Natural polymer-hydroxyapatite bone tissue engineering scaffold material with secondary three-dimensional network structure and seed-crystal induction preparation method thereof

A technology of natural polymer and hydroxyapatite, which is applied in the field of biomedical engineering scaffold materials and their preparation, can solve the problems of difficulty in realizing hydroxyapatite reconstruction, inability to discharge polymer degradation products, and difficulty in hydroxyapatite.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

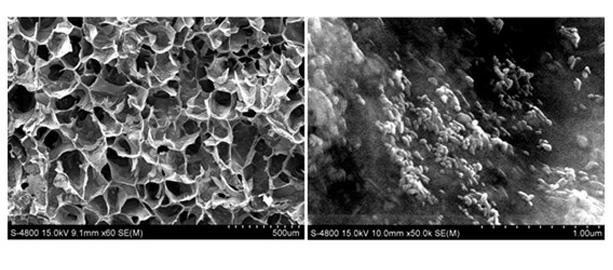

[0025] Example 1. Preparation of chitosan-hydroxyapatite secondary three-dimensional network structure bone tissue engineering scaffold material with a primary pore diameter of 50 microns and a secondary network thickness of 200 nm:

[0026] (1) Accurately weigh 1 gram of about 20 nanometers in diameter and about 120 nanometers of hydroxyapatite nanorods in length as nanoseed crystals, and disperse them in 100 milliliters of chitosan (the degree of deacetylation of chitosan is 4wt%) ≥90%, viscosity (1% solution, 20°C) ≤100 mpa.s, pH value 7.0) solution. The cross-linking agent genipin whose weight ratio of genipin to chitosan is 1:100 is added into the solution containing nanorods of hydroxyapatite, and stirred to form a sol.

[0027] (2) The sol was quickly frozen in a -80°C ultra-low temperature refrigerator, and then freeze-dried at -30°C for 36 hours to obtain a polymer porous scaffold with a primary pore diameter of 50 microns containing hydroxyapatite nanoseed crystals ...

Embodiment 2

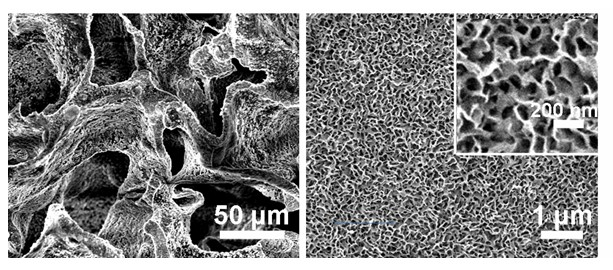

[0030] Example 2. Preparation of chitosan-hydroxyapatite secondary three-dimensional network structure bone tissue engineering scaffold material with a primary pore diameter of 100 microns and a secondary network thickness of 400 nm:

[0031] Same as Example 1, the chitosan concentration was changed to 3 wt%; the ratio of genipin to chitosan was changed to 1:200; the freeze-drying temperature was -40 o C; Mineralization time changed to 10 days;

[0032] The chitosan-hydroxyapatite secondary three-dimensional network structure bone tissue engineering scaffold material with a primary pore diameter of 100 microns and a secondary network thickness of 400 nanometers can be obtained.

Embodiment 3

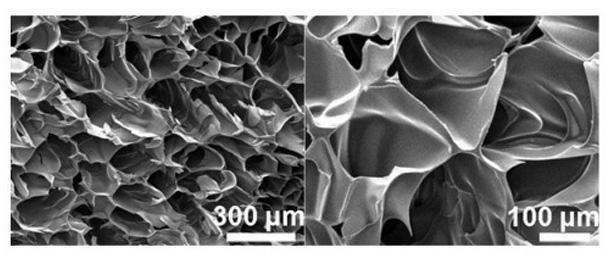

[0033] Example 3. Preparation of chitosan-hydroxyapatite secondary three-dimensional network structure bone tissue engineering scaffold material with a primary pore diameter of 150 microns and a secondary network thickness of 800 nm:

[0034] Same as in Example 1, the concentration of chitosan was changed to 2 wt%, the ratio of genipin to chitosan was changed to 1:300; the freeze-drying temperature was changed to 50° C.; the mineralization time was changed to 16 days.

[0035] The chitosan-hydroxyapatite secondary three-dimensional network structure bone tissue engineering scaffold material with a primary pore diameter of 150 microns and a secondary network thickness of 800 nanometers can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com