Optical glass with high refractive index

A technology of optical glass and high refractive index, applied in the field of optical glass, can solve the problems of no transition temperature, low or no content, low or no, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

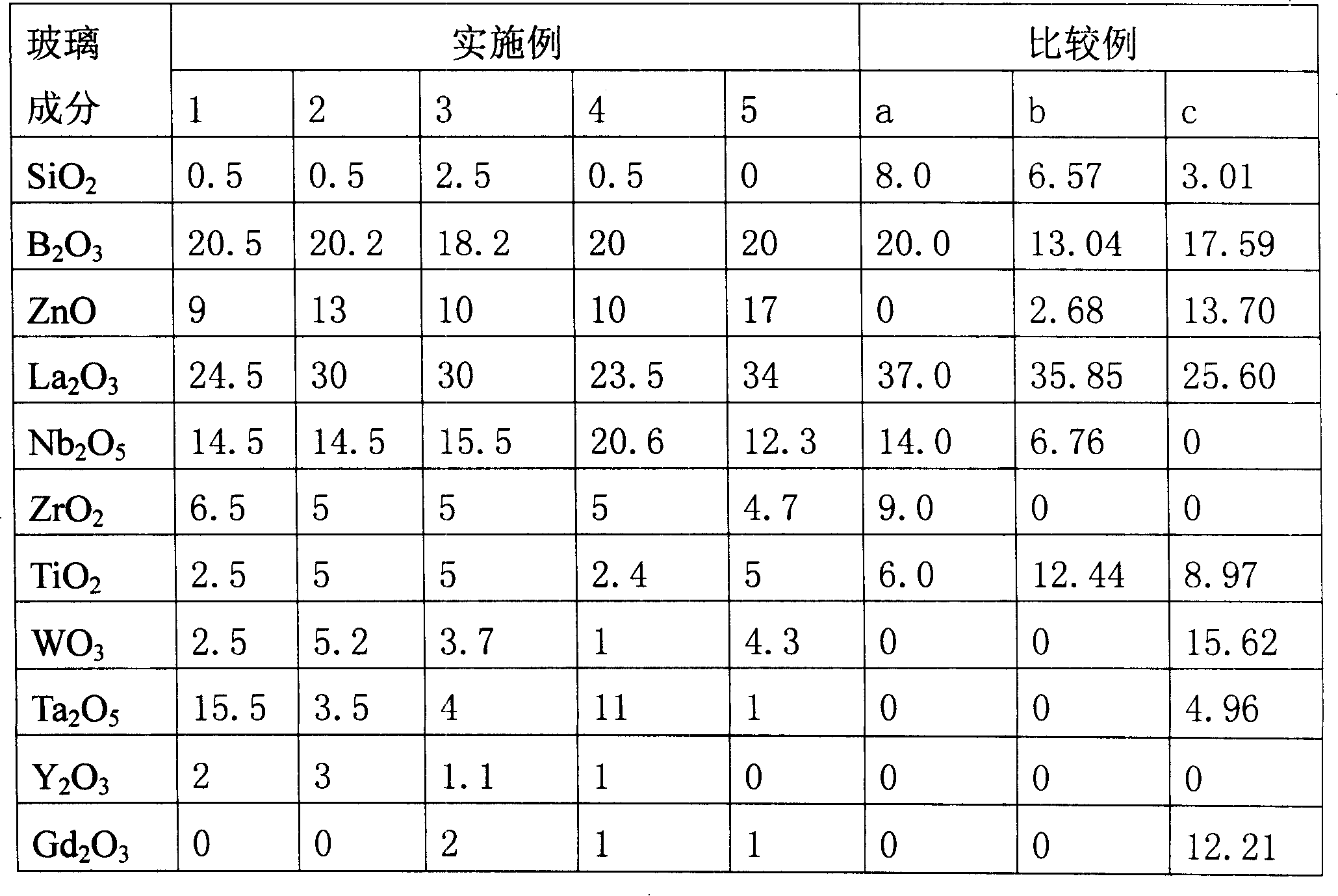

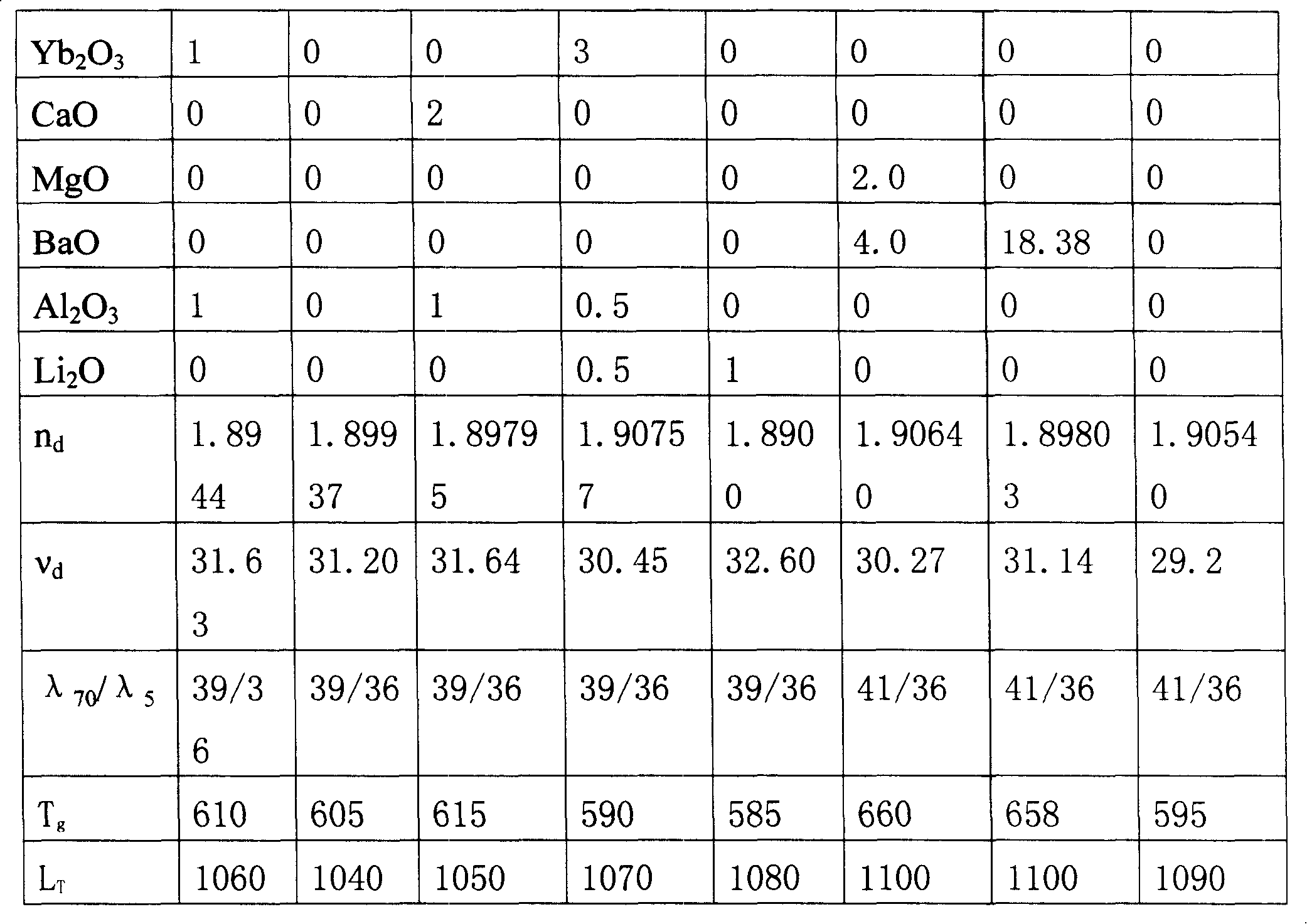

[0024] The present invention provides 5 examples and 3 existing formula comparison examples of high refractive index glass. Example 1 to Example 5, Comparative Example a to Comparative Example c glass composition (weight percentage), optical constant refractive index (n d ), dispersion coefficient (v d ), transition temperature (T g ), coloring degree (λ 70 / λ 5 ) And the upper limit of crystallization temperature (L T ) Is listed in Table 1.

[0025] The so-called crystallization test is to put 500g of the mixed glass raw materials into a 300cc platinum pot, and according to the difficulty of the solubility of each sample, use an electric furnace to smelt at 1200~1300℃ for 3 hours. The smelting process is stirred and defoamed The glass is uniform, and then the temperature is lowered. Then, each sample is kept at a temperature in the range of 1150°C to 1040°C every 10°C for 1 hour and then taken out. Finally, observe whether there is crystallization with a microscope to determine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com