Vacuum absorbing template for semiconductor wafer polishing device and polishing device

A technology of vacuum adsorption and polishing device, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding workpiece supports, etc., can solve the problems of complex polishing process, environment cost, time-consuming and labor-intensive, and reduce production costs. , Improve the yield and thickness uniformity, and shorten the processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

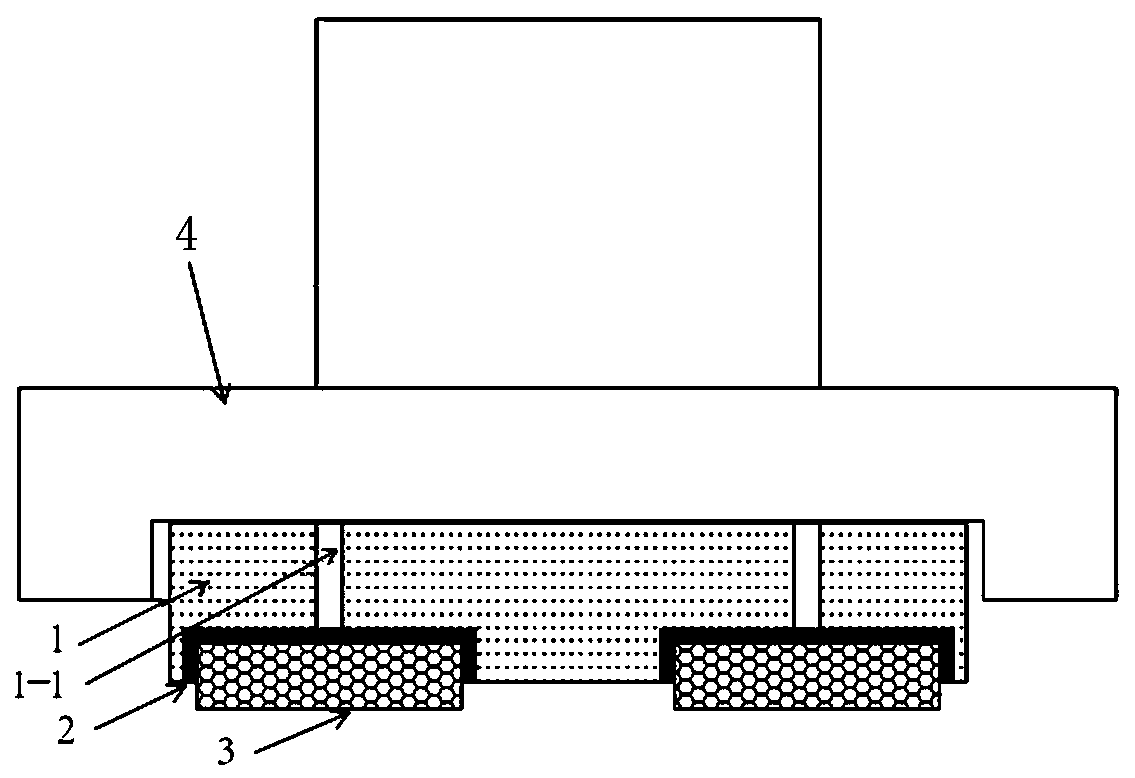

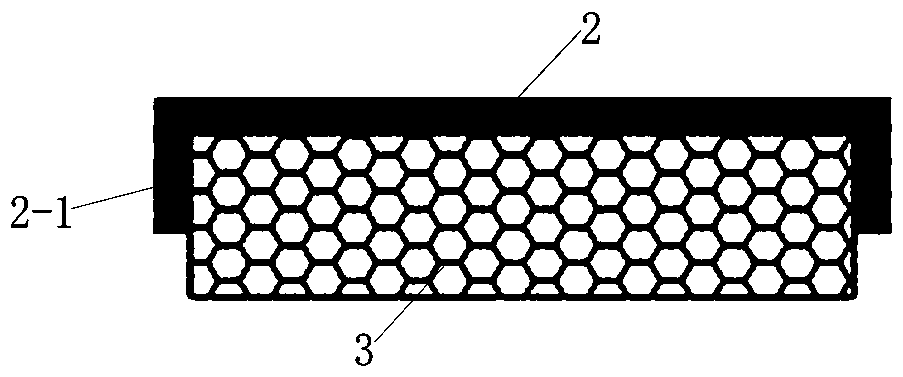

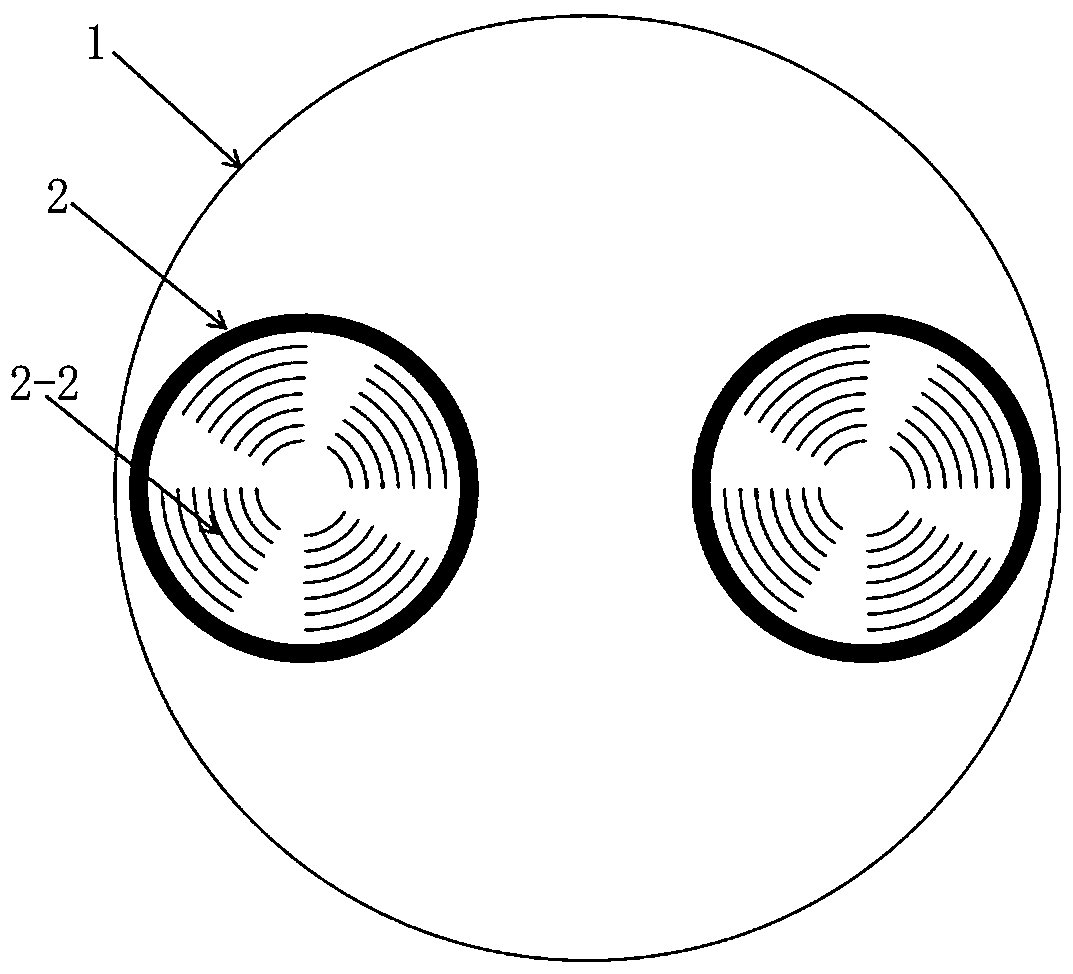

[0024] This embodiment provides a vacuum adsorption template for a semiconductor wafer polishing device, which is used to position the wafer 3 so as to realize single-sided polishing of the wafer 3, see Figure 1-3 As shown, the vacuum adsorption template includes a ceramic disc 1 positioned on the polishing head 4. The key design of this embodiment is that a groove is provided on the surface of the ceramic disc 1, and the shape of the groove is consistent with the shape of the wafer 3 to be polished. , if it can be square or other, it is cylindrical in the present embodiment; the number of grooves on the surface of the ceramic disc 1 can be customized according to the actual situation, and there are 2 in the present embodiment; a vacuum suction cup 2 is positioned in the groove , the positioning method is vacuum adsorption, the peripheral edge of the vacuum chuck 2 extends downward to form a visor 2-1 structure, because the peripheral edge extends downward, the middle part for...

Embodiment 2

[0029] The difference from Embodiment 1 is that in this embodiment, the vacuum suction cup 2 is bonded in the groove of the ceramic disc 1 to achieve positioning. If replacement is required, remove the vacuum and replace the ceramic disc 1 to achieve.

[0030]Put the InP wafer into the common porous ceramic vacuum adsorption template and the vacuum adsorption template described in the above-mentioned embodiment 1 respectively, and perform single-sided polishing. Under the same vacuum negative pressure, the vacuum adsorption template described in the embodiment 1 absorbs Strong force, firm adsorption, no shedding phenomenon, no scratches and wear on the side and the adsorbed surface; while the shedding rate of ordinary porous ceramic vacuum adsorption templates is higher than 30%, and the occurrence rate of side scratches or scratches on the adsorbed surface is higher than 30%; Slightly increase the vacuum negative pressure, the wafer packed into the vacuum adsorption template o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com