Ceramic raw material processing technique

A ceramic raw material and raw material technology, applied in the field of ceramic raw material processing, can solve the problems of expensive equipment, high energy consumption, waste, etc., and achieve the effect of saving electricity, fuel consumption and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

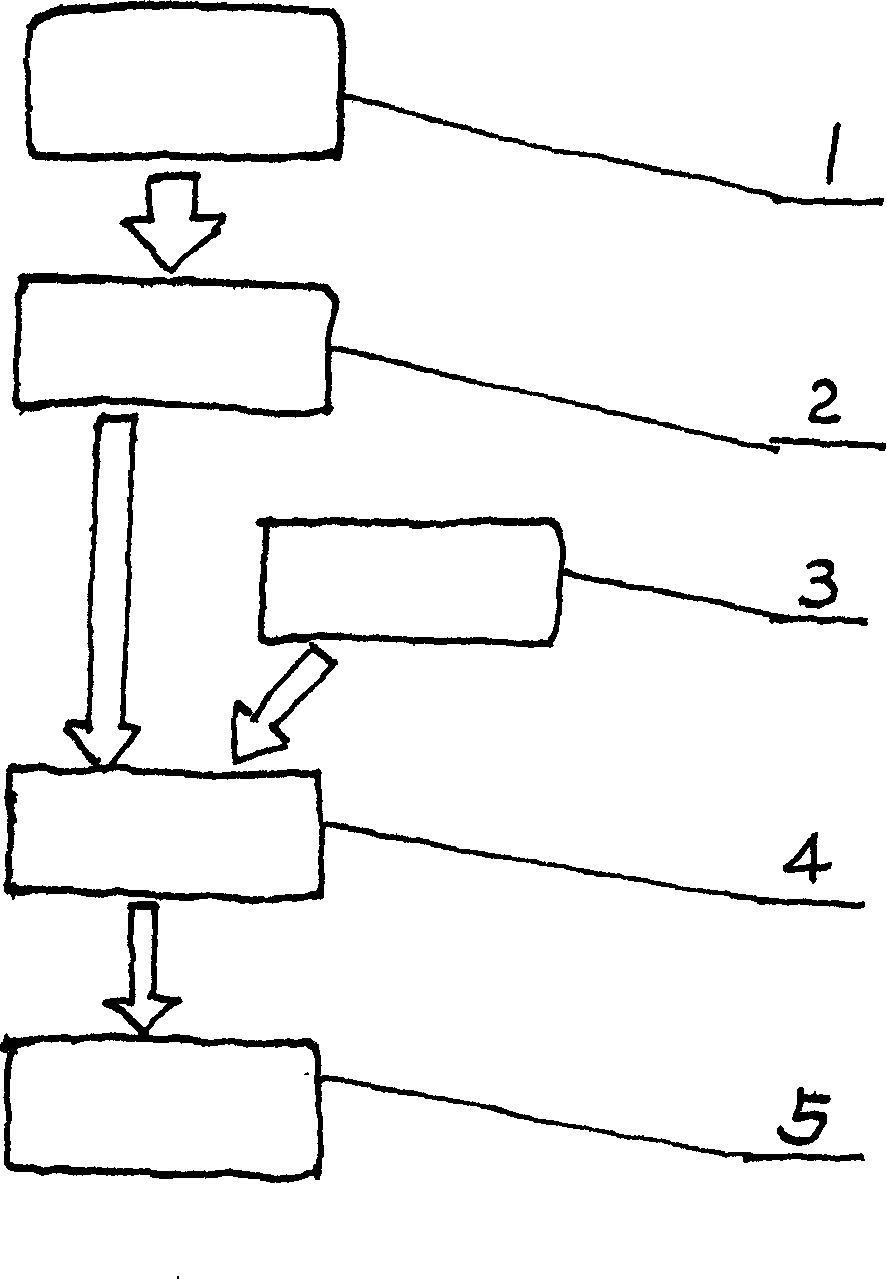

[0009] exist figure 1 Firstly, the various ingredients are crushed into fragments with a crusher (1), and then finely ground into fine powder with a mill (2) (such as a patented product, a generalized mill), and mixed evenly, and then the new binder is pressed It is required to prepare an aqueous solution as a new type of binder (3), the dry powder and the binder are respectively put into the spray granulator (4) for granulation, and the obtained raw material granules can be transported to the forming machine (5) for stamping and forming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com