A method of measuring the change of charge density on the surface of wafer

A surface charge density, wafer technology, applied in the measurement of electrical variables, measurement devices, semiconductor/solid-state device testing/measurement, etc., can solve the problem of high cost of surface charge measurement, achieve fast measurement, simple calculation method, simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

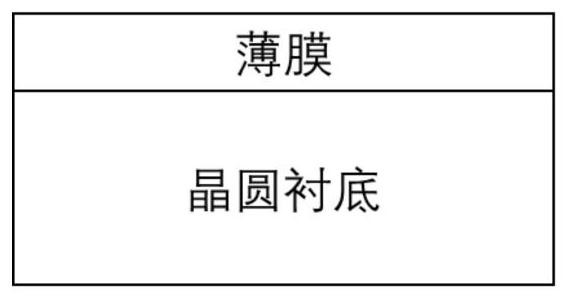

[0041] The present invention takes the P-type single-sided polished silicon wafer as an example, below in conjunction with the attached figure 2 The technical solution of the present invention is described in detail.

[0042] P-type single-sided polished silicon wafer, the resistivity is about 3000Ω-cm, the thickness is 400±20μm, and the crystal orientation silicon wafer size is 50.8±0.2mm in diameter. The surface of the silicon wafer is clean but has a natural oxide layer, which contains negligible surface charges.

[0043] The surface sheet resistance of the polished surface of the silicon wafer before film deposition was measured by four-probe measurement method to be 8.0±1.0×10 5 Ω / sq., corresponding to R in formula (4) 0 .

[0044] Aluminum oxide (AlO) with a thickness of about 15 nm was deposited by atomic layer deposition (ALD) x ) film on the polished surface of the silicon wafer. Measure the sheet resistance of the silicon wafer surface to be 6.5±0.5×10 4 Ω / sq....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com