Synergistic additive of natural-gas as welding and cutting gas

A technology of synergistic additive, welding and cutting gas, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of long preheating time, large oxygen consumption, difficult cutting, etc. The effect of smooth, low-carbon and environmentally friendly combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

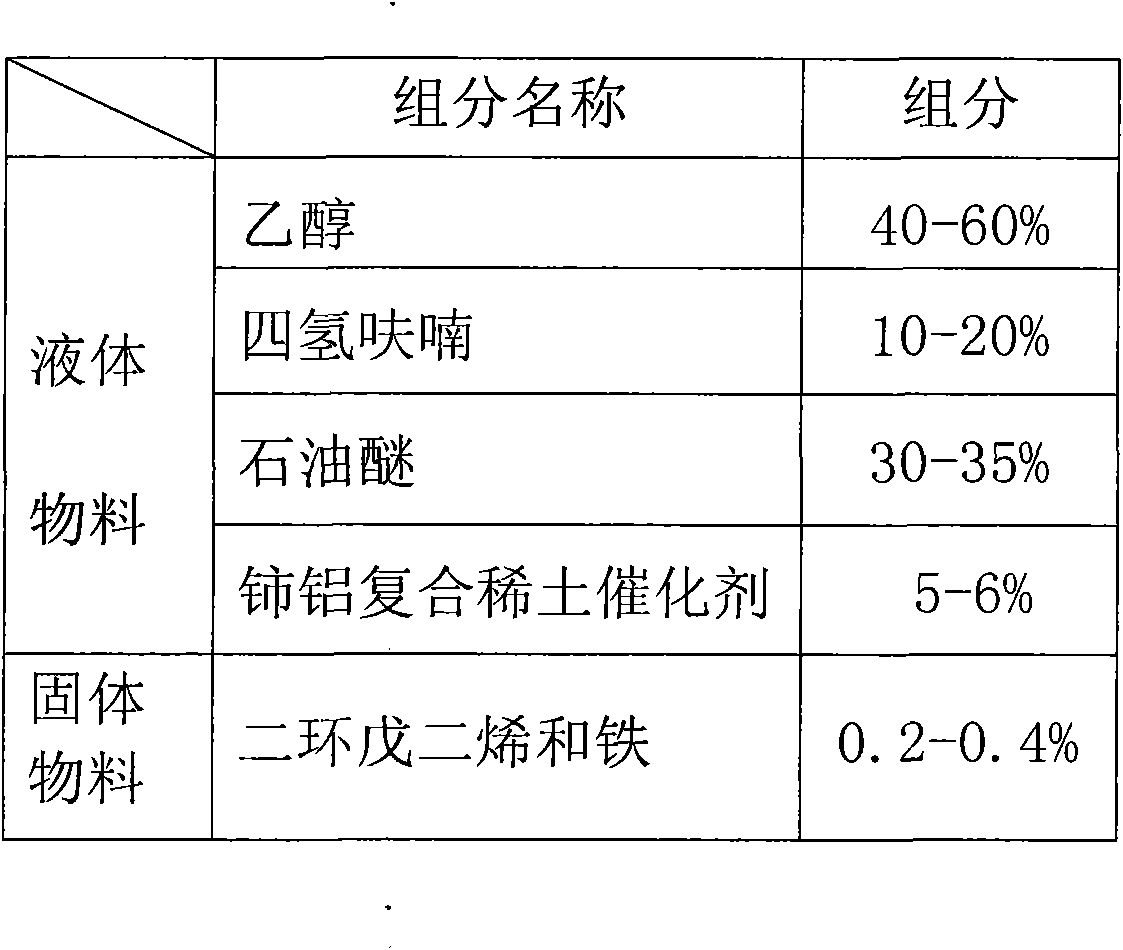

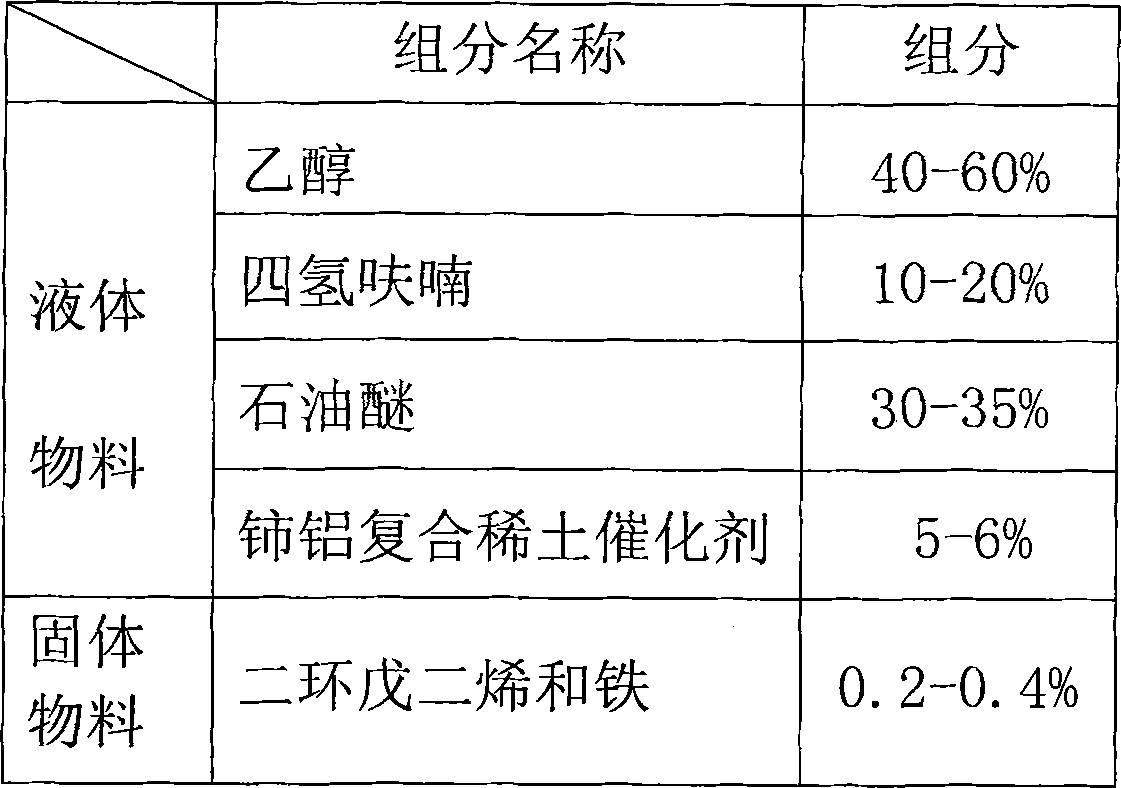

[0016] refer to figure 1 , the specific embodiment adopts the following technical scheme: its formula consists of: ethanol 42%, tetrahydrofuran 20%, petroleum ether 32%, cerium-aluminum composite rare earth catalyst 5.67%, dicyclopentadiene and iron 0.33%; its preparation The process is as follows: first, mix ethanol and petroleum ether evenly for later use; then add tetrahydrofuran into the reaction kettle, add dicyclopentadiene, iron and liquid cerium-aluminum composite rare earth catalyst into the reaction kettle for stirring, and mix them with the above mixed solution Mix; after standing for 4 hours, discharge the clear liquid through the drain valve on the side of the reaction kettle, and pour it into a plastic packaging barrel.

[0017] This embodiment has the following features:

[0018] 1. It fundamentally solves the long-standing fundamental problem that liquid additives cannot be added to natural gas or the effect is not obvious after addition.

[0019] 2. Solve th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com