.5 parts of ordinary Portland cement, fly ash, slag powder and steel slag powder to the mixer, add 37.5 parts of tap water, and start the mixer. Stir for 120s to obtain the foamed concrete slurry; add vegetable protein foaming agent 1.3 times the volume of the foamed concrete slurry to the above-mentioned foamed concrete slurry and continue stirring for 90s, and then modify the amount of rice straw fiber per cubic meter of foamed concrete slurry The modified rice straw fiber was added at a ratio of 9kg, stirred for 60 seconds, molded, formed, and naturally cured for 28 day...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com