Plate placing machine with temporary storage function

A technology of placing a board machine and a temporary storage mechanism, which is applied to conveyors, stacking of objects, conveyor objects, etc., can solve the problems of wasting manpower, unfavorable automated production, and stopping lines, and achieves the effect of ensuring service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

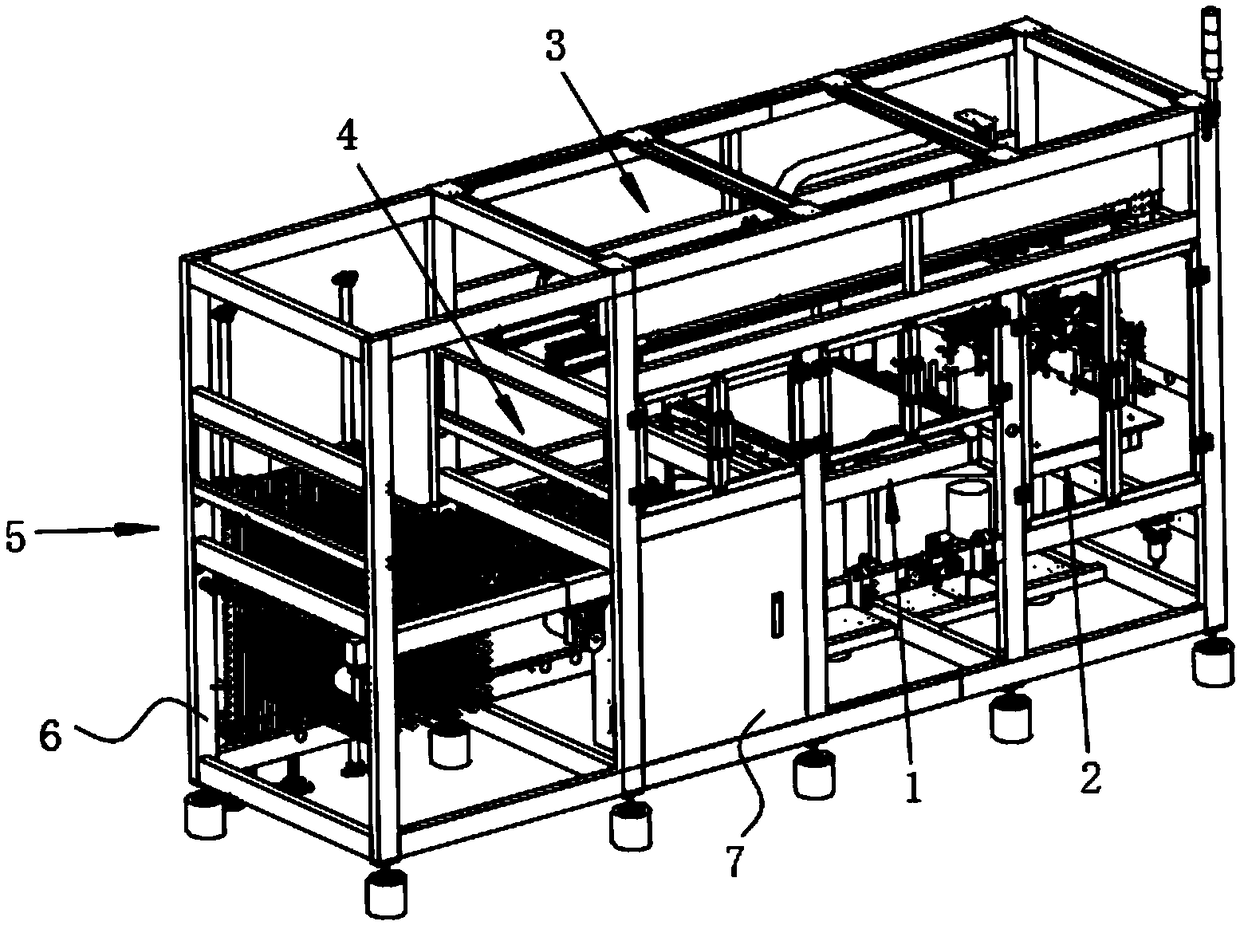

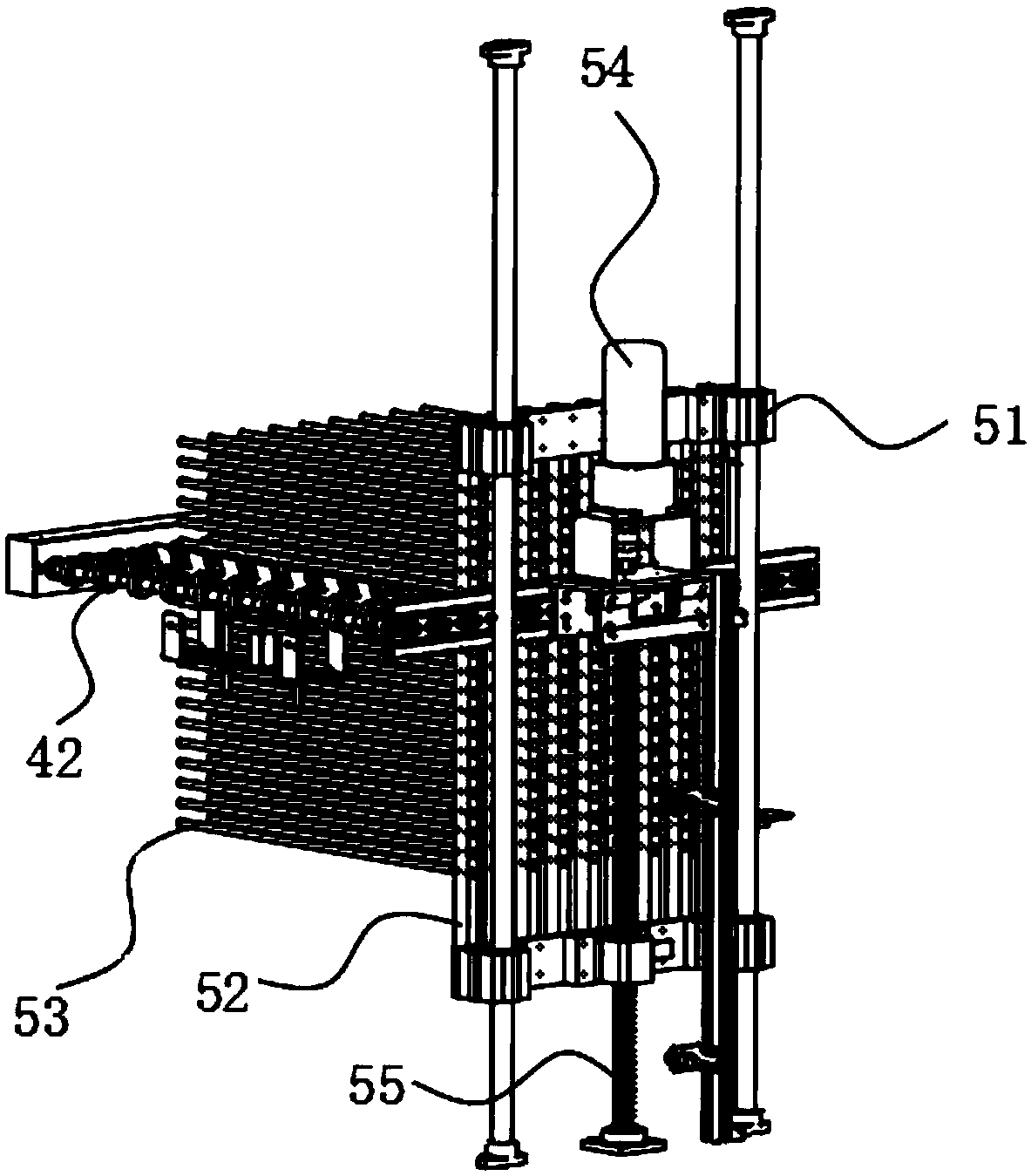

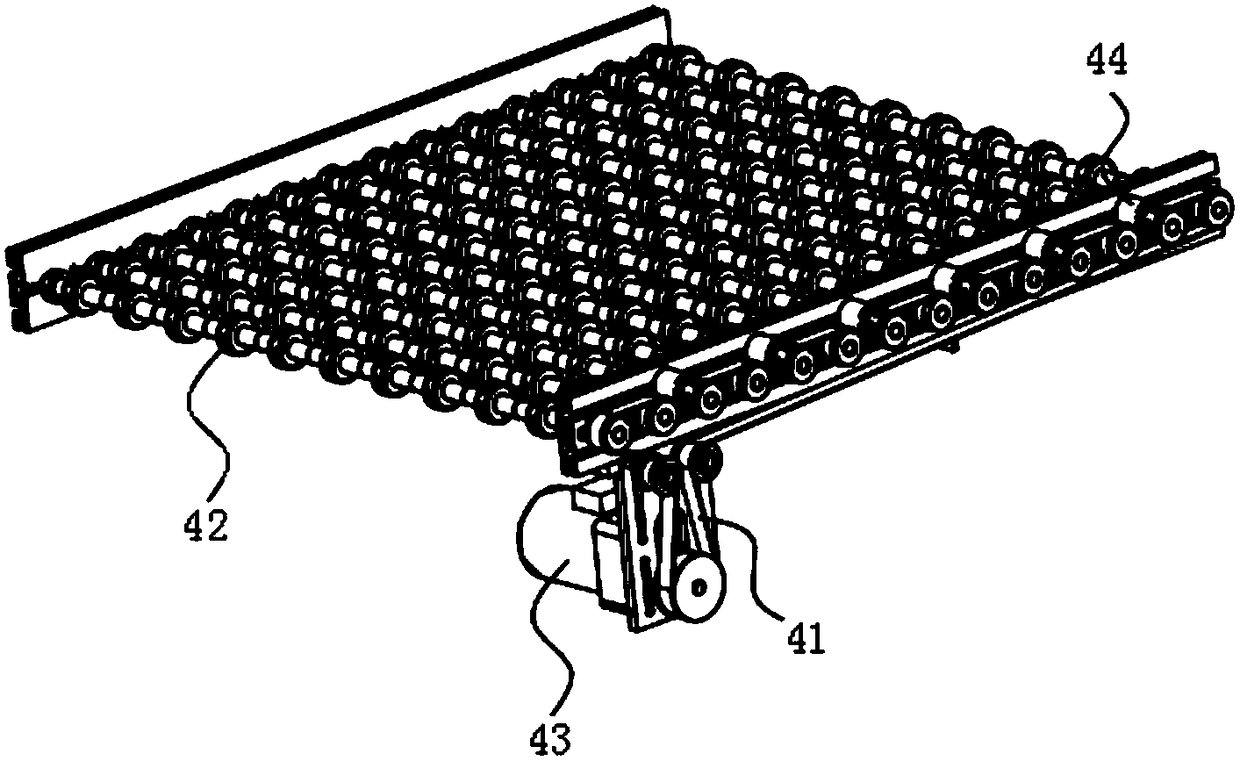

[0040] Embodiment: a kind of board machine with temporary storage function, such as Figure 1-Figure 9 As shown, it includes a PCB feeding mechanism 1, a padding feeding mechanism 2, a retrieving mechanism 3, a conveying mechanism 4 and a temporary storage mechanism 5, and the PCB feeding mechanism 1 and the padding feeding mechanism 2 are located at the Upstream of the retrieving mechanism 3, the retrieving mechanism 3 is located upstream of the conveying mechanism 4 and the temporary storage mechanism 5, the PCB feeding mechanism 1, the pad paper feeding mechanism 2, the retrieving mechanism 3. Both the conveying mechanism 4 and the temporary storage mechanism 5 are fixed on the frame 6;

[0041] The material fetching mechanism 3 includes a traverse mechanism 31 and a suction mechanism 32, and the suction mechanism 32 is fixed to the traverse mechanism 31;

[0042] The traversing mechanism 31 includes a traversing plate 311, a synchronous belt 312, a driven wheel 313, a drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com