Multilayer structure environmental barrier coating for silicon carbide ceramic matrix composite material and preparation method thereof

A silicon carbide ceramic-based, multi-layer structure technology, applied in the field of materials, can solve problems such as inability to use for a long time, failure, etc., and achieve the effects of good bonding, solving thermal mismatch, and improving thermal protection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

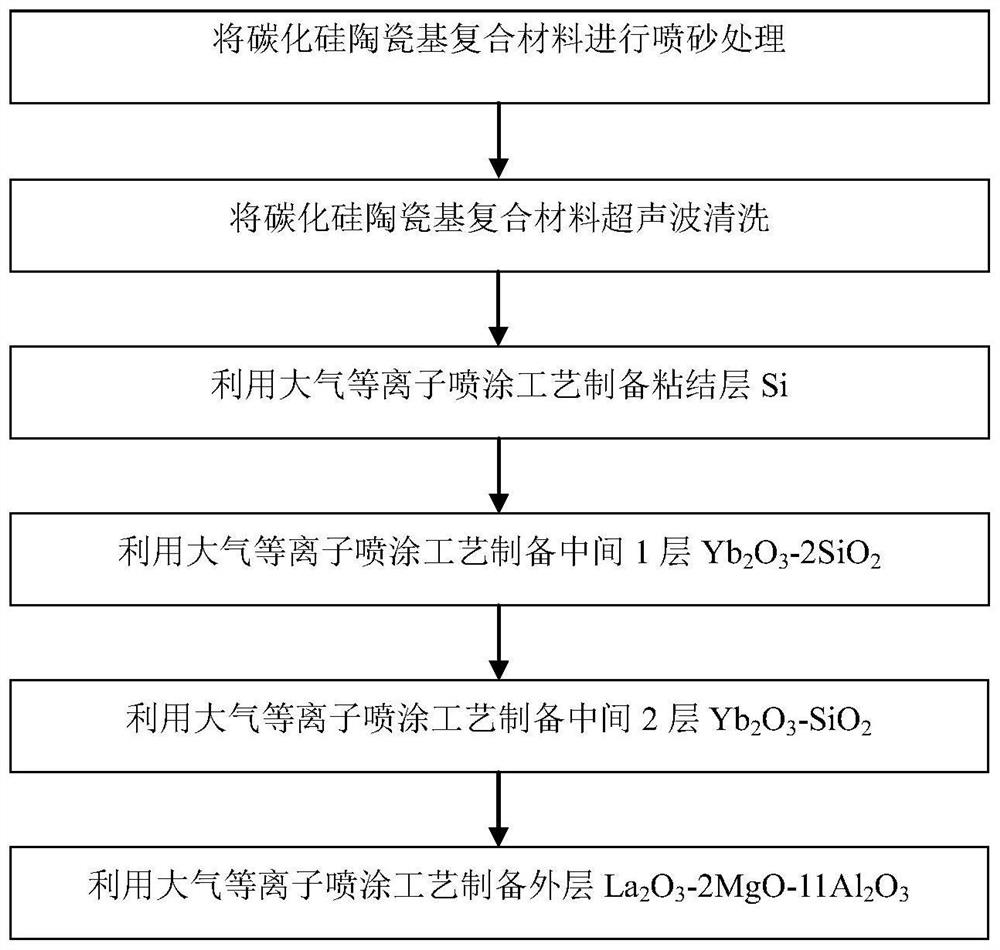

[0031] A multilayer structure environmental barrier coating for silicon carbide ceramic matrix composites and a preparation method thereof, such as figure 1 shown, including the following steps:

[0032] (1) The silicon carbide ceramic matrix composite material is subjected to sandblasting pretreatment. The sandblasting process conditions are: 100 mesh corundum sand, compressed air pressure of 0.6Mpa, and then tested with a roughness meter. The pretreated silicon carbide ceramic matrix The surface roughness of the composite material is 13.5μm;

[0033] (2) ultrasonically clean the silicon carbide ceramic matrix composite material that has been sandblasted in step (1) in alcohol with a concentration of 98%, for 12 minutes, and dry at 100°C;

[0034] (3) The silicon carbide ceramic matrix composite material that has been ultrasonically cleaned and dried in step (2) is prepared on the surface of the silicon carbide ceramic matrix composite material by atmospheric plasma spraying...

Embodiment 2

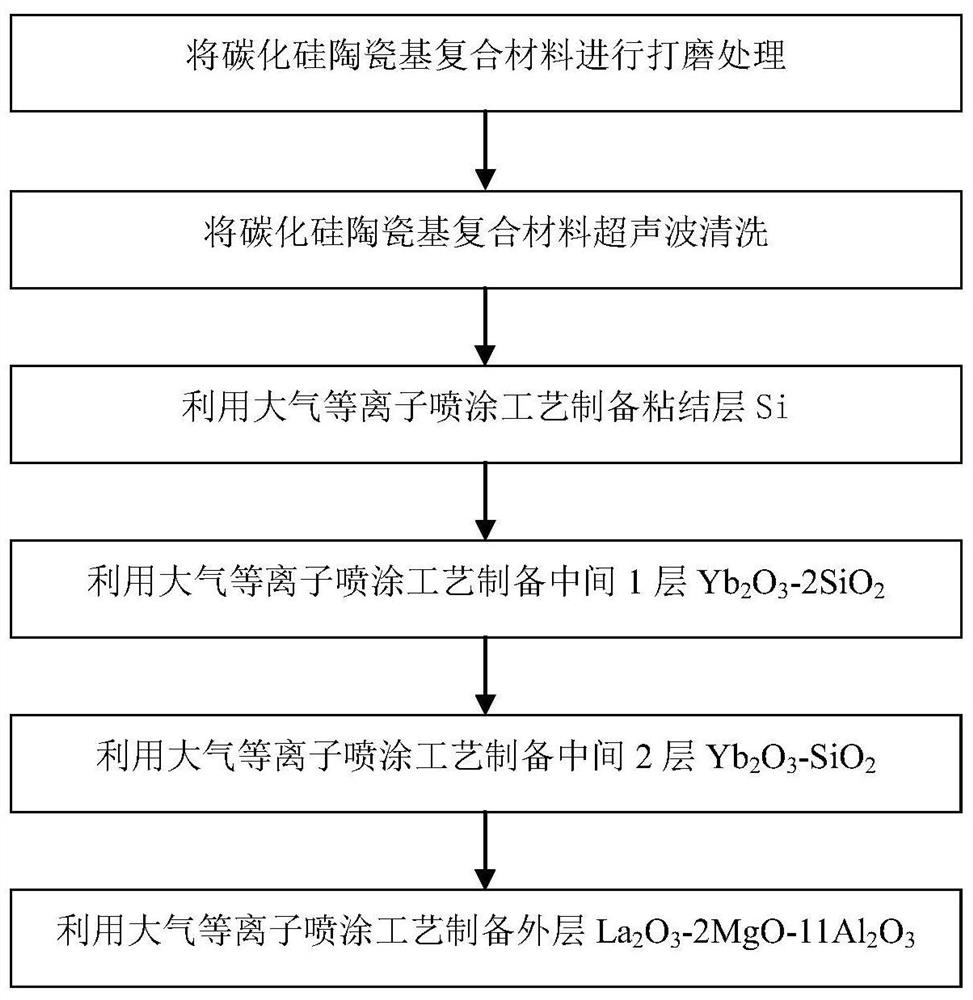

[0042] A multilayer structure environmental barrier coating for silicon carbide ceramic matrix composites and a preparation method thereof, such as figure 2 shown, including the following steps:

[0043] (1) The silicon carbide ceramic matrix composite material is pretreated by grinding. The grinding process conditions are as follows: the grinding medium is a 600-mesh diamond grinding wheel, the speed of the grinding wheel is 120 rpm, and the surface roughness of the pretreated silicon carbide ceramic matrix composite material is 5.8μm;

[0044] (2) Ultrasonic cleaning the silicon carbide ceramic matrix composite material that has been sandblasted in step (1) in 98% alcohol for 28 minutes, and then dried;

[0045] (3) Prepare the bonding layer Si on the surface of the silicon carbide ceramic matrix composite material that has been ultrasonically cleaned and dried in step (2) by atmospheric plasma spraying process. The particle size of the Si powder used for spraying is 35-60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com