Preparation method of silver-loaded palygorskite heat-resistant liquid wallpaper

The technology of liquid wallpaper and palygorskite is applied in the field of preparation of silver-loaded palygorskite heat-resistant liquid wallpaper, which can solve the problems of inability to meet the needs of wall decoration, poor heat resistance, poor antibacterial properties, etc., so as to improve the heat resistance. , The effect of increasing the crosslinking density and the matrix bond energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

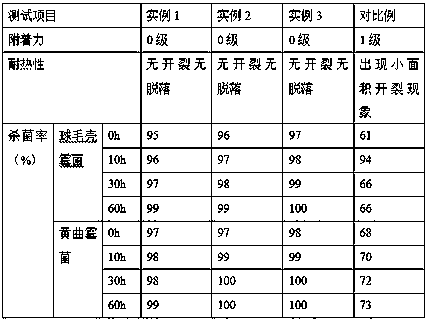

Examples

example 1

[0025] According to the volume ratio of 4:1:1, mix ethyl orthosilicate, absolute ethanol and hydrochloric acid with a concentration of 0.1 mol / L in an ultrasonic disperser and ultrasonically shake for 6 minutes. After stirring, put it in an oven at the temperature Dry for 45 minutes at 55°C, grind and discharge to obtain homemade nano silica powder, continue to make homemade nano silica powder, silane coupling agent KH-560 and sodium lauryl sulfate in a mass ratio of 5:2:1 The mixture was placed in a beaker, stirred for 1 hour at a temperature of 75°C, cooled down, and centrifuged for 20 minutes to obtain a solid product, which is a modified self-made nano-silica powder; weigh 24g palygorskite, grind and pulverize for 10 minutes, and pass 120 Mesh sieve, collect the sieved palygorskite powder, mix the sieved palygorskite powder and the silver nitrate solution with a mass fraction of 35% at a mass ratio of 1:3, place them in a beaker and stir for 20 minutes to obtain a stirring s...

example 2

[0027] According to the volume ratio of 4:1:1, mix the ethyl orthosilicate, absolute ethanol and hydrochloric acid with a concentration of 0.1 mol / L in an ultrasonic disperser and ultrasonically shake for 6 to 8 minutes. After stirring, put it in an oven. Dry for 53 minutes at 58℃, grind and discharge the material to obtain self-made nano-silica powder, continue to make self-made nano-silica powder, silane coupling agent KH-560 and dodecyl in a mass ratio of 5:2:1 Sodium sulfate was mixed and placed in a beaker, stirred for 1.5h at a temperature of 70℃, cooled down, and centrifuged for 25min to obtain a solid product, which is modified self-made nano-silica powder; weighed 28g palygorskite, ground and crushed for 11min After passing through a 120-mesh sieve, the sieved palygorskite powder is collected, and the sieved palygorskite powder and the silver nitrate solution with a mass fraction of 35% are mixed at a mass ratio of 1:3 and placed in a beaker and stirred for 22 minutes t...

example 3

[0029] According to the volume ratio of 4:1:1, mix ethyl orthosilicate, absolute ethanol and 0.1mol / L hydrochloric acid in an ultrasonic disperser and ultrasonically oscillate for 8 minutes. After stirring, put it in an oven. Dry for 60 minutes at 60°C, grind and discharge to obtain homemade nano silica powder, continue to make homemade nano silica powder, silane coupling agent KH-560 and sodium lauryl sulfate in a mass ratio of 5:2:1 The mixture was placed in a beaker, stirred for 2 hours at a temperature of 85°C, cooled down, and centrifuged for 30 minutes to obtain a solid product, which is a modified self-made nano-silica powder; weighed 32g palygorskite, ground and crushed for 12 minutes, and passed 120 Mesh sieve, collect the sieved palygorskite powder, mix the sieved palygorskite powder and the silver nitrate solution with a mass fraction of 35% at a mass ratio of 1:3, place them in a beaker and stir for 24 minutes to obtain a stirring solution. Adjust the pH of the stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com