Special intelligent motive power device of oil pumping unit

A special intelligence and power device technology, applied in the direction of transmission, machine/engine, mechanical equipment, etc., can solve the problems of narrow speed regulation range, high operating cost, large motor capacity, etc., to achieve precise speed regulation and save huge investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

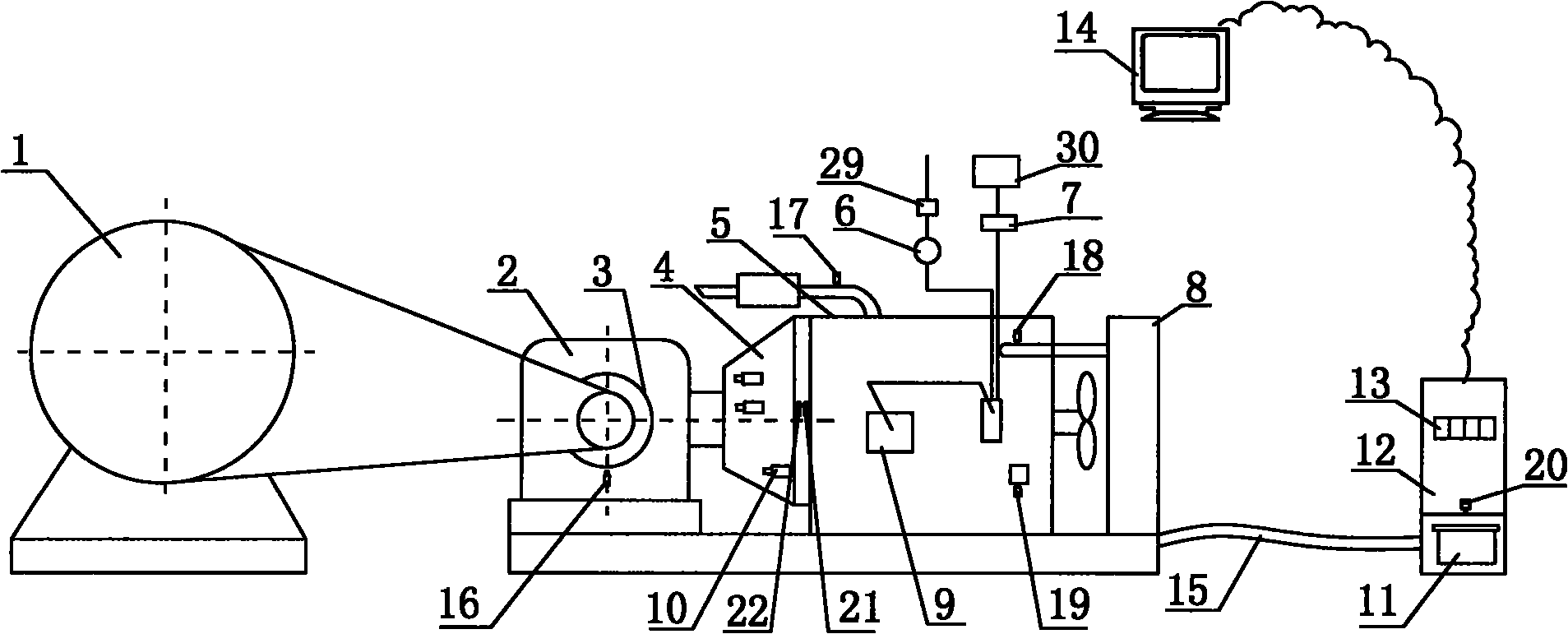

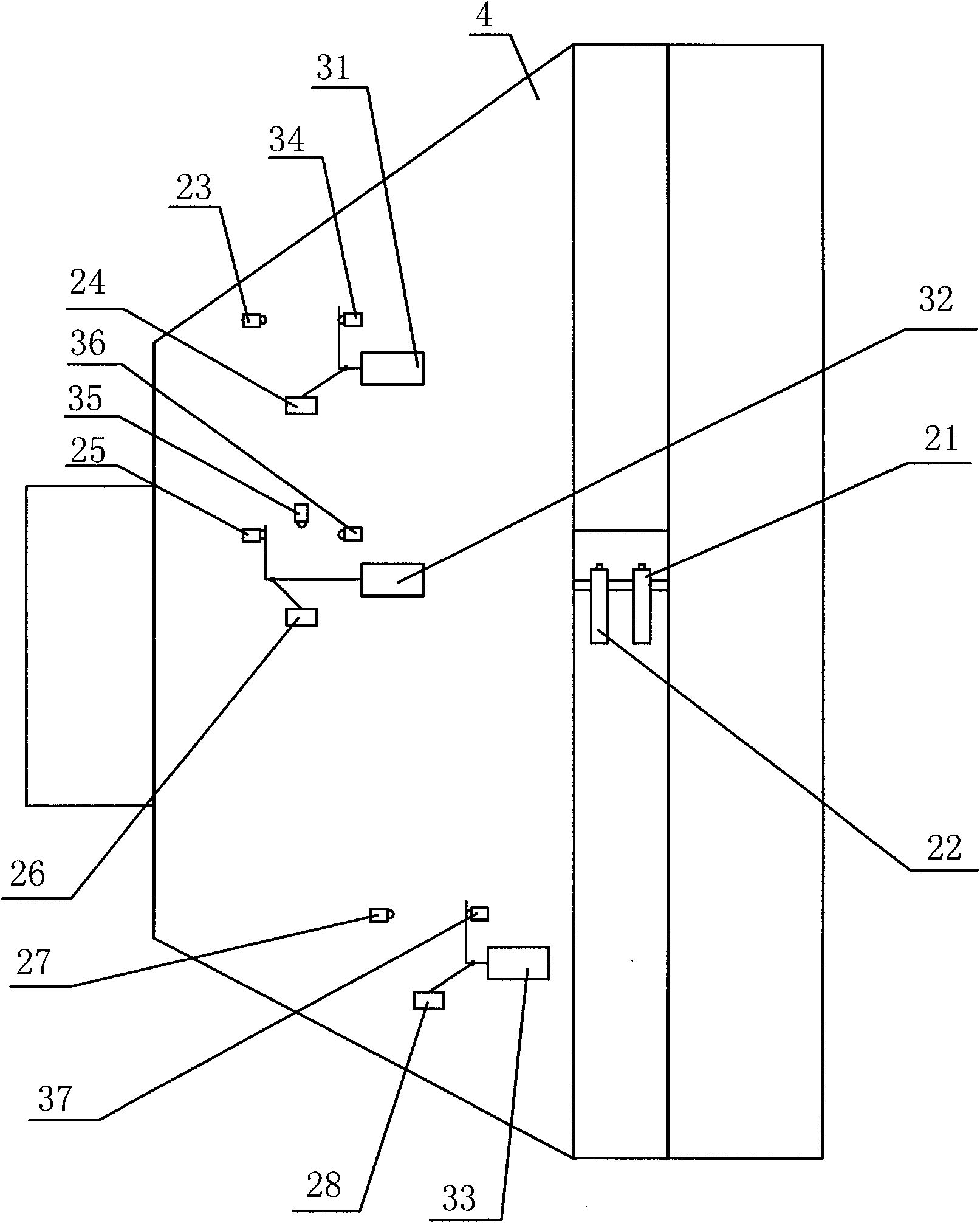

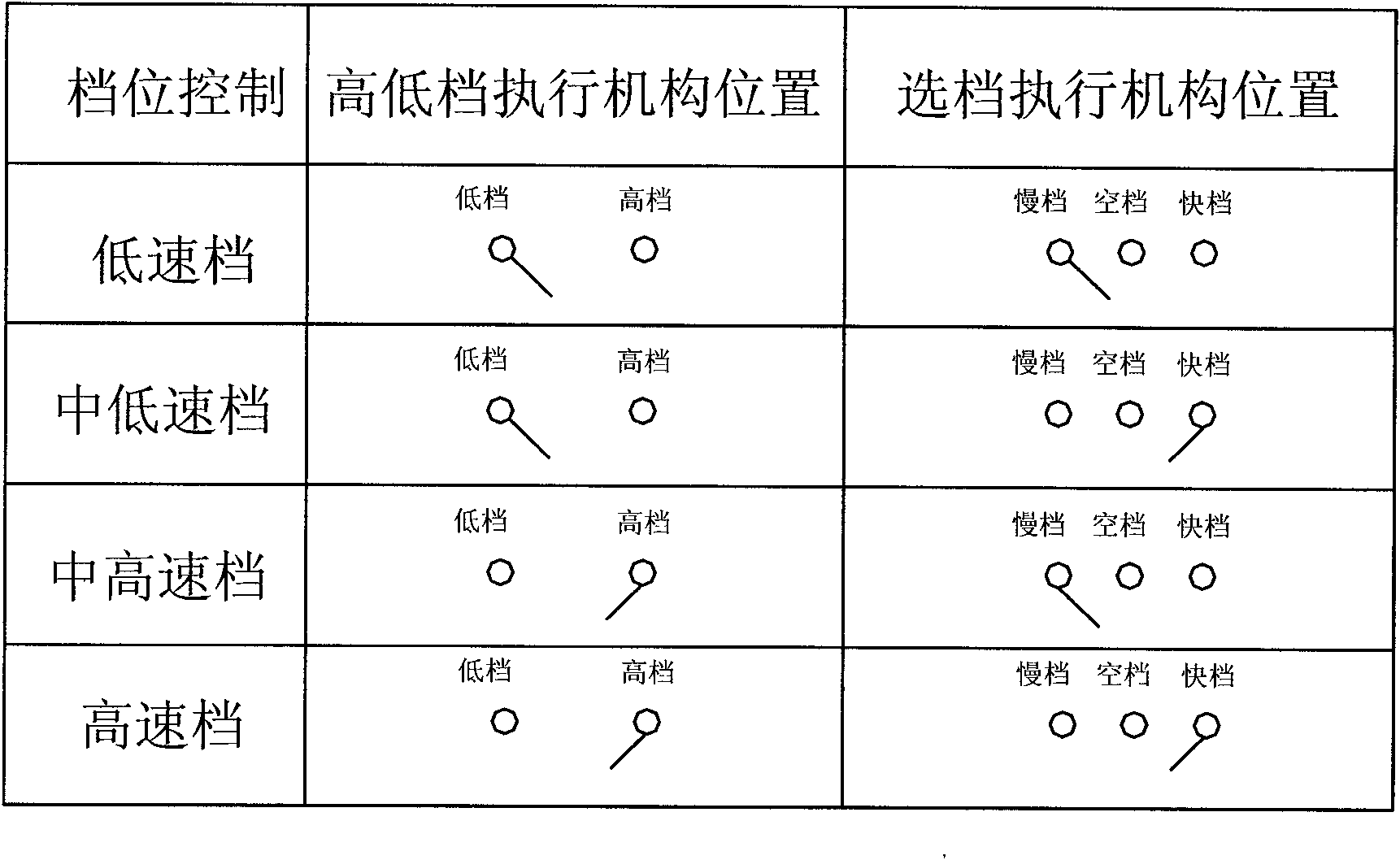

[0025] Such as Figure 1 to Figure 5 As shown, a special intelligent power device for a pumping unit of the present invention, the pumping unit 1 is driven by a variable-diameter output pulley 3, and the variable-diameter output pulley is connected with a fixed-ratio reducer 2, and the fixed-ratio The reducer 2 is connected to the multi-speed transmission 4, the power output end of the oil-air dual-purpose engine 5 is connected to the multi-speed transmission 4, the oil-air dual-purpose engine 5 is connected to the control cabinet 12 through the cable 15, and the control cabinet 12 is connected to the computer 14 through GPRS . The front end of the oil-air dual-purpose engine 5 is connected with the cooling fan water tank 8, the gasoline tank 30 is connected with the oil-air dual-purpose engine 5 through the gasoline pump 7, the solenoid valve 29 is connected with the oil-air dual-purpose engine 5 through the pressure reducing valve 6, and the oil-air dual-purpose engine 5 A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com