Production method for continuous basalt fiber

A technology of basalt fiber and production method, which is applied to glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of not being comprehensive enough and not considering the decisive effect of mineral components on the production process, so as to achieve easy homogenization and improve accuracy Sexuality and rapid effectiveness, the effect of improving homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

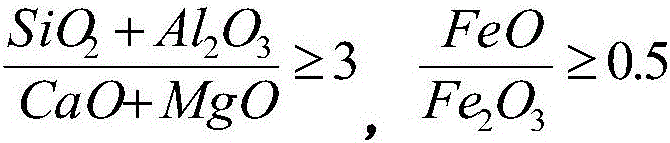

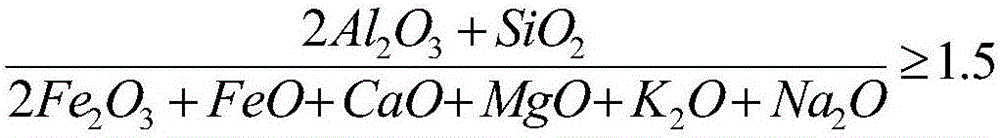

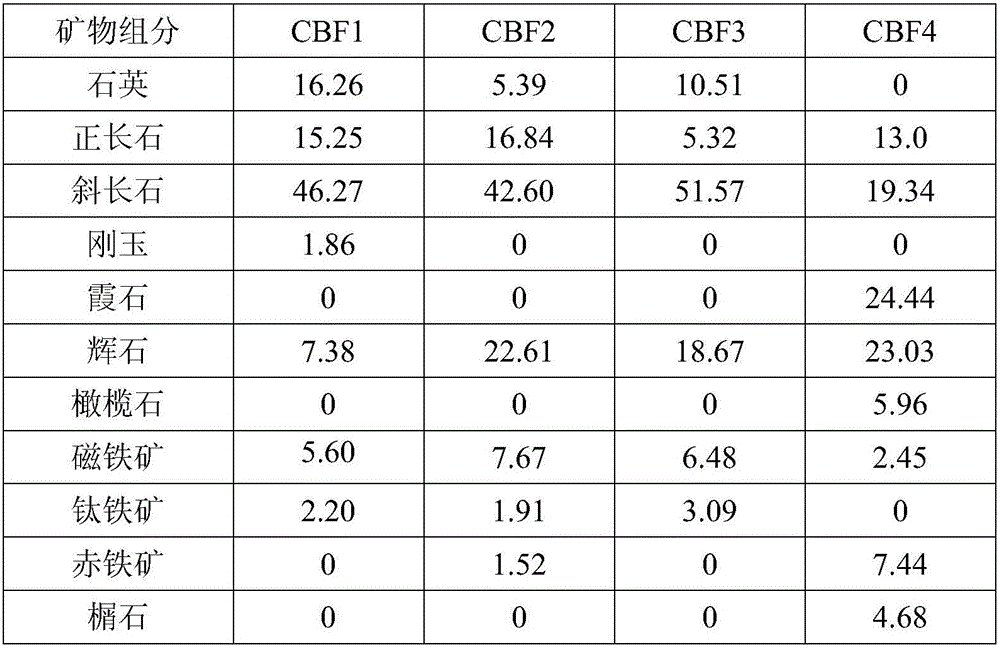

[0027] The invention collects andesite, basaltic andesite, tholeiitic basalt and alkaline basalt from four different regions in China. First determine the chemical composition and mineral composition of each basalt ore CBF1, CBF2, CBF3 and CBF4, and then prepare basalt glass and monofilament. Finally, the melting process parameters, fiber forming process parameters and tensile strength are determined. The composition, melting process parameters and fiber forming process parameters of basalt are shown in Table 1 and Table 2.

[0028] Chemical composition (wt%) of table 1 basalt

[0029] chemical composition CBF1 CBF2 CBF3 CBF4 SiO 2

57.5 54.12 51.79 46.45 Al 2 o 3

16.85 13.98 16.54 16.39 TiO 2

1.16 0.9 1.63 1.91 Fe 2 o 3

3.86 6.81 4.47 9.13 FeO 3.22 3.19 4.4 0.76 MgO 2.64 4.88 5.25 7.16 CaO 3.75 6 8.37 8.99 Na 2 o

3.27 3.24 2.29 6.6 K 2 o

2.58 2.85 0.9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com