Anti-blue-light high-strength lithium-aluminum-silicon cover plate glass and preparation method and application thereof

A cover glass, high-strength technology, used in glass manufacturing equipment, glass molding, glass tempering and other directions, can solve the problems of insufficient glass strength, no anti-blue light, etc., and achieve the effect of preventing impact or scratch damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The invention discloses a preparation method of a high-strength lithium-aluminum-silicon cover glass for preventing blue light, which specifically includes the following steps:

[0043] (1) Weighing: in mass percentage, according to SiO 2 70%, Al 2 o 3 18%, Li 2 O 2%, Na 2 O 6%, B 2 o 3 0.79%, MgO 1%, ZnO 0.5%, ZrO 2 1%, CdS 0.05%, CdSe 0.05%, SnO 2 0.6%, carbon powder 0.01% proportion weighing;

[0044] (2) Mixing: After the above-mentioned raw materials are accurately weighed according to the weight ratio, fully mix with a mixer to form a batch;

[0045] (3) Melting: first raise the temperature of the muffle furnace to 1300°C, then add the obtained batch material into a platinum crucible with a platinum cover, then put it into the muffle furnace and raise the temperature to 1680°C for 6 hours to obtain molten glass;

[0046] (4) Annealing: pour the molten glass into a mold on a stainless steel plate, and place it in an annealing furnace for annealing afte...

Embodiment 2

[0051] The invention discloses a preparation method of a high-strength lithium-aluminum-silicon cover glass for preventing blue light, which specifically includes the following steps:

[0052] (1) Weighing: in mass percentage, according to SiO 2 56%, Al 2 o 3 23%, Li 2 O 4%, Na 2 O 6%, K 2 O0.5%, MgO 1.5%, ZnO 2%, ZrO 2 3%, CdS 1%, CdSe 1%, SnO 2 1%, potassium tartrate 1% proportion weighing;

[0053] (2) Mixing: After the above-mentioned raw materials are accurately weighed according to the weight ratio, fully mix with a mixer to form a batch;

[0054] (3) Melting: first raise the temperature of the muffle furnace to 900°C, then add the obtained batch material into a platinum crucible with a platinum cover, then put it into the muffle furnace and raise the temperature to 1500°C for 4 hours to obtain molten glass;

[0055] (4) Annealing: pour the molten glass into a mold on a stainless steel plate, and place it in an annealing furnace for annealing after the glass ...

Embodiment 3

[0060] The steps are the same as in Example 1, and the parameters used therein refer to the data in the table, as shown in Table 1. The reducing agent adopts long-chain aliphatic amine.

[0061] The first chemically strengthened molten salt was 60% NaNO 3 and 40% KNO 3 The composition of the proportioned salt, the strengthening temperature is 430°C, and the strengthening time is 240min; the molten salt for the second chemical strengthening is 95% KNO 3 and 5% NaNO 3 , the strengthening temperature is 430°C, and the strengthening time is 30min.

[0062] The steps of other embodiments are the same as those of Embodiment 1, and the parameters used therein refer to the data in the table, as shown in Table 1.

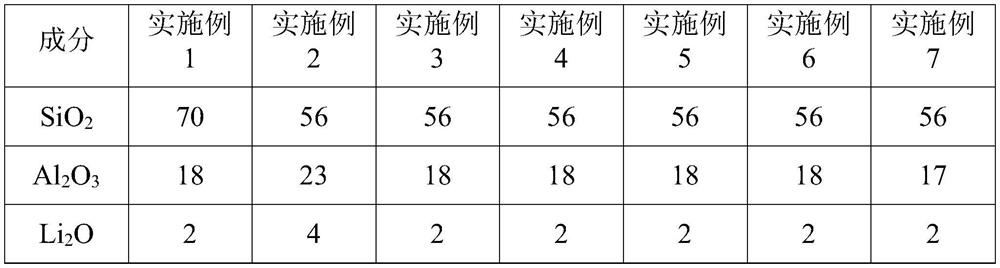

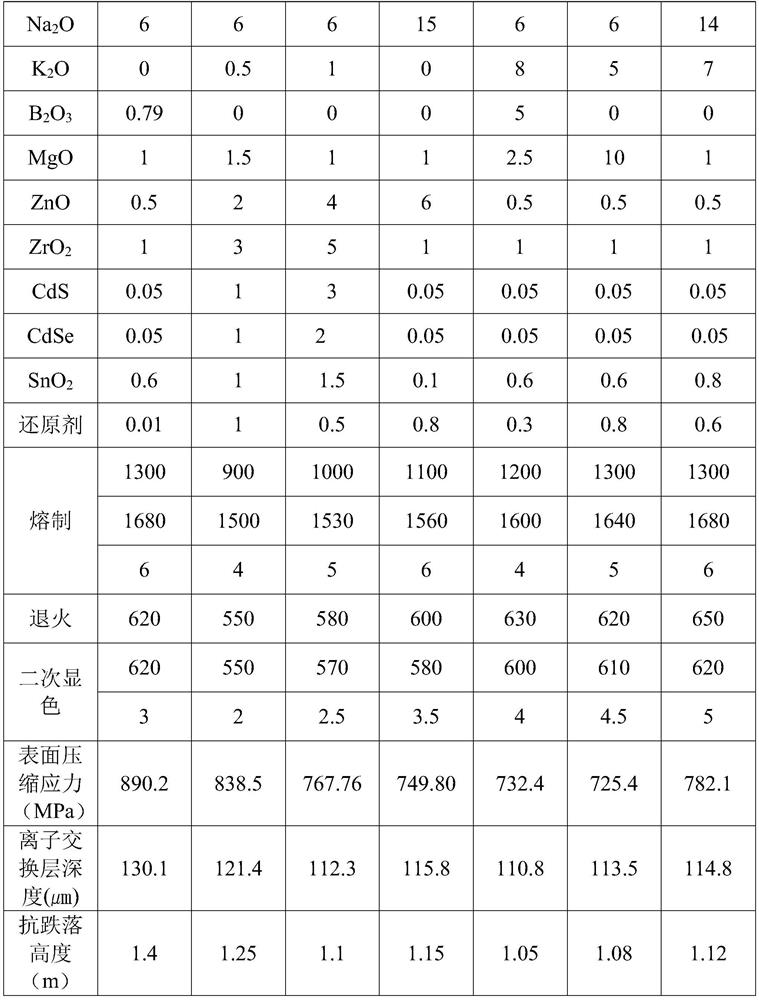

[0063] Table 1

[0064]

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com