Utilization method and system for tail gas of calcium carbide furnace

A calcium carbide furnace tail gas and limestone technology, which is applied in furnaces, furnace components, waste heat treatment, etc., can solve the problems of prone to spontaneous combustion, hidden dangers, and easily broken blue carbon, so as to eliminate hidden dangers, save investment, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

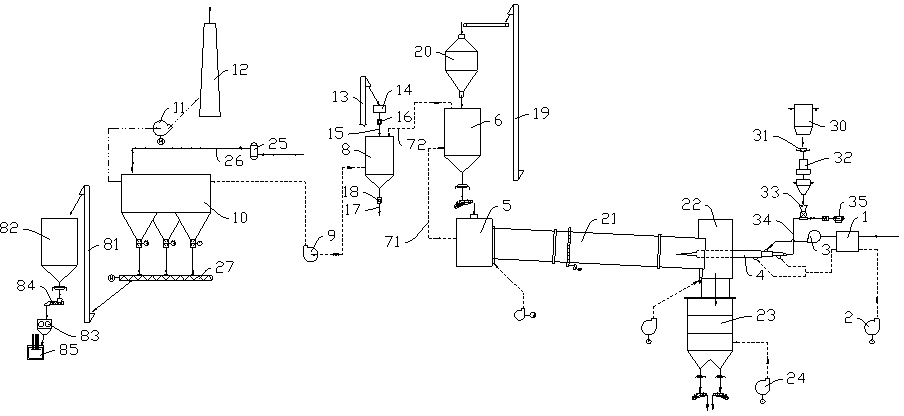

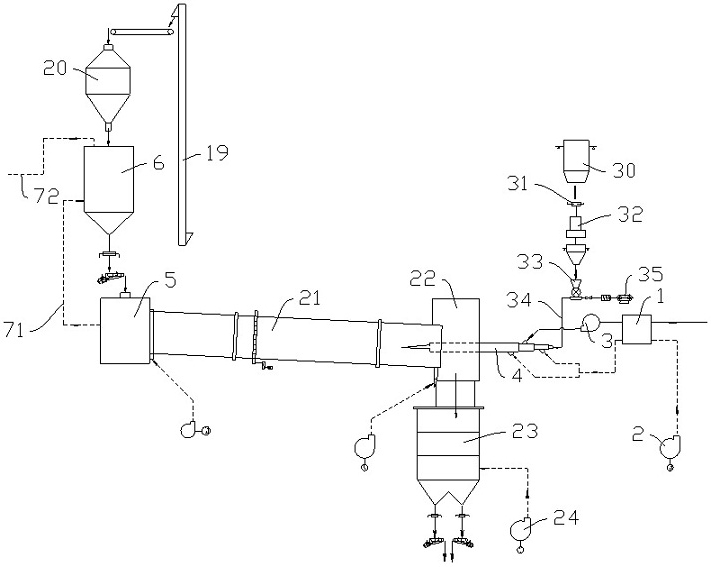

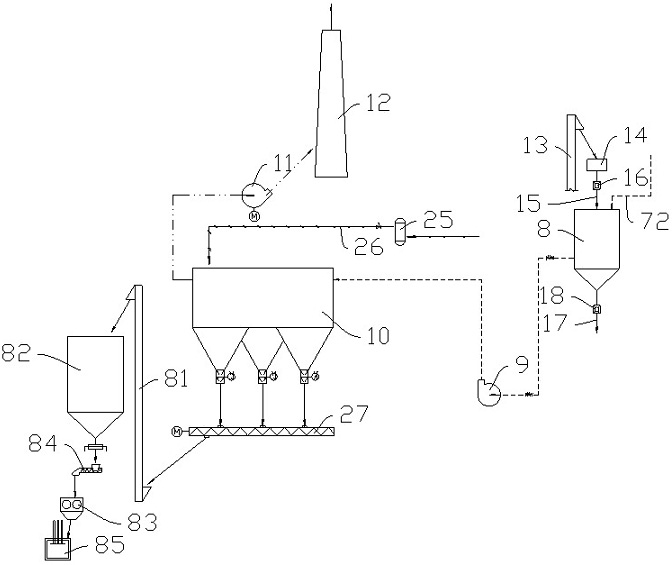

[0031] see Figure 1-4 The comprehensive utilization system of calcium carbide furnace tail gas and lime rotary kiln tail gas shown.

[0032] Burner 4 is a dual-fuel four-channel burner that can burn calcium carbide furnace gas and pulverized coal at the same time. It is a concentric sleeve composed of 4 steel pipes with different diameters. From the cross-sectional shape of the concentric sleeve, it is composed of Four concentric channels 41-44 are formed from inside to outside. The concentric channel 43 is connected with the outlet of the gas pressurized blower 3 as a gas pipe for transporting calcium carbide furnace gas. The concentric channel 41 (burner inner tube) is connected to the outlet of the coal air duct 34 as a coal air channel (auxiliary fuel pipe) for conveying pulverized coal and air. The concentric channel 44 and the concentric channel 42 serve as combustion-supporting air ducts for transporting air and are connected to the tube-side outlet of the heat excha...

Embodiment 2

[0041] see Figure 5 , 6 , 8 (and refer to image 3 , 4 , 7) The comprehensive utilization system of calcium carbide furnace exhaust gas and lime rotary kiln exhaust gas.

[0042] The difference between embodiment 2 and embodiment 1 is: see Figure 5 , 8 , it has one more pulverized coal burner 29 than embodiment 1; Certainly, its burner 4 is less than the burner 4 in embodiment 1 a concentric channel 41. Pulverized coal burner 29 links to each other with the outlet of coal air duct 34.

[0043] The specific working process of the comprehensive utilization system of this technology: pressurize the calcium carbide furnace tail gas that has been cooled by heat exchange with air, and send it to the burner of the lime rotary kiln for combustion, and use the air that has been heated by heat exchange to support combustion; The kiln exhaust gas is introduced into the vertical dryer and directly contacts the semi-coke in the vertical dryer to dry the semi-coke; the gas discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com