Sintering method red mud and Bayer method red mud mixed dam building method

A technology of sintering method and red mud, which is applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of high dam construction cost, reduce dam construction cost, improve treatment efficiency, improve The effect of stack height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

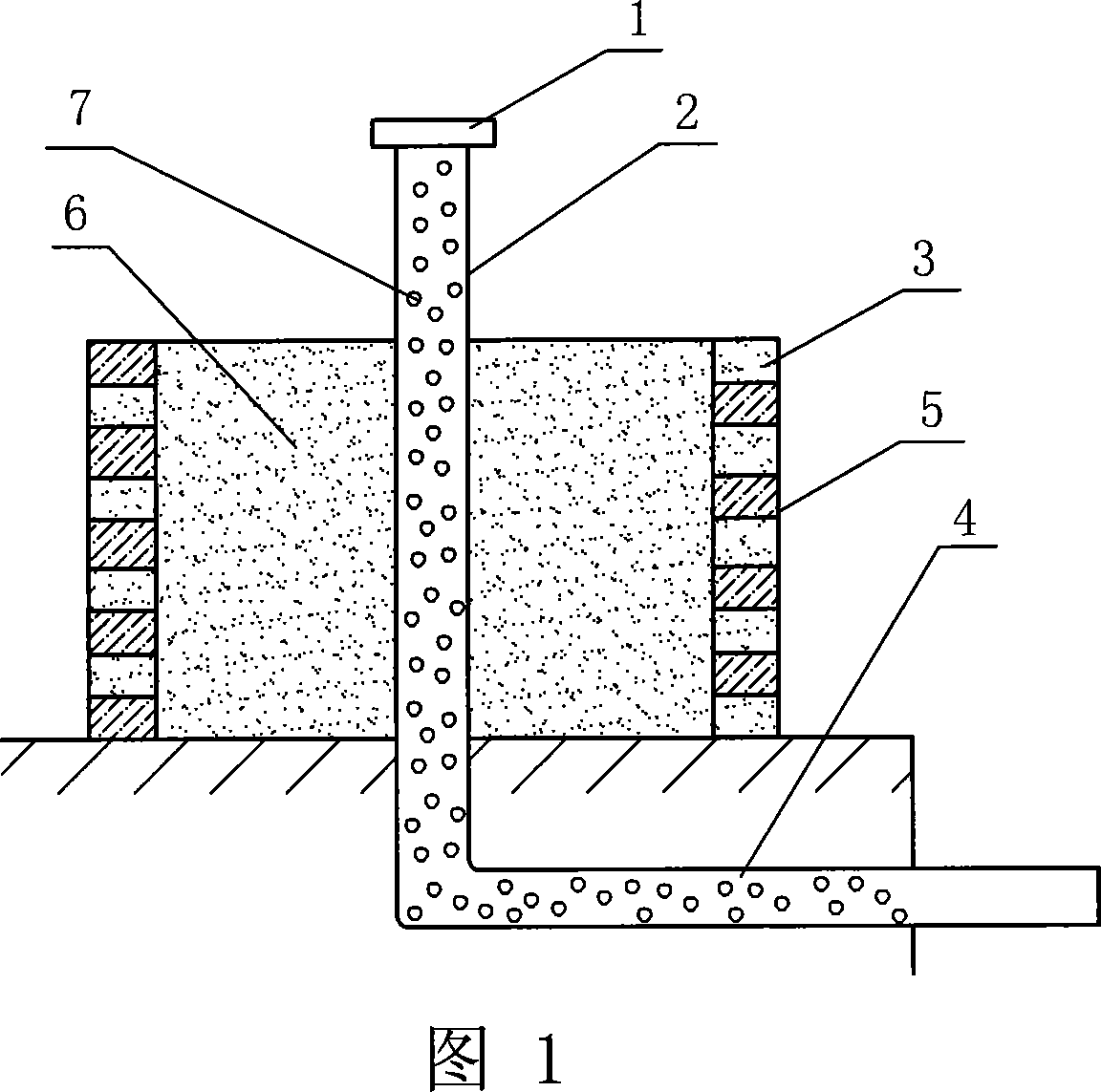

[0020] A fine sand cofferdam type seepage drainage column is arranged in the dam building, and a cofferdam column 5 with a hollowed-out 3 is built with bricks. The cofferdam column 5 is provided with a φ200mm steel pipe riser 2, and the standpipe 2 is designed It is divided into multiple sections, connected by the connecting flange 1, and the connection is increased during construction. The lower end of the standpipe 2 is connected to the seepage pipe 4. The pipe wall of the standpipe 2 is provided with a seepage hole 7 with a diameter of 10mm, and the seepage hole 7 is wrapped There is a gauze, the brick joints of the cofferdam cylinder 5 and the cavity formed by the cofferdam cylinder 5 and the standpipe 2 are filled with fine sand 6, and the particle size of the fine sand is controlled to be 0.5mm.

[0021] The imported gibbsite ore Bayer process red mud and sintering process red mud were mixed according to the weight ratio of dry red mud at 0.43:1, and then the dam was buil...

Embodiment 2

[0023] A fine sand cofferdam type seepage drainage column is arranged in the dam building, and a cofferdam column 5 with a hollowed-out 3 is built with bricks. The cofferdam column 5 is provided with a φ210mm steel pipe riser 2, and the standpipe 2 is designed It is divided into multiple sections, connected by the connecting flange 1, which is connected and raised during construction. The lower end of the standpipe 2 is connected to the seepage pipe 4. The wall of the standpipe 2 is provided with a water seepage hole 7 with a diameter of 12 mm. The water seepage hole 7 is wrapped There is gauze, the brick joints of the cofferdam cylinder 5 and the cavity formed by the cofferdam cylinder 5 and the riser 2 are filled with fine sand 6, and the particle size of the fine sand is controlled to be 0.08mm.

[0024] The imported gibbsite ore Bayer red mud and sintering red mud are mixed according to the weight ratio of dry red mud at a ratio of 1:1, and then the dam is built. The compre...

Embodiment 3

[0026] A fine sand cofferdam type seepage drainage column is arranged in the dam building, and a cofferdam column 5 with a hollowed-out 3 is built with bricks. The cofferdam column 5 is provided with a φ198mm steel pipe riser 2, and the standpipe 2 is designed It is divided into multiple sections, connected by the connecting flange 1, which is connected and raised during construction. The lower end of the standpipe 2 is connected to the seepage pipe 4, and the wall of the standpipe 2 is provided with a seepage hole 7 with a diameter of 8mm, and the seepage hole 7 is wrapped There is a gauze, the brick joints of the cofferdam cylinder 5 and the cavity formed by the cofferdam cylinder 5 and the riser 2 are filled with fine sand 6, and the particle size of the fine sand is controlled to be 0.2mm.

[0027] The imported gibbsite ore Bayer red mud and sintering red mud were mixed according to the weight ratio of dry red mud at 2.33:1, and then the dam was built. The compressive stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com