Preparation method of glass material with high compactness, glass material and application

A glass material, dense technology, applied in the field of glass material and application, glass material preparation, can solve the problem of difficult to balance the ion exchange capacity of glass samples, etc., to achieve the effect of excellent drop resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

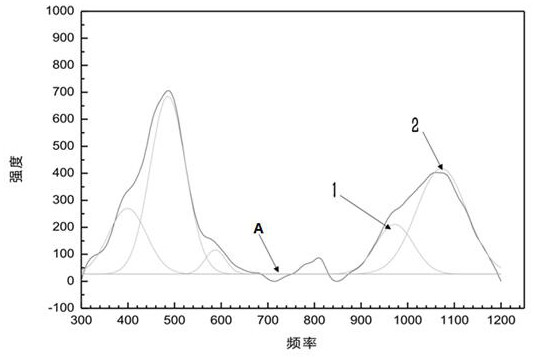

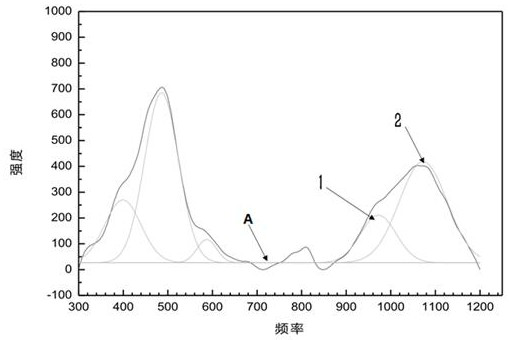

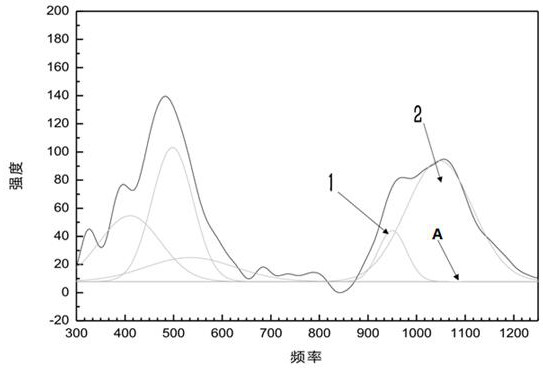

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

[0032] One, the relevant special names and relevant measuring methods involved in the present invention are explained as follows

[0033] Glass substrate: It is a glass substrate material that has not been strengthened.

[0034] Strengthened glass: It is chemically strengthened glass after high temperature ion exchange process. In the high-temperature salt bath, the alkali metal ions with large ionic radius replace the alkali metal ions with small ionic radius in the glass, resulting in a volume difference of exchanged ions, and a high-to-low compressive stress in the surface layer of the precursor glass, which hinders and delays the glass. The expansion of micro-cracks achieves the purpose of improving the mechanical strength of the glass.

[0035] Surface compressive stress CS: After the glass is chemically strengthened, the alkali met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com