Boron-free glass fiber composition

A fiber composition and boron glass technology, applied in the field of boron-free glass fiber composition, can solve the difficulty of glass melting and fiber forming without mentioning flux, the difficulty of large-scale production in pool kiln, and the danger of increasing glass devitrification, etc. problems, to achieve good glass melting performance, improve large-scale production efficiency, and improve the effect of melting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

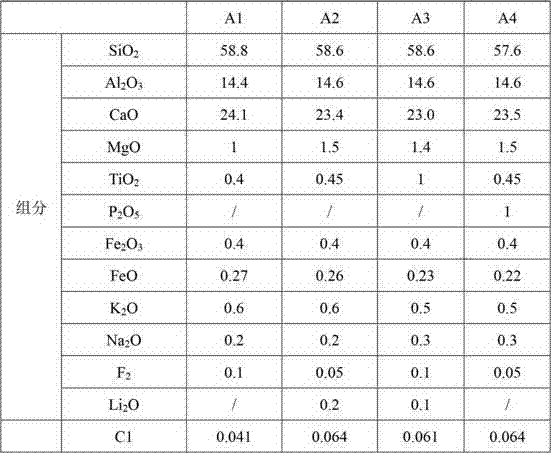

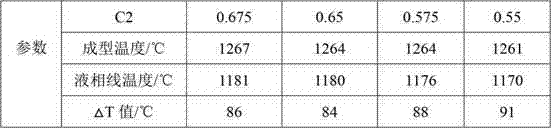

[0030] The technical solution of the present invention is specifically described below through examples, and the content of the present invention is not subject to any restriction by the following examples.

[0031] The present invention melts glass samples by means of a laboratory high-temperature electric furnace, and the raw materials used are basically natural mineral raw materials, such as the introduction of SiO 2 、Al 2 o 3 pyrophyllite or kaolin, limestone with CaO, dolomite with CaO and MgO, Li 2 Lepidolite of O, introducing P 2 o 5 of phosphoric acid. Mix various raw materials in appropriate proportions so that each component reaches the final expected weight percentage, and then put the uniformly mixed batch into a platinum-rhodium alloy crucible and melt it into a glass sample in a high-temperature electric furnace. The ease of melting and refining of each glass formulation was studied by comparing different melting times and melting temperatures, and its formi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com