Patents

Literature

63results about How to "Save huge investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for restoring mine entironment

InactiveCN101037268ALow costLow infrastructure costWaste water treatment from quariesWater contaminantsEcological environmentSulfate-reducing bacteria

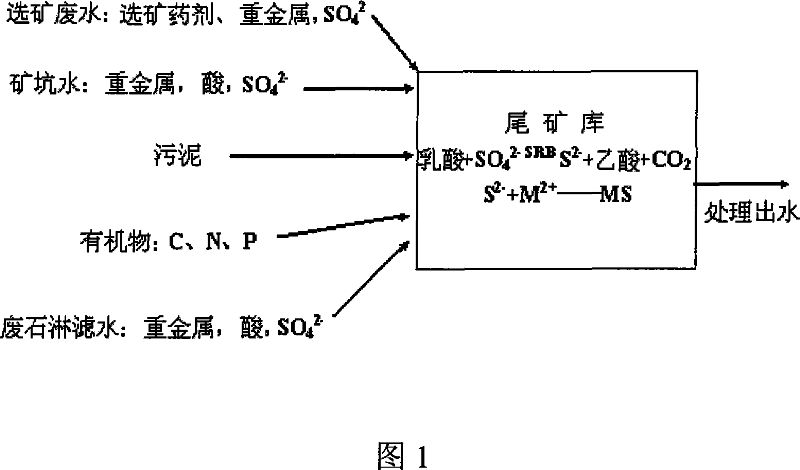

A method of repairing mine ecological environment comprises the treatment of mine environment contamination, wherein the tailings, the barren rock, the smelting slag, the waste water from ore cleaning, the waste water from smelting, the acid mine drainage and the ore yard leachwater which are generated from mine development are collected into the tailings storage, at the same time, sludge and organic matter capable of being degradated by microbiology are added therein, and then the tailings storage is given an anaerobic environment artificially, so that, under the action of microbiology and sulfate reducing bacteria, sulfur ion is generated and the pH value of the tailings storage is increased, a plurality of heavy metal ions are cured and settled by sulfur ion to avoid migration, a biomembrane layer-sulfate reducing bacteria reducing-induction biomineralization precipitation composite geochemical barrier is generated in the tailings storage. The repairing of mine ecological environment is realized by the treatment of mine environment contamination. The present invention can be used for tailings storage pollution prevention in tour, and can be used for closing the repairing of mine ecological environment, or can be used for designing new tailings storage by using the technology of the present invention.

Owner:ELION ECOLOGICAL RESTORATION

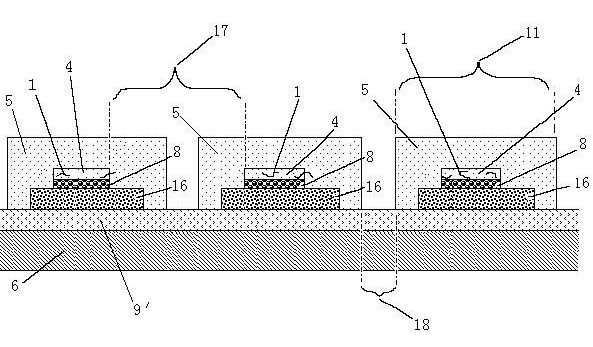

Thermo-printing texture anti-counterfeit printed product, special thermo-printing film and manufacturing method thereof

ActiveCN102394029ASimple production processSave huge investmentStampsLayered productsFiberThe Internet

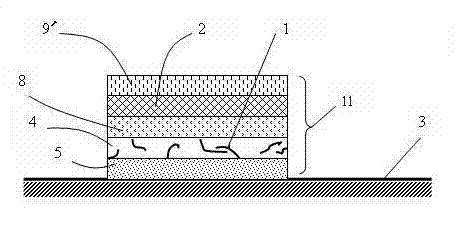

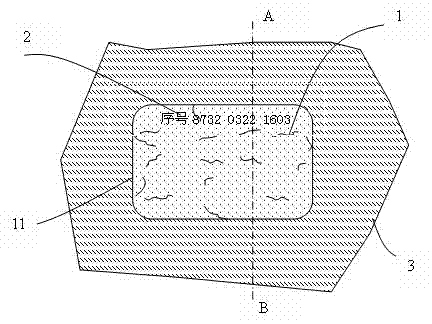

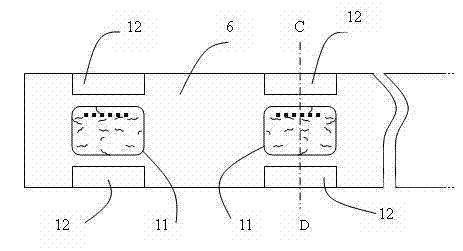

The invention provides a thermo-printing texture anti-counterfeit printed product, a special thermo-printing film and a manufacturing method thereof. Fibers are randomly thrown onto a film which is locally coated with a bonding agent, thereby preparing the thermo-printing film. Random distribution characteristic information of the fibers is scanned and collected and is stored in a database of a computer anti-counterfeit inquiring system which is connected to a telephone network and / or internet, so that people can check authenticity according to the random distribution characteristic information. A printing factory can thermo-print and produce the local texture anti-counterfeit printed product in background art by utilizing a traditional thermo-printing technique and device and utilizing the thermo-printing film. Huge investment of special equipment is saved, production process is simplified, production efficiency is promoted, production cost is lowered and texture limitation of prior art is broken through. The invention provides another novel anti-counterfeit technical method based on fiber usage.

Owner:HAINAN PPK NETWORK TECH

Low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material and preparation method thereof

ActiveCN102093625AReliable Extrusion PerformanceReliable degree of cross-linkingInsulated cablesInsulated conductorsMasterbatchLow smoke zero halogen

The invention relates to a low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material and the cable material contains the raw materials of flame retardant masterbatch, catalyst masterbatch and crosslinking compounding agent. The preparation method comprises the following steps: mixing flame retardant masterbatch, catalyst masterbatch and crosslinking compounding agent in a sealed mixer for absorption, discharging after 3-5 hours, and packaging to obtain the low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material finished product. Compared with the common low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material, the temperature resistant grade and mechanical properties of the product of the invention can be increased and the problem that the common low smoke non-halogen polyolefin cable material is easy to crack can be eliminated.

Owner:中广核三角洲(江苏)塑化有限公司

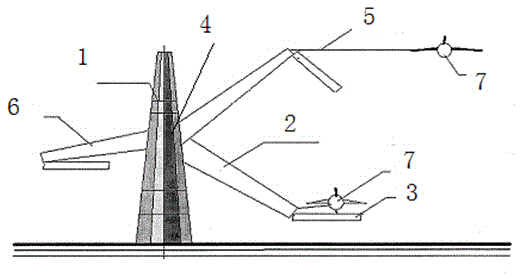

Device for launching and landing aircrafts

InactiveCN104058100AImprove people's livelihoodStrong defenseArresting gearLaunching/towing gearRotational axisFlight vehicle

The invention discloses a device for launching and landing aircrafts. The device comprises a fixedly arranged rotary launching tower, wherein a rotating shaft is arranged at the middle part of the rotary launching tower; a group of rotating arms extending outwards is arranged on the rotating shaft, one end of each rotating arm is hinged to the rotating shaft, and a bearing platform capable of adjusting an angle of inclination is arranged at the extending end of each rotating arm; telescopic flexible elastic ropes matched with the aircrafts are arranged at the extending ends of the rotating arms. The device adopts a brand-new launching and landing manner for the aircrafts, and a large-area runway is not needed, so that a heavy investment is saved; a plurality of aircrafts can be launched at the same during launching, so that the time is reduced compared with the time used during conventionally successive launching; the device is high in controllability and high in reliability, and the requirement for the operant level of navigating mates of the aircrafts is low.

Owner:杨举 +1

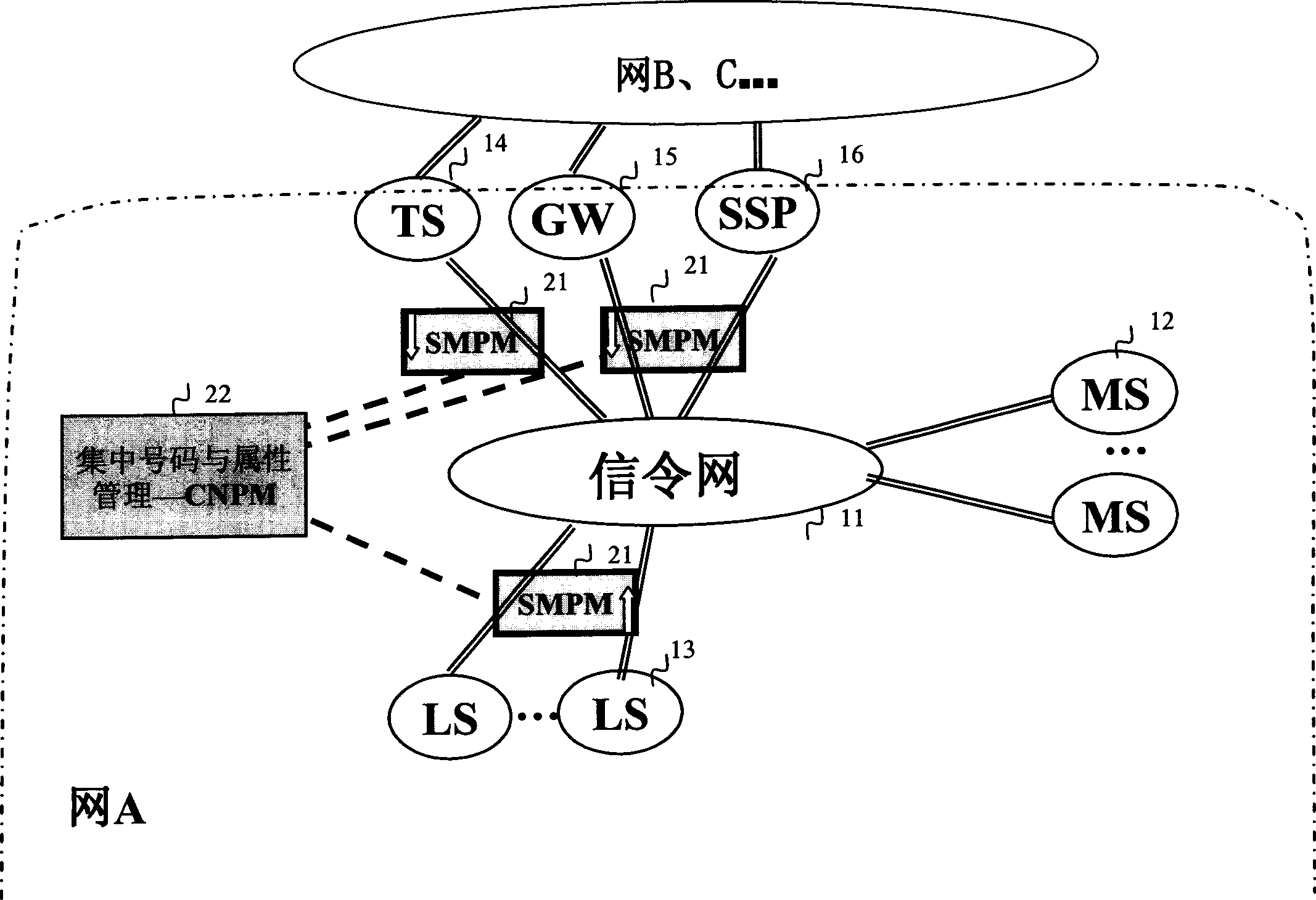

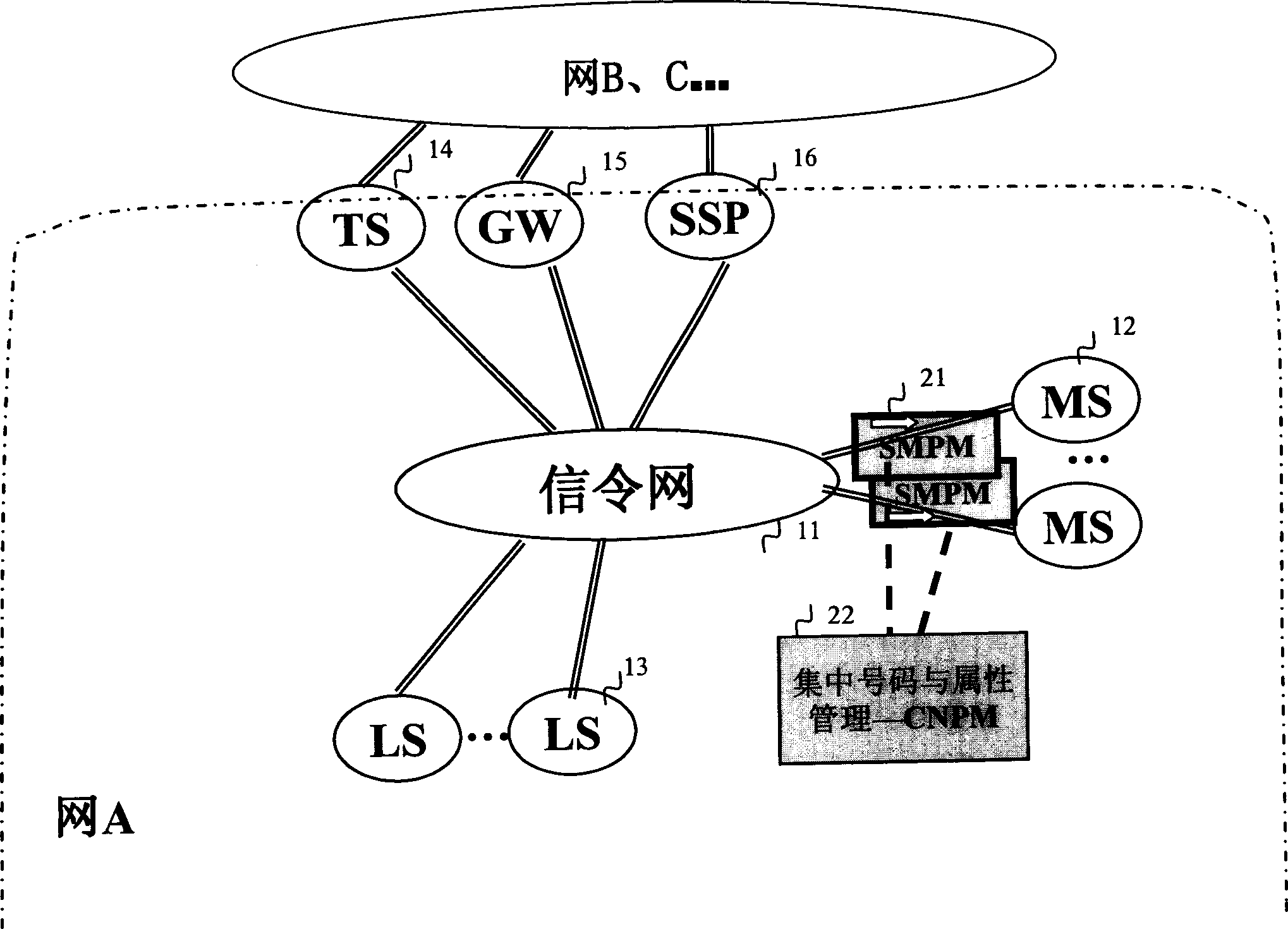

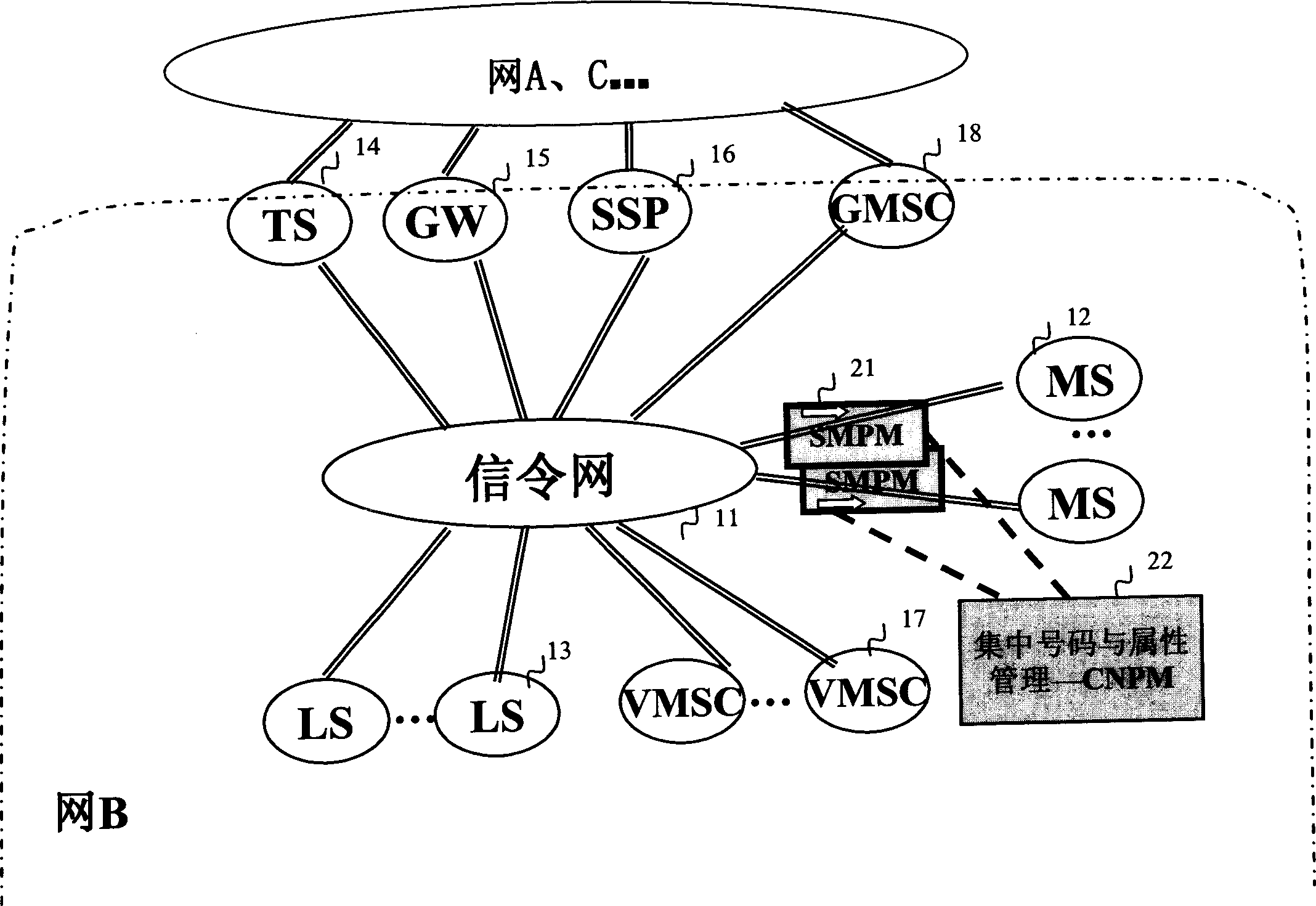

A system and method for implementing communication number portability service

InactiveCN1691787AAvoid constructionReduce riskTransmissionSelection arrangementsQuality of serviceReal time analysis

The invention relates to system and method for carriable affair of communication signal. The system is based on communication network composed by some telephone switch nodes with signaling chain circuit connect to seventh signaling network, and comprises some signaling message processing device and an integrated management center of user number and attribution; wherein, signaling message processing device is used to analyze and deal with real-time signaling message for controlling calling succeeded, executes operation of decoding and changing to user number; integrated management center of user number and attribution is used to register and manage mapping relation between logic number of portable user and route number and user affair attribution. The invention breaks technique limit of existing intelligence network and other systems, avoids improvement and upgrade of running switching device and signaling device, ensures communication serving quality, with low cost, independent to existing communication network, realizes number carriable affair both in and out network quickly, steadily and efficiently, and also fit to development and advance of communication network..

Owner:SHANGHAI LIANGJIANG COMM SYST

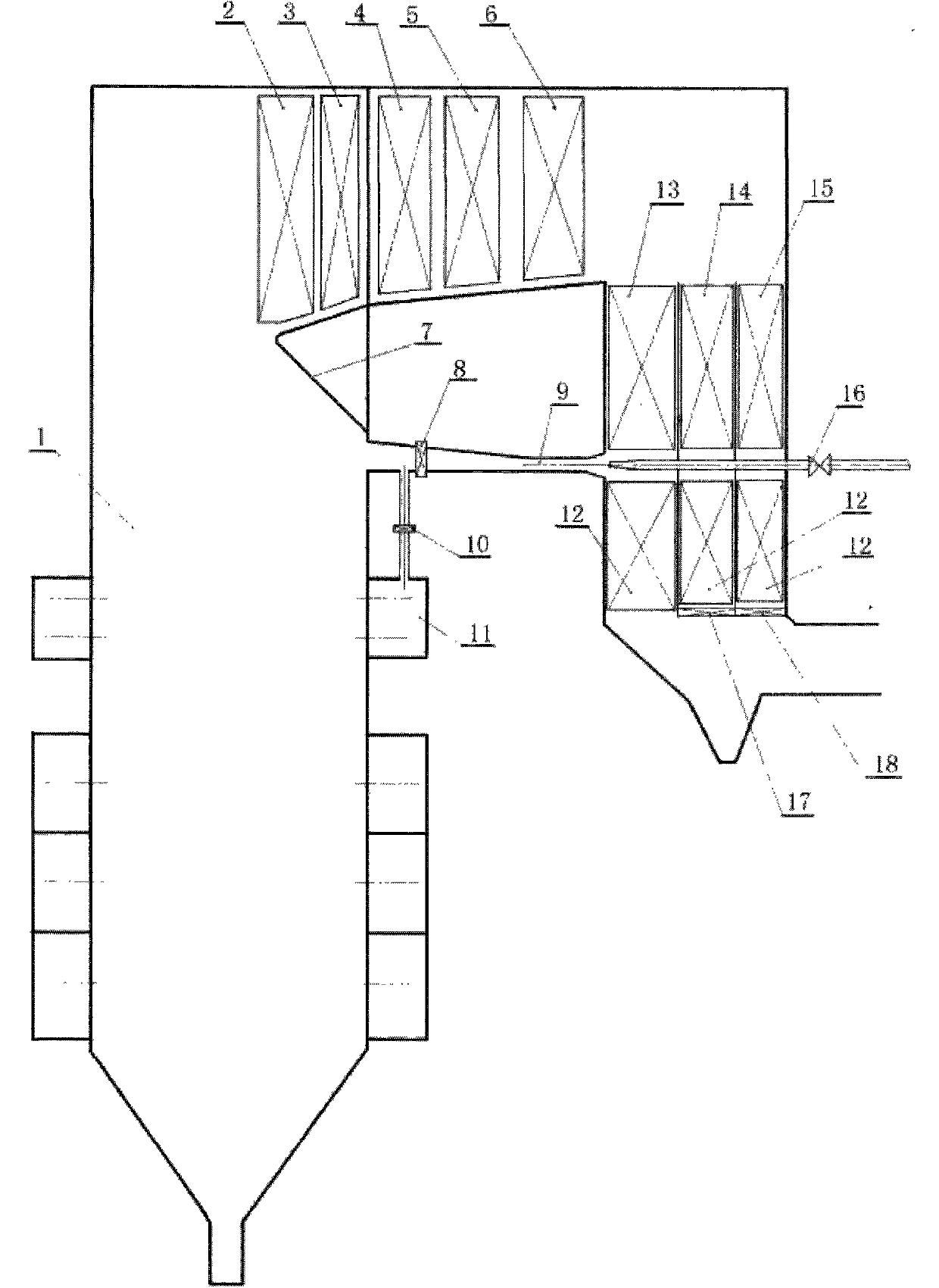

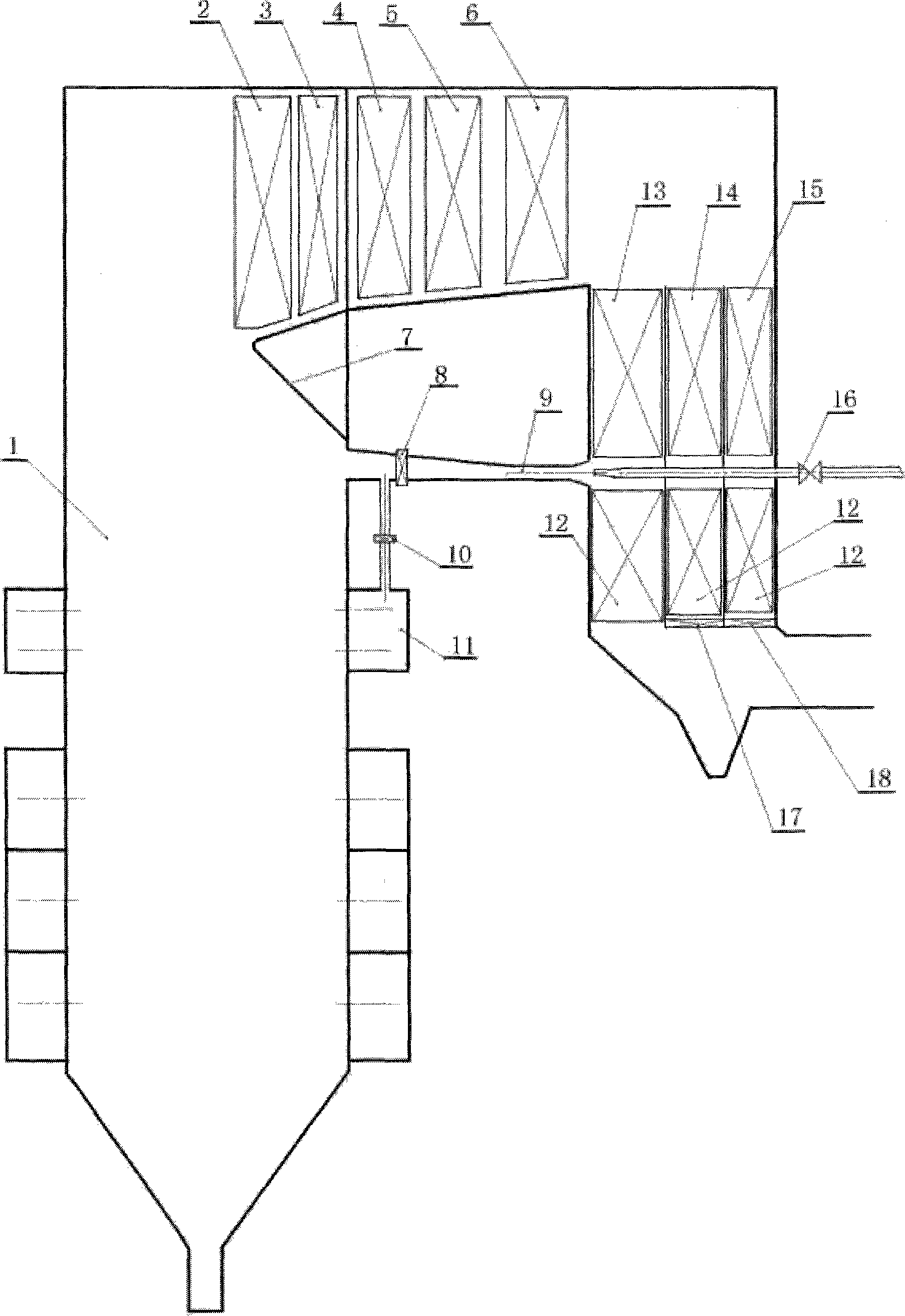

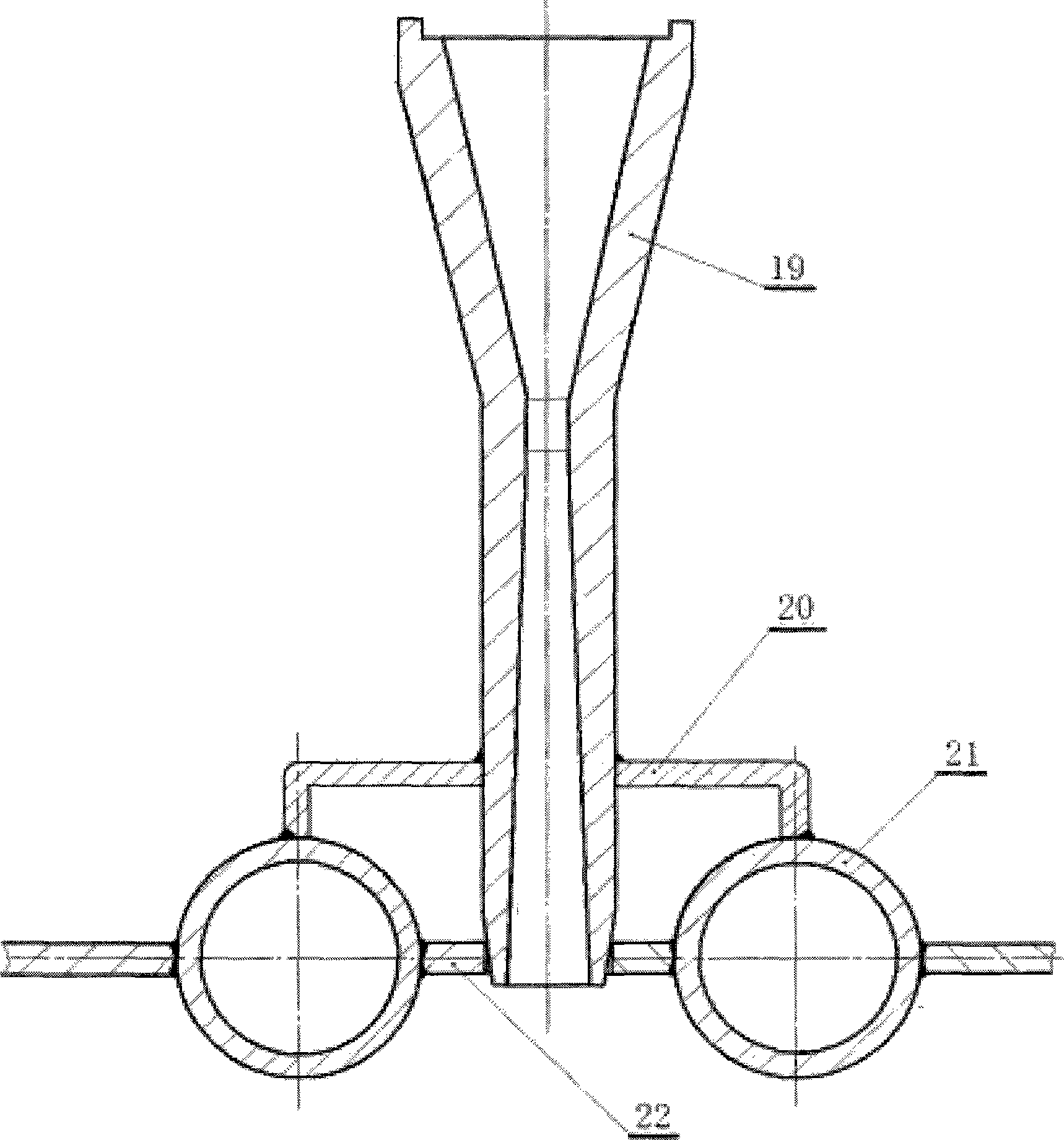

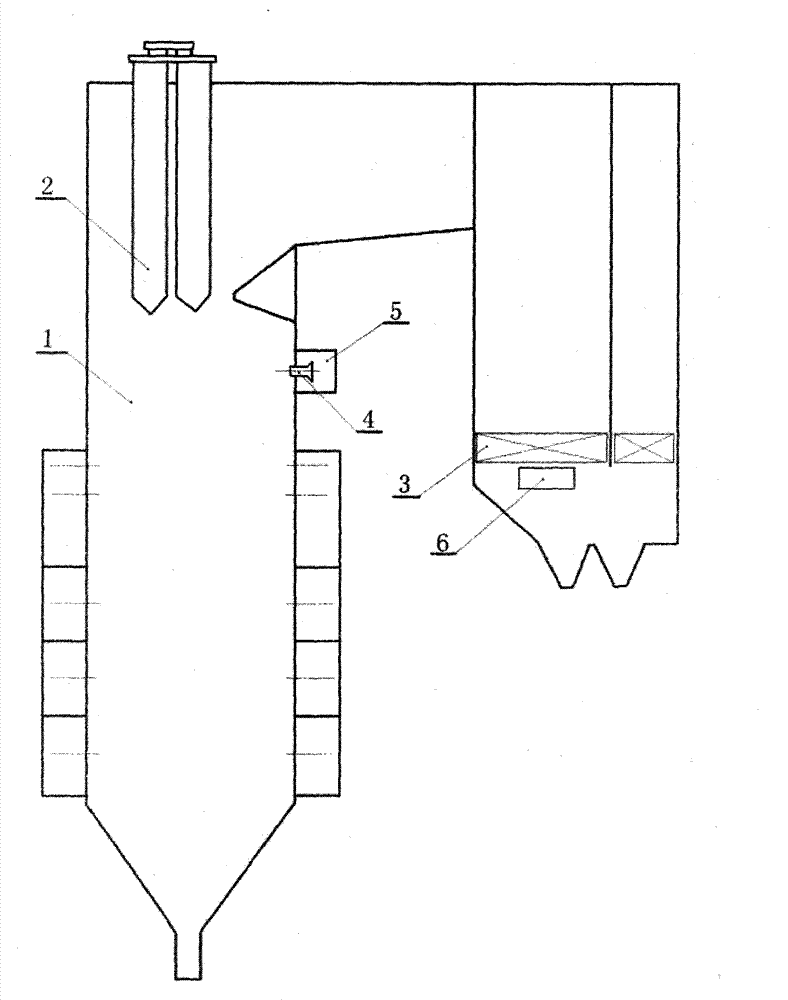

Double reheat power station boiler with three rear flues and double rear baffles and capable of recycling jet flow flue gas

ActiveCN103776020ASave huge investmentRadiation characteristic hedgingSteam superheatersLow loadSuperheater

The invention provides a double reheat power station boiler with three rear flues and double rear baffles and capable of recycling jet flow flue gas, and relates to a double reheat boiler which is used in a thermal power station and combusts bituminous coal, low moisture brown coal or lean coal. When the boiler bears a high load or a medium load, a worker adjusts a flue gas adjusting baffle on a rear flue so as to control heat absorption distribution between a low temperature super heater and a single low temperature reheater and between the low temperature super heater and a double low temperature reheater, and adjusts a flue gas adjusting baffle on a middle flue so as to control heat absorption distribution between the single low temperature reheater and the double low temperature reheater, and therefore enables single and double reheat air temperature to reach rated value. When the boiler bears the medium load or a low load, an ejector heat primary air adjusting baffle is opened, and sucks flue gas from the rear of the double low temperature reheater, a mixture of smoke and air enters a hearth from the lower portion of a smoke deflecting corner, a proportion of radiation heat exchange amount and convection heat exchange amount in the hearth is changed, flue gas volume flow is increased, the opening degree of the ejector heat primary air adjusting baffle is controlled so as to maintain the double reheat air temperature at the rating value in a range from 40% BMCR (boiler maximum continuous rating) to 100% BMCR, and no water needs to be sprayed.

Owner:章礼道

Eastern-Junggar-coal fired double-reheat steam power plant boiler

InactiveCN104075309ASave huge investmentClear thermostat logicSteam superheatersSteam boilersEngineeringSupersonic speed

The invention discloses an eastern-Junggar-coal fired double-reheat steam power plant boiler, and relates to a double-reheat steam power plant boiler which can be used by a thermal power station for a long time, and is safe, economical, and completely eastern-Junggar-coal fired. A tail flue is divided into a front flue, a middle flue and a rear flue by division walls, and the three flues all adopt structural supports; an ejector primary hot wind regulation baffle opens when the boiler is at middle or lower load, and the opening of the ejector primary hot wind regulation baffle is controlled to enable double reheat steam temperature to be kept at a rated value in the range of 40% to 100% BMCR; sequence and quantity of temperature-regulation air-flue ejectors along the width direction of the boiler are changed, so that thermal deviations of high-temperature heating surfaces along the width direction of the boiler can be compensated and reduced; a strong directional supersonic steam flow soot blower system is arranged on the ceiling, DCS controls continuous soot blowing time and interval time of each supersonic steam flow nozzle set, and thereby the thermal deviation of each high-temperature heating surface can be further compensated; the low thermal deviations effectively relieve the growing process of an oxide skin on the inner side of each high-temperature heating surface, so that operational reliability is significantly improved.

Owner:章礼道

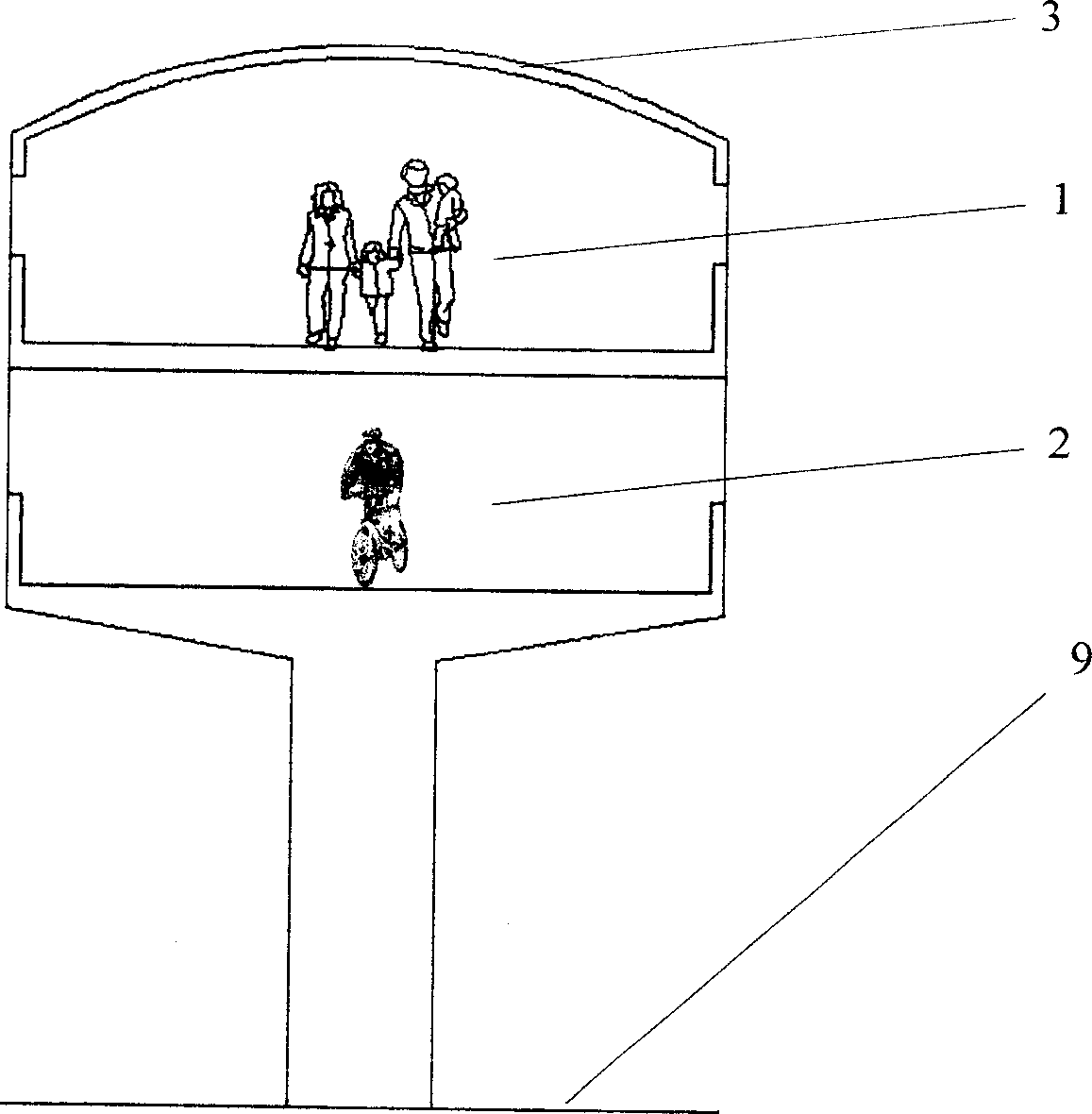

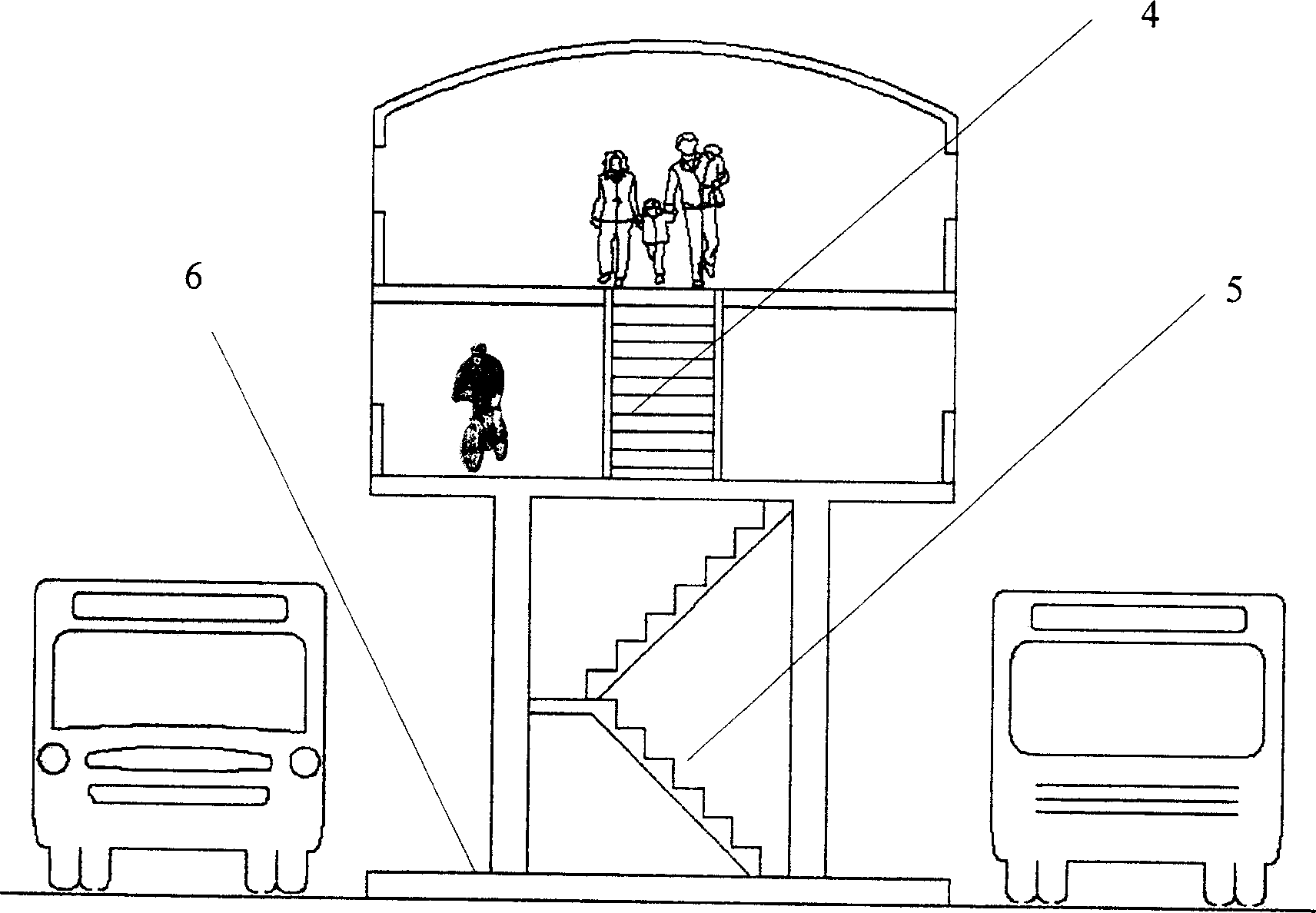

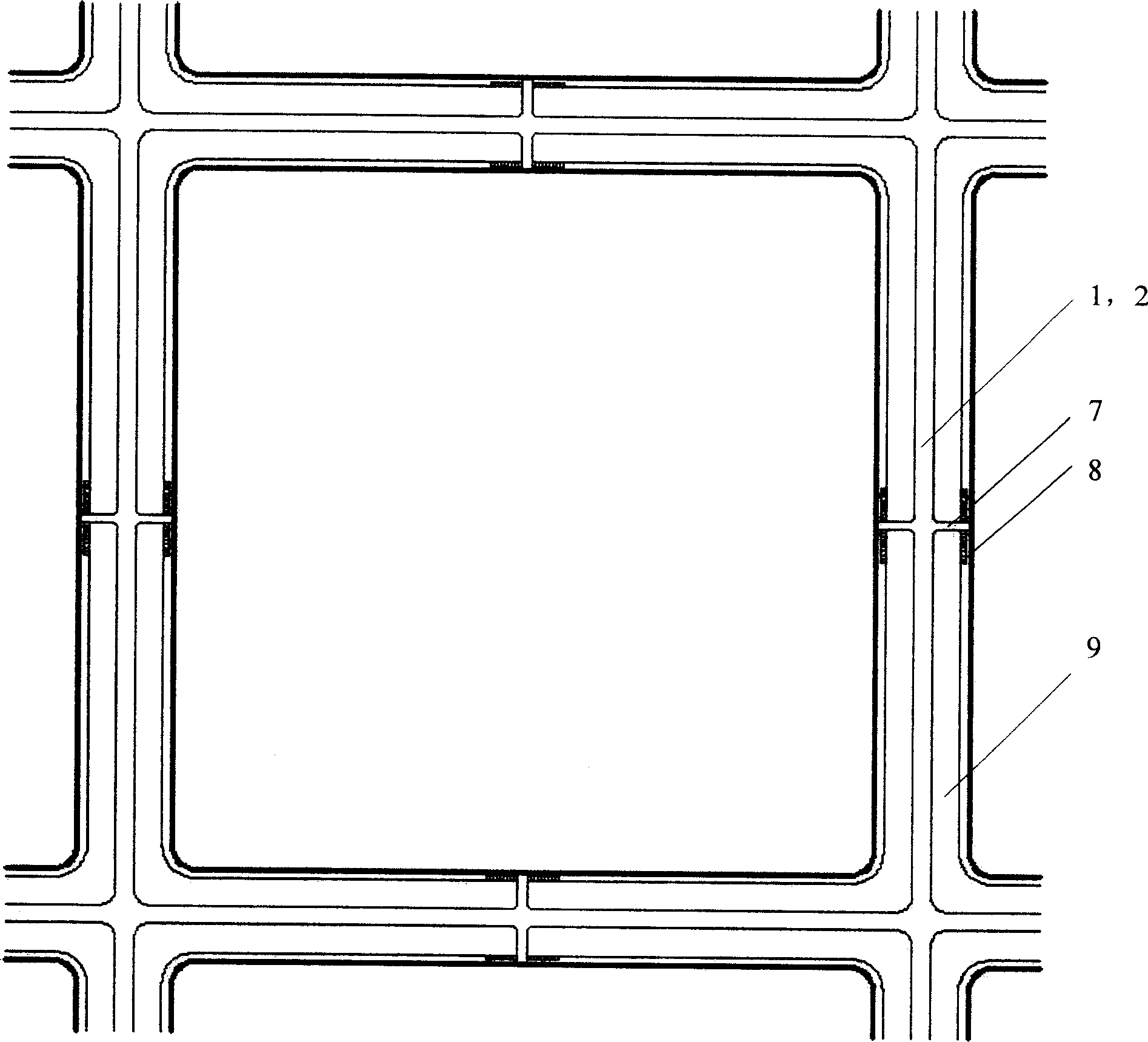

Road system having man, bicycle lane and motor vehicle separated, and traffic method thereof

Owner:董国良 +4

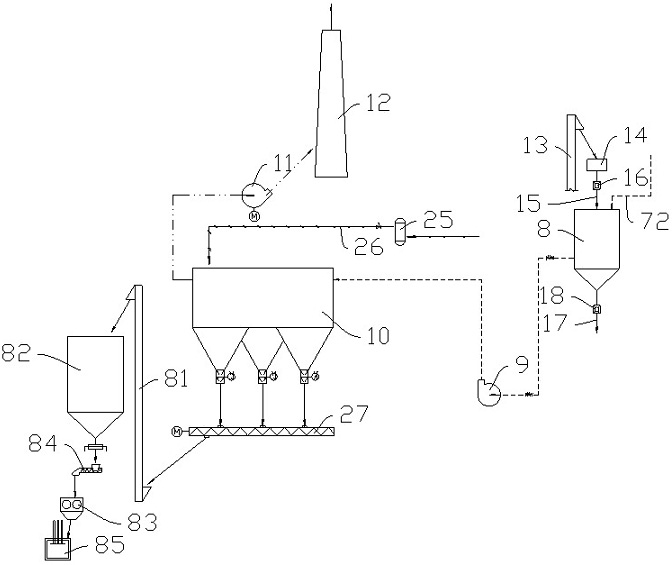

Utilization method and system for tail gas of calcium carbide furnace

InactiveCN102620573AEliminate potential safety hazardsLess investmentWaste heat treatmentHigh concentrationCombustor

The invention provides a utilization system for the tail gas of a calcium carbide furnace. By the system, without purification treatment, the tail gas of the calcium carbide furnace is directly conveyed into a burner and then burnt, investment to the purification treatment of the tail gas of the calcium carbide furnace is eliminated, and hidden danger in the purification treatment of the tail gas of the calcium carbide furnace, which contains high-concentration carbon oxide (CO), is eliminated. The utilization system for the tail gas of the calcium carbide furnace comprises a heat exchanger, a pressurizing conveying fan and a lime rotary kiln, wherein the heat exchanger cools the tail gas of the calcium carbide furnace; the lime rotary kiln is provided with the burner; and a calcium carbide furnace tail gas discharge pipe, the heat exchanger, the pressurizing conveying fan and the burner are sequentially connected in series. The invention also provides a utilization method for the tail gas of the calcium carbide furnace. The method comprises the following steps of: reducing the temperature of the tail gas of the calcium carbide furnace to 200 to 400 DEG C; pressurizing the tail gas of the calcium carbide furnace to be over 3,000 Pa by using the pressurizing conveying fan; conveying the tail gas of the calcium carbide furnace into the burner of the lime rotary kiln; and burning the tail gas of the calcium carbide furnace.

Owner:NANJING SUYE CALCIUM IND TECH

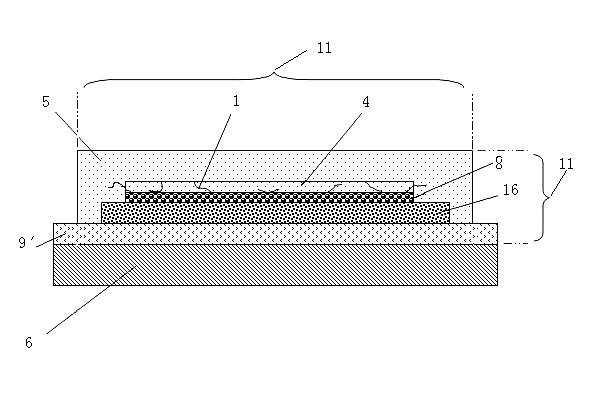

Fiber anti-counterfeiting identification strip

ActiveCN102682659ASimplify anti-counterfeiting production processSave huge investmentStampsIdentification meansFiberAdhesive

The invention provides a fiber anti-counterfeiting identification strip. A fiber anti-counterfeiting identification layer is formed by randomly spreading fibers on a thin film strip which is printed with a local adhesive, the random distribution characteristic information of fibers is scanned, acquired and stored in a computer anti-counterfeiting query system database which accesses a telephone network and / or the internet, and truth can be determined by people; and a user can laminate the fiber anti-counterfeiting identification layer on an article which is required to be anti-counterfeited by using the conventional labeling machine. By adoption of the fiber anti-counterfeiting identification strip, the heavy investment of the user is saved, production process is simplified, production efficiency is improved, and production cost is reduced.

Owner:HAINAN PPK NETWORK TECH

Sintering method red mud and Bayer method red mud mixed dam building method

ActiveCN101164925AIncrease stack heightImprove processing efficiencySludge treatmentAluminium oxides/hydroxidesVertical tubeBrick

This invention discloses a method for damming by using mixed mud from sintering process and Bayer process. In this invention, the gibbsite Bayer process and sintering process red mud are mixed in the ratio of (0.43-2.33):1(dried mud) are used for the damming. Bricks are used for building cofferdam columns, in which are placed the vertical tubes which are then connecting filtration tubes and water-drainage ditch. There are permeating holes on the walls of the tubes. Between the column and its tube filled is fine sands. Due to the material of the dam is the same as the material decking-up, it makes simple building process and saving area for decking up Bayer process red mud. Advantages are low cost and saving raw materials.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

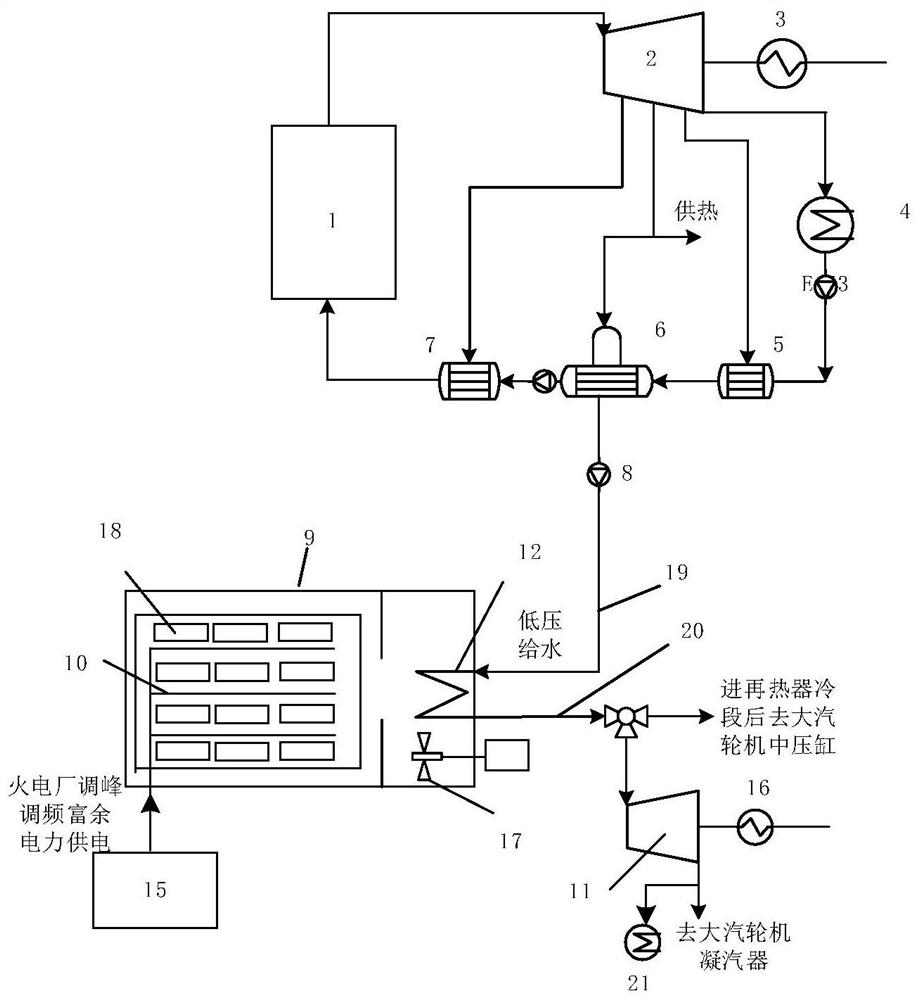

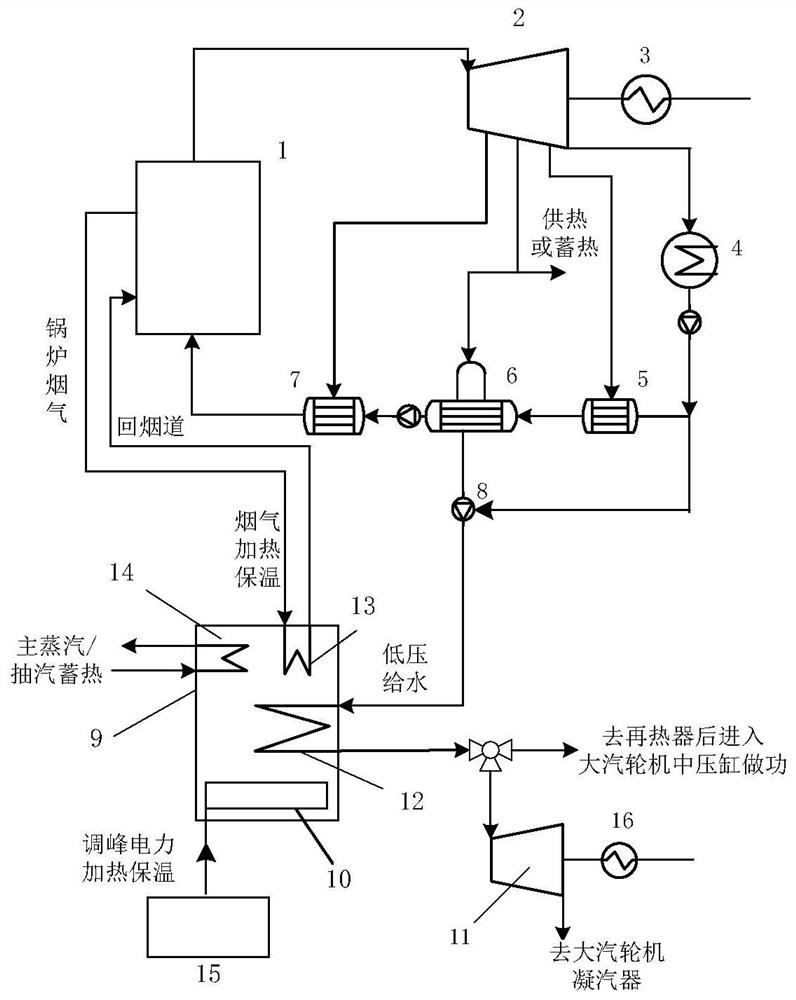

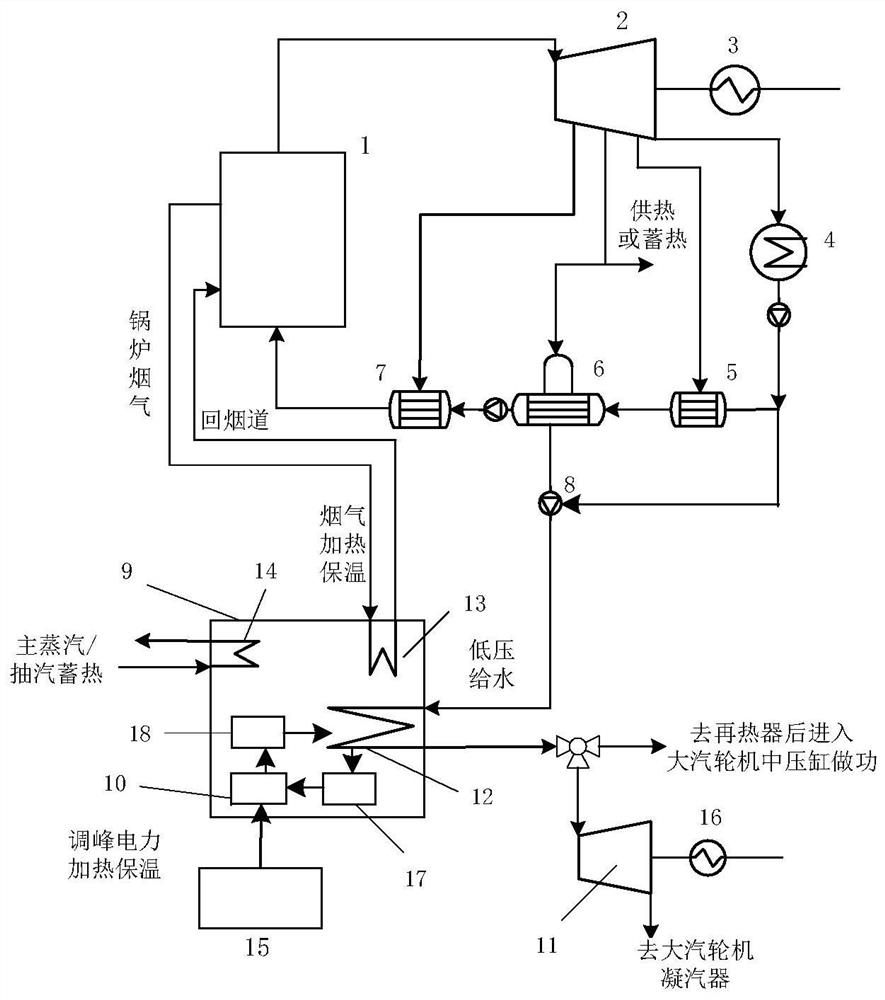

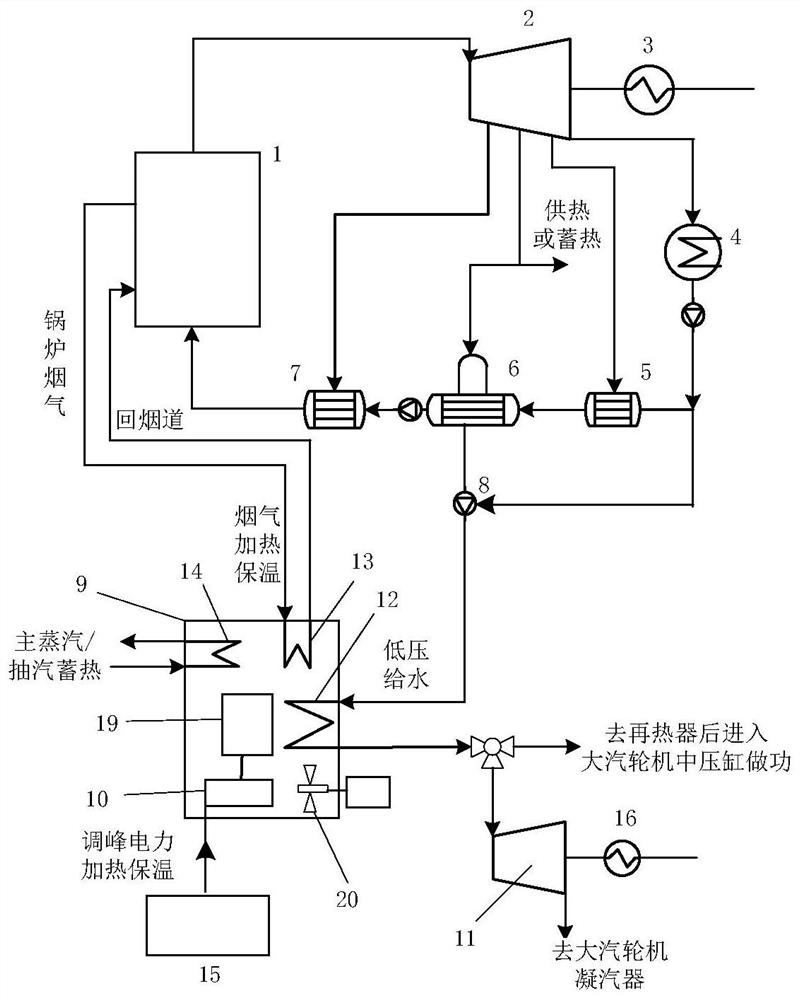

Solid heat storage power generation peak and frequency modulation system for thermal power plant and working method

PendingCN113390075AIncrease power generationSave energySteam generation heating methodsHeat storage plantsProcess engineeringGenerating capacity

The invention discloses a solid heat storage power generation peak regulation and frequency modulation system for a thermal power plant and a working method. The system comprises a solid heat storage electric boiler, a water supply pipeline and a steam connection pipeline thereof and a unit peak regulation control unit. The solid heat storage electric boiler comprises solid heat storage bricks, a peak and frequency regulation electric heater, a high-temperature-resistant fan and an air-water heat exchanger. The peak and frequency regulation electric heater supplies power to heat the solid heat storage bricks in an off-peak electricity period, and the high-temperature-resistant fan sucks air into the solid heat storage electric boiler to exchange heat with the solid heat storage bricks in a non-off-peak electricity period to form hot air. The wind-water heat exchanger heats water in the water supply pipeline into superheated steam through hot air, and the superheated steam is fed into the steam turbine to drive the generator to generate electricity. The system has the beneficial effects that surplus electric power of the thermal power plant is stored in the solid heat storage bricks in the electricity consumption valley period, the generating capacity of the thermal power plant is increased in an auxiliary mode in the electricity consumption peak period, and therefore heat storage peak regulation and frequency modulation of the thermal power plant are achieved.

Owner:HEPU ENERGY ENVIRONMENTAL TECHNOLOGY CO LTD

Atmospheric pre-treatment method of plant fiber material

InactiveCN101424056ASave huge investmentLess investmentPaper material treatmentThermal energyPretreatment method

The invention discloses a normal pressure pre-treatment method for a plant fibrous material. Under normal pressure conditions, the plant fibrous material is cooked by dilute sulfuric acid first to hydrolyze hemicellulose into a pentaose solution; then a remaining part is cooked by dilute alkali solution to separate out most of lignin to obtain single fibriform cellulose; and the sulfuric acid and the alkali solution are recovered for circulating use. The single fibriform cellulose has a loose structure due to the fact that no hemicellulose is contained and only a small amount of lignin is contained, which can ensure that the rate of concentrated acid hydrolysis or enzyme hydrolysis of the cellulose is greatly accelerated. The pretreatment is finished under normal pressure, so the huge investment for a pressure vessel during high-temperature pretreatment is saved; the cooking temperature is basically lower than 100 DEG C, and the cheap heat energy obtained by the light-heat conversion of solar energy can be utilized as the heat energy for heating, so the using amount of coal is reduced; and process reagents, namely the sulfuric acid and sodium hydroxide can be recycled, so the method is a method which has less investment and is environment-friendly.

Owner:陈培豪

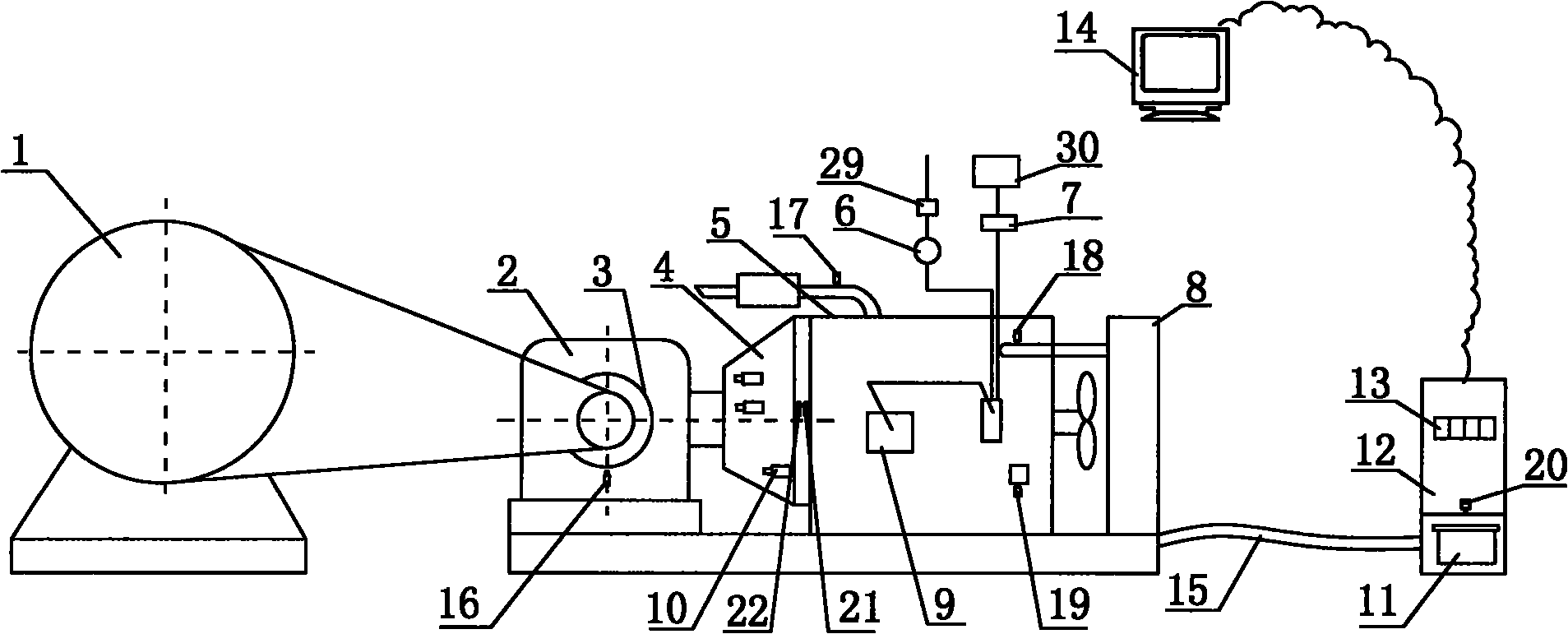

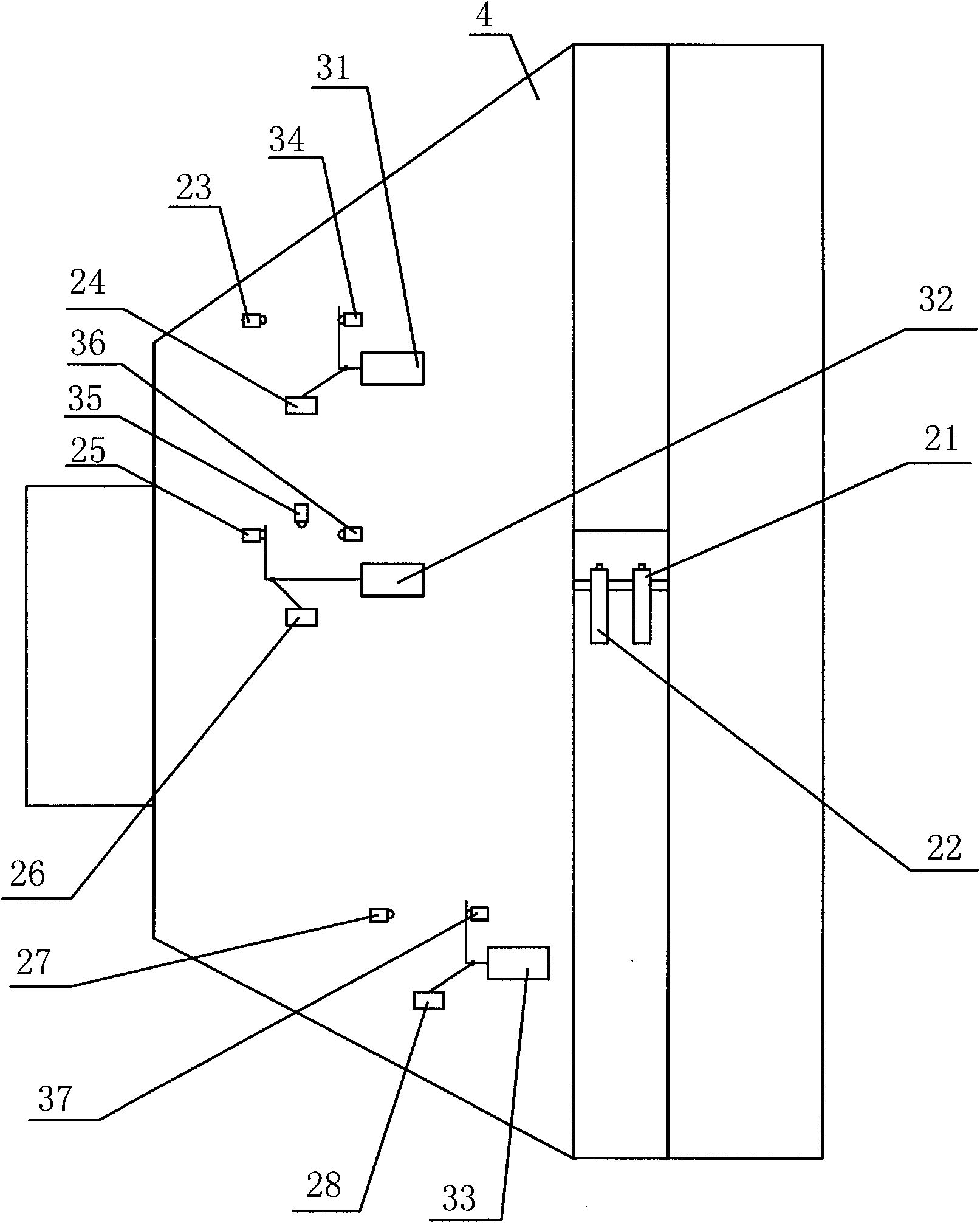

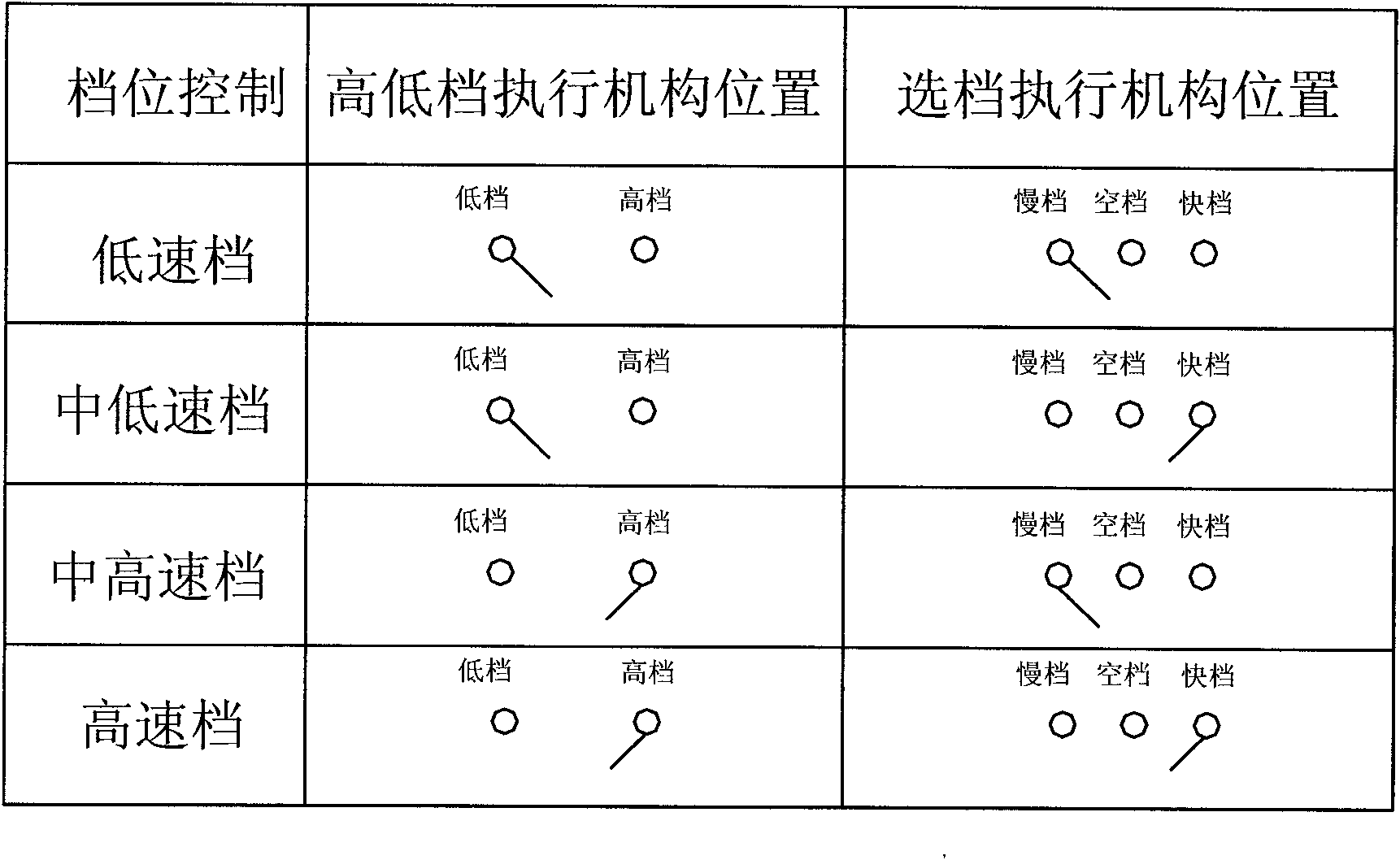

Special intelligent motive power device of oil pumping unit

InactiveCN101852072ASave huge investmentNo power consumptionGearingFluid removalReduction driveElectric consumption

The invention relates to a special intelligent motive power device of an oil pumping unit. The oil pumping unit is driven by an output belt pulley with the variable diameter, the output belt pulley with the variable diameter is connected with a speed reducer with the fixed transmission ratio, the speed reducer with the fixed transmission ratio is connected with a multi-gear shifting speed changer, the motive power output end of an oil and gas dual purpose engine is connected with the multi-gear shifting speed changer, the oil and gas dual purpose engine is connected with a control cabinet through a cable, and the control cabinet is connected with a computer through GPRS. The invention can be widely used for the motive power of the oil pumping unit used for the coal bed or natural gas pumping extraction operation, the huge investment of the high-voltage and low-voltage electric network is saved, the electric consumption of the operation of the oil pumping unit is avoided, and the effects of energy saving and exhaust reduction are reached. The invention has wide speed regulation ratio range, can realize remote stepless speed regulation and remote starting and stopping, can reduce the manual perambulation cost, and is favorable for the centralized monitoring of the mass operation of the oil pumping unit.

Owner:JIANGSU SHENGYUAN GAS POWER +1

Method for redevelopment of junked drowned oil field

InactiveCN1664306AEasy to masterIncrease mining rateFluid removalSealing/packingGeomorphologyOil field

The invention relates to a method to explore the oil field that has been rejected by flood. It includes the following steps: applying part gelate water shut off to the original water injection well, and forcing the water flowing along the portrait direction and the radial direction; applying gelate water shut off to the water flooded layer of the original production well; taking large cubic capacity pumping draining to the original production well until emptying the seeper; injecting high pressure intensified water into the original flooded oil well and the quantity is 3-5 times of the normal injecting rate; adopting pumping method to the oil field that can not flow; adjusting the output proportion and the speed to realize producing steadily.

Owner:胡振起

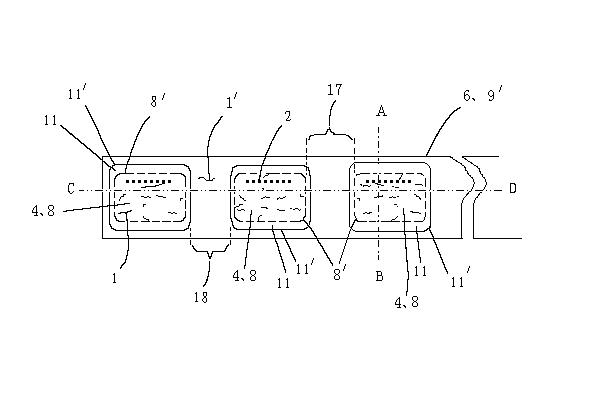

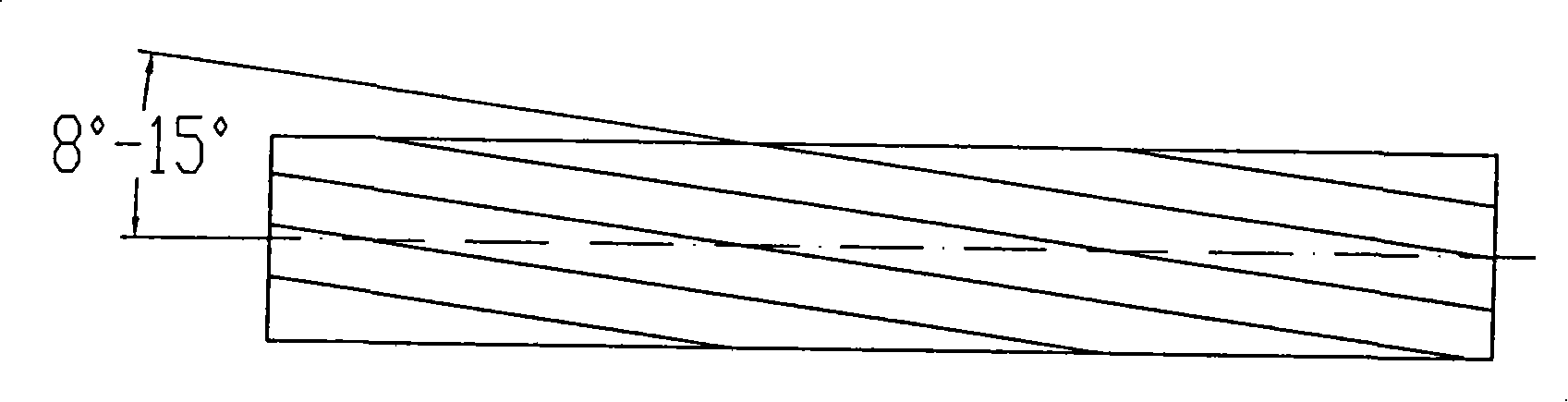

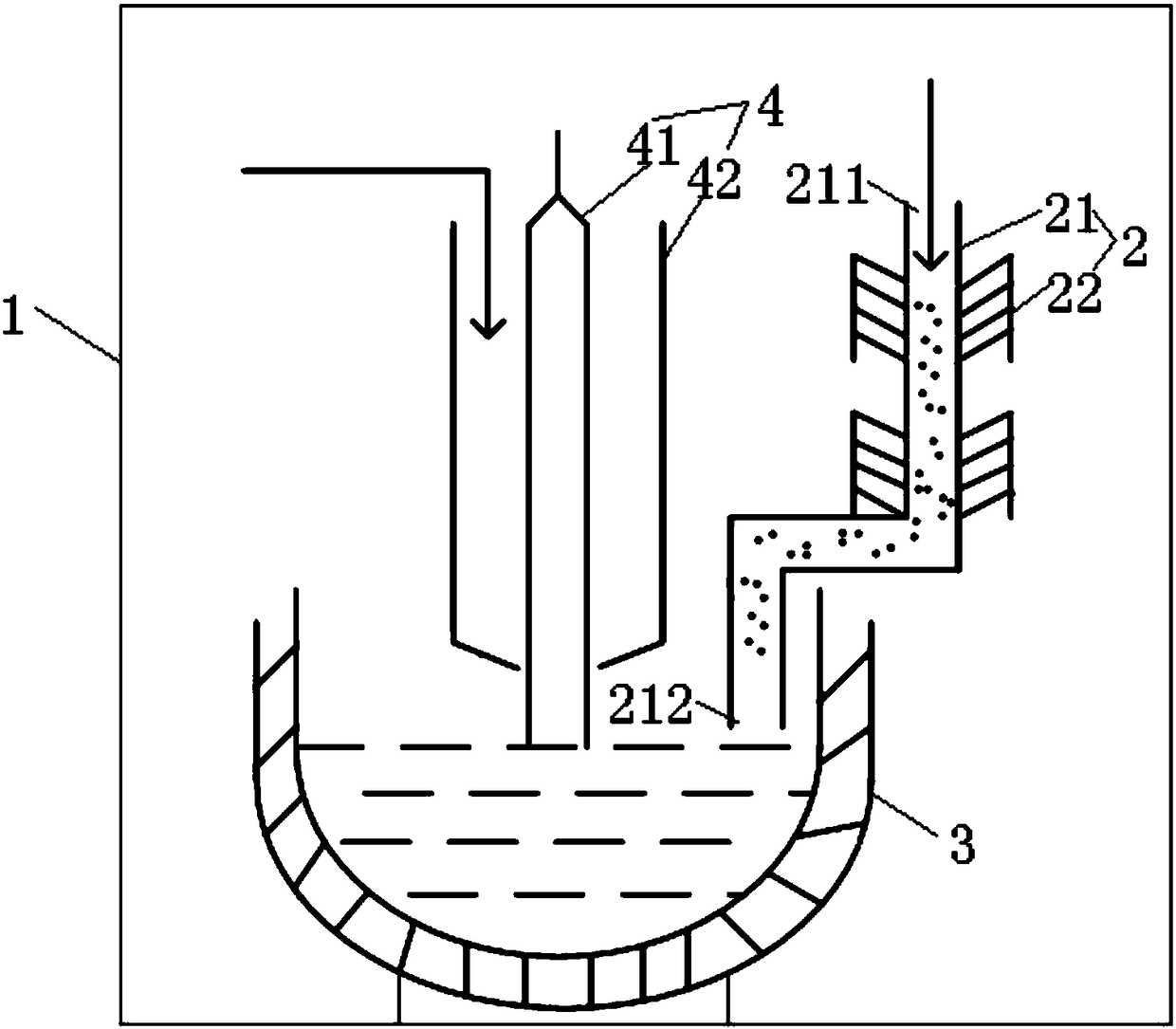

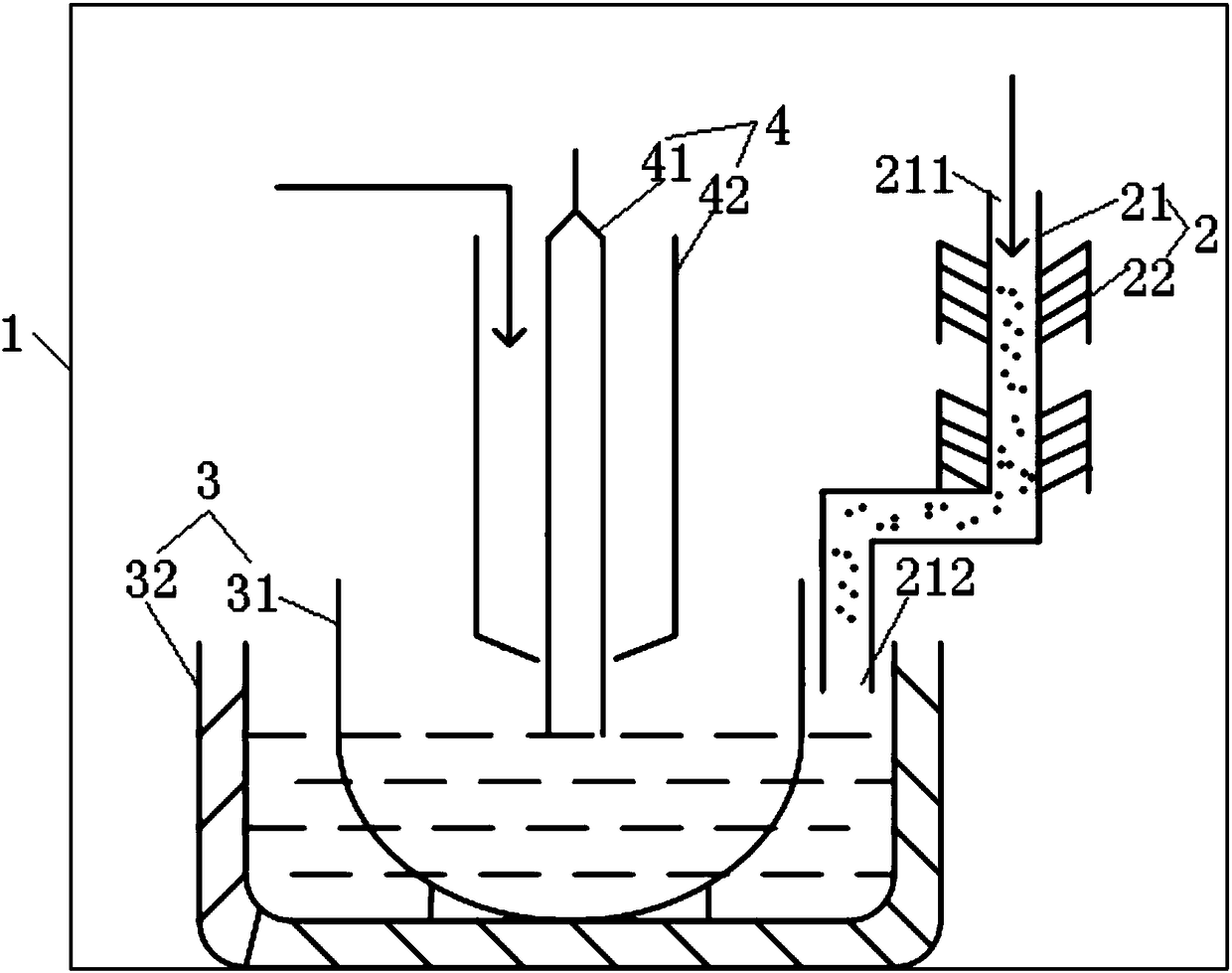

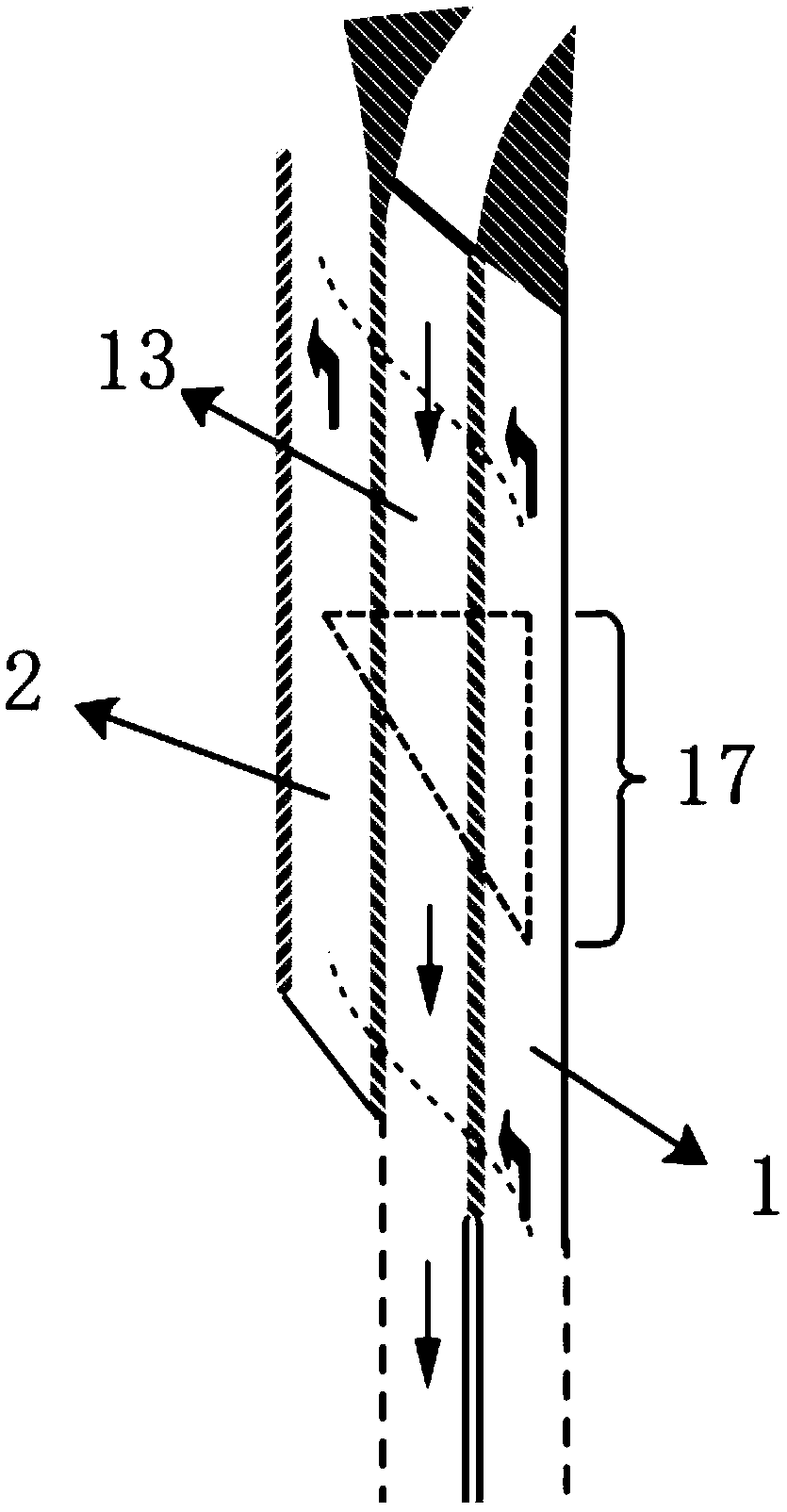

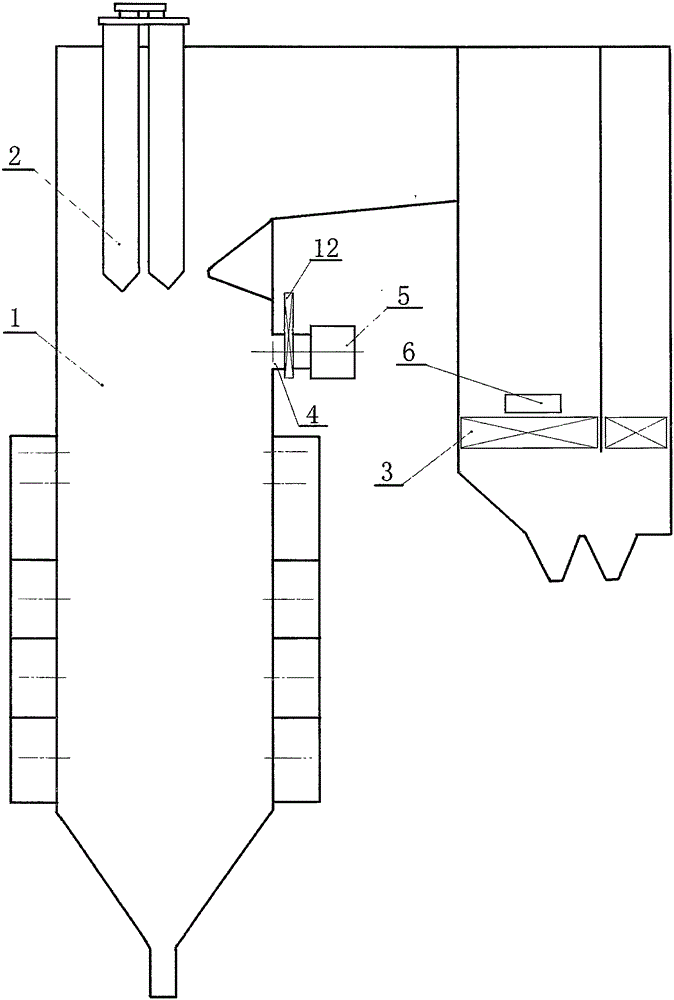

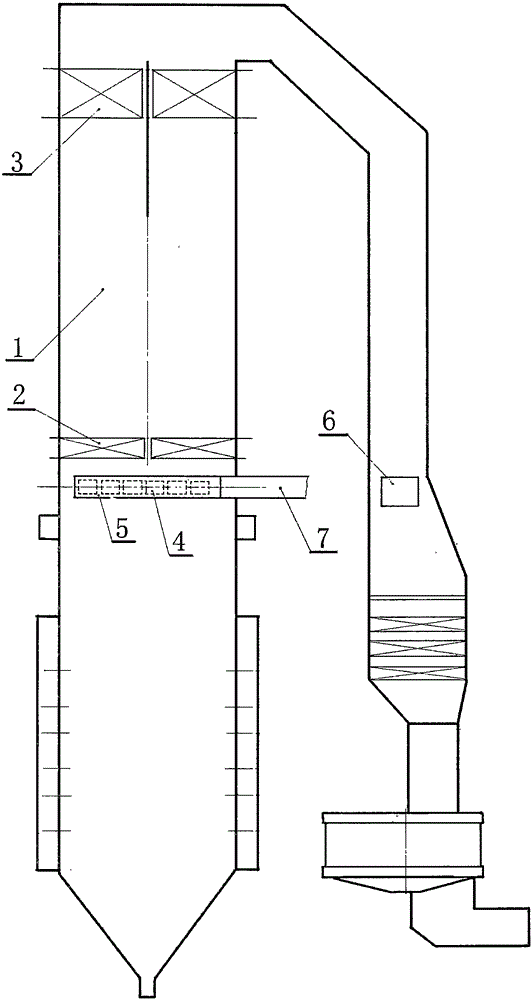

Production method and equipment for carbon fiber multi-use compound stranded wire

ActiveCN101295564BReduce weightLight weightManufacturing wire harnessesInsulating conductors/cablesFiberCollocation

The invention discloses a manufacture method for a carbon fiber multifunctional compound stranded wire and a device thereof which belong to a cable manufacture method and a device thereof. The invention is characterized in that the method mainly includes two steps of twisting forming of each strand as well as strand combining, rotating and twisting. The manufacture device mainly consists of a strand twisting mechanism (1) and a strand combining rotating stranded wire mechanism (2) as well as a traction rotating rewinding mechanism (3). The invention has the advantages of simple method, reasonable collocation, simple structure as well as being convenient to be manufactured, mounted, debugged and maintained.

Owner:南京诺尔泰复合材料设备制造有限公司

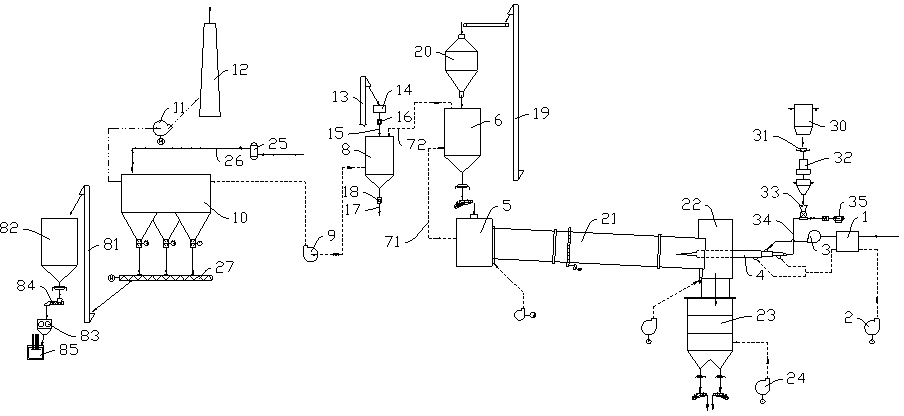

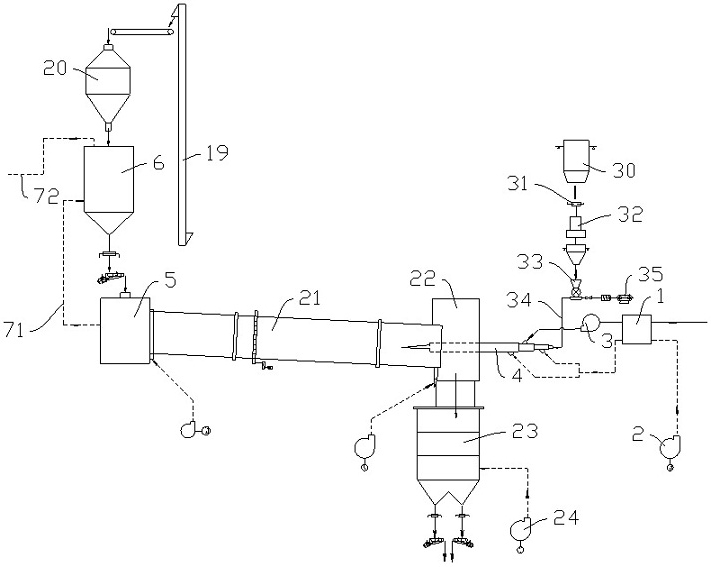

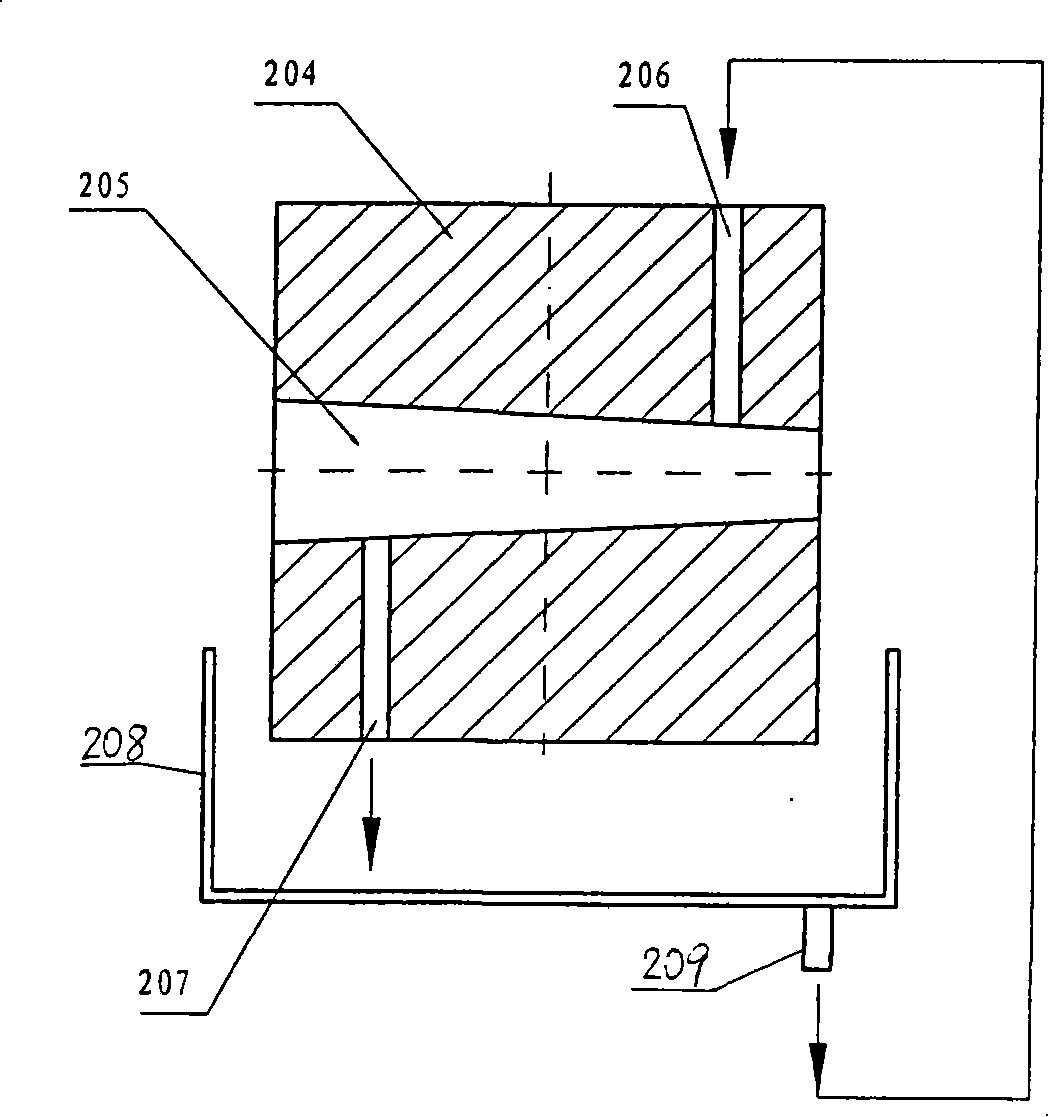

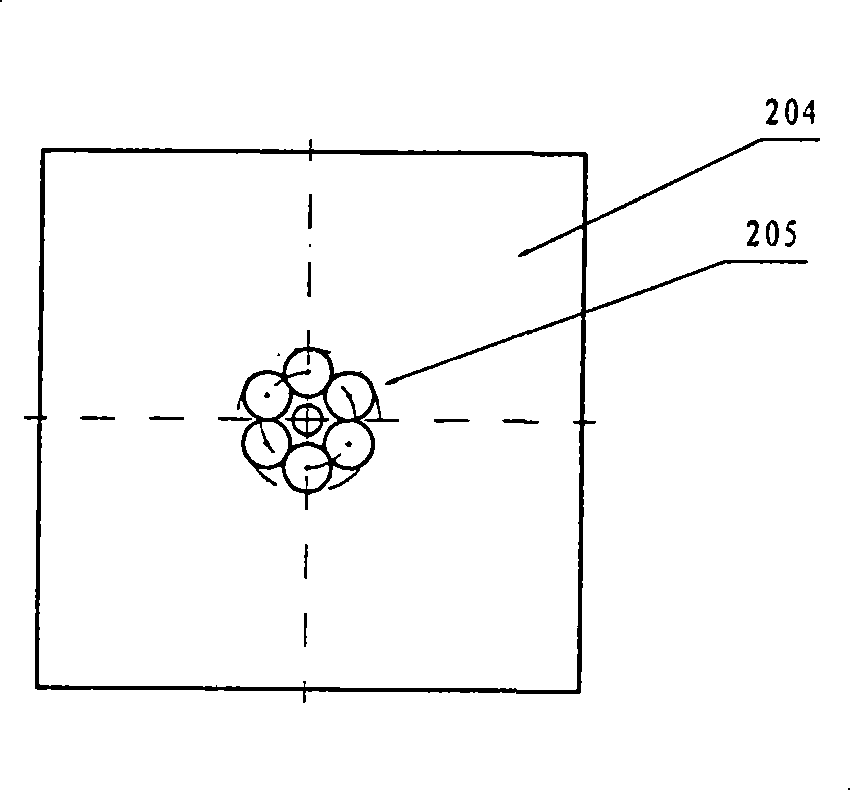

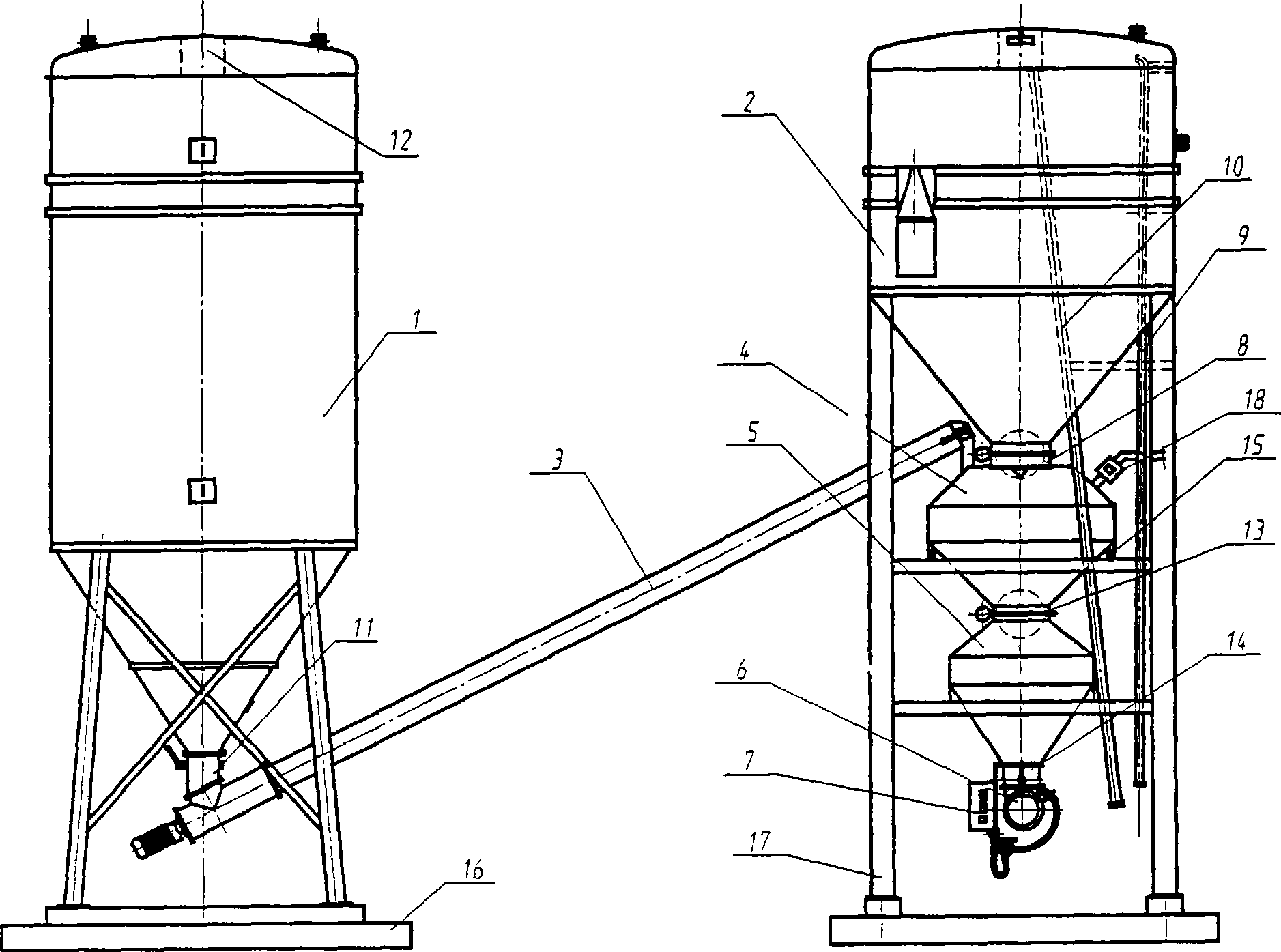

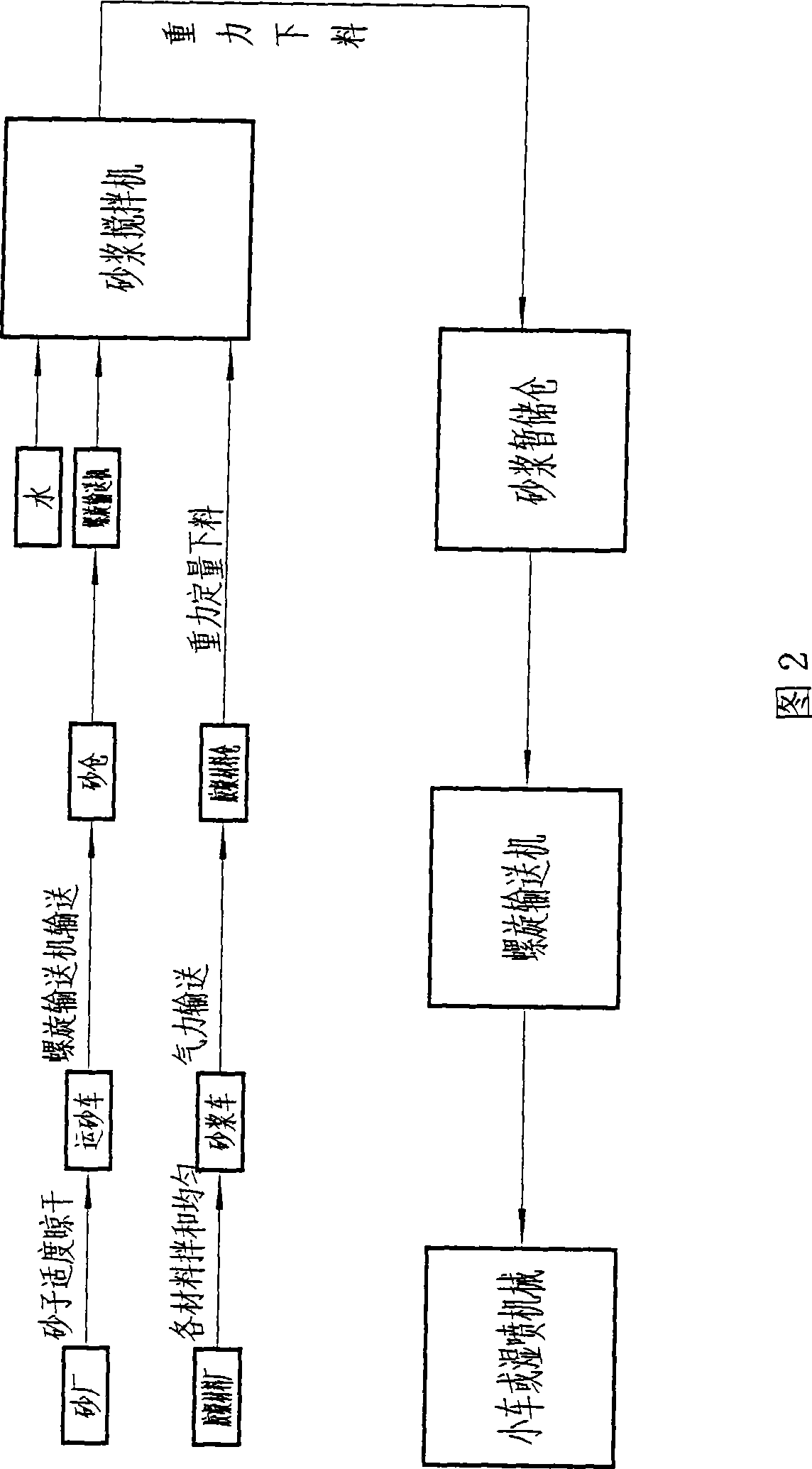

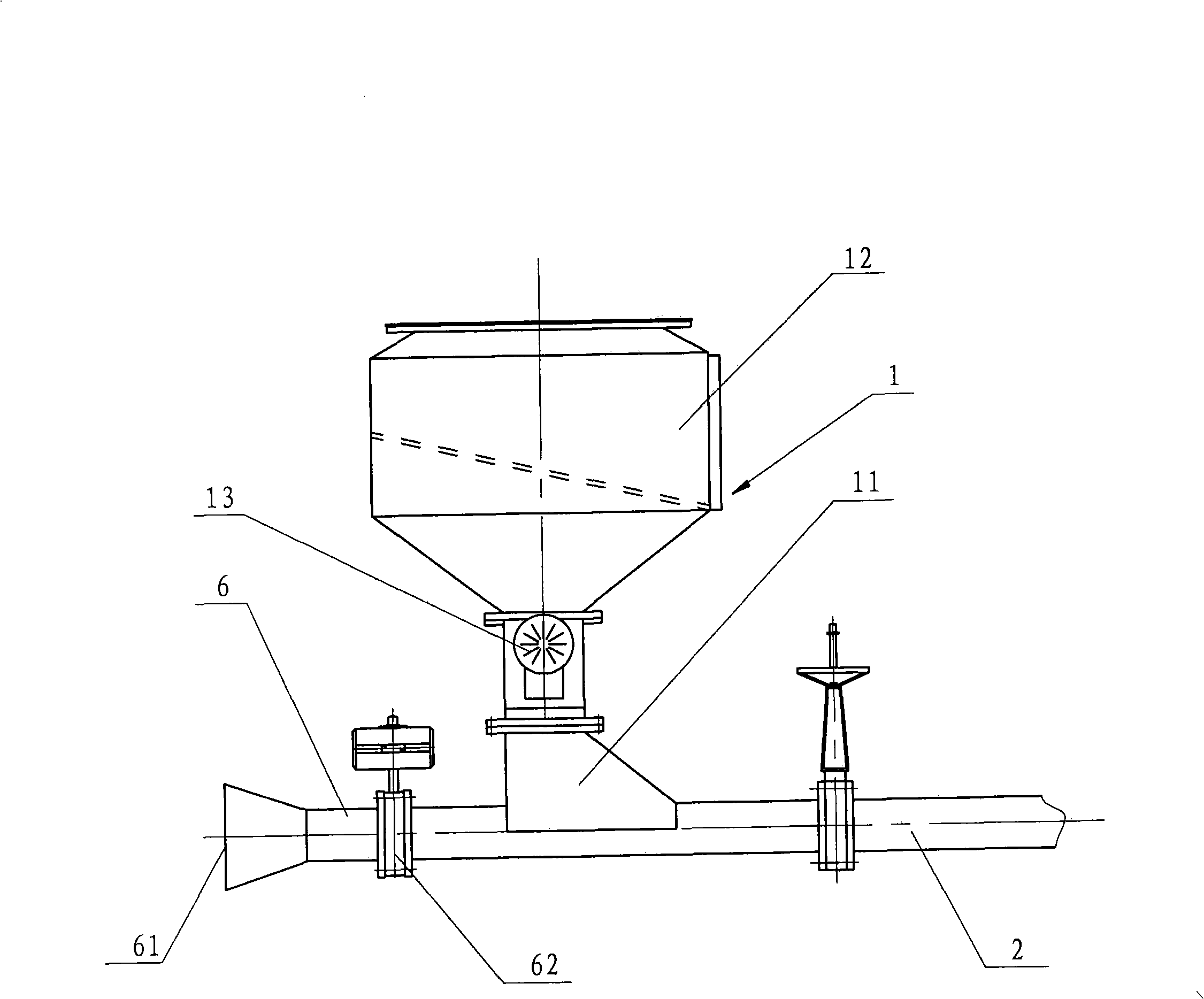

Movable premixing mortar production device

The invention discloses a movable premixing mortar producing equipment aiming at solving the problems of heavy pollution caused by the field wet-mixing mortar preparation and high cost of the commercial dry-blending mortar. The invention is characterized in that the equipment comprises a large bin (1) which is used for storing sands with the moisture content not higher than 10 percent, a cementing material bin (2) which is used for storing cementing materials and a raw material screw conveyor (3) which is arranged between the large bin (1) and the cementing material bin (2). A feed end of the screw conveyor (3) is connected with an outlet of a discharge valve (11) arranged on the lower part of the large bin (1), and a discharge end of the screw conveyor is connected with another feed inlet of a mortar mixer (4). Through the energy saving property and the production in sealed equipment, the production cost of the movable premixing mortar producing equipment is greatly reduced. Without environmental pollutions, the movable premixing mortar producing equipment has good popularizing prospect.

Owner:南京天印科技股份有限公司

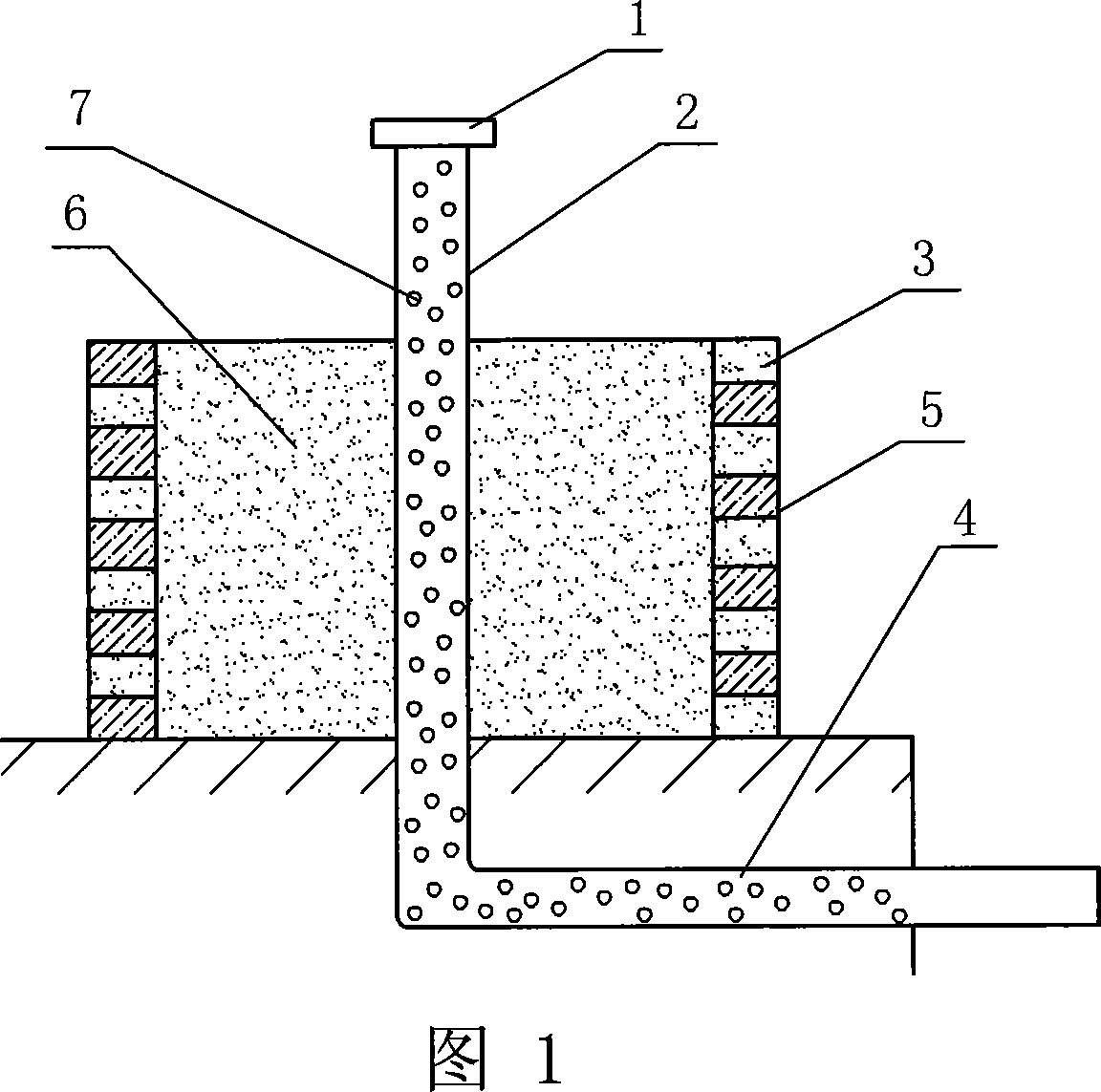

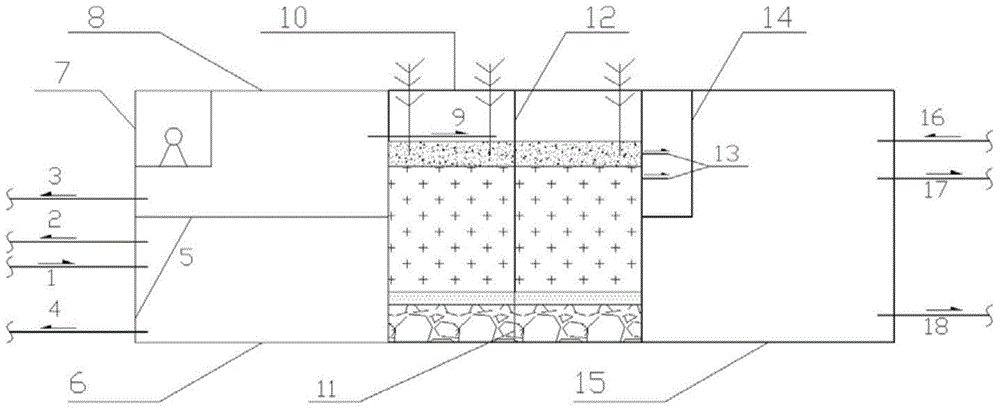

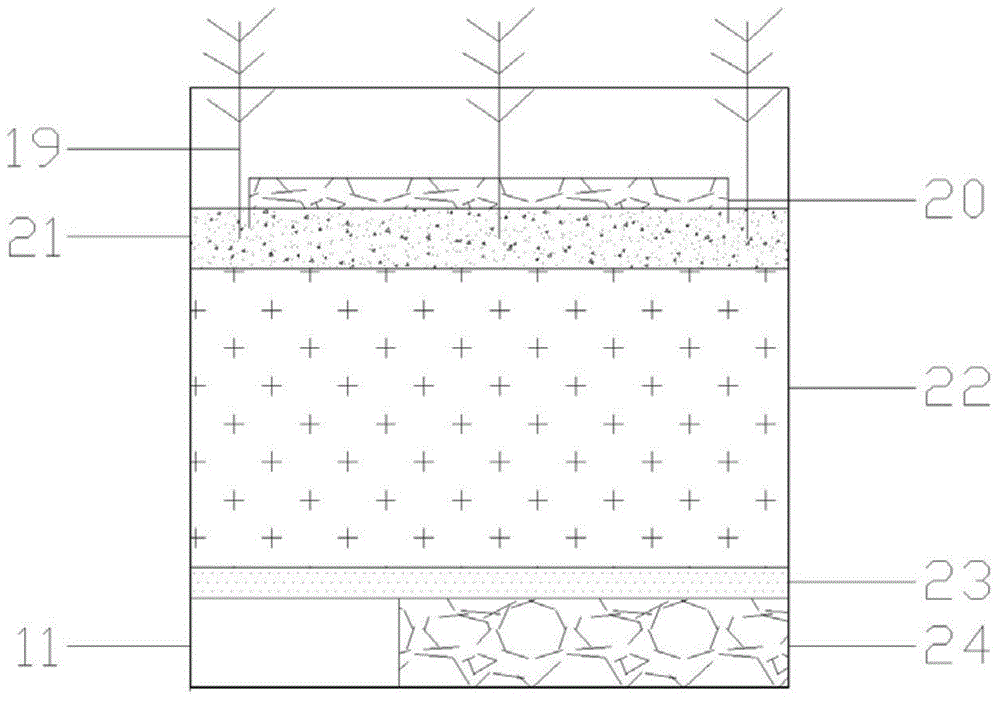

Water reusing device and method based on integrated vertical-flow constructed wetland

InactiveCN104310589ACompact designSmall footprintMultistage water/sewage treatmentSustainable biological treatmentConstructed wetlandSlag

The invention discloses a water reusing device and method based on an integrated vertical-flow constructed wetland. The water reusing device comprises a constructed wetland, wherein one side of the constructed wetland is provided with a regulation water box and a water storage box from top to bottom, and the other side of the constructed wetland is provided with a clear water box; the constructed wetland sequentially consists of a vegetation layer, a crushed rock layer, a soil layer, a mixed layer of furnace slag and limestone, a sand particle layer and a crushed rock layer from top to bottom; a water distribution tube is connected between the regulation water box and the soil layer; a flow passage hole is formed in the bottom of each crushed rock layer. The water reusing device collects rainwater and domestic wastewater by virtue of a gravity flow without needing to use a water pump and the like to provide additional powder, and thus energy is saved. According to the water reusing device disclosed by the invention, a small-sized aerator can be arranged in the regulation water box and can provide oxygen for subsequent constructed wetland unit treatment according to the needs for water quality, and thus aerobic reaction and facultative reaction are realized, and removal of nitrogen and phosphorus is promoted. Meanwhile, with the adoption of the water reusing device, influences on water treatment caused by water quality fluctuation and weather variation are overcome, and thus effluent effect is ensured.

Owner:SOUTH CHINA UNIV OF TECH

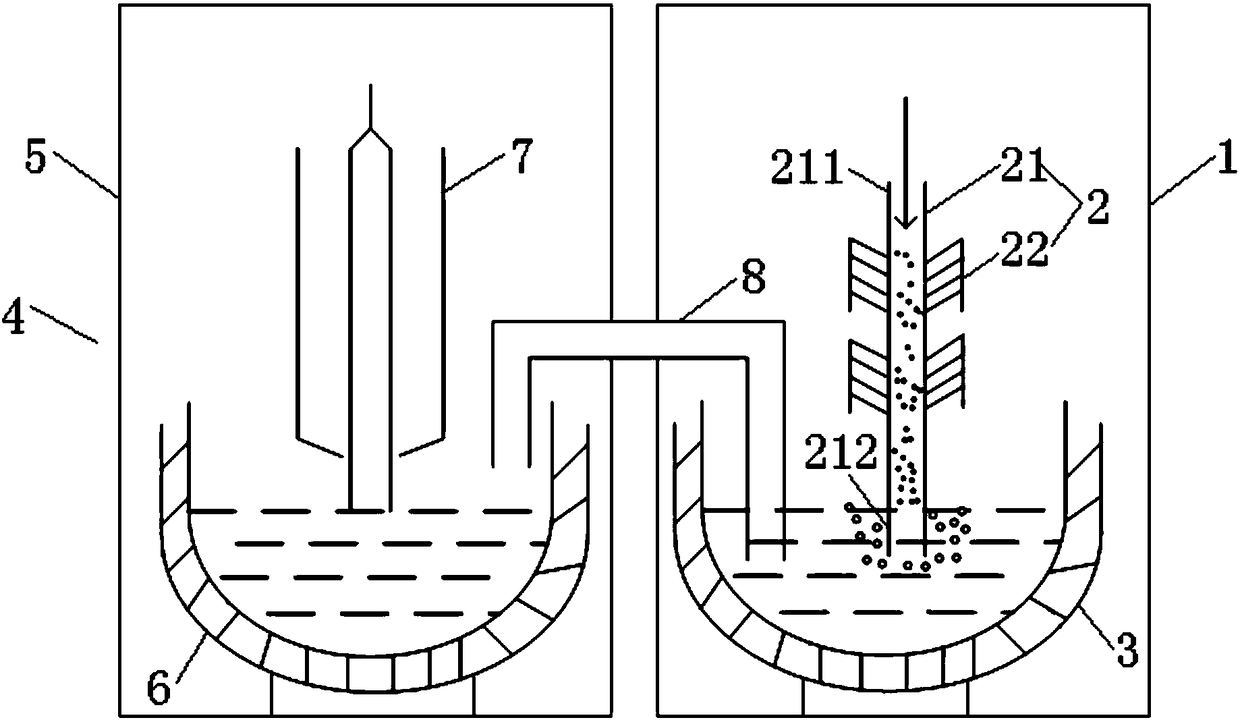

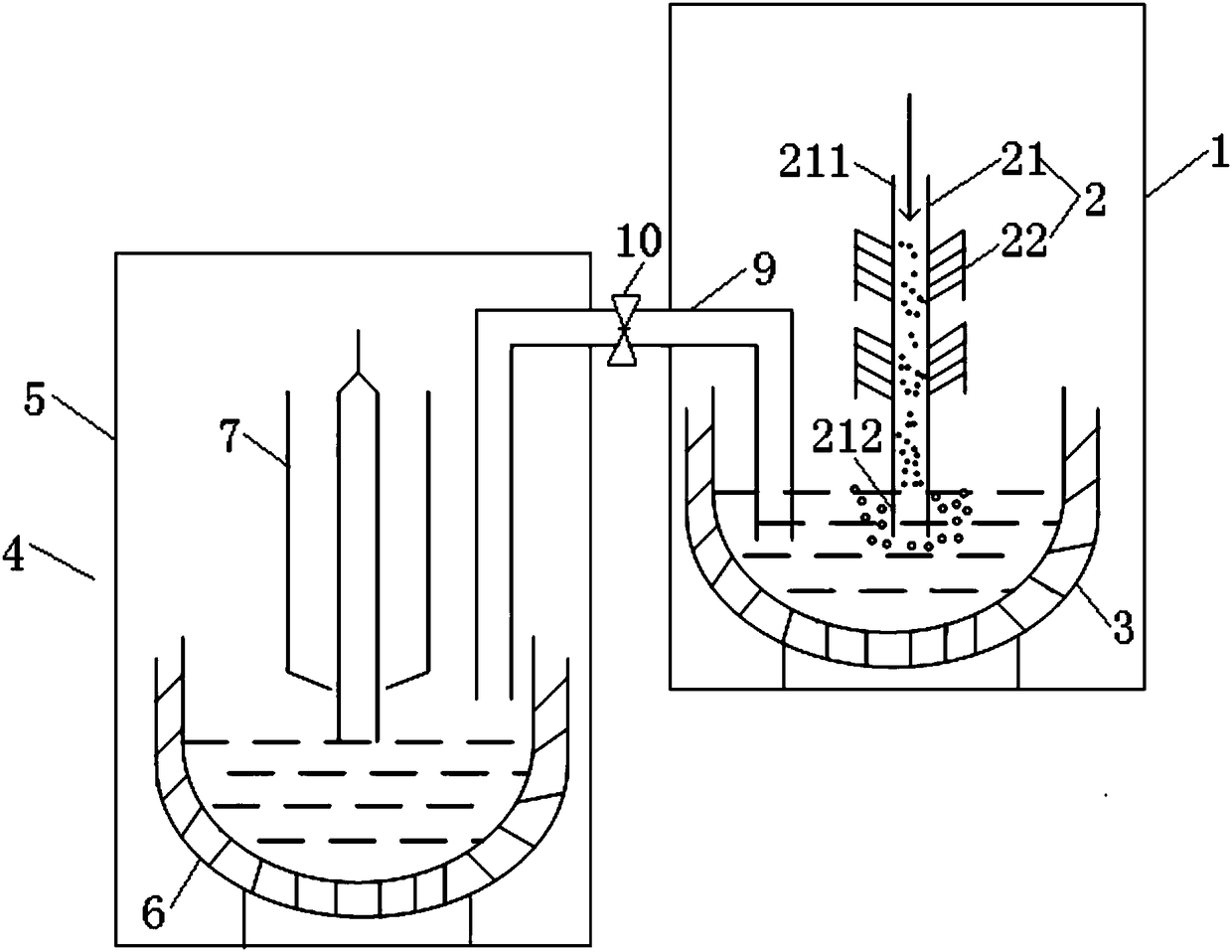

Monocrystalline silicon pulling furnace, and pulling method for growing monocrystalline silicon

InactiveCN108301038AReduce energy consumptionLess investmentPolycrystalline material growthBy pulling from meltMolten siliconSeed crystal

The invention discloses a monocrystalline silicon pulling furnace, and a pulling method for growing monocrystalline silicon. The monocrystalline silicon pulling furnace comprises a furnace chamber, atubular reactor for heating, a crucible, a monocrystalline silicon pulling mechanism and a heater for heating the crucible are arranged in the furnace chamber, a gaseous silicon source undergoes a thermal decomposition reaction in the tubular reactor to generate silicon powder, the silicon powder or molten silicon formed after melting the silicon powder enters the crucible, the monocrystalline silicon pulling mechanism is arranged above the crucible, and the monocrystalline silicon pulling mechanism is used for pulling seed crystals to achieve pulling growth of the molten silicon in the crucible into monocrystalline silicon. The furnace and the method omit the production step of a solid silicon material, so the energy consumption is reduced, the huge investment for the production and processing of the solid silicon material is saved, and the pollution introduction problem of the solid silicon material is avoided, thereby the purity of the generated monocrystalline silicon is ensured; and compared with continuous feeding of the solid silicon material, the supplementation of the molten silicon material through the thermal decomposition of the gaseous silicon source has the advantagesof simplicity in realization, and accuracy in control of the supplementing speed of the molten silicon material.

Owner:新疆知信科技有限公司

Pulling device and pulling method for growing monocrystalline silicon

InactiveCN108301039AOmit production stepsReduce energy consumptionPolycrystalline material growthBy pulling from meltEnergy consumptionRaw material

The invention discloses a pulling device and a pulling method for growing monocrystalline silicon. The device comprises: a first chamber, wherein a tubular reactor for heating and a first crucible arearranged in the first chamber, a gaseous silicon source undergoes a thermal decomposition reaction in the tubular reactor to generate silicon powder, and the silicon powder or molten silicon formed after melting the silicon powder enters the first crucible; a monocrystalline silicon pulling furnace used for pulling the molten silicon used as a raw material to grow the monocrystalline silicon; anda conveying mechanism respectively connected with the first chamber and the monocrystalline silicon pulling furnace, wherein the conveying mechanism is used for introducing the molten silicon in thefirst crucible of the first chamber into the monocrystalline silicon pulling furnace in order to make the molten silicon used as the raw material for the pulling growth of the monocrystalline siliconin the monocrystalline silicon pulling furnace. The device and the method for growing the monocrystalline silicon by using the gaseous silicon source as the raw material omit a step for producing a solid silicon material, so the energy consumption is reduced, and huge investment for producing and processing the solid silicon material is saved.

Owner:新疆知信科技有限公司

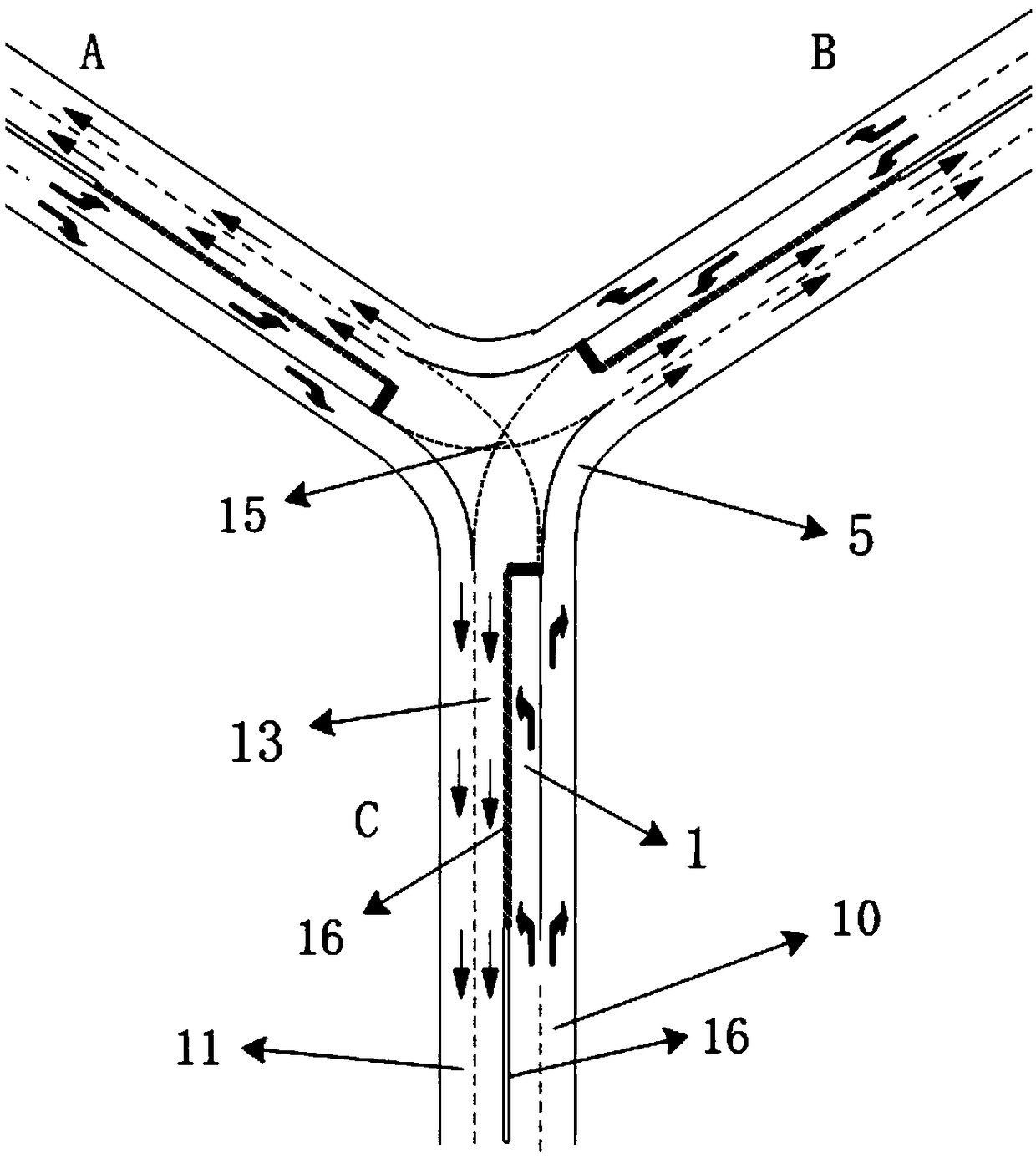

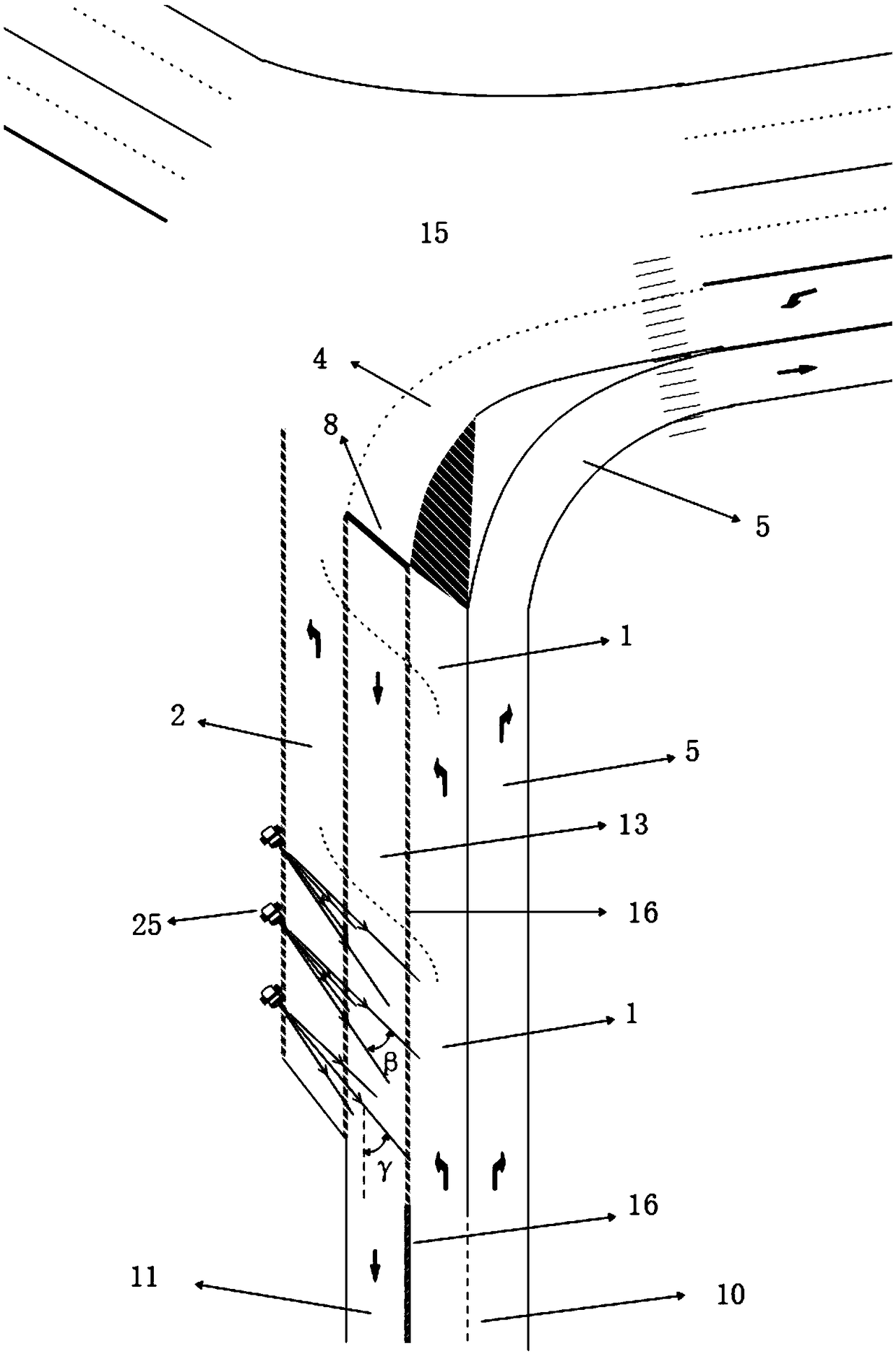

Batched variable-region junction and application thereof

The invention relates to the traffic field, in particular to a batched variable-region junction and application thereof. A reversing region is arranged on the outside of an exit lane of an exit of thebatched variable-region junction, and is connected with a left turning lane of a next junction. A bank light is arranged in the left front direction of a left turning waiting region, and under guidance of a green bright belt of the bank light, vehicles of the left turning waiting region independently run to the left front direction, and then run into the reversing region to leave away from the exit lane so as to relieve and avoid blockage to the exit lane as much as possible. By the method, blockage to the outlet lane in the whole cycle is quite less. If the junction is used at a crossroad, two-phase control can be implemented. If the junction is used at a three-way intersection, single-phase control can be implemented. Various junctions of a turn plate use the batched variable-region junctions, then the turn plate becomes a leftward turn plate, and the vehicles leftwards turn to enter the turn plate. An overpass bridge uses one layer of the left turn plate, or uses one layer of the left turn plate and one layer of a common turn plate, and thus, interweaving of the turn plate can be relieved. By application of the batched variable-region junction, the traffic capacity of urban junctions is greatly enhanced, and delay is relieved.

Owner:珠海达理宇航科技有限公司

Ceramic raw material processing technique

A novel ceramic material process uses dry process to break and granulate, which eliminates water ball mill and drying abundant water, thereby saving device investment and energy consumption.

Owner:苏国干

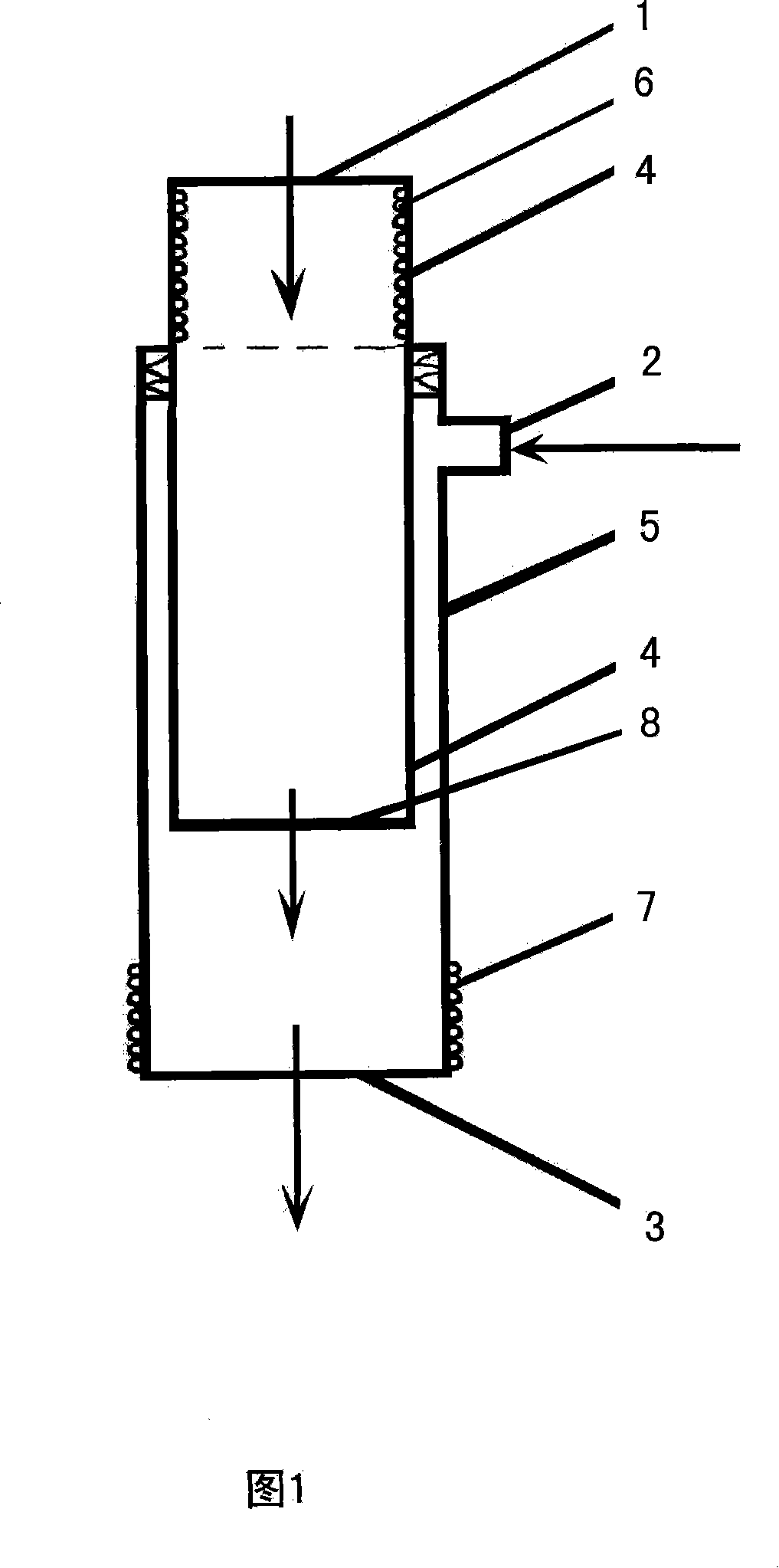

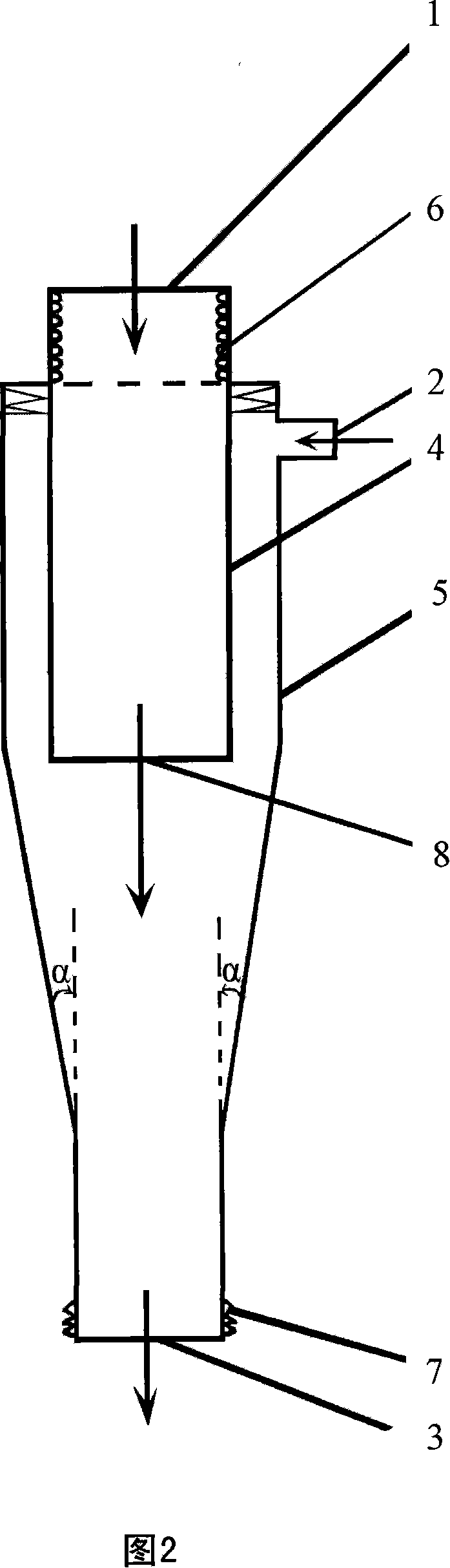

Solid powder particle dissolution dispersing device

InactiveCN101113027ASolve the "fish eye" phenomenonShorten the dissolution timeWater/sewage treatment by flocculation/precipitationSocial benefitsWater soluble

The invention pertains to the technological field of a solution device for solid soluble powder, in particular to an agentia dispersing device for dissolving solid powders and gains in water treatment for solving fish-eye problem caused by solution of powder such as polyacrylamide and other soluble powder. The invention comprises an internal casing tube, an external casing, an agentia feeding opening, a water feeding opening and a water discharging opening. The invention is characterized in that the internal casing is arranged in the external casing, the upper part of the internal casing is an agentia feeding opening, the external casing is provided with the water feeding opening, the bottom of the external casing is the water discharging opening. The design based on hydraulic vacuum principle, and dismountable connection and rational internal and external screws of the invention dramatically shortens dissolving time. The invention is characterized by simple structure, easy installation and connection, small volume and remarkable dissolving and dispersing effects and low production cost, etc. The invention is suitable for dispersing and emulsification of solid powders and gains in a water soluble polymer manufacturing factory, a proportioning factory, a sewage treatment factory, a tap water factory, a foods processing factory and petroleum, chemical enterprises and so on. The invention has remarkable market benefits and social benefits.

Owner:LIAONING LIAOHE OIL FIELD GUANGYUAN GRP CO LTD

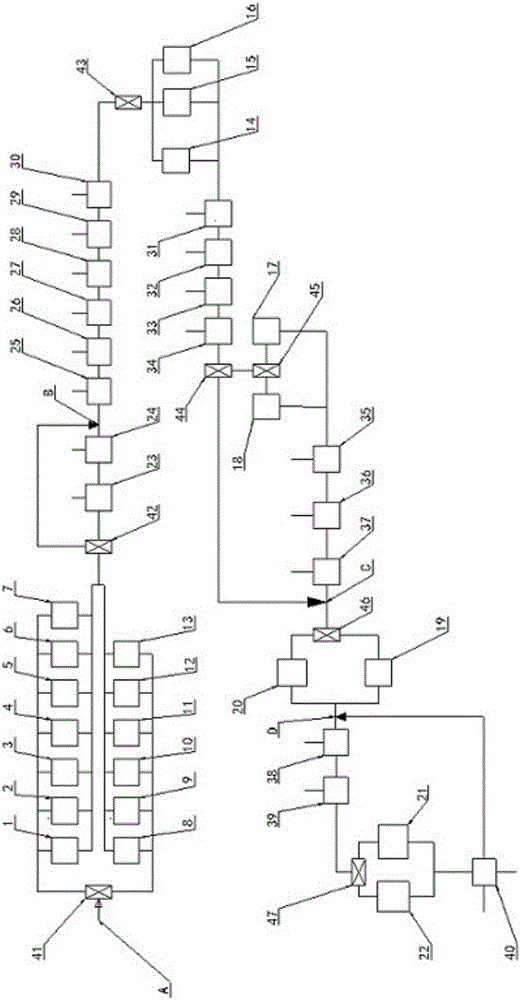

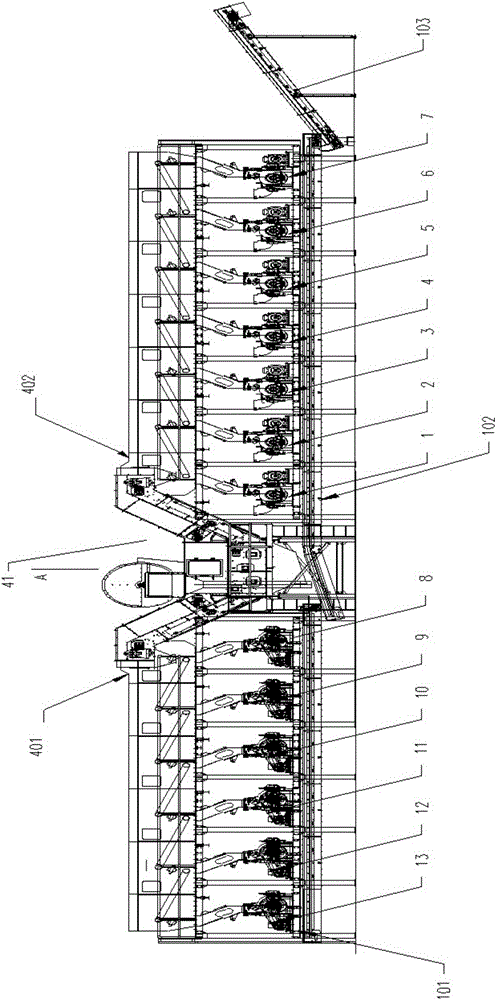

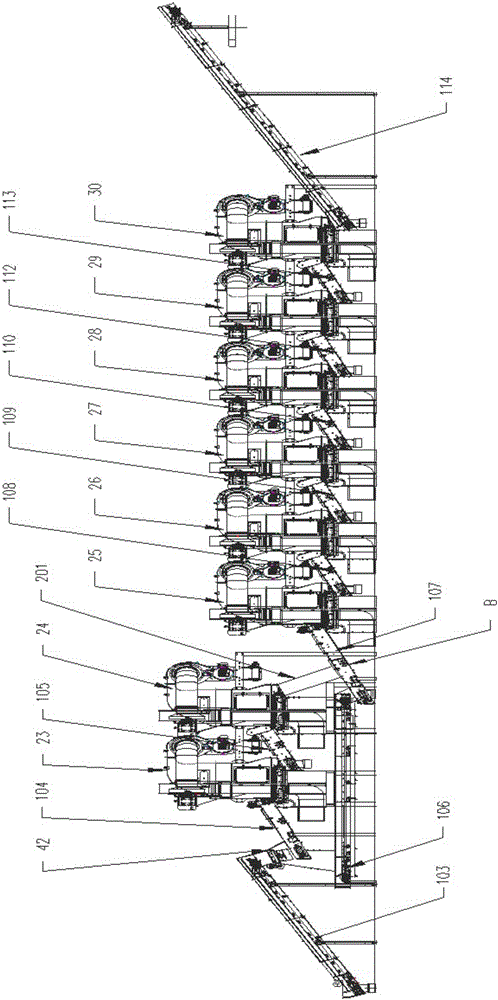

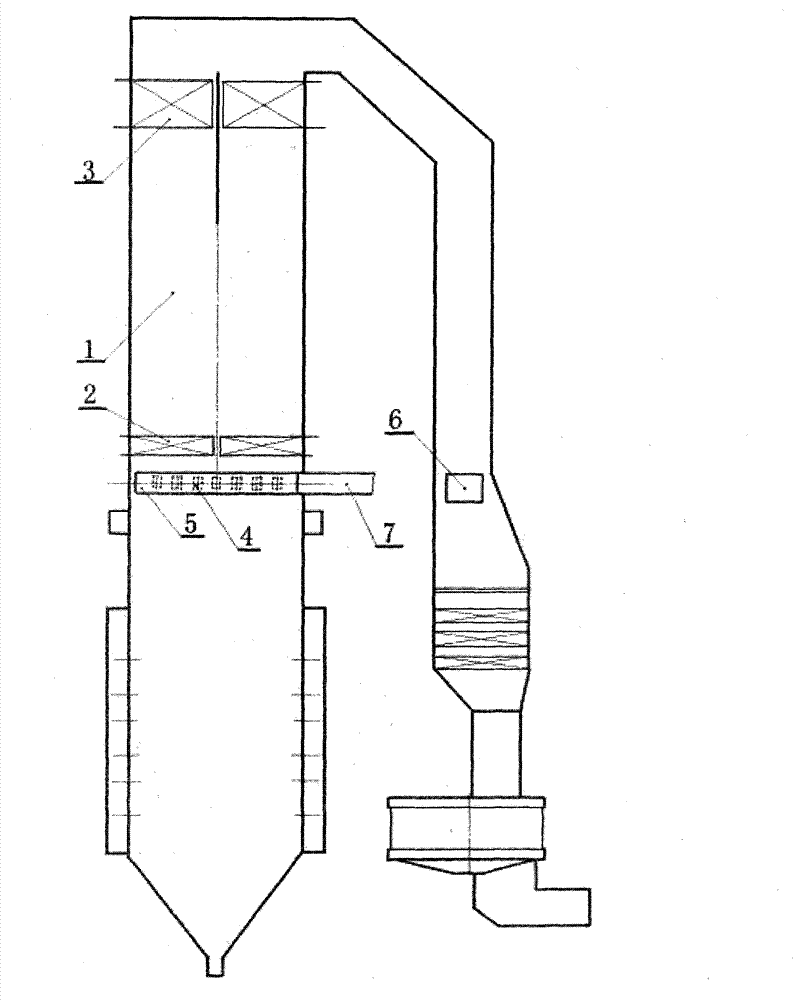

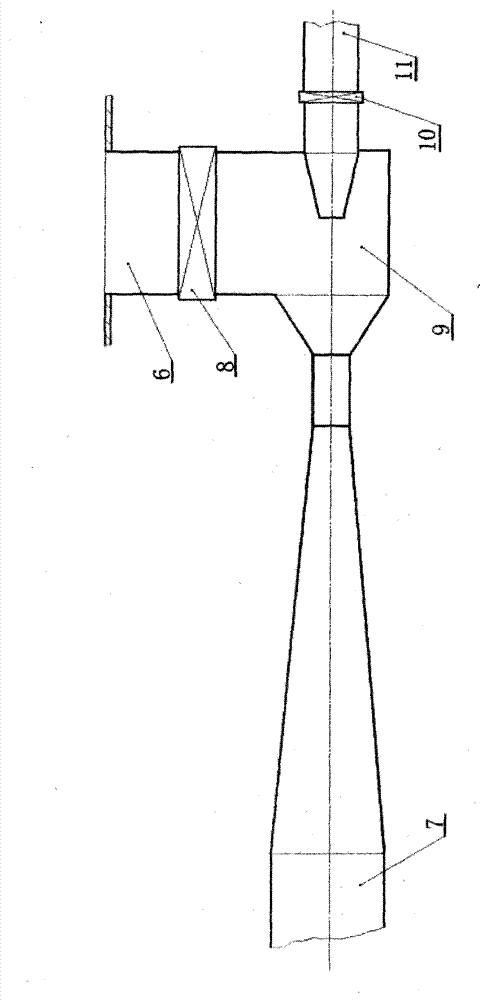

Threshing wind separation set and method for processing tobacco leaves by utilizing five-threshing and eighteen-separation process

ActiveCN106174682AExpand the scope of processingGood processing rangeTobacco preparationTobacco treatmentProduction lineEngineering

The invention provides a threshing wind separation set and method for processing tobacco leaves by utilizing a five-threshing and eighteen-separation process, which can be used for classification and mixing processing of leaf-base, non-leaf-base and full-leaf module tobacco leaves. A whole production line is compact and equipment investment is saved, wherein five grades of threshing sets and eighteen sets of wind separation devices are alternately arrayed in sequence to form linear arrangement; first-grade threshing wind separation is realized by 6 threshing sets and 7 threshing sets, and 8 wind separation device sets; second-grade threshing wind separation is realized by 3 threshing sets and 4 wind separation device sets; three-grade threshing wind separation is realized by 2 threshing sets and 3 wind separation device sets; four-grade threshing wind separation is realized by 2 threshing sets and 2 wind separation device sets; five-grade threshing wind separation is realized by 2 threshing sets and 1 wind separation device set; the first and second wind separation devices and the three grades of threshing wind separation can be selectively used; and selection channels are configured by adopting a bidirectional feeder, a proportional distribution feeder, a double-channel switching device and a material distributor. The threshing wind separation set also has the flexible and fine machining characteristics and realizes intelligent, efficient and low-cutting threshing wind separation.

Owner:HONGTA TOBACCO GRP

Flue gas recirculating temperature-regulation system of novel double reheating power station boiler

ActiveCN102865572ASave huge investmentSolve the problem that the temperature is difficult to reach the design valueSuperheating controlFlueInjector

The invention discloses a flue gas recirculating temperature-regulation system of a novel double reheating power station boiler and relates to a regulation system for regulating the main steam temperature, the single reheating steam temperature and the double reheating steam temperature of a double reheating power station boiler which is used by a thermal power station. The system comprises a temperature-regulation flue-air injector set, a temperature-regulation flue-air header, a temperature-regulation flue-air duct, a temperature-regulation air-flue ejector, an ejector flue gas suction side shutoff baffle plate, an ejector thermal primary air regulation baffle plate, a thermal primary air duct and a distributed control system (DCS), wherein the primary air regulation baffle plate is opened when the boiler load is lower than 70% of the boiler maximum continuous rating (BMCR), and the weight flow of a temperature-regulation flue-air mixture is adjustable within a range of 0-15% of the BMCR flue gas weight flow. By the aid of the system, the problem that the double reheating steam outlet temperature is difficult to reach the designed value under working conditions of 50%-60% of the BMCR when a flue gas recirculating fan is not used in the prior art is solved, the energy consumption required for flue gas recirculating temperature-regulation is greatly reduced, the infrastructure investment is saved, the plant electrical consumption is saved, the system is wear-resistant, and operation and maintenance costs are saved.

Owner:章礼道

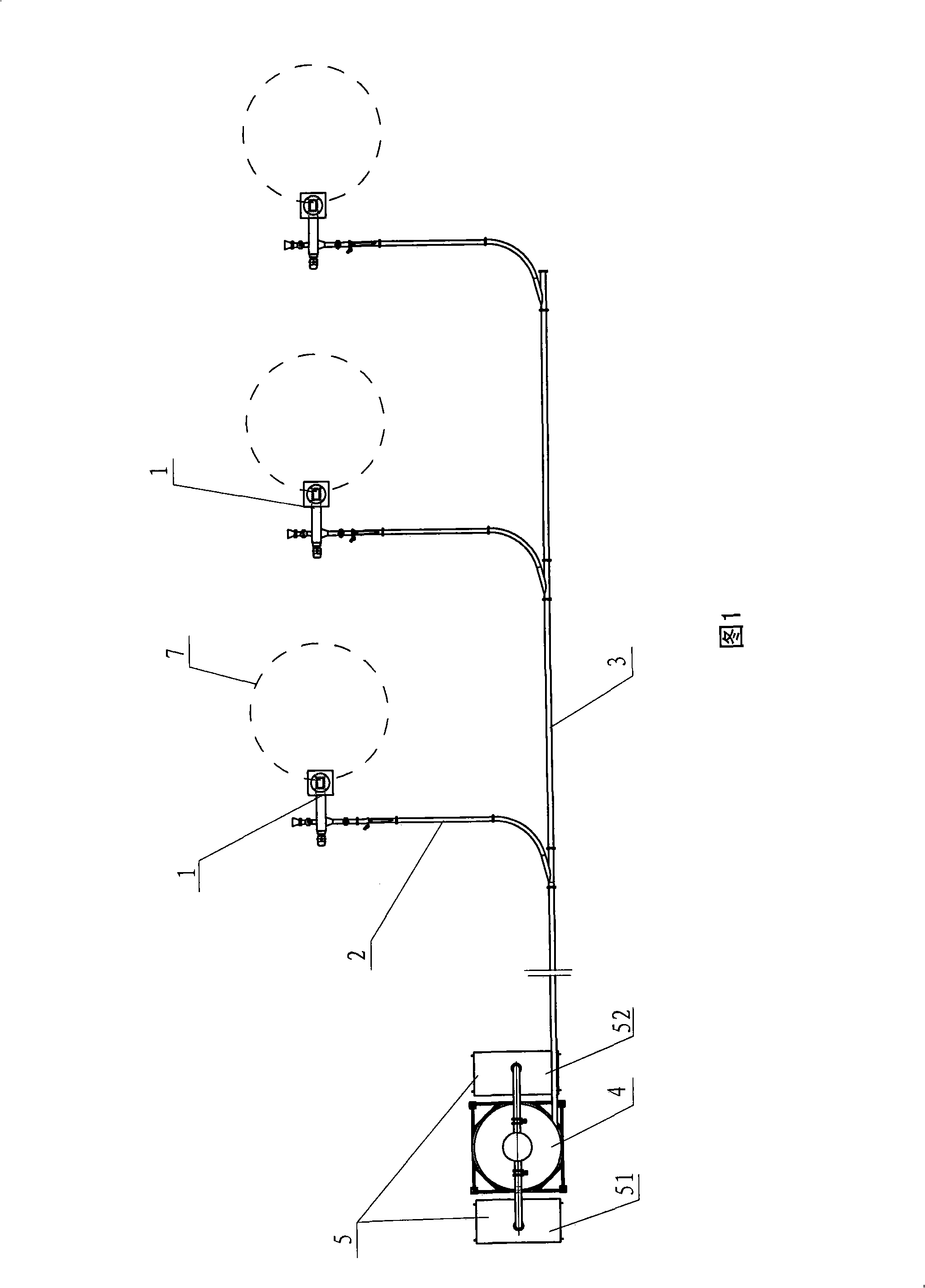

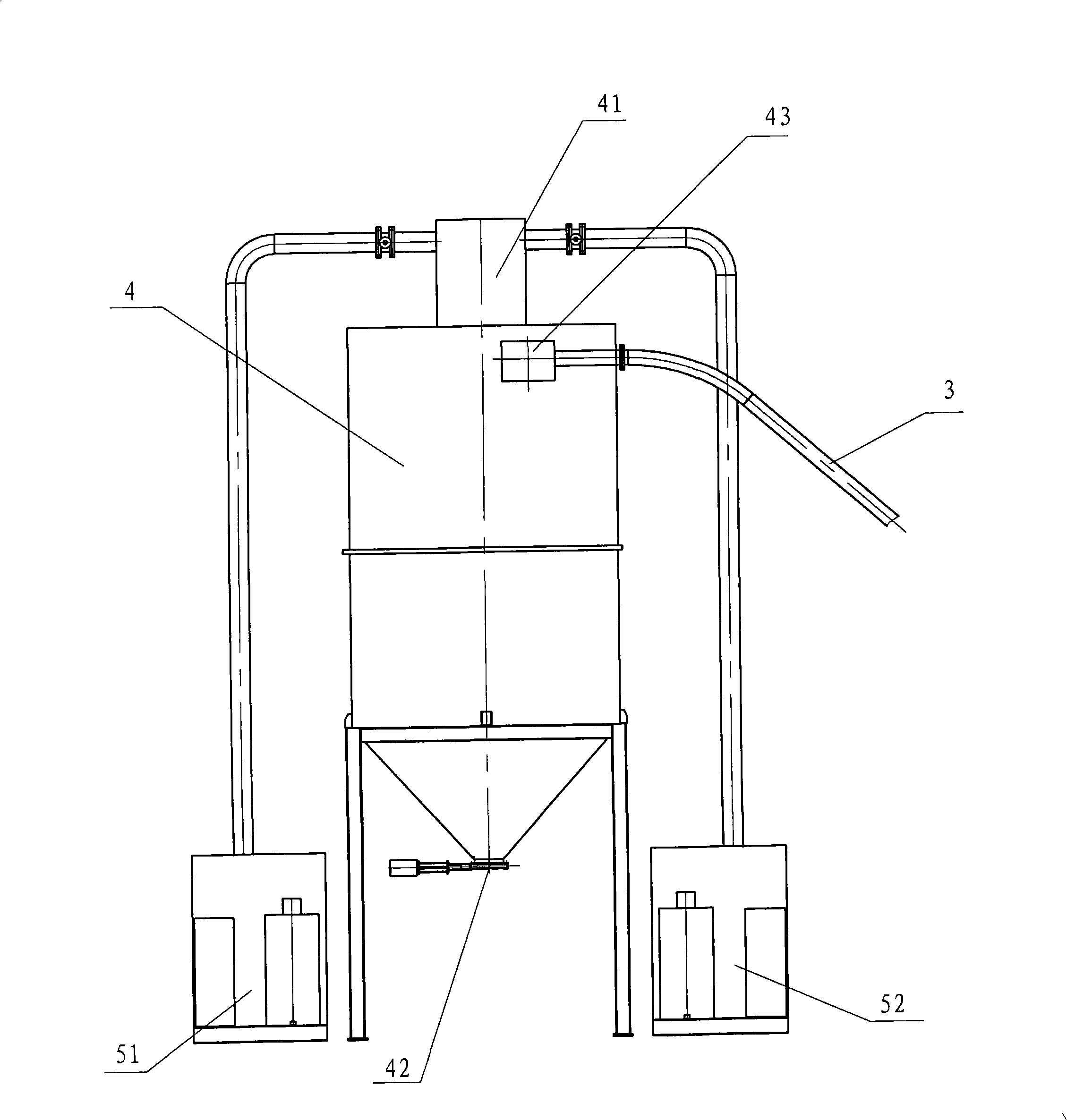

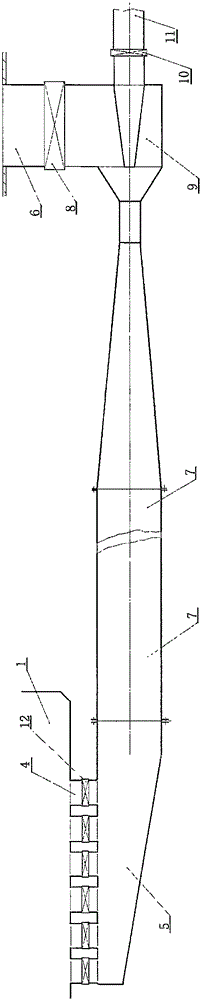

Pebble coal vacuum clearing system

The invention relates to a matching device of a coal grinding mill in a heat power plant, in particular to a vacuum cleaning system for cleaning and conveying stone coal, wastes of the coal grinding mill. The stone coal vacuum cleaning system of the invention comprises a plurality of stone coal gathering units which are respectively connected with a plurality of coal grinding mills, the discharge hole of each stone coal gathering unit is respectively connected with a main delivery duct by a branch pipeline, and one end of the main delivery duct is connected with an air pump by a stone coal bin. The matching device of the invention has simple structure, convenient use, low equipment cost and running cost and long service life.

Owner:ZHENJIANG EAST CHINA ELECTRIC POWER EQUIP FACTORY CO LTD

Low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material and preparation method thereof

ActiveCN102093625BEliminate easy crackingReduce harmInsulated cablesInsulated conductorsMasterbatchLow smoke zero halogen

The invention relates to a low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material and the cable material contains the raw materials of flame retardant masterbatch, catalyst masterbatch and crosslinking compounding agent. The preparation method comprises the following steps: mixing flame retardant masterbatch, catalyst masterbatch and crosslinking compounding agent in a sealed mixer for absorption, discharging after 3-5 hours, and packaging to obtain the low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material finished product. Compared with the common low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material, the temperature resistant grade and mechanical properties of the product of the invention can be increased and the problem that the common low smoke non-halogen polyolefin cable material is easy to crack can be eliminated.

Owner:中广核三角洲(江苏)塑化有限公司

Electroslag remelting method for producing large steel ingots by plurality of small furnaces

The invention discloses an electroslag remelting method for producing large steel ingots by a plurality of small furnaces. The method comprises the following steps of A, electroslag remelting machinery preparation: using three-phase electroslag remelting furnaces, and installing nine consumable electrodes in each furnace of the three-phase electroslag remelting furnaces; B, slag material proportioning: proportionally mixing fused alumina, limestone and high-purity fluorite; C, remelting refining: gradually putting the proportioned slag materials into a crystallizer until all slag materials are thoroughly melted in the crystallizer, charging the materials into the consumable electrodes after most slag materials are thoroughly melted, and after the consumable electrodes in the furnace are melted to the proper degree, changing a next group of consumable electrodes for continuous remelting until the remelting of all of the consumable electrodes is completed; D, deoxygenation: continuously adding complex deoxidizers into the crystallizer while the slag materials are gradually put into the crystallizer; and E, mold stripping: performing mold stripping after 3 to 6 hours from the electroslag remelting completion, and then performing hot delivery and furnace entering. Through the electroslag remelting by the plurality of small furnaces, the content of each ingredient can be conveniently controlled.

Owner:ZHEJIANG ELECTROSLAG NUCLEAR MATERIAL

Jet flue gas recycling method for preventing spray opening burning loss of secondary reheating boiler

InactiveCN105114940ASave huge investmentGuaranteed for a long timeSuperheating controlFlue gasControl system

The invention provides a jet flue gas recycling method for preventing spray opening burning loss of a secondary reheating boiler and relates to a method for adjusting main steam temperature, primary reheating steam temperature and secondary reheating steam temperature of a secondary reheating power plant boiler capable of being used by a thermal power plant safely and economically for a long time. According to the method, a temperature-regulating flue wind spraying nozzle set, a temperature-regulating flue wind connection box, a temperature-regulating flue wind duct, a temperature-regulating wind-flue ejector, an ejector flue gas suction side closing baffle, an ejector heat primary wind adjusting baffle, a heat primary air duct, a multi-hole switch type throttling baffle and a DCS control system are included. By means of the method, the problems that in the prior art, a temperature-regulating system of the secondary reheating power plant boiler does not use a furnace flue recycling fan, and it is difficult for the temperature of a secondary reheating steam outlet to reach the design value under the work condition of 50%-65% BMCR are solved, the distribution uniformity of primary air for cooling in all temperature-regulating flue wind spray nozzles is remarkably improved, and it is guaranteed that the jet flue gas recycling system can operate safely and economically for a long time.

Owner:章礼道

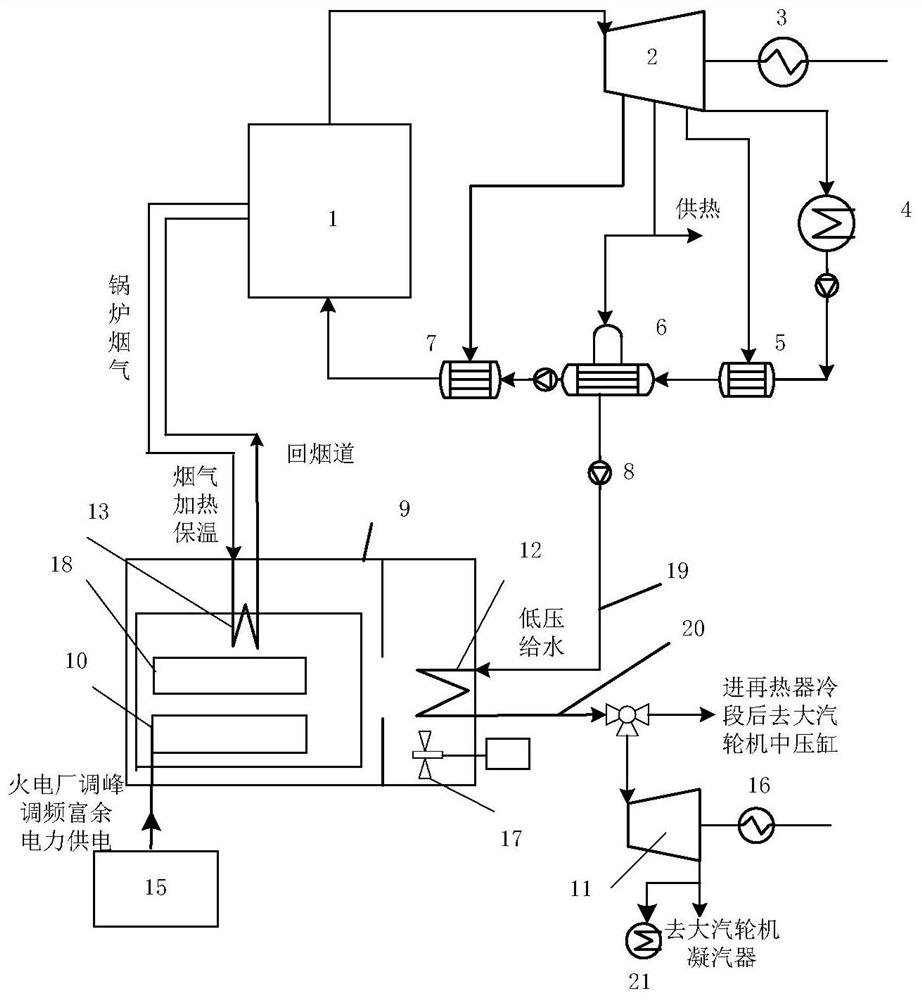

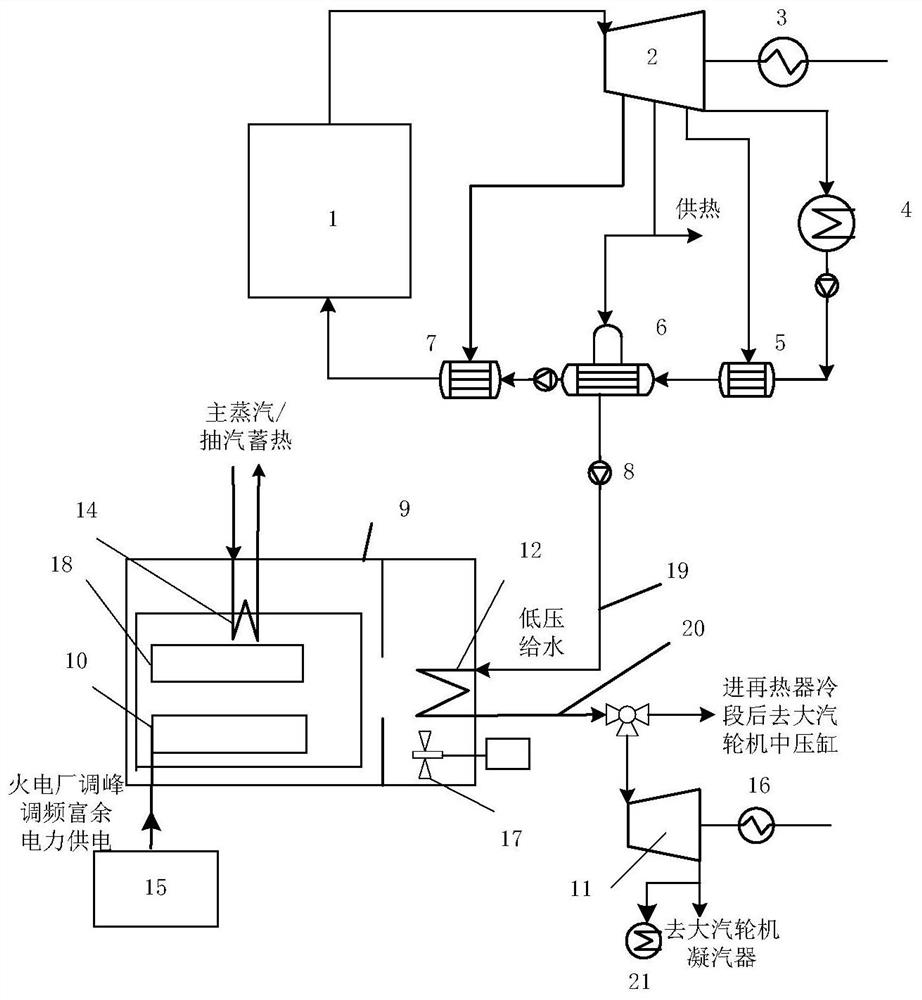

Thermal power plant heat storage power generation peak load and frequency regulation system and working method

PendingCN113390074ARealization of peak regulation and frequency regulation of heat storage power generationSave energySteam generation heating methodsHeat storage plantsFlue gasControl cell

The invention discloses a thermal power plant heat storage power generation peak load and frequency regulation system and a working method . The system comprises a heat storage device and a unit peak load and frequency regulation control unit. The heat storage device comprises a heat storage medium, a peak load and frequency regulation electric heater and a low-pressure heating overheating heat exchanger; the peak load and frequency regulation electric heater is used for heating the heat storage medium by utilizing peak load and frequency regulation surplus power of a thermal power generating unit; and superheated steam generated after the feed water or the condensed water is heated by the low-pressure heating overheating heat exchanger is fed into a thermal power generating unit reheater or a heat storage small steam turbine. The thermal power plant heat storage power generation peak load and frequency regulation system provided by the invention has the beneficial effects that in the electricity consumption trough period, the heat storage medium is heated through surplus high-temperature steam or high-temperature flue gas of the thermal power plant or electric power to achieve peak regulation, frequency modulation and heat storage, and the flexible peak regulation and frequency modulation auxiliary service of the thermal power plant is achieved.

Owner:HEPU ENERGY ENVIRONMENTAL TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com