Method for restoring mine entironment

An ecological environment and mine technology, which is applied in the field of mine ecological environment governance and mine ecological environment restoration, to achieve the effect of eliminating potential pollution sources, improving resource utilization, and improving enthusiasm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

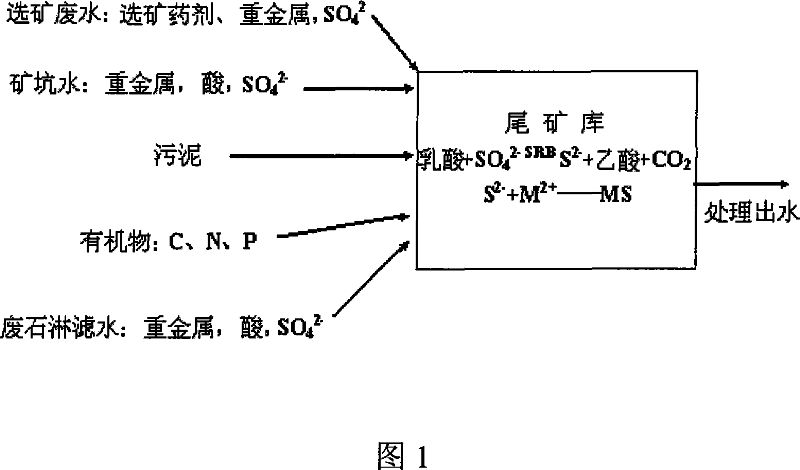

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Simulate the construction of a new tailings pond, and lay straw at the bottom of the tailings pond to control heavy metal pollution in mines. Add straw to the bottom of the simulation experiment column with a diameter of 10cm and a height of 1.5m to form an organic layer with a filling height of 10cm. Add 100ml of urban biological sludge to the straw to inoculate bacteria, and then add tailings to a filling height of 100cm. Add the simulated water with a zinc ion concentration of 20mg / L, a sulfate ion concentration of 100mg / L, and a pH of 5, into the simulated experimental column, and let it stand for 3 days to continuously enter the simulated water. After the experimental system is stable, it will be tested. The pH value, zinc ion concentration and sulfate ion concentration of the effluent. Zinc ion was determined by 4-2-pyridylazoresorcinol spectrophotometry, and sulfate was determined by barium chromate spectrophotometry. The concentration of zinc ions in the efflue...

Embodiment 2

[0028] Simulate the tailings pond in service, and directly add organic matter to the tailings pond to control heavy metal pollution in mines. According to the proportion of 0.01%, the straw is added to the tailing sand and mixed evenly, inoculated with municipal domestic sludge, and then the mixed tailings are added to the simulation experiment column with a diameter of 10cm and a height of 1.5m, and the filling height is 100cm. Add the simulated water with a zinc ion concentration of 20mg / L, a sulfate ion concentration of 100mg / L, and a pH of 5, into the simulated experimental column, and let it stand for 3 days to continuously enter the simulated water. After the experimental system is stable, it will be tested. The pH value, zinc ion concentration and sulfate ion concentration of the effluent. Zinc ion was determined by 4-2-pyridylazoresorcinol spectrophotometry, and sulfate was determined by barium chromate spectrophotometry. The concentration of zinc ions in the effluent...

Embodiment 3

[0030] Simulate the tailings pond in service, and directly add organic matter to the tailings pond to control heavy metal pollution in mines. Fill the tailings sand with a height of 100 cm in a simulation experiment column with a diameter of 10 cm and a height of 1.5 m. Simulated water and domestic sewage with a concentration of 20mg / L zinc ion concentration, 100mg / L sulfate ion concentration, and pH 5 are added to the simulation experiment column at the same time in a ratio of 100:1, and the filtration rate is controlled to be 0.1-3m / d. After 3 days of operation, the system is basically stable, and the pH value, zinc ion concentration, and sulfate ion concentration of the water are detected by sampling. Zinc ion was determined by 4-2-pyridylazoresorcinol spectrophotometry, and sulfate was determined by barium chromate spectrophotometry. The effluent zinc ion concentration is less than 1.0mg / L, the sulfate ion concentration is less than 50mg / L, and the pH value is greater th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com