Pebble coal vacuum clearing system

A pebble coal and vacuum technology, applied in conveyors, transportation and packaging, conveying bulk materials, etc., can solve the problems of easy corrosion of equipment, impact on service life, equipment cost, equipment energy consumption and operating cost, and achieve no secondary Pollution, simple system, small investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

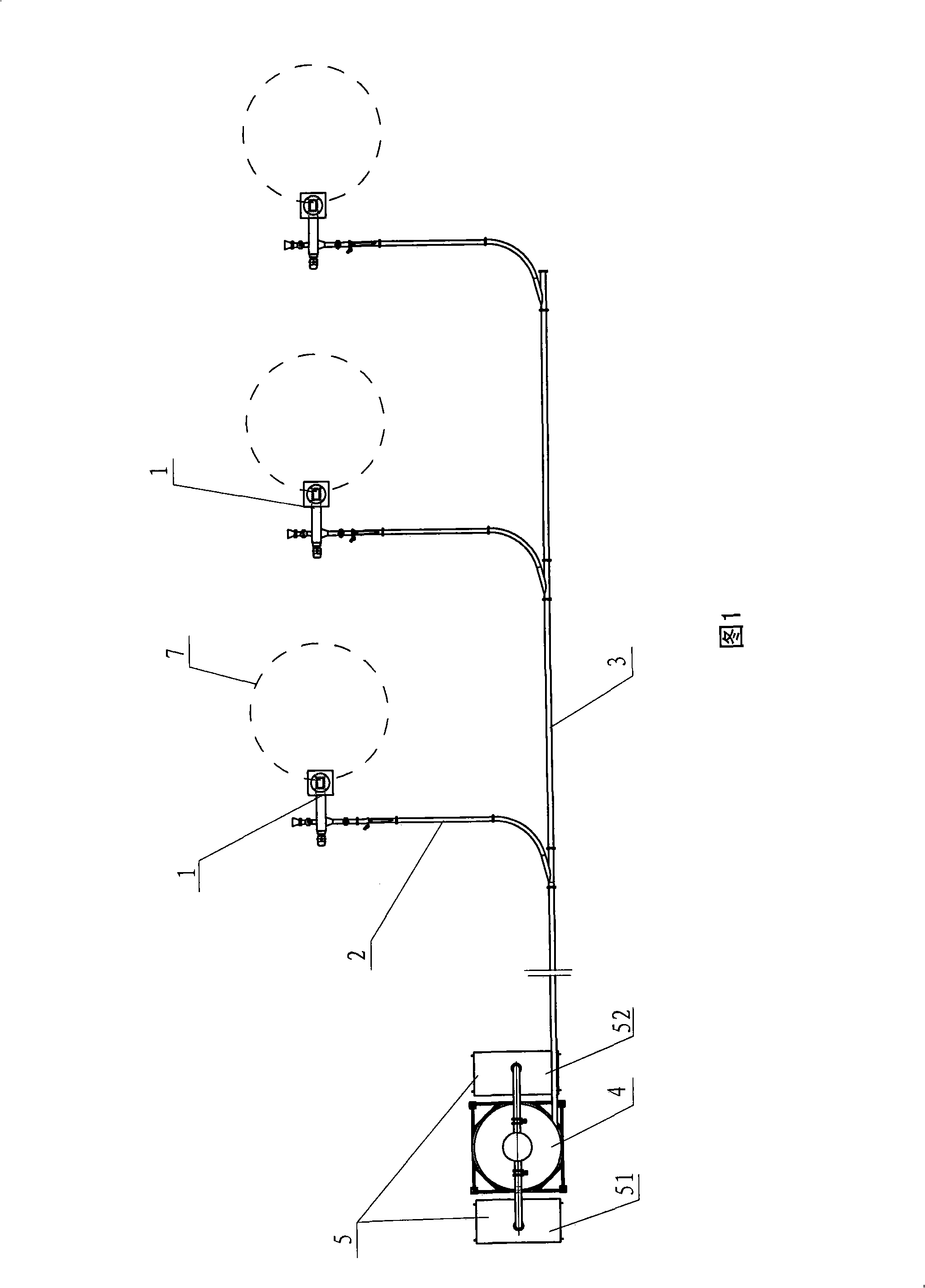

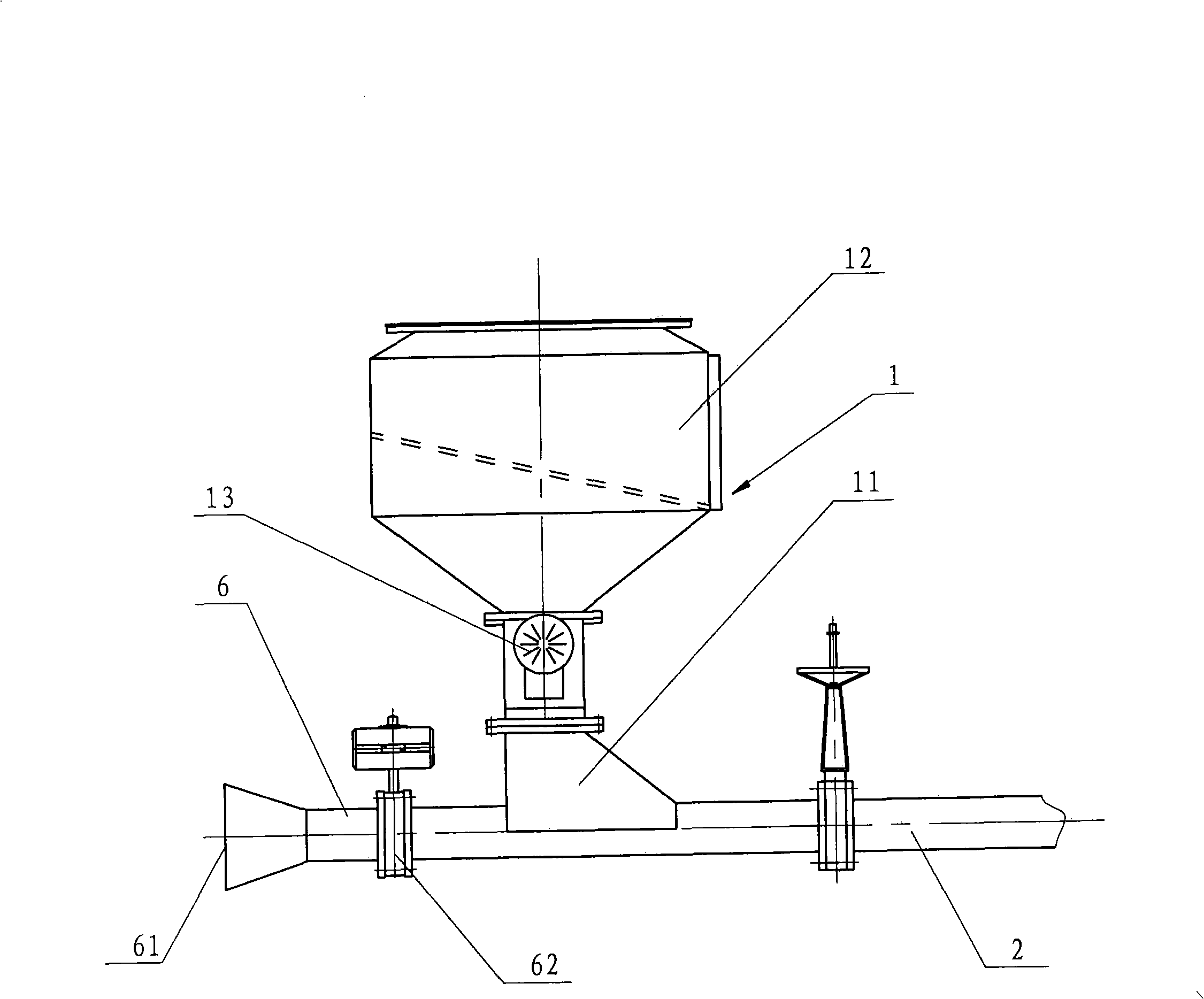

[0015] As shown in FIG. 1 , the pebble coal vacuum cleaning system includes a plurality of pebble coal collection devices 1 respectively connected with a plurality of coal mills 7, and the discharge ports 11 of each pebble coal collection device pass through the discharge pipeline 2 and a main conveying device respectively. The pipeline 3 is connected, and one end of the main conveying pipeline is connected to the vacuum pump 5 through the stone coal bunker 4 . The vacuum pump includes a main vacuum pump 51 and a backup vacuum pump 52 .

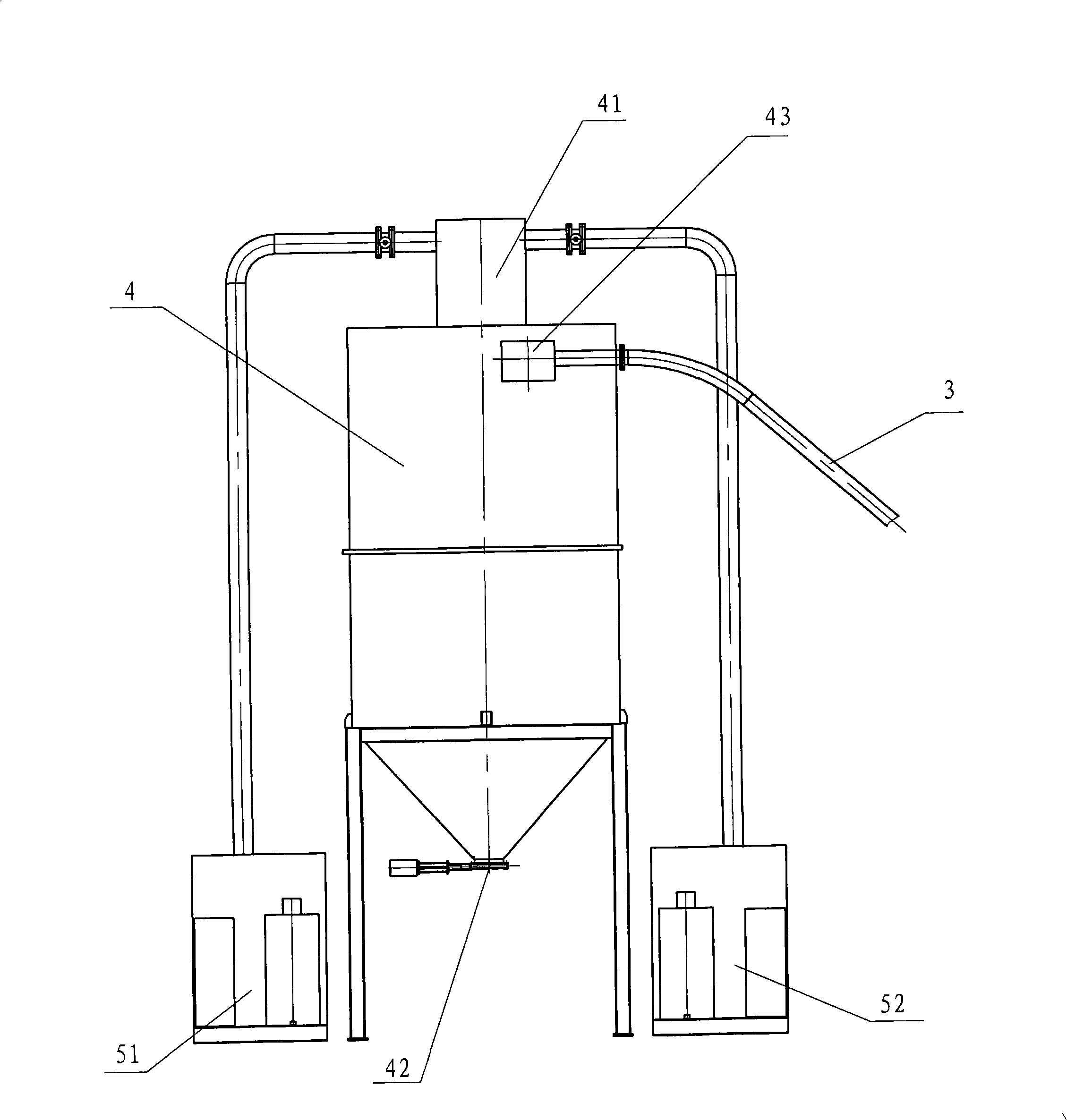

[0016] like figure 2 As shown, a dust removal device 41 is provided at the air outlet at the top of the stone coal bunker 4, a discharge door 42 is arranged at the bottom of the stone coal bunker, the main conveying pipeline enters from the upper part of the stone coal bunker, and is set at the discharge end of the pipeline The pebble coal separation device 43 . The dust removal device can use filter and dust removal equipment such as bag fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com