Production method and equipment for carbon fiber multi-use compound stranded wire

A technology of composite stranded wire and manufacturing method, which is applied in the manufacture of wire harnesses, cable/conductor manufacturing, and conductor/cable insulation, etc., can solve the problems of high wire loss, self-weight, low strength, etc. Large, high conductivity effect

Active Publication Date: 2010-12-01

南京诺尔泰复合材料设备制造有限公司

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to invent a carbon fiber composite stranded wire with the same shape as the existing steel stranded wire to solve the problems of low strength, heavy weight and high line loss in the current power transmission line using steel stranded wire as the load-bearing core wire. Methods and equipment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

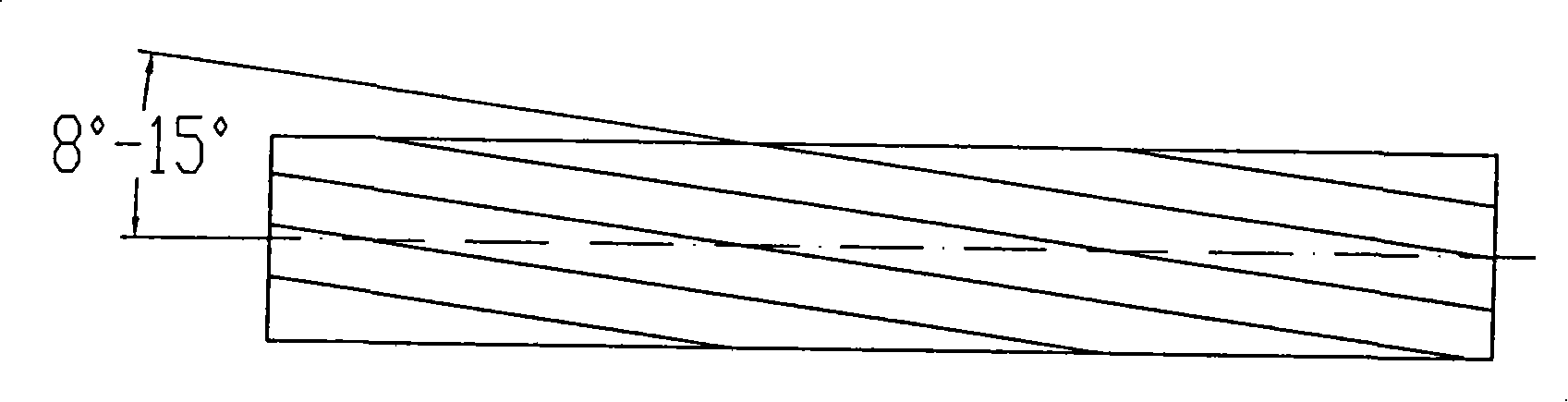

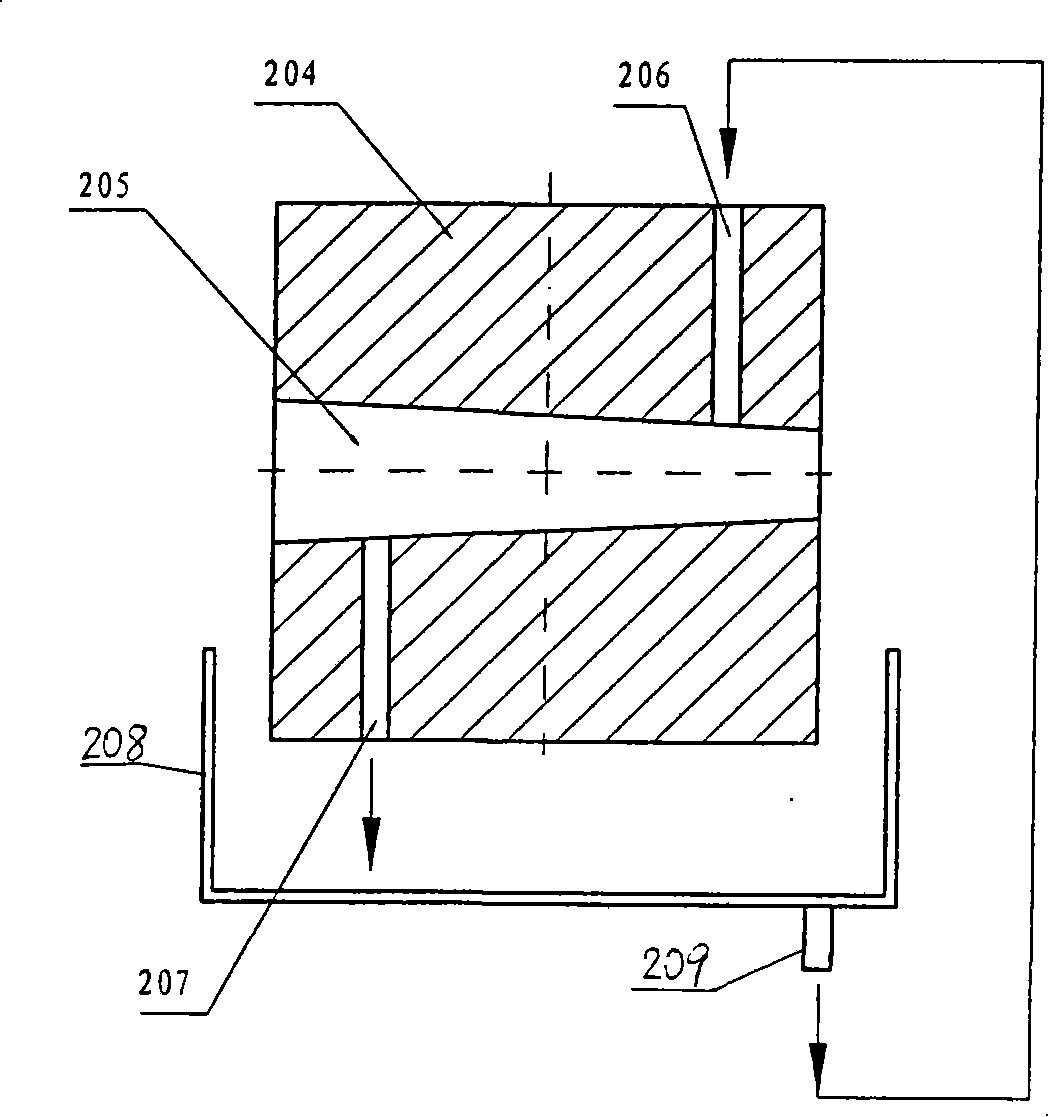

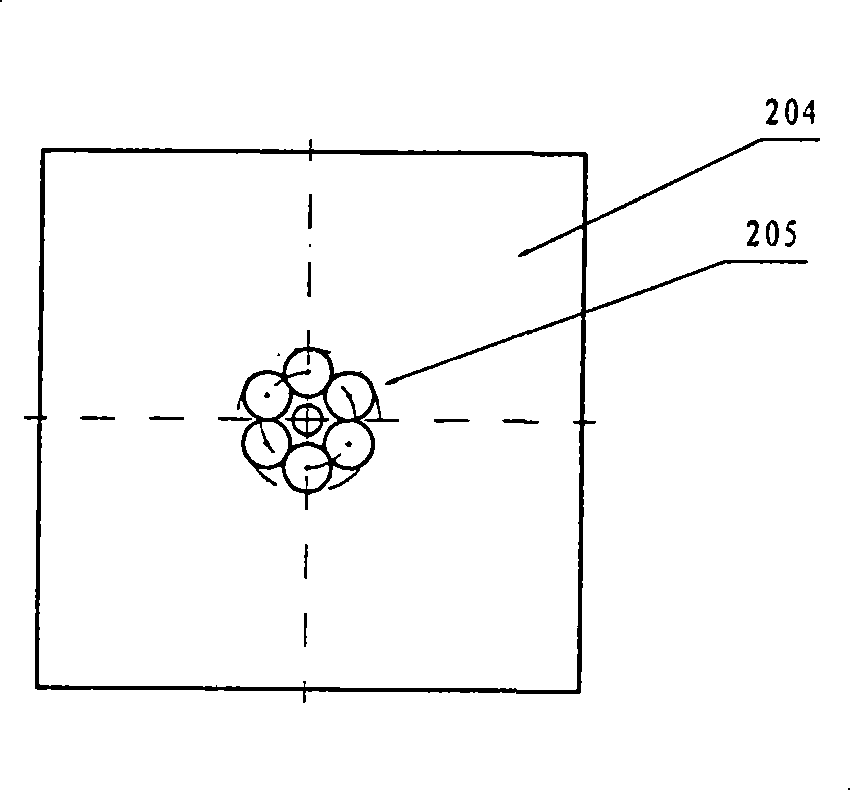

The invention discloses a manufacture method for a carbon fiber multifunctional compound stranded wire and a device thereof which belong to a cable manufacture method and a device thereof. The invention is characterized in that the method mainly includes two steps of twisting forming of each strand as well as strand combining, rotating and twisting. The manufacture device mainly consists of a strand twisting mechanism (1) and a strand combining rotating stranded wire mechanism (2) as well as a traction rotating rewinding mechanism (3). The invention has the advantages of simple method, reasonable collocation, simple structure as well as being convenient to be manufactured, mounted, debugged and maintained.

Description

Carbon fiber composite strand manufacturing method and equipment Technical field The invention relates to a conductor core wire of a power transmission line, in particular to a method and equipment for manufacturing a composite material core wire used to replace the steel core in a steel core aluminum stranded wire, in particular to a carbon fiber composite stranded wire manufacturing method And equipment. Background technique With the rapid development of my country's economic construction, the continuous growth of power demand, the continuous increase of power load, the growth of power supply capacity and power demand, the increasing tension of resources and energy, the continuous improvement of environmental protection requirements, my country’s existing transmission lines are no longer To meet the needs of rapid expansion of transmission capacity, power transmission has become a bottleneck in the development of the power industry. Further improving the power transmission c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01B13/00H01B13/012H01B13/02H01B13/16H01B13/30

Inventor 程逸建程正珲

Owner 南京诺尔泰复合材料设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com