Superfine non-alkali glass fiber cotton and preparation method thereof

A technology of alkali-free glass fiber and glass fiber cotton, which is applied in glass manufacturing equipment, manufacturing tools, textiles and paper making, etc., can solve the problems of poor material fluidity, product warping and deformation, and high cost, so as to improve mechanical strength and reduce analysis. The effect of uniform crystal orientation and diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In terms of parts by weight, select 42 parts of quartz sand, 26 parts of wax stone, 13 parts of limestone, 11 parts of dolomite, 9 parts of leucoporite, 4 parts of fluorite, 3.5 parts of Glauber's salt and 2.5 parts of colemanite, and mix well Then put it into the kiln for calcination, the temperature of the glass liquid is controlled at 1460°C, and the glass liquid with uniform composition is melted; then the glass liquid passes through the leak plate to form a glass filament stream; Secondary melting and pulling into ultrafine glass fibers, and then formulating 2% methyl silicone oil, 0.5% ammonium sulfate, 3% KH560 silane coupling agent, 1% SS-200 bonding aid relative to the weight ratio of ultrafine glass fibers Evenly atomize and spray on the surface of ultra-fine alkali-free glass fiber cotton, and evenly disperse on the forming net; finally dry in a drying room at 148°C for 8 minutes;

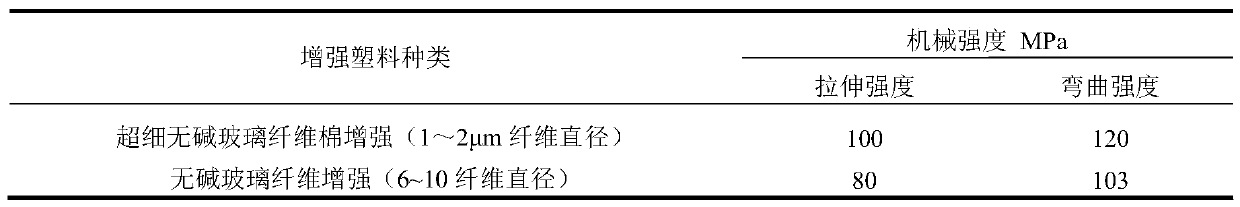

[0023] After testing, the average fiber diameter of ultra-fine alkali-free gl...

Embodiment 2

[0027] In terms of parts by weight, select 40 parts of quartz sand, 23 parts of wax stone, 15 parts of limestone, 10 parts of dolomite, 11 parts of white foam, 5 parts of fluorite, 2.5 parts of Glauber's salt and 1.5 parts of colemanite, and mix them evenly Then put it into the kiln for calcination, the temperature of the glass liquid is controlled at 1460°C, and the glass liquid with uniform composition is melted; then the glass liquid passes through the leak plate to form a glass filament stream; Secondary melting and pulling into ultrafine glass fibers; then formulating 2.5% methyl silicone oil, 0.5% ammonium sulfate, 3% KH560 silane coupling agent, 3% SS-100 bonding aid relative to the weight ratio of ultrafine glass fibers Evenly atomize and spray on the surface of ultra-fine alkali-free glass fiber cotton, and evenly disperse on the forming net; finally dry in a drying room at 152°C for 9 minutes;

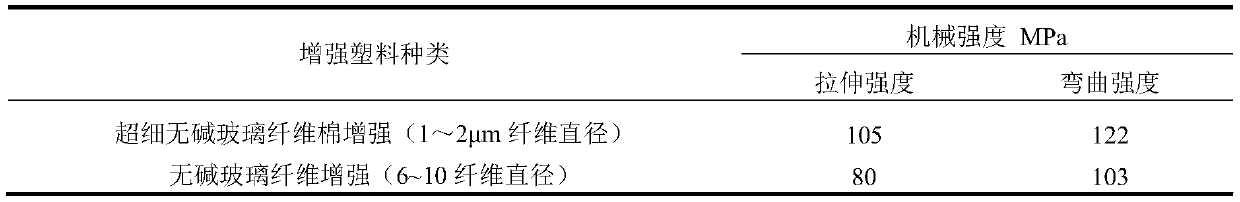

[0028] After testing, the average fiber diameter of the ultra-fine alkal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com