Manufacturing method for combined ceramic tile with complete pattern, spliced by plurality of ceramic tiles

A manufacturing method and combined technology, applied in the field of ceramic tiles, can solve the problems of not being able to reflect the atmosphere and grandeur of natural stone, the patterns are easy to be blurred and unclear, and the patterns cannot be inlaid as a whole. The effect of quality and grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

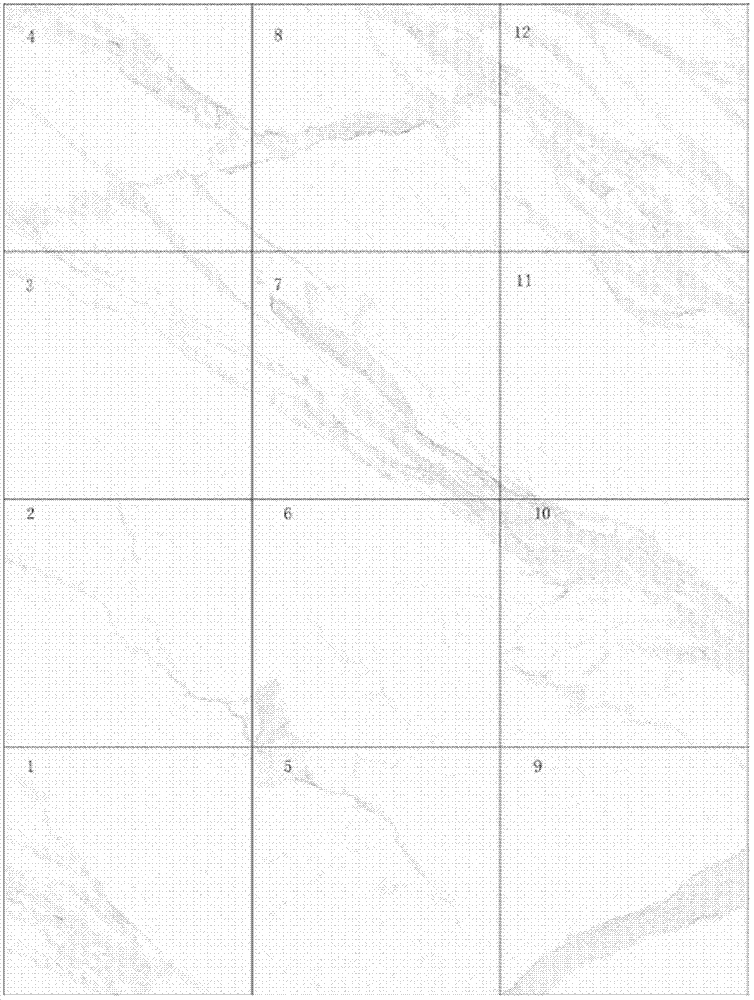

[0038] A method for manufacturing combined ceramic tiles with multiple pieces of ceramic tiles spliced into a complete pattern. The method includes mixing raw materials with conventional techniques to make powder, pressing them into bricks, printing, spraying glaze, and firing them into tiles. The tiles with different or the same patterns are seamlessly spliced to form a combined tile with a complete pattern.

[0039] The raw materials include base materials and auxiliary materials. The base materials include the following components and weight percentages: clay 34%, feldspar 30%, light-colored filter mud 20%, vitrified recycled material 10%, vitrified Porcelain powder 6%; the auxiliary materials include the following components and contents: based on the mass of the base material as 100%, 0.375% of composite sodium tripolyphosphate, 0.2% of Otao reinforcing agent, and 0.05% of sodium hydroxymethyl cellulose.

[0040] Wherein: the printing process described above adopts in...

Embodiment 2

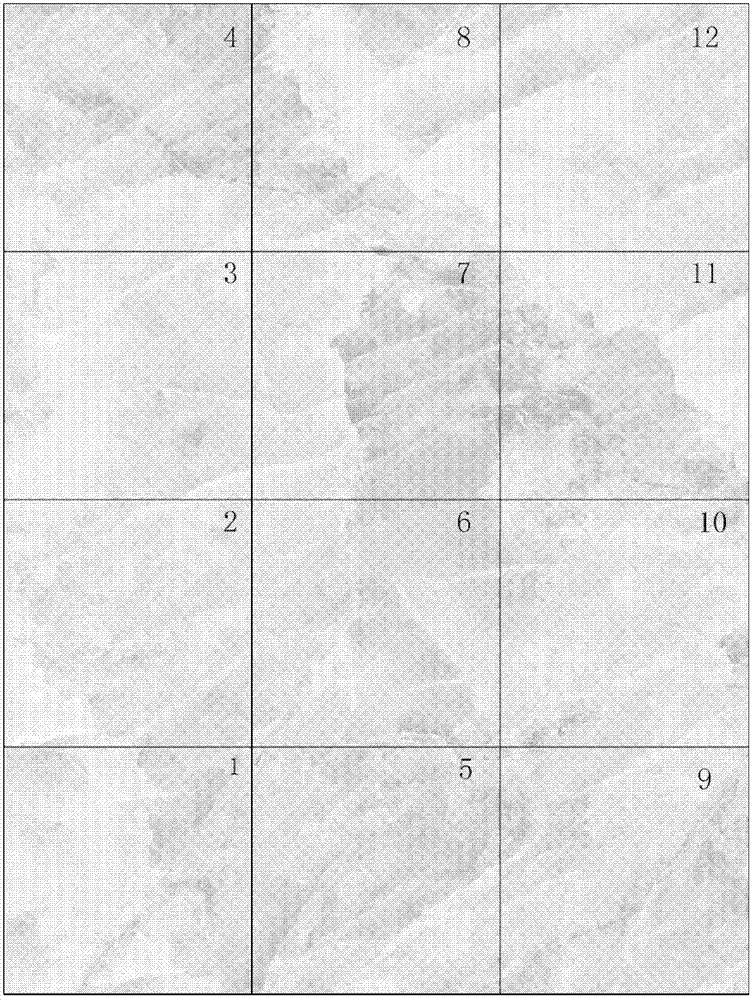

[0044] A manufacturing method of combined ceramic tiles with multiple pieces of ceramic tiles spliced into a complete pattern. The method includes mixing raw materials to make powder, pressing them into bricks, printing, spraying glaze, and firing them into tiles. The tiles with different or the same patterns are seamlessly spliced to form a combined tile with a complete pattern.

[0045] The raw materials include base materials and auxiliary materials. The base materials include the following components and weight percentages: 30% clay, 30% feldspar, 22% light-colored filter mud, 8% vitrified recycled material, vitrified 10% of porcelain powder; the auxiliary materials include the following components and contents: based on the mass of the base material as 100%, 0.3% of composite sodium tripolyphosphate, 0.1% of Otao reinforcing agent, and 0.01% of sodium hydroxymethyl cellulose.

[0046] Such as Figure 4~6 As shown, 24 tiles with a single size of 400mm×800mm are seamle...

Embodiment 3

[0049] A manufacturing method of combined ceramic tiles with multiple pieces of ceramic tiles spliced into a complete pattern. The method includes mixing raw materials to make powder, pressing them into bricks, printing, spraying glaze, and firing them into tiles. The tiles with different or the same patterns are seamlessly spliced to form a combined tile with a complete pattern.

[0050] The raw materials include base materials and auxiliary materials. The base materials include the following components and weight percentages: clay 35%, feldspar 25%, light-colored filter mud 18%, vitrified recycled material 12%, vitrified Porcelain powder 10%; the auxiliary materials include the following components and contents: based on the mass of the base material as 100%, 0.4% of composite sodium tripolyphosphate, 0.2% of Otao reinforcing agent, and 0.1% of sodium hydroxymethyl cellulose.

PUM

| Property | Measurement | Unit |

|---|---|---|

| greyscale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com