Optical system fixed through UV glue and lamp thereof

An optical system and glue column technology, applied in the field of optical systems and their lamps, can solve the problems of great influence on installation operability, difficulty in ensuring operability, product design restrictions, etc., achieving easy operation, unchangeable positioning, The effect of space flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

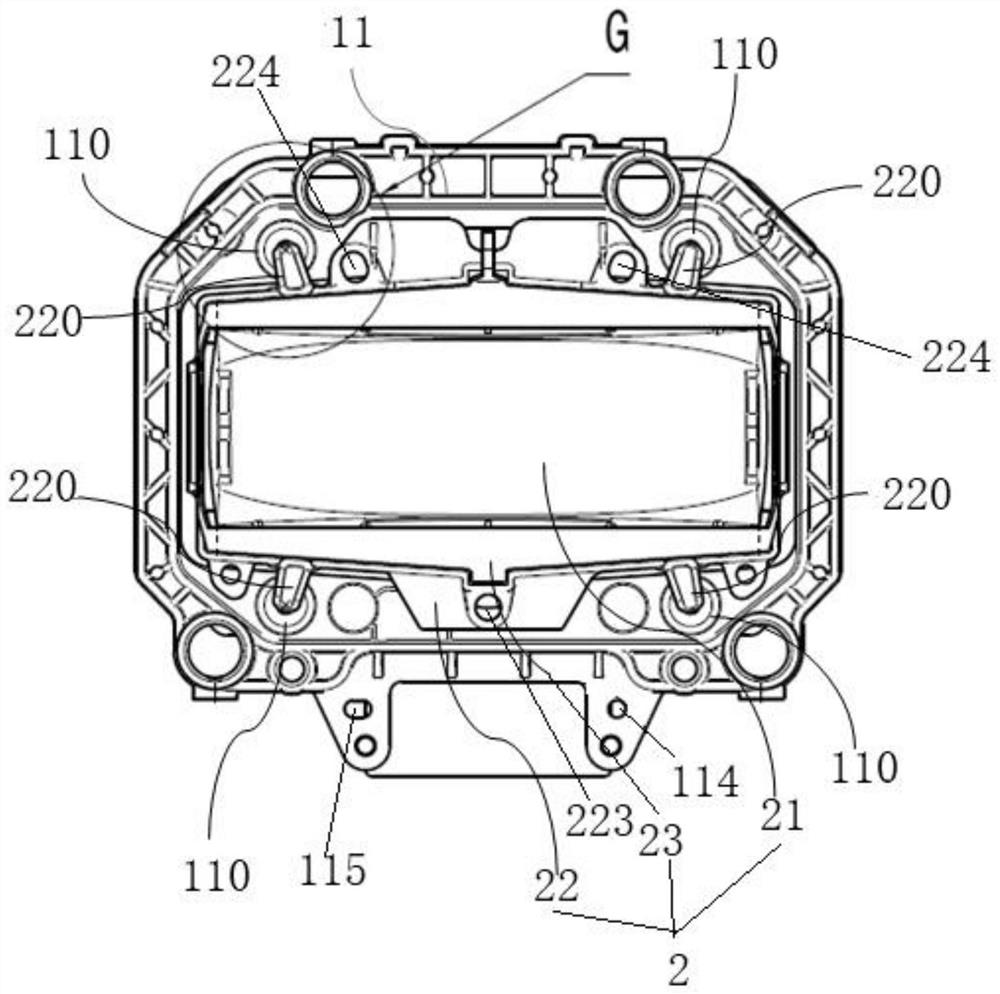

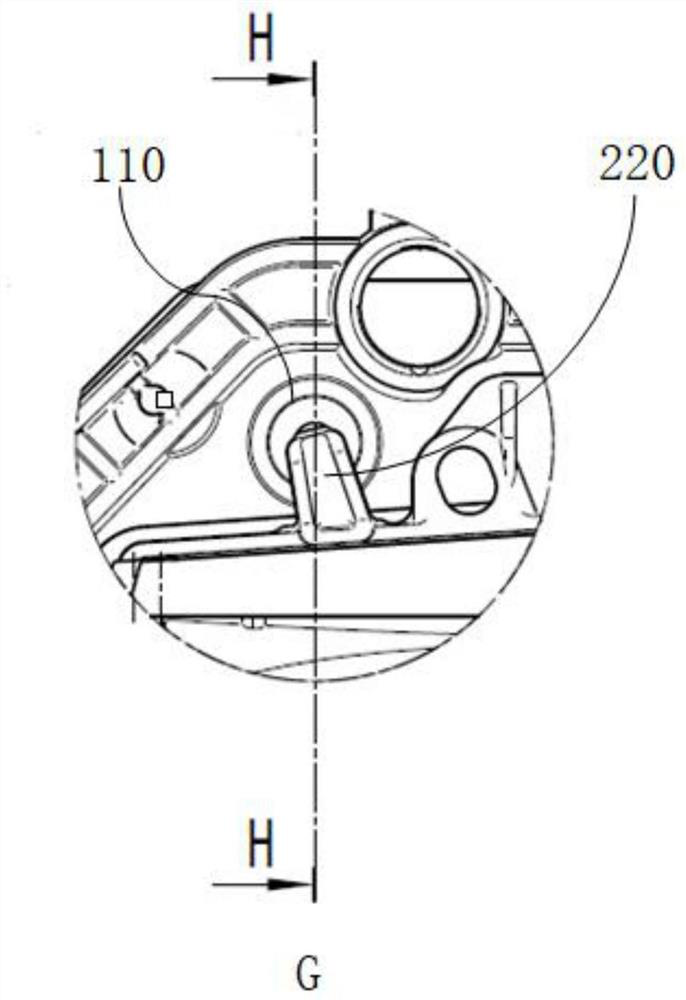

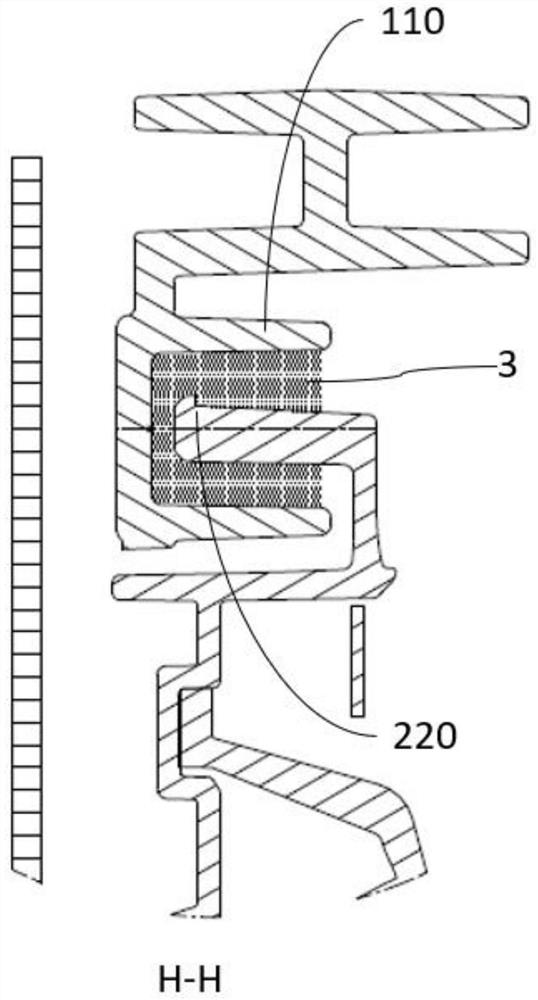

[0048] According to an optical system fixed by UV glue provided by the present invention, it includes a circuit board device 1 and a lens device 2, and the circuit board device 1 and the lens device 2 are bonded and fixed by UV glue 3 to form an optical system as a whole .

[0049]The circuit board device 1 includes a bracket 11 and a PCB board 12, the PCB board 12 includes a PCB board body 121, LED light emitting diodes 122, round holes 123, waist holes 124 and screw posts 125, and a plurality of LED light emitting diodes 122 arrays are distributed on the PCB board Preferably, 84 LED light emitting diodes are used on the body 121 . The round holes 123 and the waist holes 124 are respectively distributed around the PCB body 121 , and the round holes 123 are fitted and connected with the first positioning pins 111 on the bracket 11 one by one. Preferably, the round hole 123 and the first positioning pin 111 serve as the first positioning reference. The waist holes 124 are fit...

Embodiment 2

[0066] The invention also provides a lamp, which includes an optical system fixed by UV glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com