Solid heat storage power generation peak and frequency modulation system for thermal power plant and working method

A technology of solid heat storage, peak regulation and frequency regulation, applied in steam generation methods, heat storage equipment, steam superheating, etc., can solve the problems of low load power grid capacity, waste, generator set shutdown and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

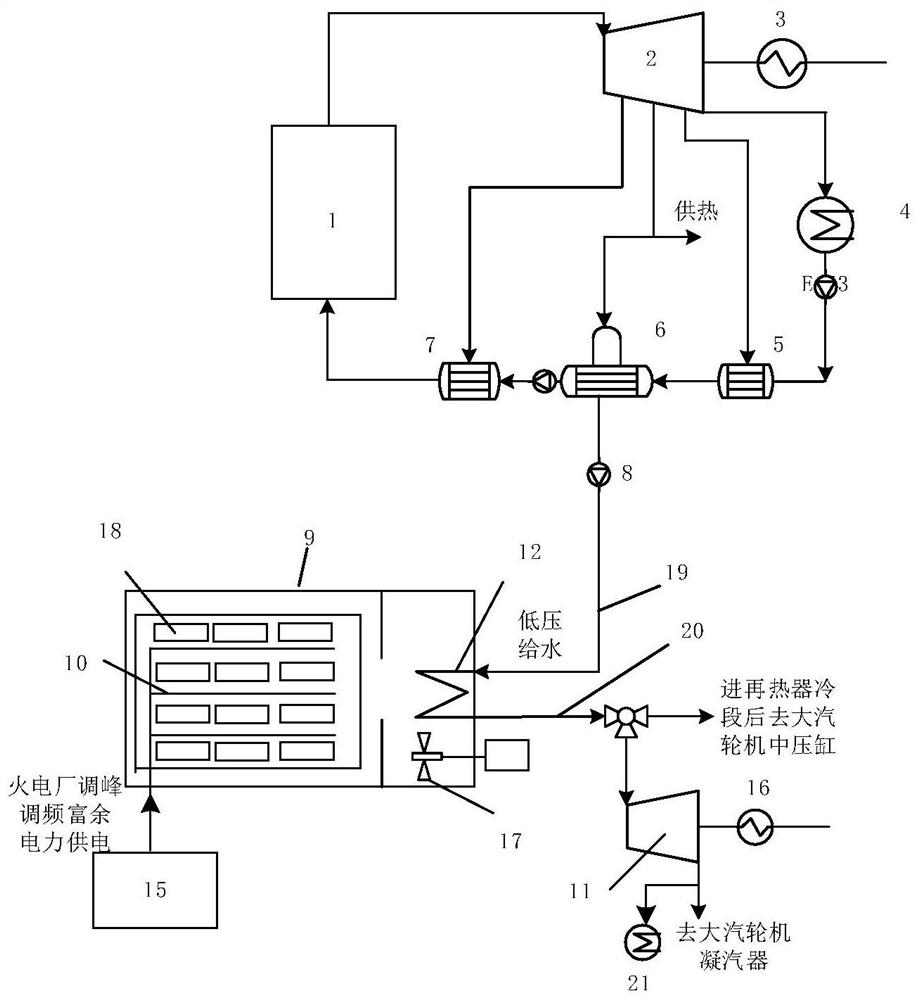

Embodiment 1

[0042] Such as figure 1As shown, a thermal power plant solid heat storage power generation peak regulation and frequency regulation system includes a solid heat storage electric boiler 9 and its water supply pipeline 19 , steam connecting pipeline 20 and unit peak regulation and frequency regulation control unit 15 . The solid thermal storage electric boiler includes solid thermal storage bricks 18, peak-shaving and frequency-regulating electric heaters 10, high-temperature-resistant fan 17 and wind-water heat exchanger 12. The peak-shaving and frequency-regulating system of solid heat storage power generation in thermal power plants is set in thermal power plants. The utility boiler 1 in the thermal power plant burns pulverized coal to heat the water in the boiler to generate water vapor, which drives the large steam turbine 2 to generate kinetic energy, and the large steam turbine drives the rotor of the generator 3 to move and cut the magnetic force lines to generate electr...

Embodiment 2

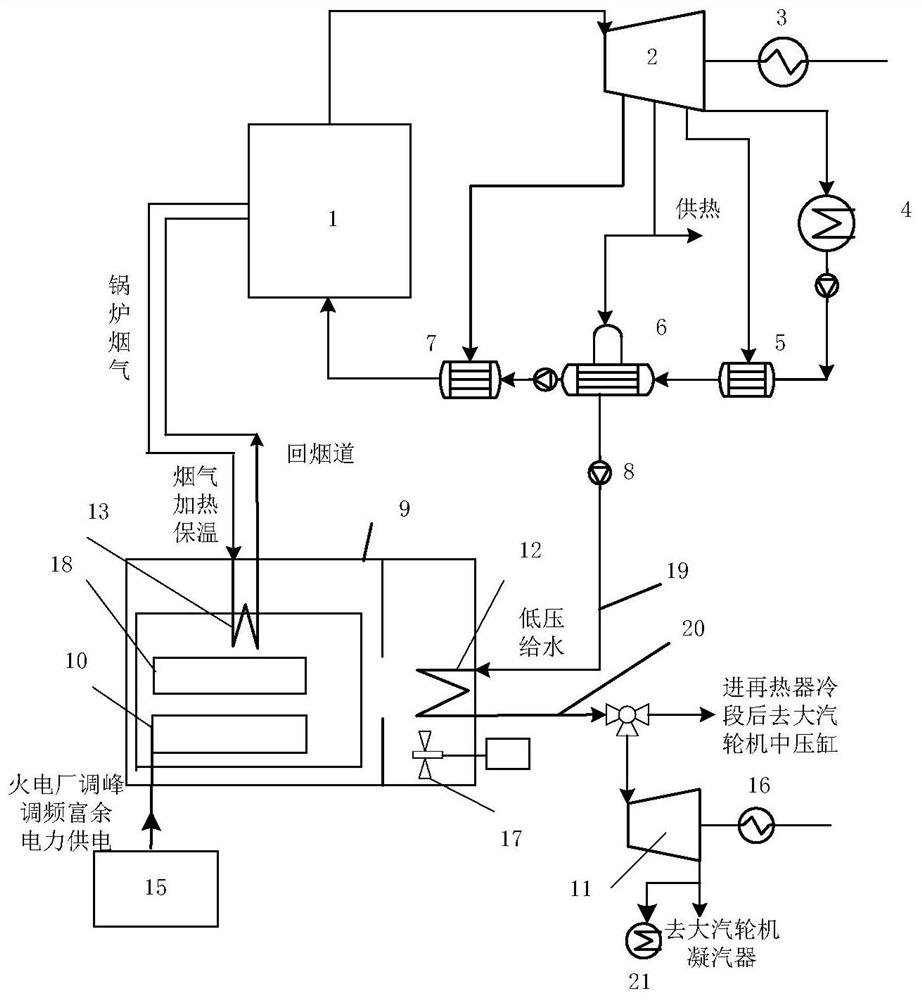

[0053] Such as figure 2 As shown, in this embodiment, a high-temperature flue gas heat exchanger 13 is also arranged in the solid heat storage electric boiler 9 to connect the flue gas supply and return pipeline of the utility boiler 1 of the thermal power plant. The flue gas supply and return pipeline includes a flue gas supply pipeline and a flue gas return pipeline. An inlet valve is installed on the flue gas supply pipeline, and an outlet valve is installed on the flue gas return pipeline. When it is necessary to store heat on the solid heat storage bricks, open the inlet valve on the flue gas supply pipeline, and the high-temperature resistant fan 17 draws the high-temperature flue gas from the boiler of the thermal power plant through the flue gas supply pipeline to heat the solid heat storage bricks, and the solid heat storage electric boiler After the solid heat storage brick absorbs the heat of the high-temperature flue gas, it reaches its heat storage temperature. ...

Embodiment 3

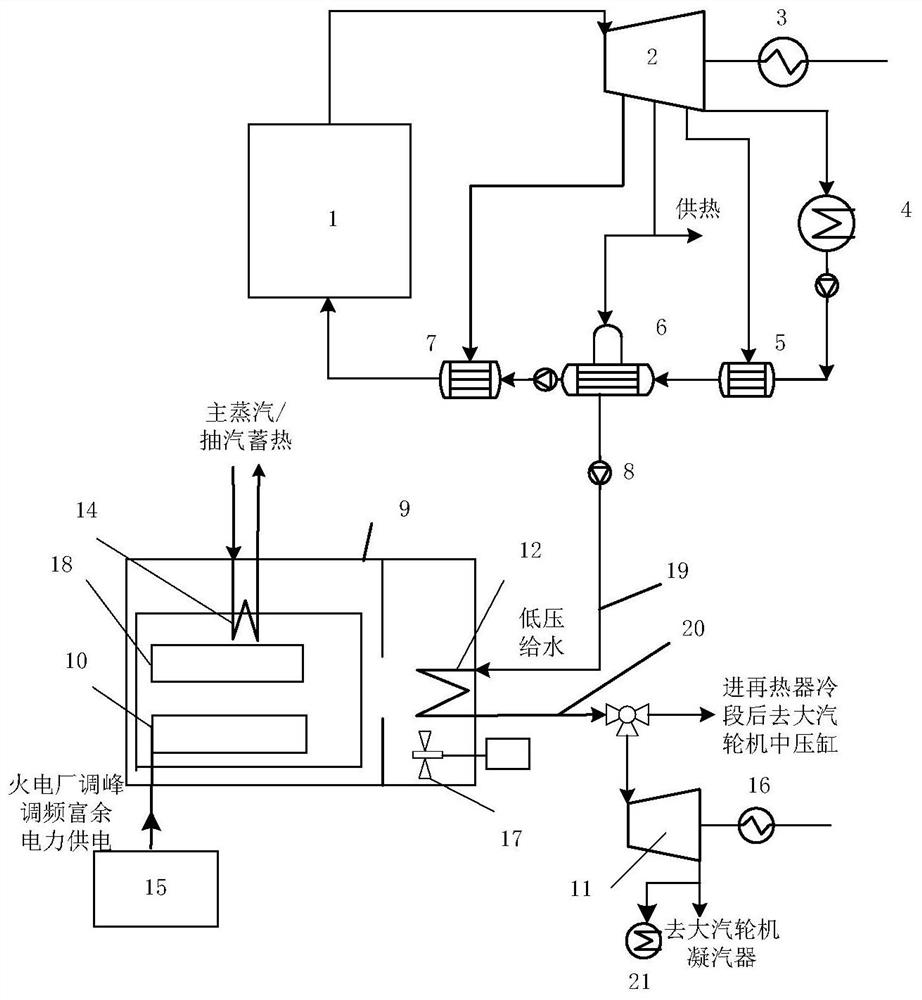

[0055] Such as image 3 As shown, in this embodiment, a high-temperature steam heat exchanger 14 is also arranged in the solid thermal storage electric boiler, and the high-temperature steam heat exchanger 14 is connected to a high-temperature steam pipeline, and the high-temperature steam pipeline is connected to the main steam pipe of a power station boiler in a thermal power plant through an inlet valve. The reheater pipeline and steam turbine extraction pipeline extract any high-temperature steam from the main steam, reheat steam or steam turbine extraction steam of the power plant boiler. The solid heat storage brick in the solid heat storage electric boiler reaches its heat storage temperature after absorbing the heat of high-temperature steam. When the solid heat storage bricks are required to release heat energy for power generation, the high temperature resistant fan 17 pushes the air through the air duct to flow to the solid heat storage bricks, and the solid heat st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com