Solid powder particle dissolution dispersing device

A technology for dissolving and dispersing solid powder, applied in water/sewage treatment, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc. Problems such as chemical operation, to achieve the effects of shortening the dissolution time, significant dissolution and dispersion effects, significant market and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

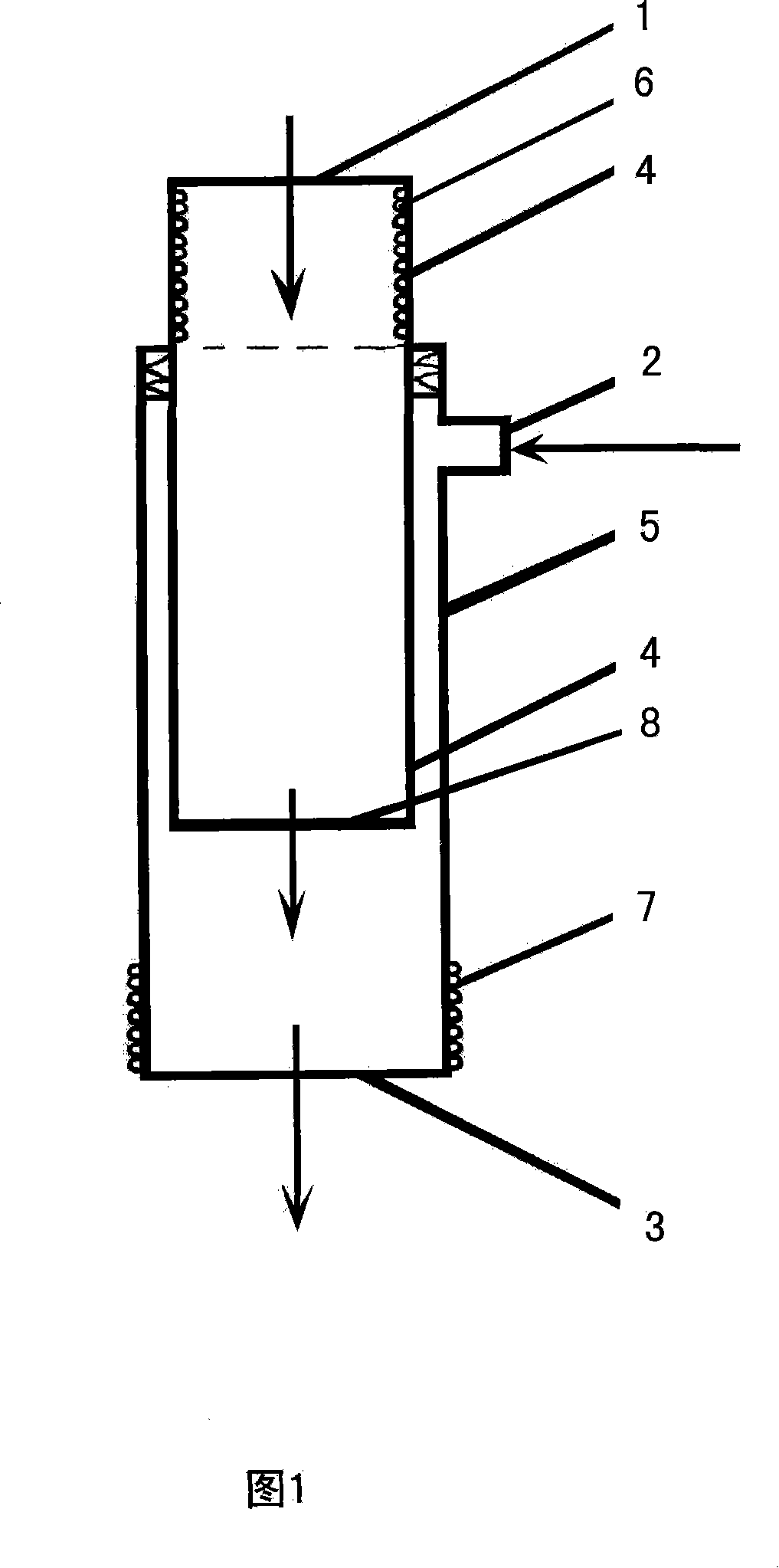

[0021] As shown in FIG. 1, FIG. 1 is a schematic structural diagram of the present invention.

[0022] The invention is a solid powder and granule dissolving and dispersing device, which realizes the dissolving and dispersing of solid medicament by water flow by utilizing the true principle of hydraulic power and using two hollow tubes with different diameters.

[0023] It includes an inner casing 4 , an outer casing 5 , a drug inlet 1 , a water inlet 2 and a water outlet 3 . It mainly sets the inner sleeve 4 on the inner side of the straight outer sleeve 5; the inner upper part of the inner sleeve 4 is provided with an internal thread 6, which can be connected with the valve body, and the upper part of the inner sleeve is a drug inlet 1 , the bottom is the drug outlet 8; the outer sleeve 5 and the inner sleeve 4 are detachably connected. The upper part of the outer casing 5 is provided with a water inlet 2, the bottom of the outer casing 5 is a water outlet 3, and the outer ...

Embodiment 2

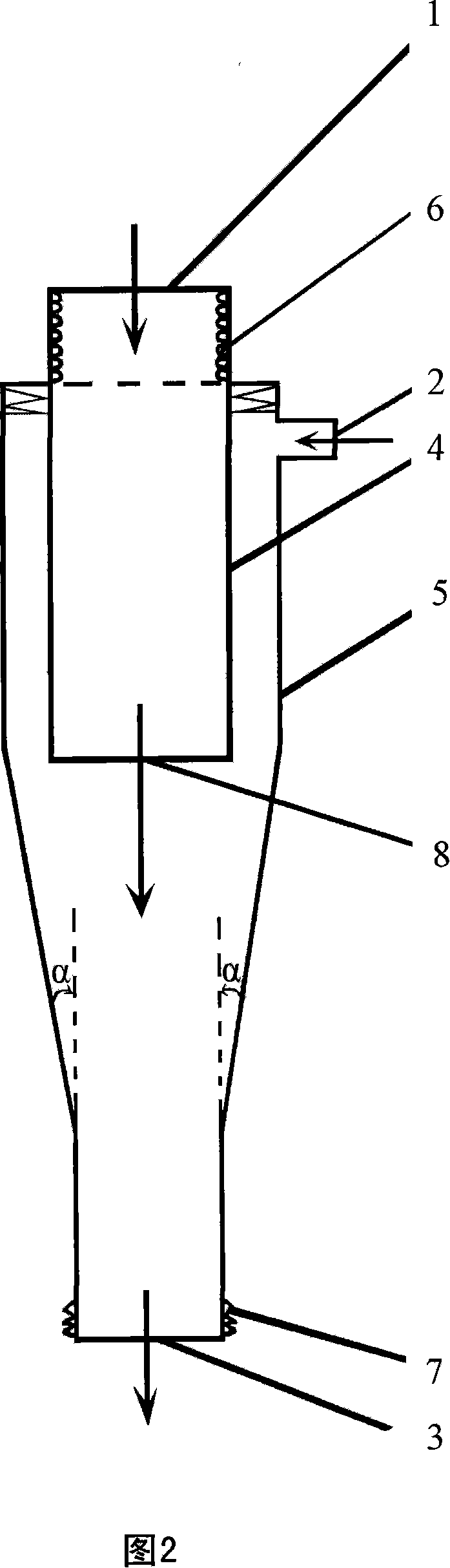

[0029] As shown in FIG. 2, FIG. 2 is a schematic structural diagram of another embodiment of the present invention.

[0030] A device for dissolving and dispersing solid powder and particles, characterized in that the outer sleeve 5 is a diameter-reducing structure, and its diameter-reducing angle α<30°. The middle and lower part of the outer sleeve 5 is an inwardly inclined structure, which can increase the hydraulic vacuum negative pressure at the bottom of the medicine outlet 8, and is suitable for use when the liquid pressure flow rate is insufficient, and the water flow is easy to form a stronger swirl state. At the same time, the variable diameter angle α<30° can prevent water from entering the inner casing 4, facilitate the dissolution and dispersion of solid powder or particles, and the dissolution and dispersion effect is more significant. Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com