Low-dielectric-constant high-frequency glass ceramic LTCC material and preparation method thereof

A glass-ceramic, high-frequency technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of large loss, achieve the effects of lower melting temperature, lower dielectric loss, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

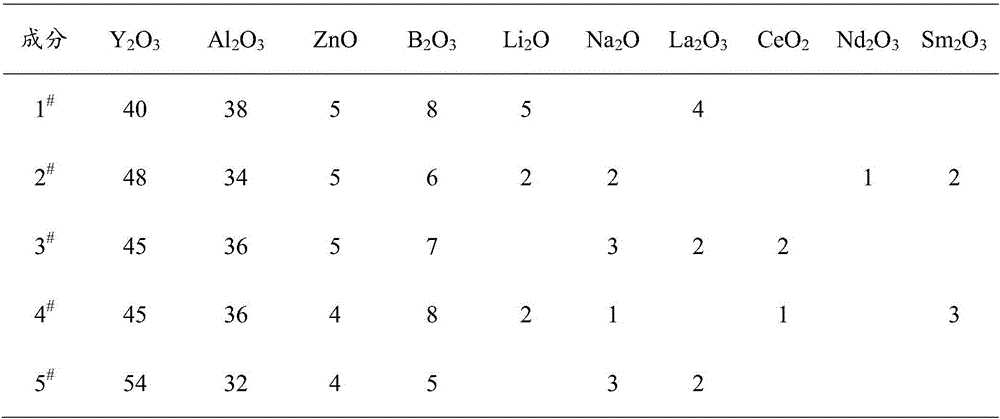

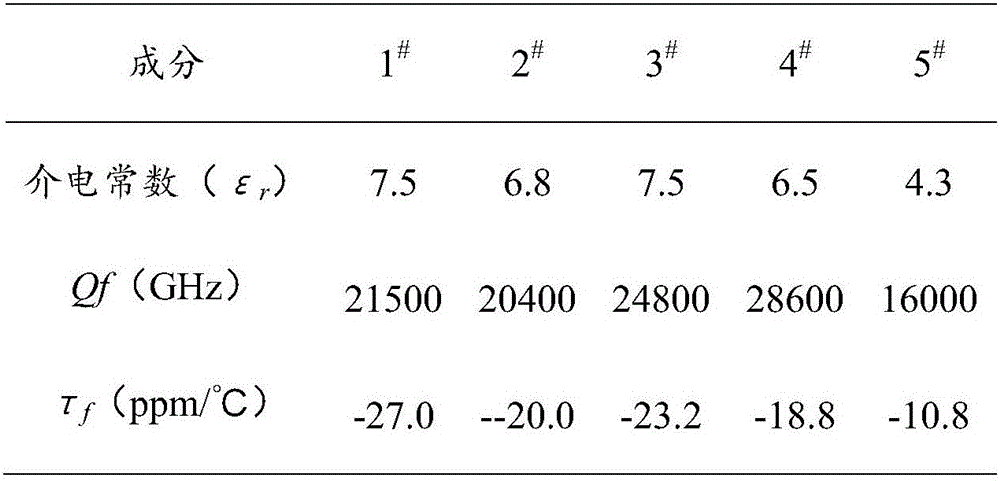

[0030] A low-dielectric and high-frequency glass-ceramic LTCC material, according to 1 in Table 1 # ~5 # The ingredients shown are equipped with mixed powder respectively, and 1 # mixed powder, 2 # mixed powder, 3 # powder mix, 4 # Mix powder and 5 # Mix the powder.

[0031] A method for preparing a low-dielectric and high-frequency glass-ceramic LTCC material, comprising the steps of:

[0032] The first step, ingredients: will 1 # The mixed powder is placed in a planetary ball mill for ball milling for 4 hours, and the speed of the planetary ball mill is 200rpm;

[0033] The second step is to prepare glass powder: the ball milled 1 # The mixed powder is placed in a high-temperature glass melting furnace, heated and melted, and the heating and melting process is as follows: heat up to 1400°C, keep warm for 4 hours, stir with a quartz glass rod every 1 hour; cool down after the melt is clarified, pour the melt Quenched in distilled water to obtain 1 # Glass powder; mi...

Embodiment 2

[0041] A low-dielectric and high-frequency glass-ceramic LTCC material, according to 1 in Table 1 # ~5 # The ingredients shown are equipped with mixed powder respectively, and 1 # mixed powder, 2 # mixed powder, 3 # powder mix, 4 # Mix powder and 5 # Mix the powder.

[0042] A method for preparing a low-dielectric and high-frequency glass-ceramic LTCC material, comprising the steps of:

[0043] The first step, ingredients: will 1 # The mixed powder was placed in a planetary ball mill for ball milling for 8 hours, and the speed of the planetary ball mill was 150rpm;

[0044] The second step is to prepare glass powder: the ball milled 1 # The mixed powder is placed in a high-temperature glass melting furnace, heated and melted. The heating and melting process is as follows: heat up to 1500°C, keep warm for 2 hours, and stir with a quartz glass rod every 1 hour; after the melt is clarified, cool down and pour the melt Quenched in distilled water to obtain 1 # Glass powd...

Embodiment 3

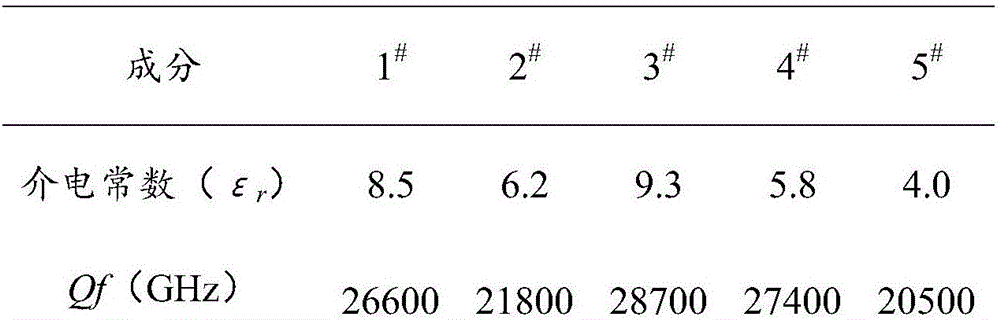

[0053] A low-dielectric and high-frequency glass-ceramic LTCC material, according to 1 in Table 1 # ~5 # The ingredients shown are equipped with mixed powder respectively, and 1 # mixed powder, 2 # mixed powder, 3 # powder mix, 4 # Mix powder and 5 # Mix the powder.

[0054] A method for preparing a low-dielectric and high-frequency glass-ceramic LTCC material, comprising the steps of:

[0055] The first step, ingredients: will 1 # The mixed powder was placed in a planetary ball mill for ball milling for 6 hours, and the speed of the planetary ball mill was 180rpm;

[0056] The second step is to prepare glass powder: the ball milled 1 # The mixed powder is placed in a high-temperature glass melting furnace, heated and melted, and the heating and melting process is as follows: heat up to 1450°C, keep warm for 3 hours, stir with a quartz glass rod every 1 hour; cool down after the melt is clarified, pour the melt Quenched in distilled water to obtain 1 # Glass powder; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com