Improved solvent cold laid asphalt as well as preparation process and using method thereof

A cold-paved asphalt and improved technology, applied in the direction of on-site coagulation pavement, building components, building thermal insulation materials, etc., can solve the problems of being easily affected by the climate, unable to construct, and the environmental pollution has a great impact on the health of workers. The effect of convenient and open traffic, convenient construction and operation, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

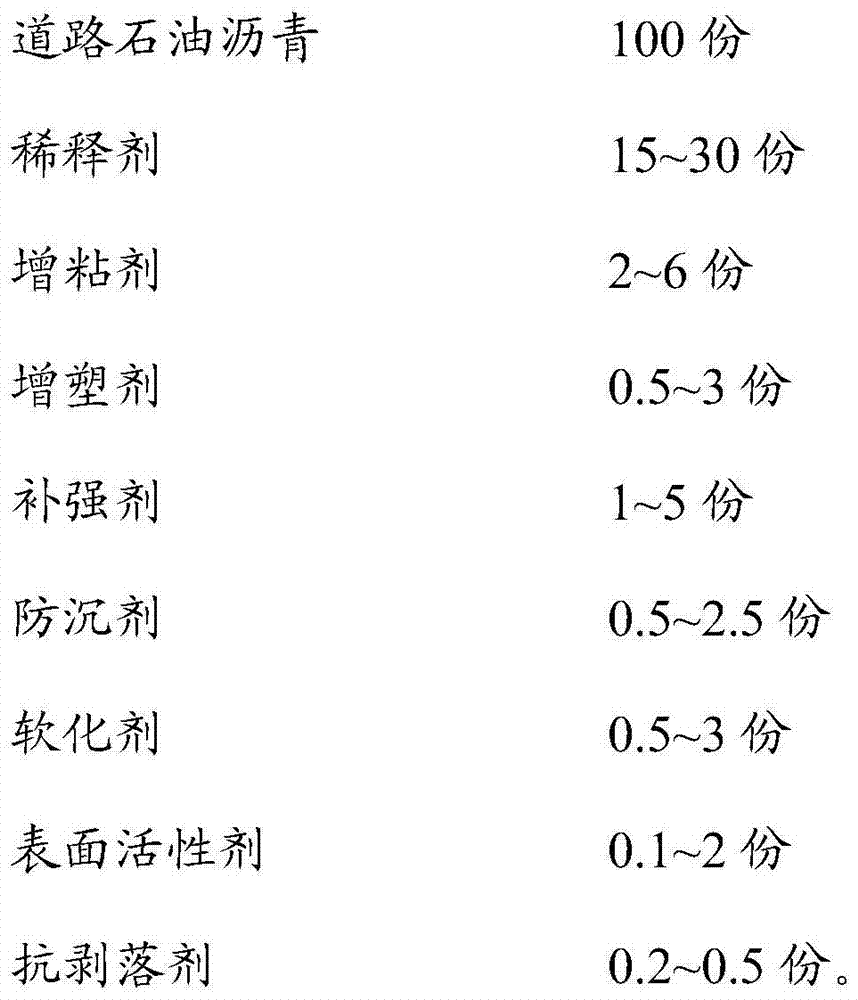

[0034] The invention also discloses a preparation method of the improved solvent cold paving asphalt, which comprises the following steps:

[0035] 1) According to the mass parts, add 2-6 parts of tackifier, 0.5-3 parts of plasticizer, 1~5 parts of reinforcing agent, 0.5~2.5 parts of anti-settling agent, 0.5~ 3 parts of softener and 0.1 to 2 parts of surfactant are miscible and stirred evenly to obtain mixture A;

[0036] 2) Take 100 parts of road petroleum asphalt and heat it to a molten state, and then pour the molten road petroleum asphalt into a mixing equipment with a rotation speed of 200 ~ 500r / min;

[0037] 3) Add 15-30 parts of diluent to the road petroleum asphalt in the mixing equipment, and fully mix to form diluted asphalt;

[0038] 4) Add mixture A to the diluted bitumen and mix it evenly to obtain mixture B;

[0039] 5) Add 0.2-0.5 parts of PA-1 to the mixture B and mix evenly to obtain an improved solvent cold paving asphalt; among them, in step 1) to step 5), the total...

Embodiment 1

[0041] First, mix 2.9% of tackifier, 0.7% of plasticizer, 3.7% of reinforcing agent, 1.8% of anti-settling agent, 1.5% of softener and 0.6% of surfactant in mass percentage, and stir thoroughly. , Ready; secondly, pour the 73.7% of the base asphalt heated to the molten state into the mixing equipment, adjust the speed of the mixing equipment, and control its speed at 200~500r / min; again add 14.7% of the diluent to the asphalt and stir fully Form the diluted asphalt; then add the pre-prepared mixture of tackifier, plasticizer, reinforcing agent, anti-settling agent, softener and surfactant into the diluted asphalt and stir it fully; finally add 0.4% anti-stripping agent , Stir thoroughly. It is bound to stir for several minutes when adding each additive, and the total stirring time should be controlled within 30 minutes.

[0042] Precautions:

[0043] After heating the base asphalt to a molten state, you should stop for a few minutes before adding the diluent into the asphalt, bec...

Embodiment 2

[0052] 1) In terms of parts by mass, combine 2 parts of terpene resin, 0.5 parts of dioctyl phthalate DOP, 1 part of carbon black, 0.5 parts of white carbon black anti-settling agent, and 0.5 parts of Mineral oil and 0.1 part of C l7 ~C 20 Or C 7 ~C 9 Alkyl propylene diamine dihydrochloride and alkyl amine hydrochloride are miscible, and stir evenly to obtain mixture A;

[0053] 2) Take 100 parts of 70# base pitch and heat it to a molten state, and then pour the melted state 70# base pitch into a mixing equipment with a rotation speed of 200~500r / min;

[0054] 3) Add 15 parts of gasoline to 70# base asphalt in the mixing equipment, and fully mix to form diluted asphalt;

[0055] 4) Add mixture A to the diluted bitumen and mix it evenly to obtain mixture B;

[0056] 5) Add 0.2 parts of PA-1 to the mixture B and stir evenly to obtain an improved solvent cold paving asphalt; among them, in step 1) to step 5), the total mixing time is less than or equal to 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com