Hydrophobic porous ceramic product and preparation technology thereof

A technology of porous ceramics and preparation technology, applied in the field of ceramic products, can solve the problems of porous ceramics, such as the brittleness of porous ceramics has not been effectively solved, lack of continuity, large-scale system production, etc., to make up for the shortcomings of brittleness, shorten drying time, and low density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

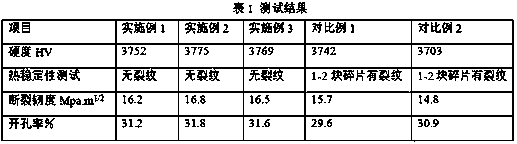

Examples

Embodiment 1

[0026] A hydrophobic porous ceramic product, comprising a body and a glaze, the body comprising the following raw materials in parts by weight: 24 parts of silicon nitride, 15 parts of zirconium dioxide, 11 parts of clay, 23 parts of aluminum silicate, cordierite 14 parts, 18 parts of silicon carbide, 10 parts of diatomaceous earth, 9 parts of albite, 14 parts of aluminum oxide, 12 parts of fluxing material, described fluxing material is by weight ratio of talc, wollastonite and sodium silicate Mixed in a ratio of 2:3:3; the glaze includes the following raw materials in parts by weight: 18 parts of dolomite, 22 parts of silicon carbide, 14 parts of calcium oxide, 13 parts of potassium feldspar, 4 parts of clay, hexametaphosphoric acid Sodium 1 part.

[0027] This embodiment also provides a process for preparing the hydrophobic porous ceramic product, comprising the following steps:

[0028] Step 1. Weigh the green body raw material according to the weight and pulverize it, pu...

Embodiment 2

[0036] A hydrophobic porous ceramic product, comprising a body and a glaze, the body comprising the following raw materials in parts by weight: 29 parts of silicon nitride, 16 parts of zirconium dioxide, 15 parts of clay, 25 parts of aluminum silicate, cordierite 16 parts, 19 parts of silicon carbide, 12 parts of diatomaceous earth, 11 parts of albite, 17 parts of aluminum oxide, 15 parts of fluxing material, described fluxing material is by weight ratio of talc, wollastonite and sodium silicate Mixed in a ratio of 2:3:3; the glaze includes the following raw materials in parts by weight: 22 parts of dolomite, 24 parts of silicon carbide, 15 parts of calcium oxide, 14 parts of potassium feldspar, 5 parts of clay, hexametaphosphoric acid Sodium 2 parts.

[0037] This embodiment also provides a process for preparing the hydrophobic porous ceramic product, comprising the following steps:

[0038] Step 1. Weigh and pulverize the green body raw material according to the weight, put...

Embodiment 3

[0046] A hydrophobic porous ceramic product, comprising a green body and a glaze. The green body includes the following raw materials in parts by weight: 32 parts of silicon nitride, 17 parts of zirconium dioxide, 16 parts of clay, 28 parts of aluminum silicate, cordierite 18 parts, 22 parts of silicon carbide, 15 parts of diatomite, 12 parts of albite feldspar, 21 parts of aluminum oxide, 16 parts of fluxing material, described fluxing material is by weight ratio of talc, wollastonite and sodium silicate Mixed in a ratio of 2:3:3; the glaze includes the following raw materials in parts by weight: 24 parts of dolomite, 26 parts of silicon carbide, 16 parts of calcium oxide, 18 parts of potassium feldspar, 6 parts of clay, hexametaphosphoric acid Sodium 3 parts.

[0047] This embodiment also provides a process for preparing the hydrophobic porous ceramic product, comprising the following steps:

[0048] Step 1. Weigh the green body raw material according to the weight and pulv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com