High-solid environment-friendly single-component polyurea coating and preparation method thereof

An environmentally friendly, single-component technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of high cost of single-component polyurea coatings, cannot be widely promoted, and is not environmentally friendly, so as to improve storage stability, Easy to promote and avoid pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

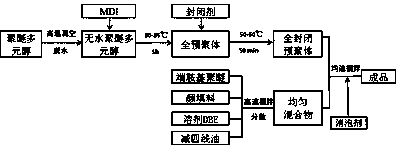

Method used

Image

Examples

Embodiment 1

[0025] High-solid environment-friendly one-component polyurea coating is prepared from the following raw materials by weight:

[0026] Polyether polyol (330N) 10-20 parts, polyether polyol (DDL-2000) 170-200 parts, polyether polyol (DDL-1000) 60-70 parts, diphenylmethane diisocyanate (MDI) 60 parts -70 parts, blocking agent 1: 30-50 parts; amino-terminated polyether (T-5000) 1-5 parts, amino-terminated polyether (D-2000) 50-70 parts, amino-terminated polyether (D-2000) -400) 10-15 parts, sealing agent 2: 10-15 parts, chain extender diethyltoluenediamine (DETDA) 3-5 parts, pigment black carbon black 1-3 parts, polyamide wax powder 0.3- 1.0 parts, fumed silica 10-20 parts, ultra-fine fly ash 30-50 parts, toughening agent minus four line oil 10-20 parts, defoamer 0.2-0.4 parts, high boiling point solvent dibasic acid ester ( DBE) 10-20 parts.

Embodiment 2

[0028] High-solid environment-friendly one-component polyurea coating is prepared from the following raw materials by weight:

[0029] Polyether polyol (330N) 30-40 parts, polyether polyol (DDL-2000) 170-200 parts, polyether polyol (DDL-1000) 40-60 parts, diphenylmethane diisocyanate (MDI) 80 parts -90 parts, blocking agent 1: 30-50 parts; amino-terminated polyether (T-5000) 5-10 parts, amino-terminated polyether (D-2000) 50-70 parts, amino-terminated polyether (D-2000) -400) 5-10 parts, blocking agent 2: 10-15 parts, chain extender diethyltoluenediamine (DETDA) 3-5 parts, pigment black carbon black 1-3 parts, polyamide wax powder 0.3- 1.0 parts, fumed silica 10-20 parts, ultra-fine fly ash 30-50 parts, toughening agent minus four line oil 10-20 parts, defoamer 0.2-0.4 parts, high boiling point solvent dibasic acid ester ( DBE) 10-20 parts.

Embodiment 3

[0031] High-solid environment-friendly one-component polyurea coating is prepared from the following raw materials in parts by weight:

[0032] Polyether polyol (330N) 40-50 parts, polyether polyol (DDL-2000) 170-200 parts, polyether polyol (DDL-1000) 40-50 parts, diphenylmethane diisocyanate (MDI) 90 parts -100 parts, sealing agent 1: 40-60 parts; amino-terminated polyether (T-5000) 5-10 parts, amino-terminated polyether (D-2000) 50-70 parts, amino-terminated polyether (D-2000) -400) 5-10 parts, blocking agent 2: 10-15 parts, chain extender diethyltoluenediamine (DETDA) 3-5 parts, pigment black carbon black 1-3 parts, polyamide wax powder 0.3- 1.0 parts, fumed silica 10-20 parts, ultra-fine fly ash 30-50 parts, toughening agent minus four line oil 10-20 parts, defoamer 0.2-0.4 parts, high boiling point solvent dibasic acid ester ( DBE) 10-20 parts.

[0033] Among them, blocking agent 1 includes γ-aminopropyl triethoxysilane, γ-glycidyl etheroxypropyl trimethoxysilane, γ-mer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com