Mechanical arm force control assembling device and method

An assembly device and manipulator technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as less than ±0.01mm, difficult shaft hole assembly, etc., to prevent scratch damage, improve assembly efficiency, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

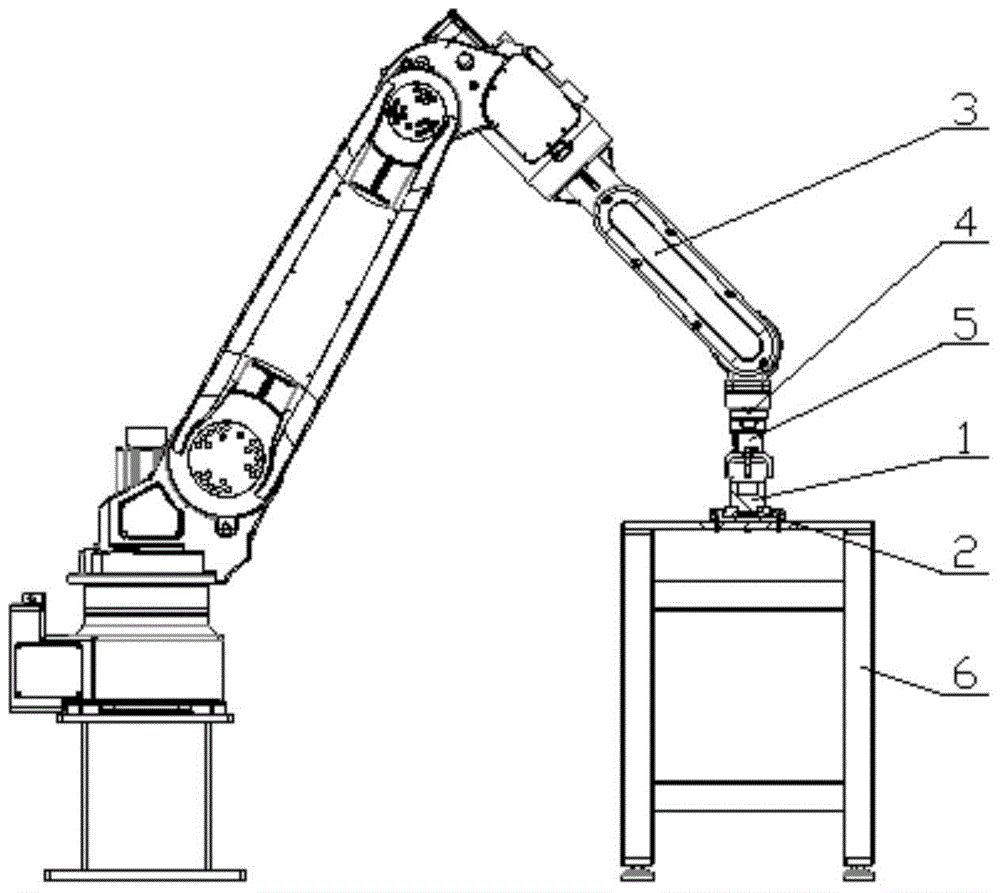

[0035] see figure 1 , this embodiment discloses a manipulator force control assembly device, including a manipulator main body 3 with a complete movable mechanism, a control system (not shown), a force sensor 4, a gripper 5 and an assembly platform 6 provided with a clamp; The system is installed inside the manipulator main body 3; the force sensor 4 is installed at the end of the manipulator main body 3 and connected to the control system; the gripper 5 is installed on the force sensor 4; the assembly platform 6 is arranged on the side of the manipulator main body 3, located Directly below hand 5.

[0036] The main body 3 of the manipulator undertakes the overall movement function, and drives the shaft workpiece 1 for assembly movement. The control system is equivalent to the "brain" of the device, used for processing and analyzing data information, and ordering the manipulator main body 3 to perform corresponding movements. The force sensor 4 is used to detect the contact ...

Embodiment 2

[0043] The present invention also provides a mechanical hand force control assembly method, comprising the following steps:

[0044] S01, fix the hole workpiece 2 on the assembly platform 6, the manipulator main body 3 drives the gripper 5 to grab and clamp the shaft workpiece 1, so that the shaft workpiece 1 is facing the hole workpiece 2 axially;

[0045] S02. The manipulator main body 3 drives the shaft workpiece 1 for axial trial assembly. If the force sensor 4 detects that the contact force during the trial assembly is zero, the assembly is performed directly;

[0046] S03. If the force sensor 4 detects that the contact force during the trial assembly is not zero, the control system analyzes and commands the manipulator main body 3 to drive the shaft workpiece 1 to find the hole center position of the hole workpiece 2 for reassembly.

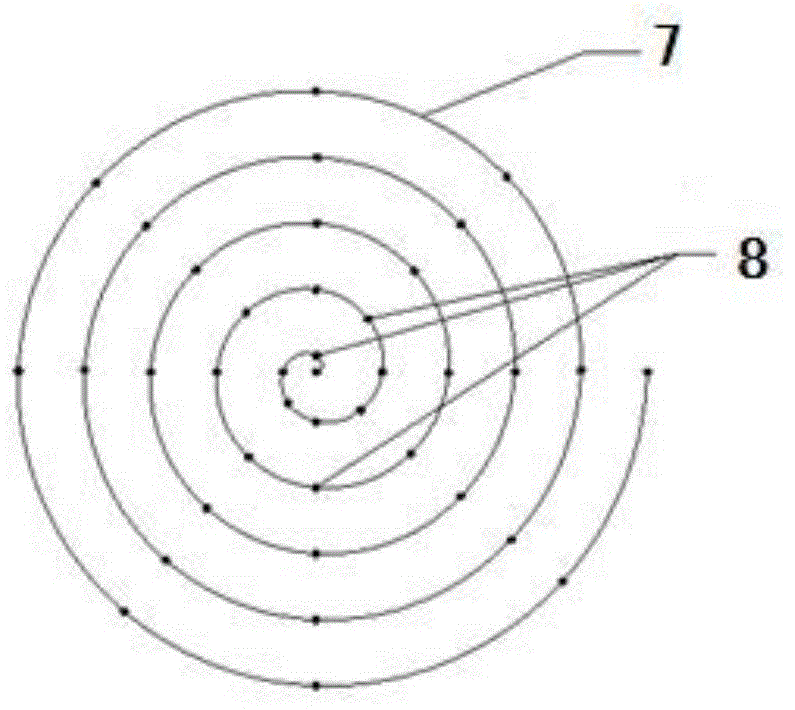

[0047] see figure 2 , further, the step S03 includes the following steps:

[0048] S031. If the force sensor 4 detects that the contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com