Bismuthate low-melting point and lead-free sealing grass and preparation method thereof

A low melting point, bismuth salt technology, applied in the field of sealing glass powder and its preparation, can solve the problems of not being able to meet lead-free, easy to produce crystallization, and difficult to control the crystallization speed, so as to improve chemical stability and thermal stability. Stability, lower thermal expansion coefficient, and improved chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

[0033] Embodiments 1-10 prepare bismuth salt low melting point lead-free sealing glass according to the following method:

[0034] Step 1: Take the raw materials according to the glass ratio determined in Table 1, and the raw materials are selected from Bi 2 o 3 , B 2 o 3 , ZnO, BaO, Al 2 o 3 and R 2 O, where R is Na, K or Li; mix the weighed raw materials evenly to make a mixture.

[0035] Step 2: Melt the mixture in a high-temperature furnace according to the melting temperature and melting time corresponding to Table 1 to form molten glass. After the molten glass is cast and shaped, it is crushed into basic glass or ground into basic glass after water quenching.

[0036] Step 3: Fully mix the basic glass and filler prepared in step 2 and pulverize it in a ball mill to make glass powder, wherein the mass percentage of the basic glass is 75% to 90%, and the mass percentage of the filler is 10% ~25%, the filler is calcium zirconium phosphate, barium zirconium phosphate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sealing temperature | aaaaa | aaaaa |

| sealing temperature | aaaaa | aaaaa |

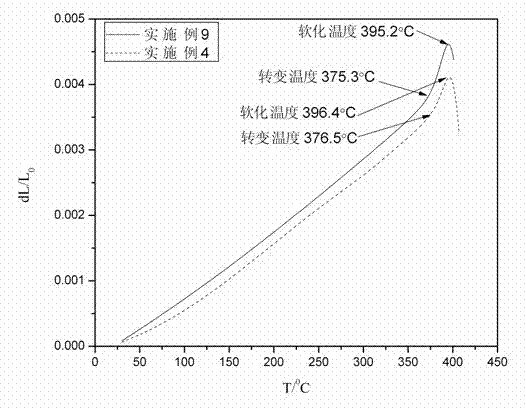

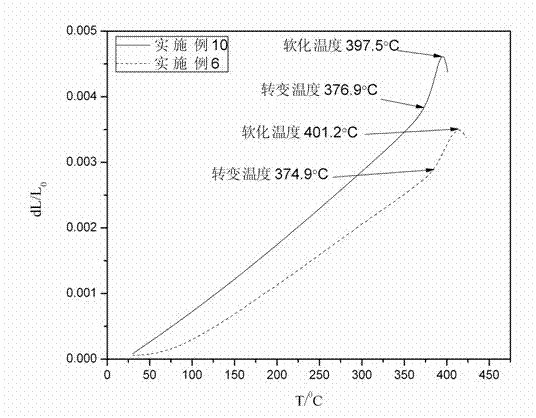

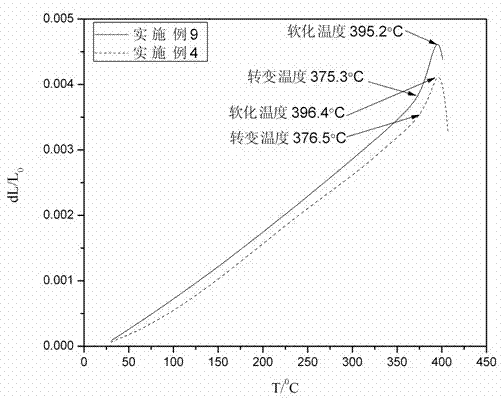

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com