3D-shaped colorable ion exchange glass and preparation method thereof

A technology of ion exchange and glass, which is applied in the field of ion exchange glass and its preparation, can solve the problems that glass is not suitable for rising temperature, damage glass and degrade mold, and is expensive, and achieve the effects of low cost, increased glass strength, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

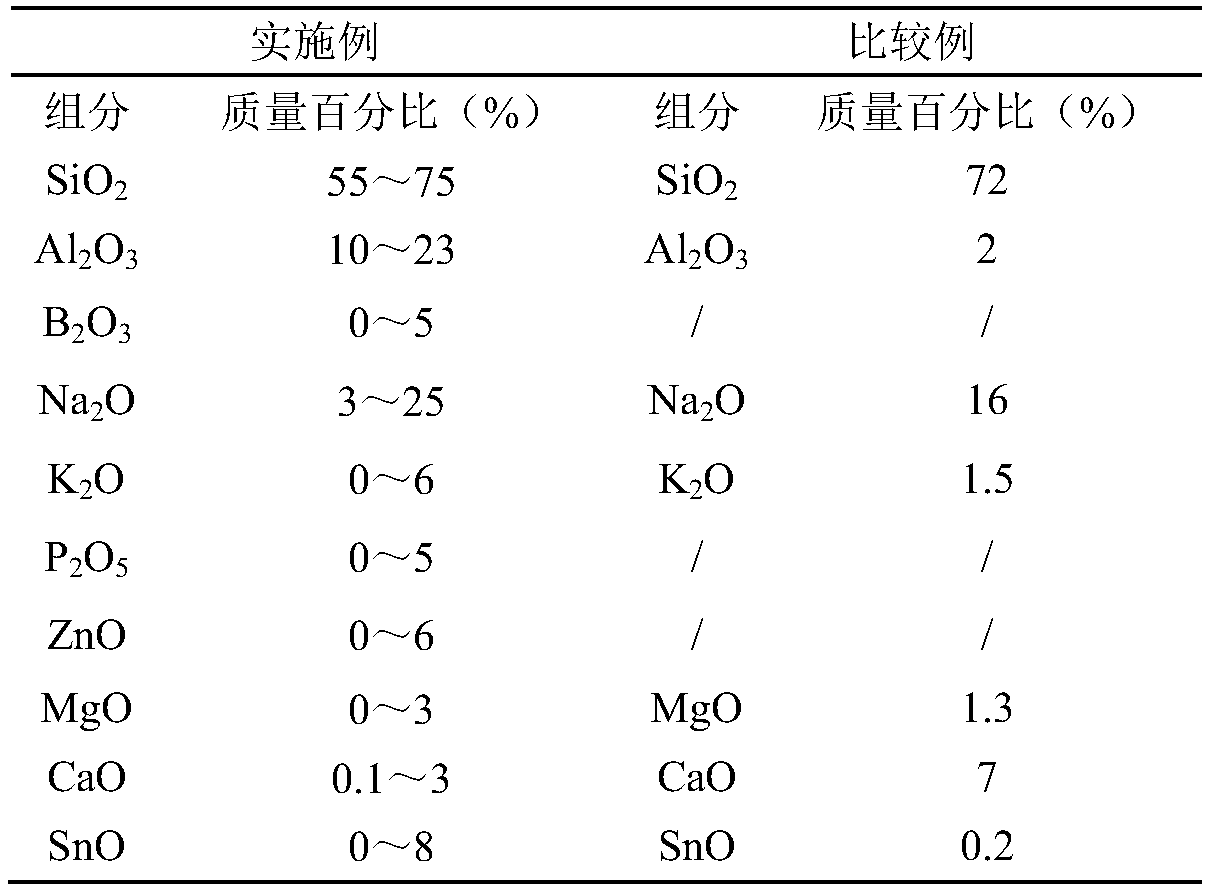

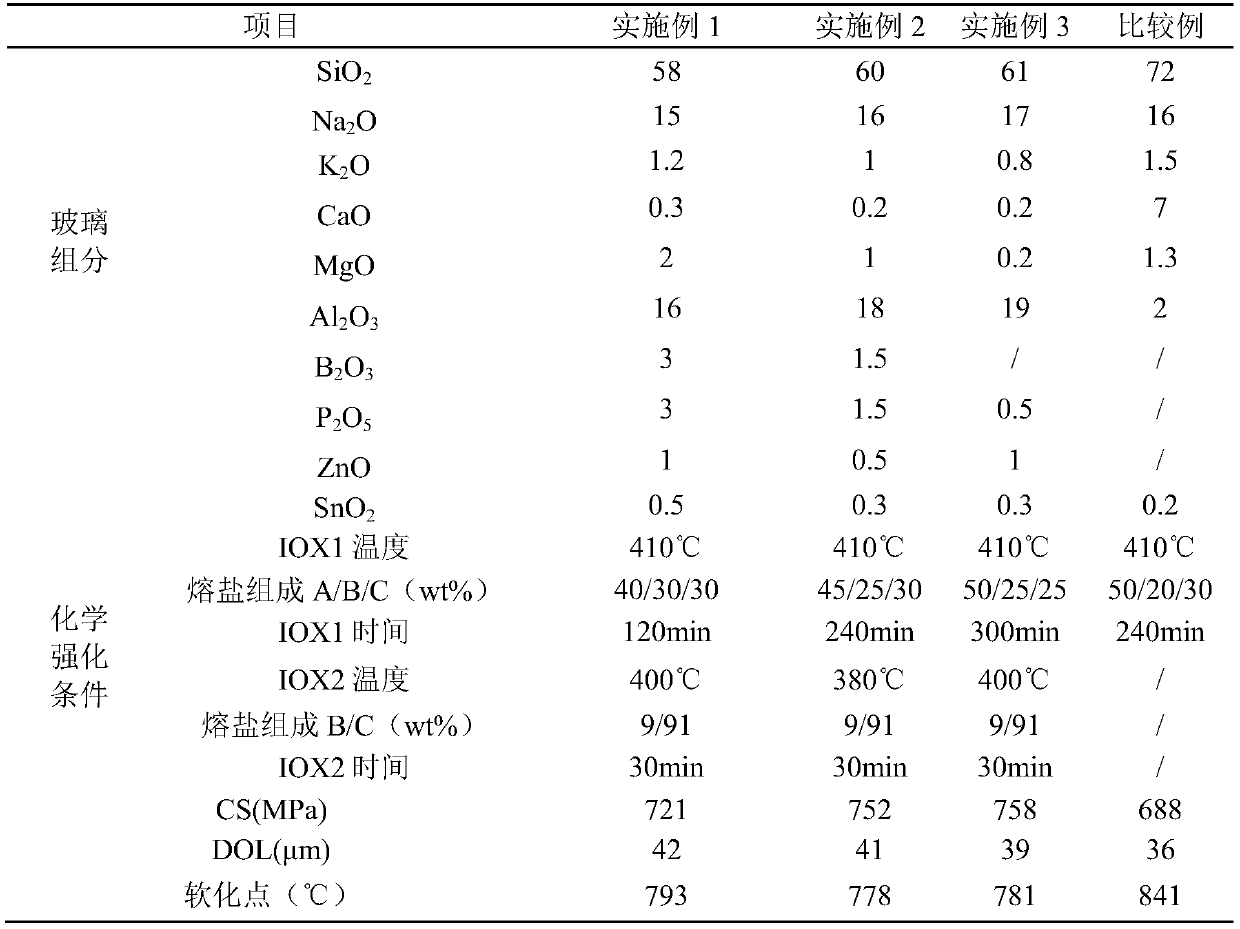

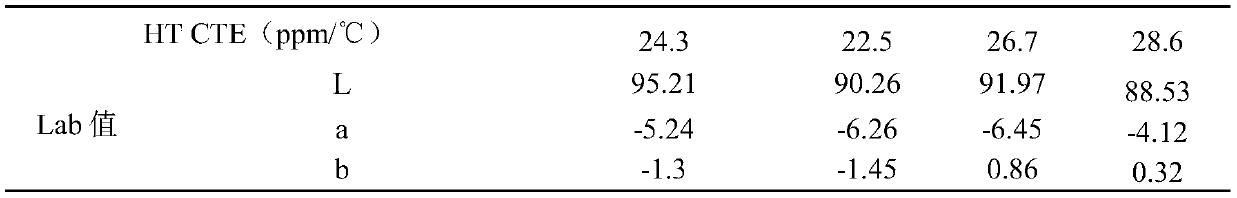

[0025] The 3D forming colorable ion-exchange aluminosilicate glass of the present invention contains the following components by mass percentage, SiO 2 55%~75%, Al 2 o 3 7% to 23%, B 2 o 3 0~5%,Na 2 O 3%~25%, K 2 O 0~6%, P 2 o 5 0~5%, ZnO 0~6%, MgO 0~3%, CaO 0.1%~3%, SnO 2 0~4%.

[0026] The function and specific content of each component in the above-mentioned 3D formable colorable ion-exchanged aluminosilicate glass are discussed below, and the unit of content is mass percent.

[0027] SiO 2 : 55% to 75%.

[0028] SiO 2 It is an essential component for forming a glass skeleton. When SiO in glass 2 At lower concentrations, the resulting glass has lower chemical durability, however, if the glass contains SiO 2 The concentration of SiO is too high, which can reduce the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com