Threshing wind separation set and method for processing tobacco leaves by utilizing five-threshing and eighteen-separation process

A technology of threshing wind and 18 points, which is applied in the fields of tobacco, application, and preparation of tobacco, and can solve the problems of uncontrollable quality of sheet tobacco and clean stems, high energy consumption, and large investment in equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Below in conjunction with accompanying drawing and embodiment the threshing air subunit and the method of the present invention are further described with five dozen eighteen points processing tobacco leaves:

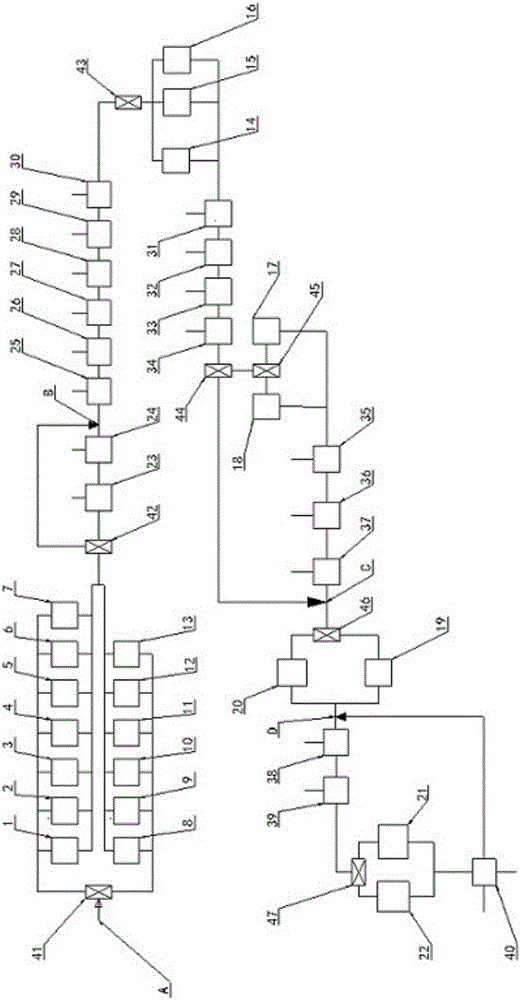

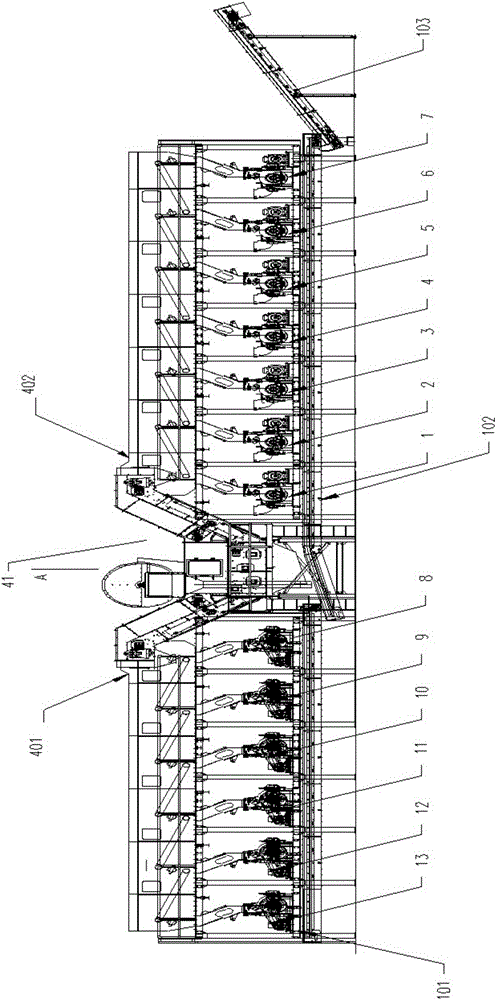

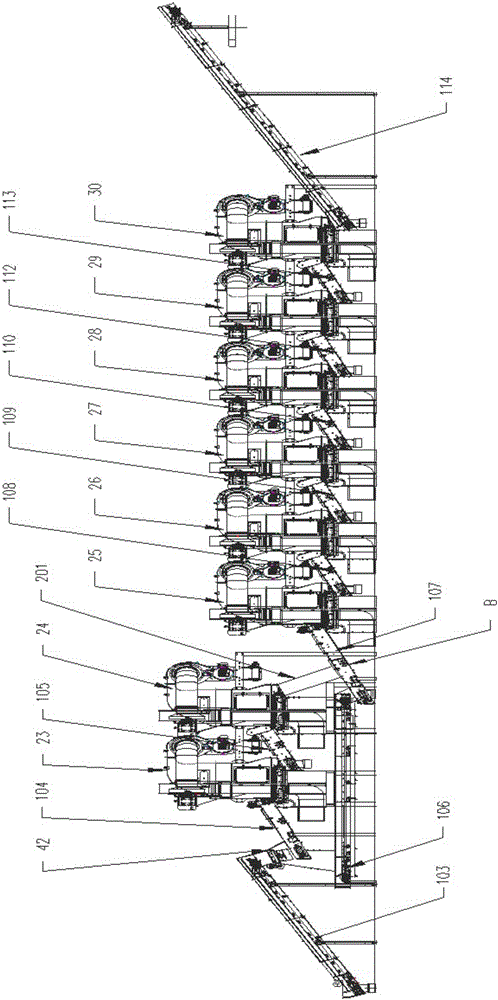

[0059] figure 1 As shown, the process flow diagram of the leaf thresher subunit and method for processing tobacco leaves with five beats and eighteen points of the present invention includes the first to twenty-second leaf threshers 1 to 22, the first to the eighteenth Air dividers 23-40, two-way feeder 41, first distributor 42, dual-channel switcher 44, second to third distributors 45-47, where point A indicates the starting point of feeding; point B indicates For the leaf base, the material after the first-stage beating is transported to the third air distributor 25 after passing through the first distributor 42; for non-leaf base and full leaves, part of it is transported to the third air distributor Before 25, some of them are sent to the front of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com