Thermo-printing texture anti-counterfeit printed product, special thermo-printing film and manufacturing method thereof

A printing and texture technology, which is applied in the subordinate invention and its special hot stamping film and manufacturing field, can solve the problems of destroying the design layout, long order cycle, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

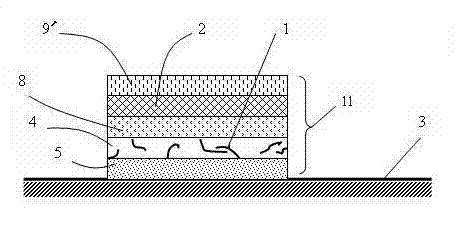

[0093] Such as Figure 5 , Image 6 As shown, a 25-micron-thick, biaxially stretched high-temperature-resistant PET transparent film roll is selected as the carrier layer (6), and a layer of 2-micron-thick release agent is coated on one side as the release layer (9 ′ ).

[0094] In the release layer (9 ′ ) and apply a layer of adhesive layer (8) on the full plate.

[0095] Such as Figure 9 As shown, a 20-micron-thick PET golden high-temperature-resistant film is selected, and a transparent hot-melt adhesive layer (10) with a thickness of 5 microns (for example, a melting point of 80-140° C.) is coated on both sides of the front and back sides. In order to make the fibers not entangled and clumped, it is best to add 1.5-3.2% ethoxylated alkylamine and 2-5% rosin powder to the glue of the hot melt adhesive layer (10). After drying, use a powder machine to pulverize it into a square piece of 0.8mm×0.8mm to make a fiber (1) coated with a hot-melt adhesive layer (10) on the s...

Embodiment 2

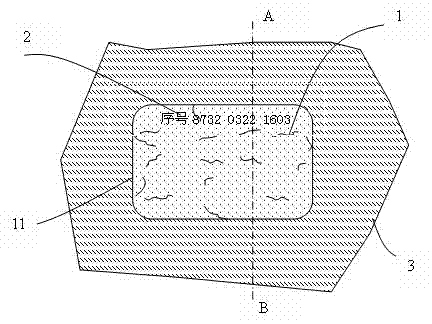

[0105] Such as image 3 , Figure 4 , Figure 12 , Figure 13 , Figure 14 As shown, select a 25-micron-thick, biaxially stretched high-temperature-resistant PET transparent film roll material as the carrier layer (6), and coat a layer of 2-micron-thick release agent on one side as the release layer (9 ′ ). Release layer (9 ′ ) can be either full-scale coating, or a printing layer that coincides with the shape and size of the hot stamping texture anti-counterfeiting label layer (11).

[0106] In the release layer (9 ′ ) and print a set of identification serial numbers (2) every certain distance.

[0107] In the release layer (9 ′ ) on the position corresponding to the identification number (2), and then print a piece of adhesive layer (8).

[0108] Such as Figure 9 As shown, choose a 20-micron thick PET gold high-temperature resistant film or iron foil, and coat a transparent hot-melt adhesive layer (10) with a thickness of 5 microns (for example, a melting point of...

Embodiment 3

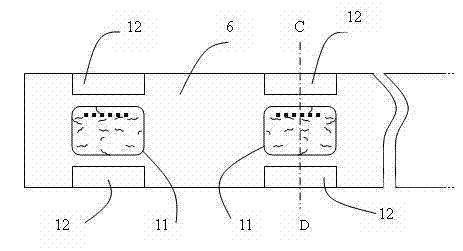

[0122] Referring to the previous embodiment and combining Figure 15 , Figure 16 , assuming that the diameter of each piece of hot stamping texture anti-counterfeiting label layer (11) is 26 mm, a transparent ink protective layer (12) is printed on the area 0.4 mm away from each piece of hot stamping texture anti-counterfeiting label layer (11), and a small amount of of residual fibers (1 ′ ) are fixed thoroughly to avoid falling. In this way, a narrow area of 0.4mm blank gap (15) is formed between the hot stamping texture anti-counterfeiting label layer (11) and the protective layer (12).

[0123] In order to avoid residual fibers (1 ′ ) affect the smooth progress of hot stamping transfer, a die-cutting knife plate with a diameter of 26.2mm can be used to die-cut an intermittent incision (14) in alignment with the blank gap (15), so that the remaining hot stamping texture anti-counterfeiting marks Residual fiber (1 ′ ) cut off. In this way, the residual fibers (1 ′ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com