Pulling device and pulling method for growing monocrystalline silicon

A technology for growing single crystal silicon and single crystal silicon, applied in chemical instruments and methods, crystal growth, single crystal growth and other directions, can solve problems such as uneconomical and complex production process of solid silicon material, save investment and reduce energy consumption , to ensure the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

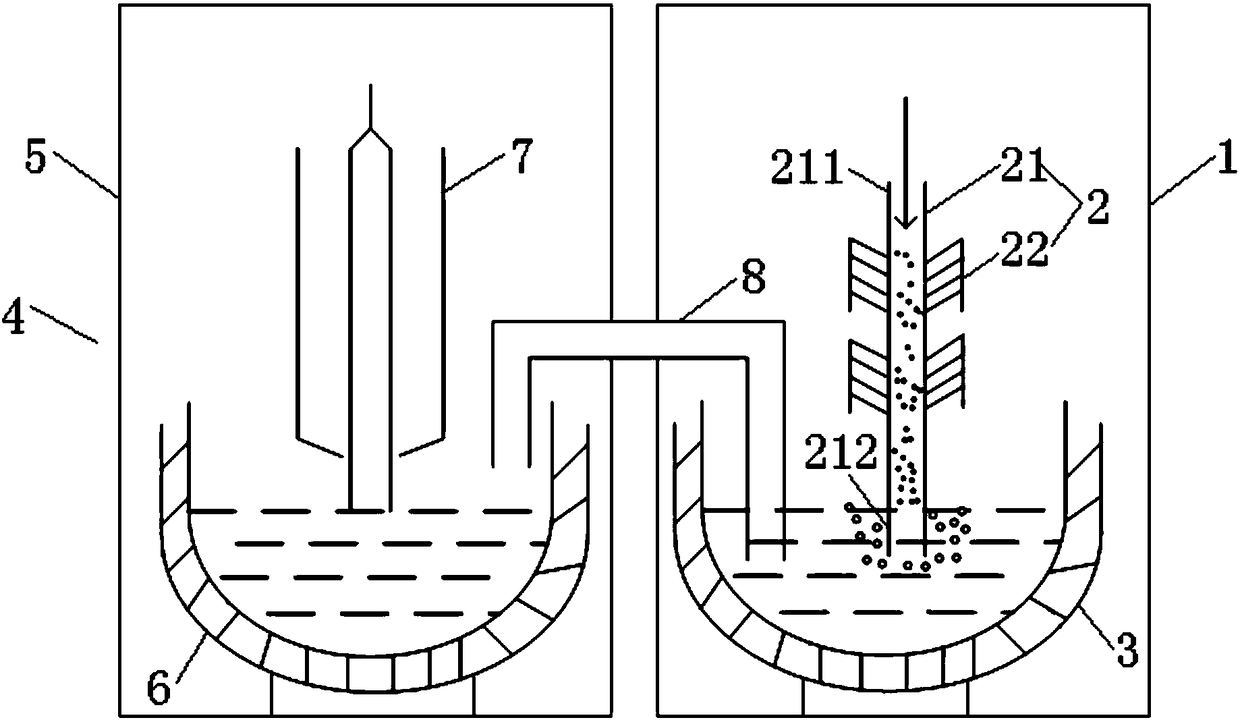

[0038] Such as figure 1 As shown, this embodiment provides a pulling device for growing single crystal silicon, including:

[0039] The first chamber 1 is provided with a tubular reactor 2 for heating and a first crucible 3 inside the first chamber 1. The first crucible 3 is used to hold molten silicon, and the gaseous silicon source is thermally decomposed in the tubular reactor 2 The reaction generates silicon powder, and silicon powder or silicon powder is melted into molten silicon and enters into the first crucible 3; specifically, the tubular reactor 2 in this embodiment includes a tube body 21 and a heating element for heating the tube body 21 The tube body 21 includes a tube body inlet 211 and a tube body outlet 212. The gas silicon source passes into the tube body 21 through the tube body inlet 211 to be heated and reacts in the tube body 21, and is discharged from the tube body outlet 212.

[0040] Single crystal silicon pulling furnace 4, used to pull and grow sing...

Embodiment 2

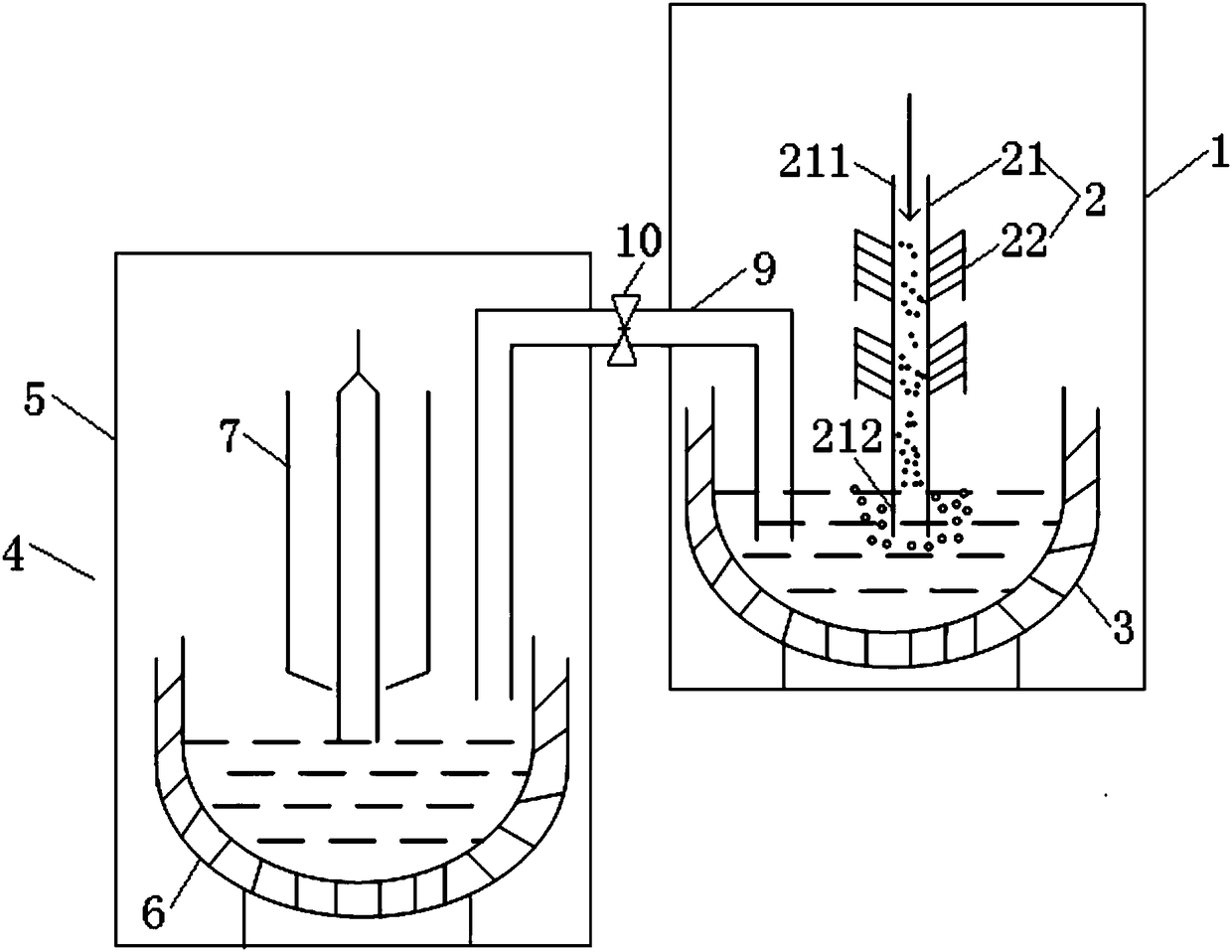

[0071] Such as figure 2 As shown, the difference between the pulling device for growing single crystal silicon in this embodiment and that in Embodiment 1 is that: the conveying mechanism in this embodiment includes a siphon 9, when the liquid level of molten silicon in the first crucible 3 is higher than The liquid level of the molten silicon in the second crucible 6, one end of the siphon tube 9 is positioned under the liquid level of the molten silicon in the first crucible 3, and the siphon tube 9 is used to siphon the molten silicon in the first crucible 3 into the second crucible 6 , The delivery mechanism also includes a valve 10 that is arranged on the siphon 9 and can be opened and closed.

[0072] It should be noted that the tubular reactor 2 in this embodiment is made of silicon carbide;

[0073] The inner wall of the tubular reactor 2 is coated with high-purity Si 3 N 4 .

[0074] This embodiment also provides a method for growing single crystal silicon using ...

Embodiment 3

[0084] This embodiment also provides a pulling method for growing single crystal silicon using the pulling device for growing single crystal silicon in embodiment 1. The difference between the method in this embodiment and the method in embodiment 1 is that:

[0085] The gaseous silicon source in this embodiment is dichlorodihydrosilane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com