Pipe fitting inside expansion clamping device

A clamping device and a technology of expanding and tightening, applied in the direction of expanding the mandrel, etc., can solve the problems such as the rupture of the pipe fittings, the inability to complete the outer wall of the pipe fittings, and the processing at one time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

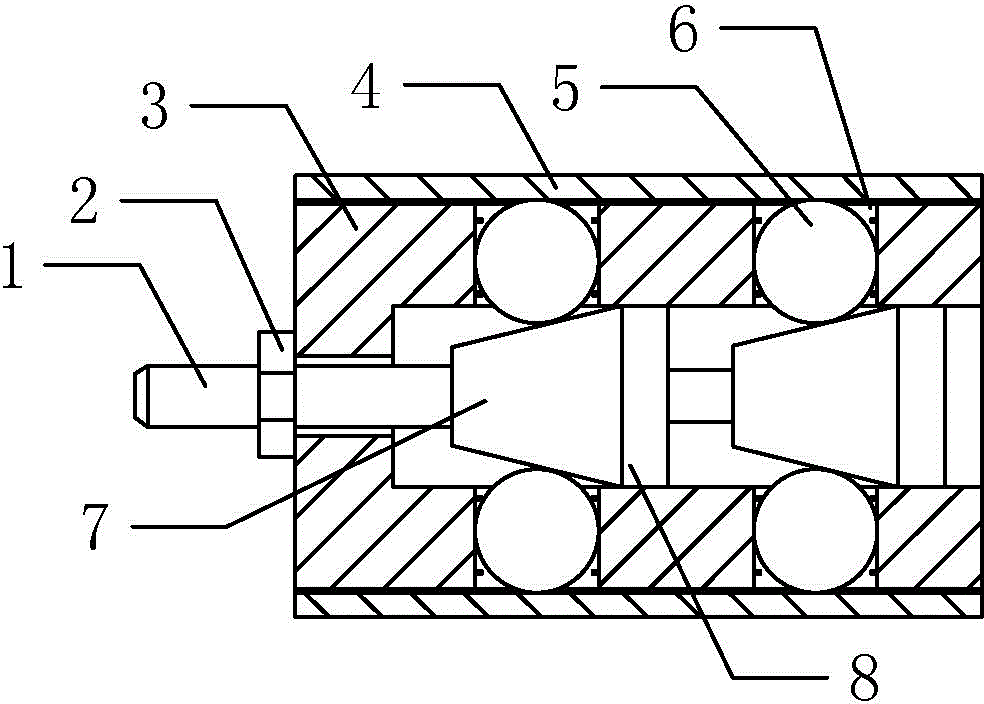

[0012] Among them: tie rod 1, lock nut 2, positioning cylinder 3, pipe fitting 4, positioning ball 5, through hole 6, cone truss 7, sliding column 8.

[0013] Such as figure 1 As shown, the expansion device in the pipe fitting 4 of the present invention includes a positioning cylinder 3, which is placed horizontally, and the side wall of the positioning cylinder 3 is provided with eight through holes 6, and the centers of the eight through holes 6 are distributed in two On the circumference, each circumference includes four through holes 6, and the four through holes 6 are evenly distributed along its circumference, and the centers of the two circumferences are all located on the axis line of the positioning cylinder 3, and the through holes 6 are provided with Positioning ball 5 is arranged, and positioning ball 5 is steel ball, and the outer side of steel ball is covered with rubber layer, and positioning ball 5 and through hole 6 clearance fits, and the diameter of position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com