Patents

Literature

290results about How to "Improve mass production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

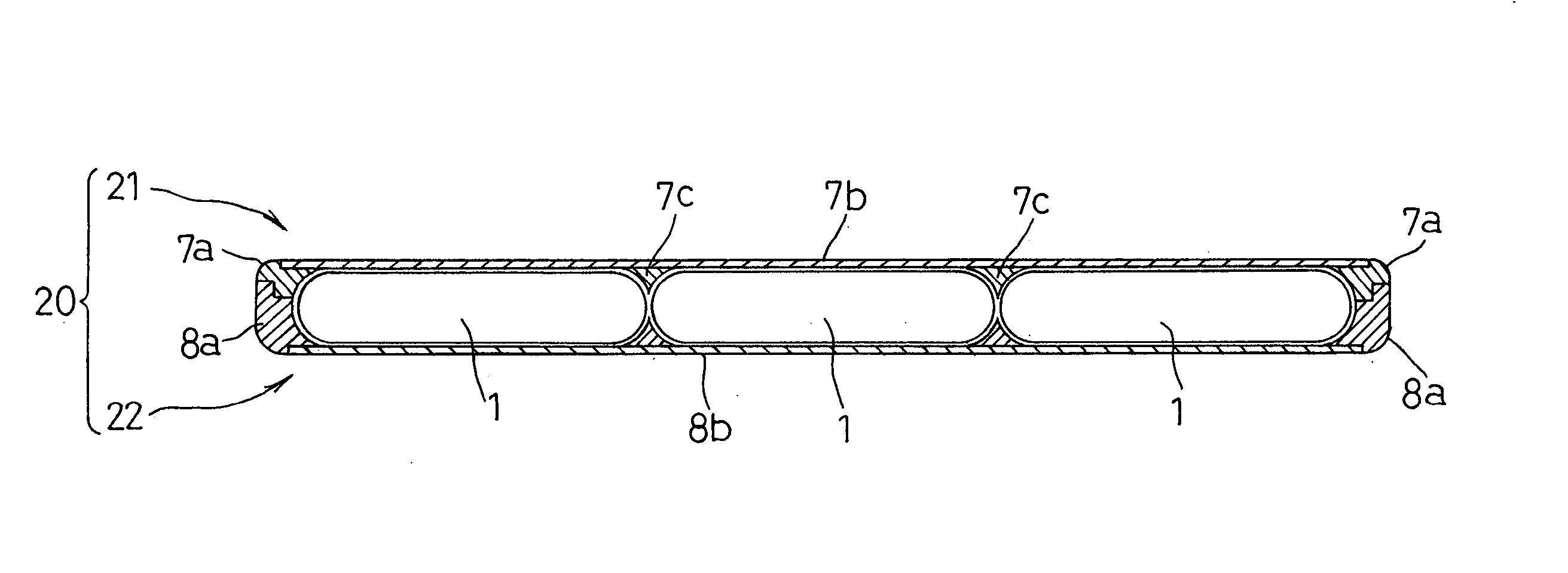

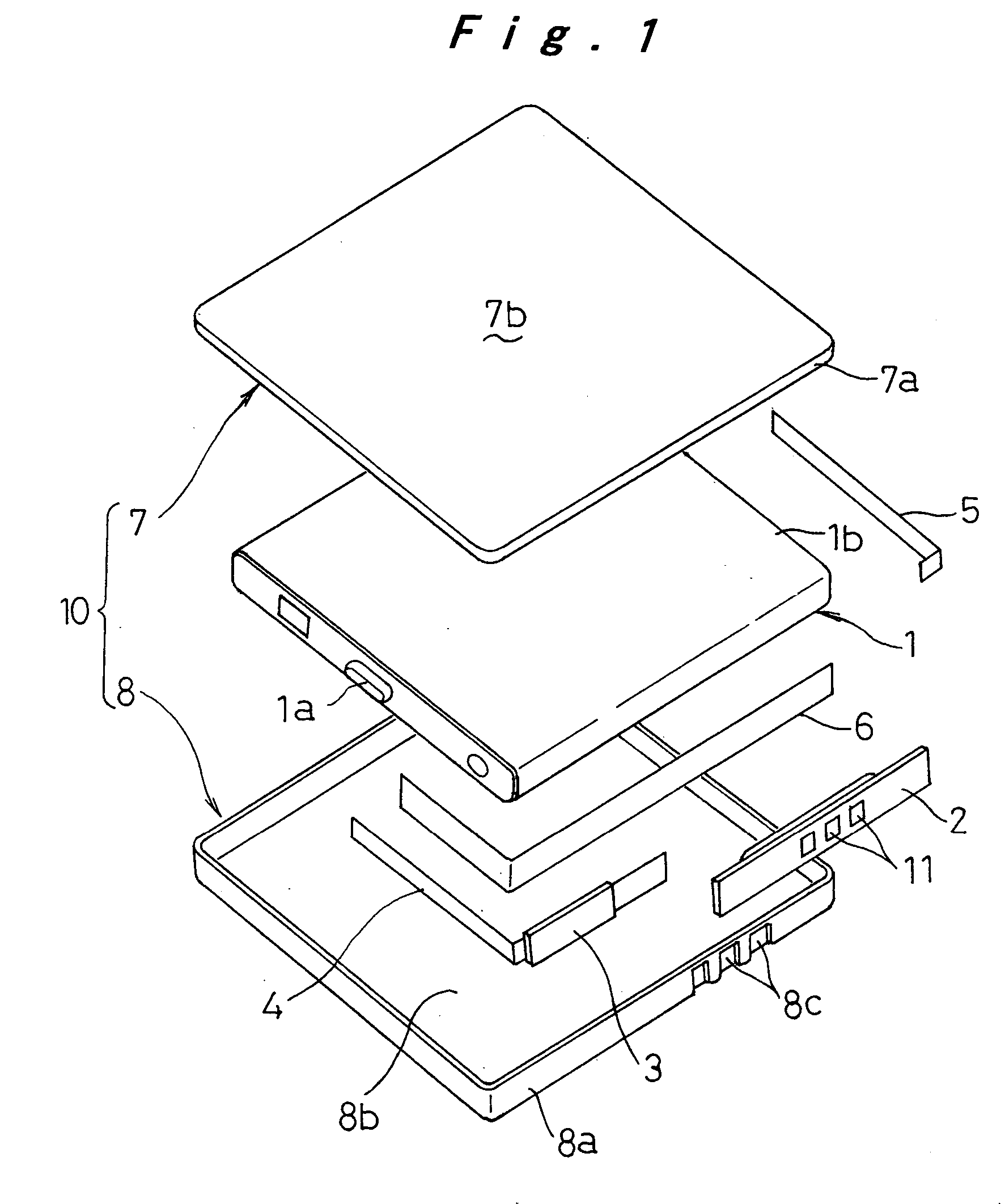

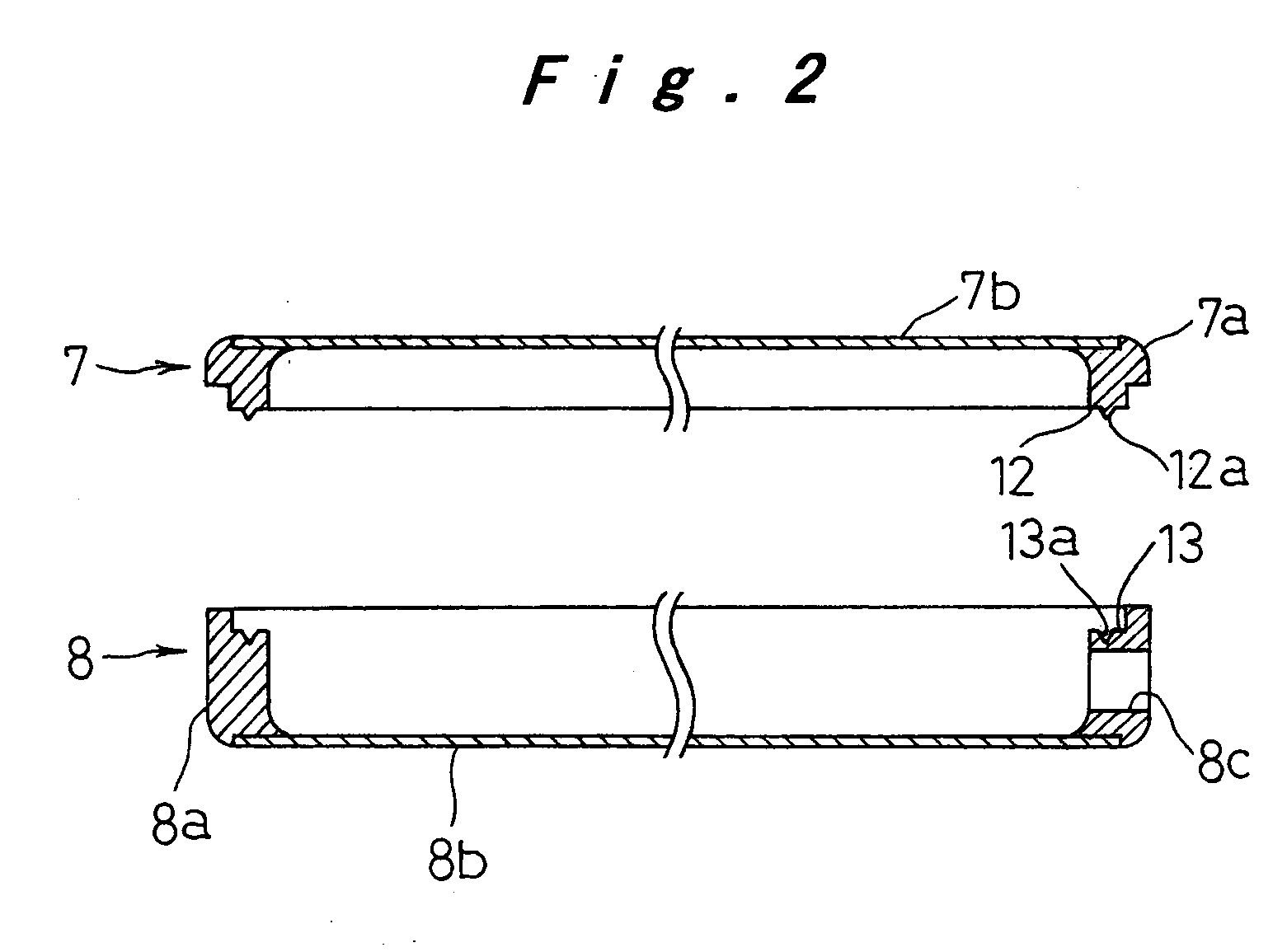

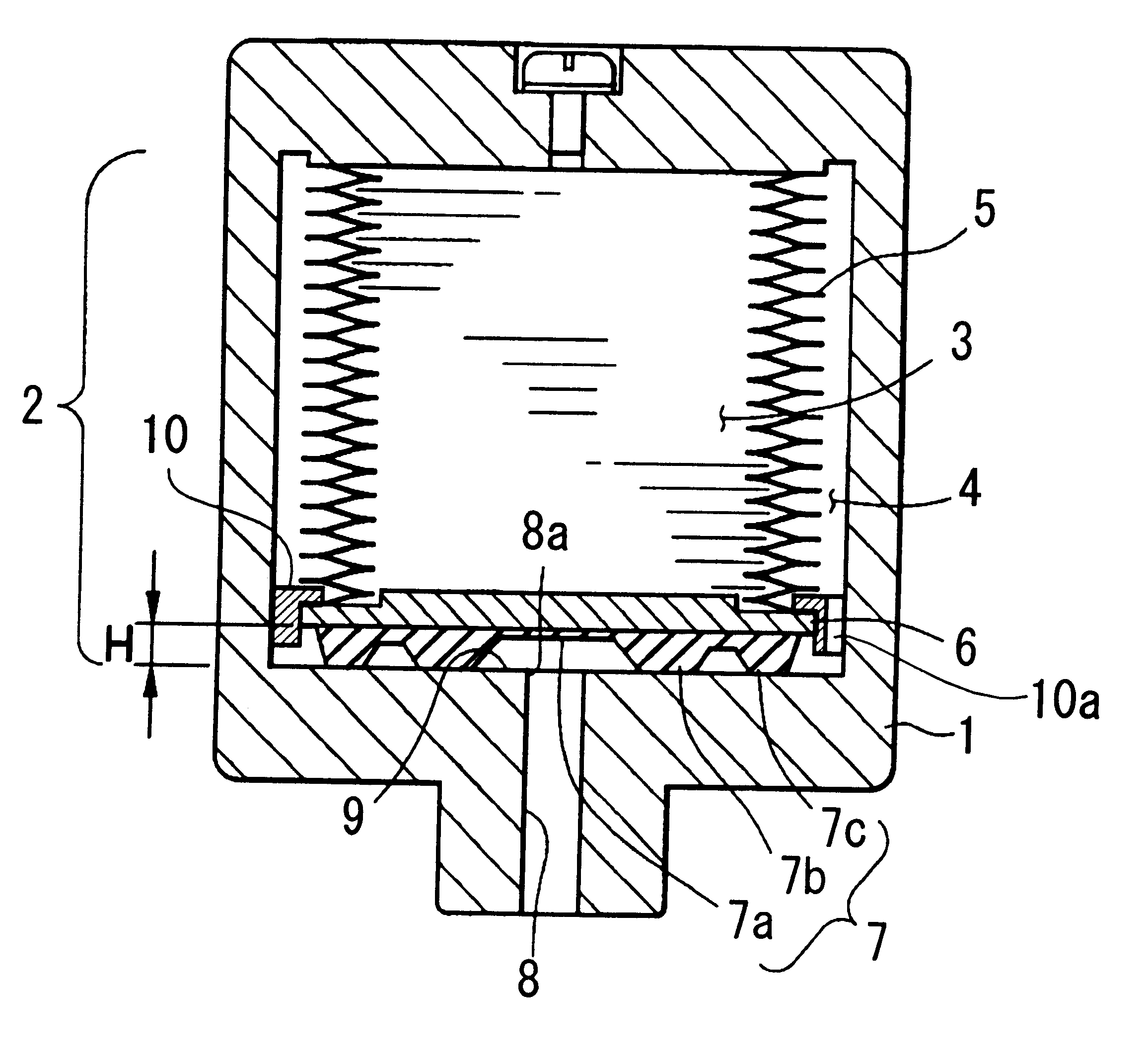

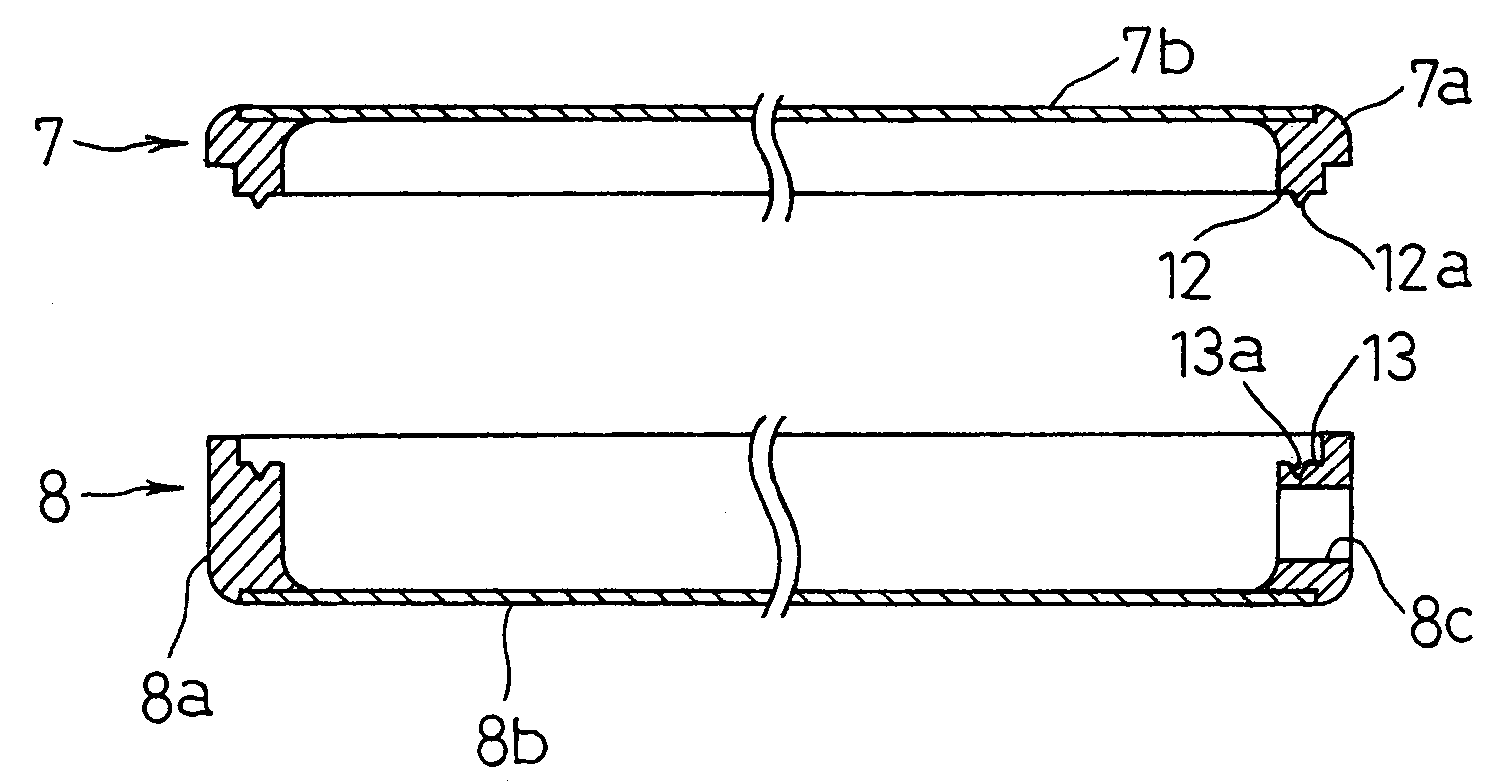

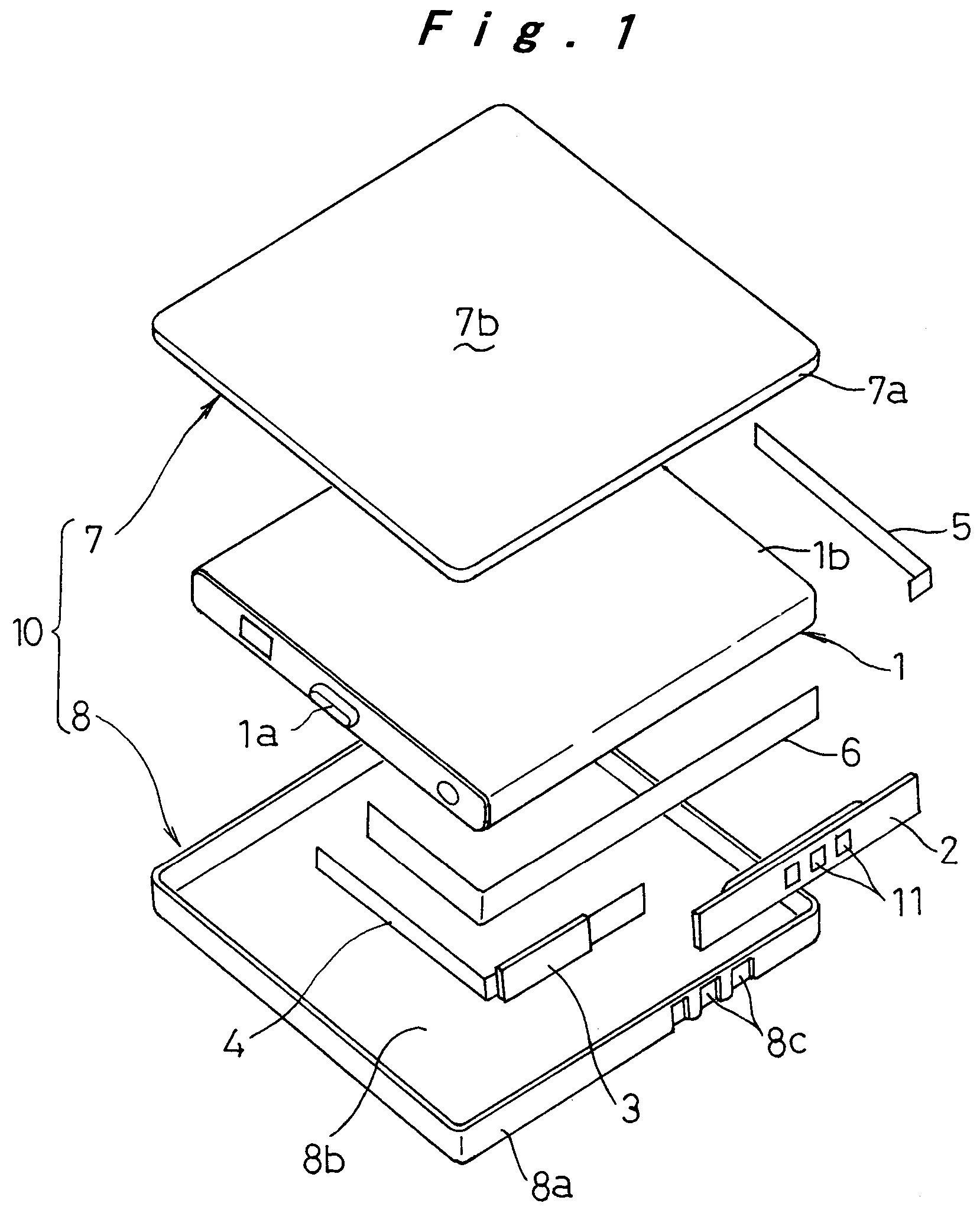

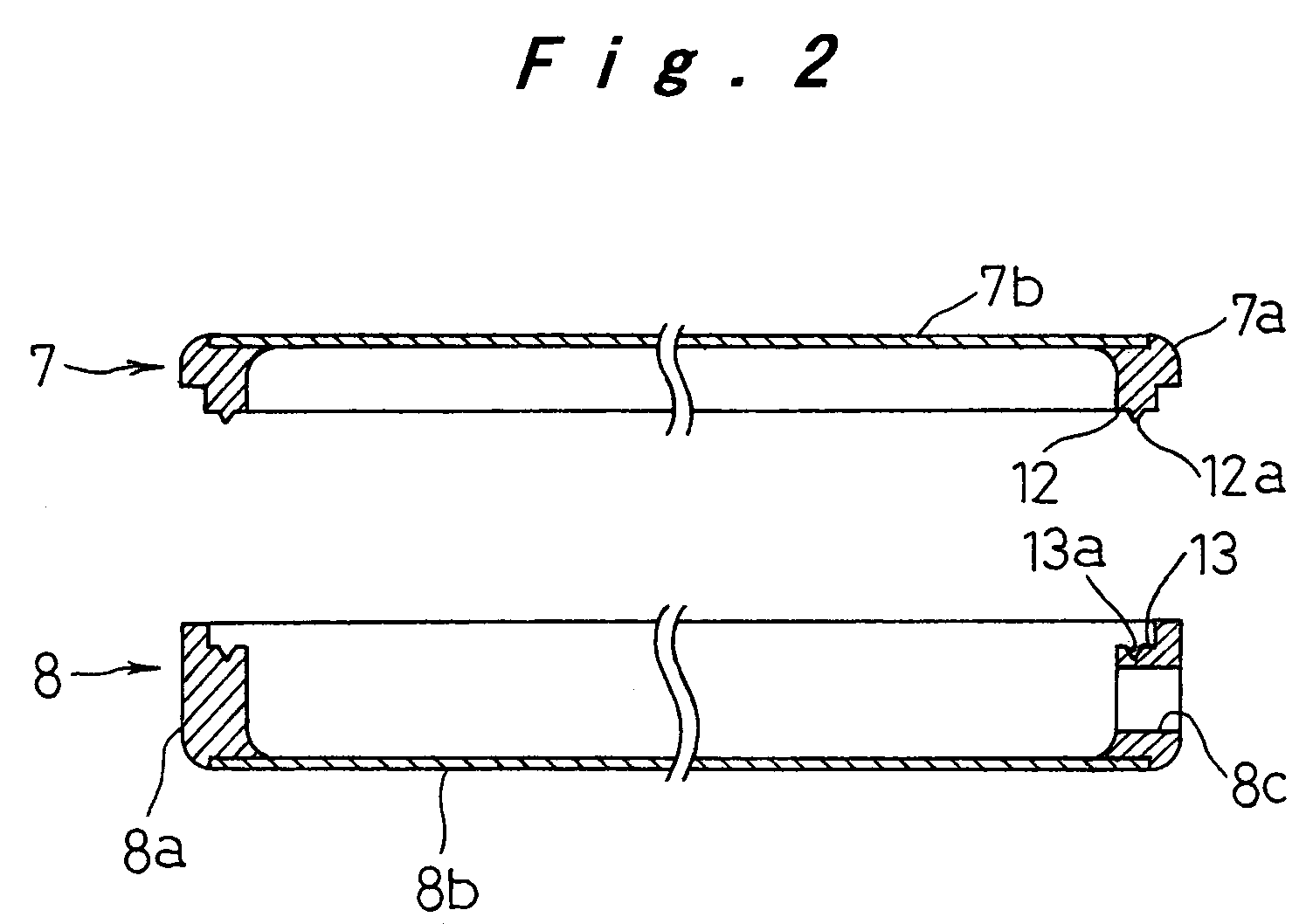

Battery pack

InactiveUS20050164080A1Easy to operateWell formedSmall-sized cells cases/jacketsVent arrangementsRechargeable cellEngineering

Owner:PANASONIC CORP

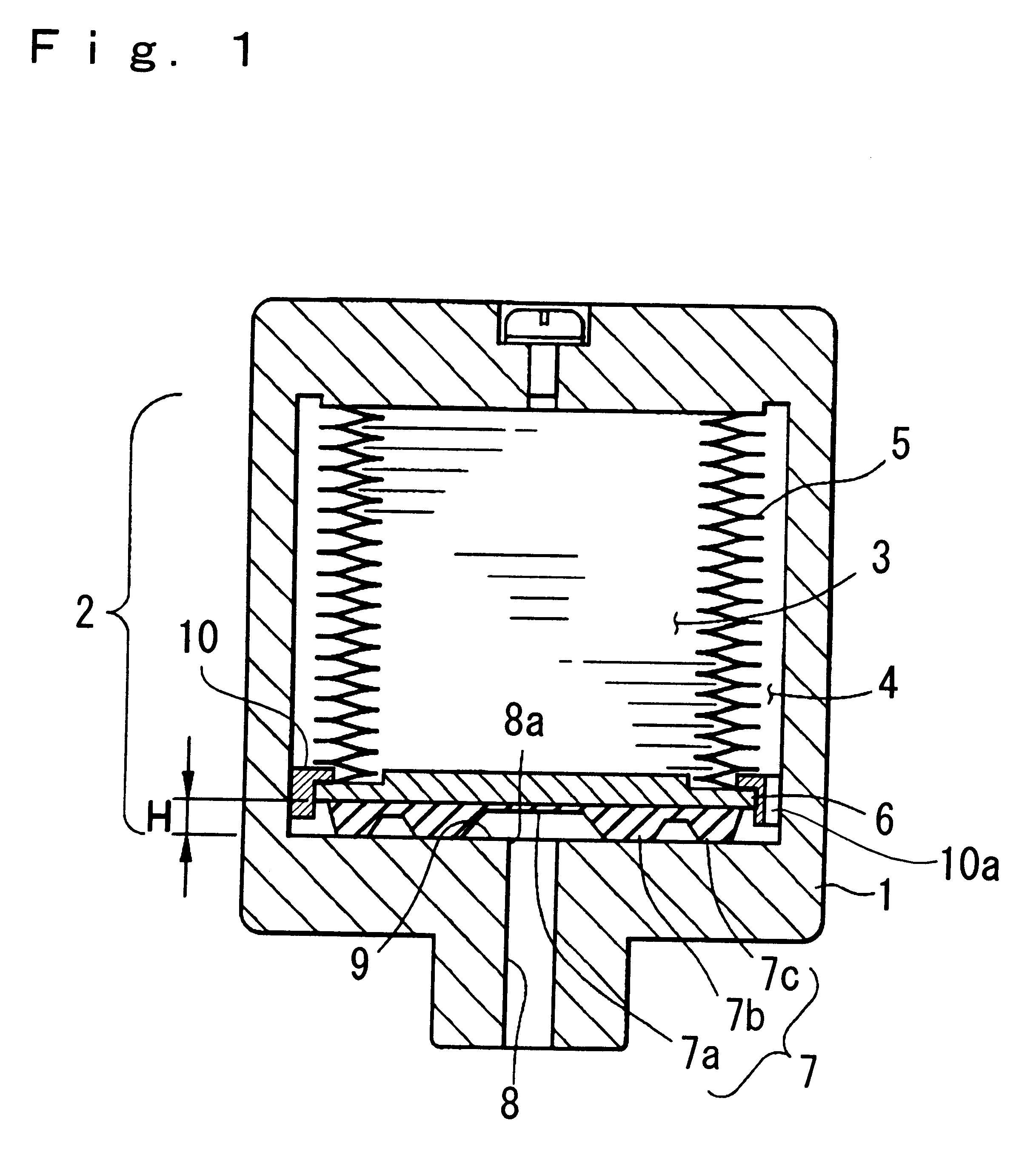

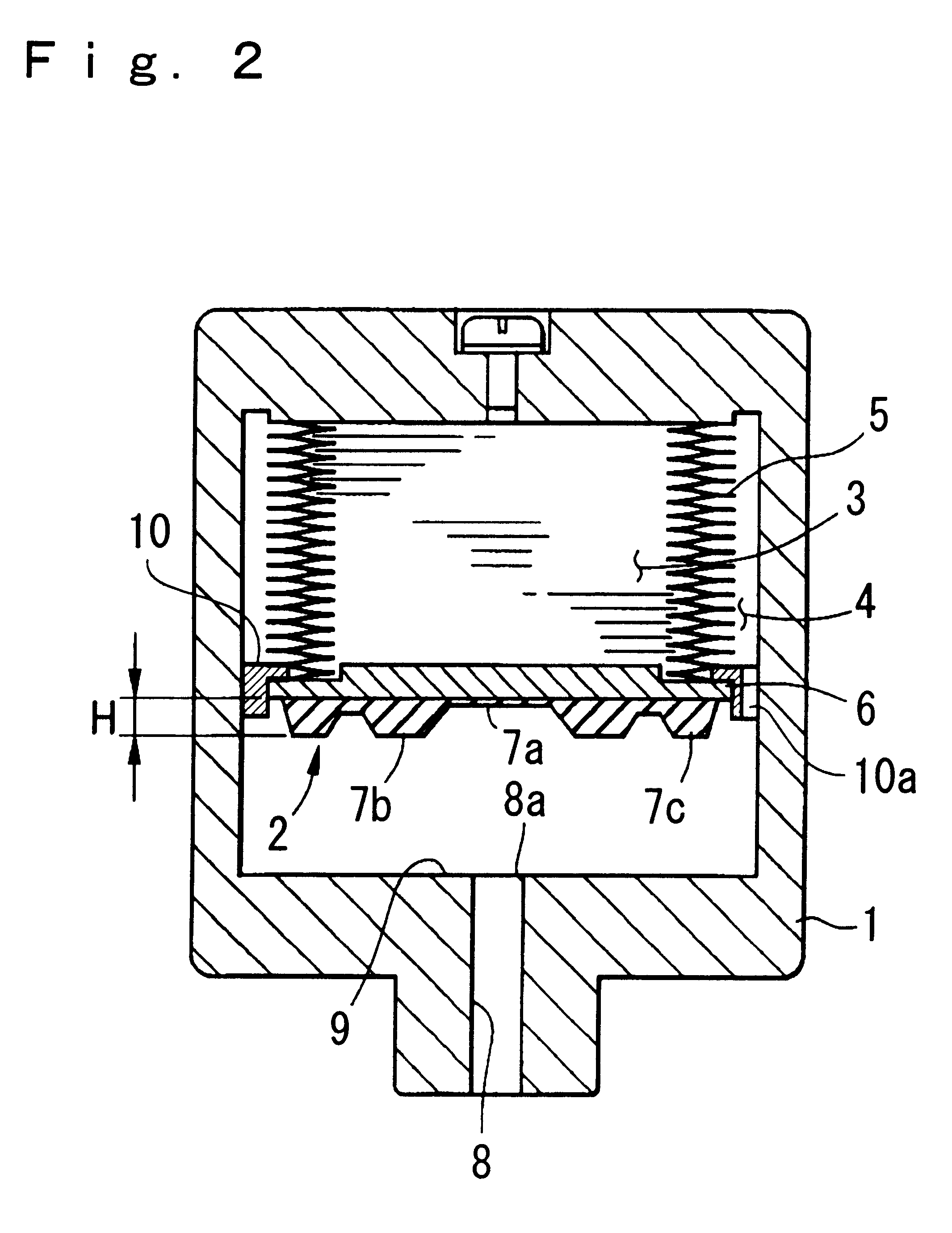

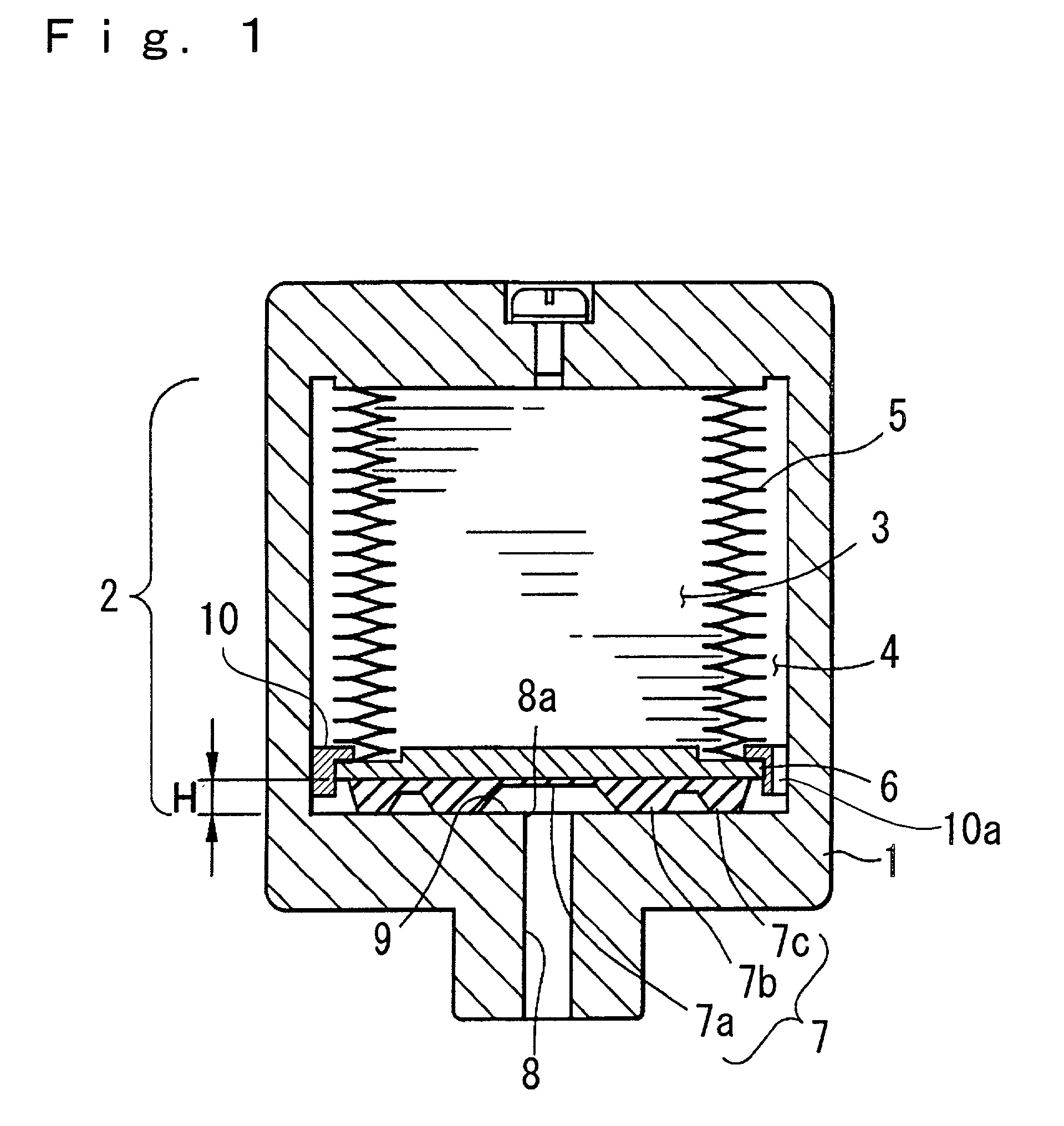

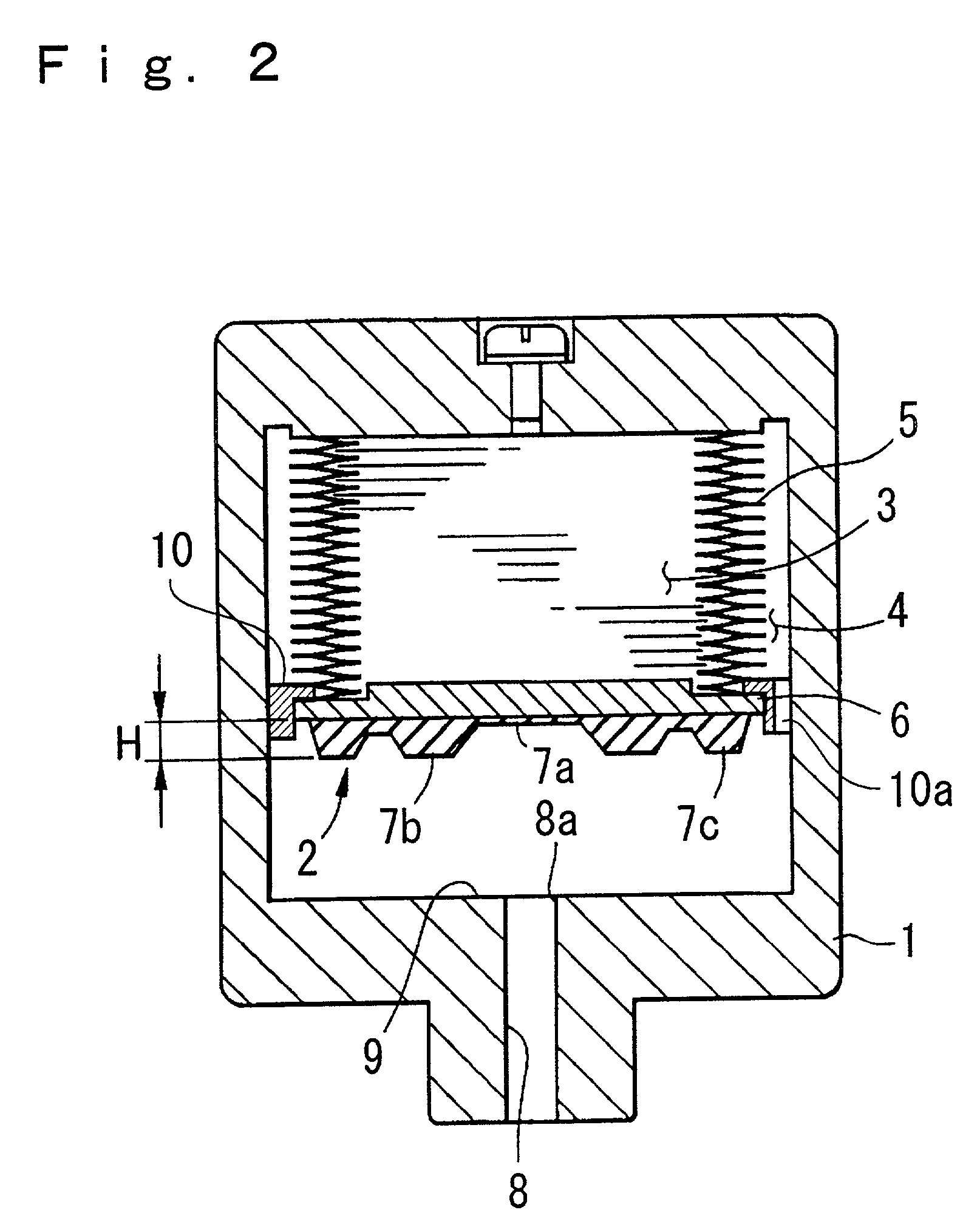

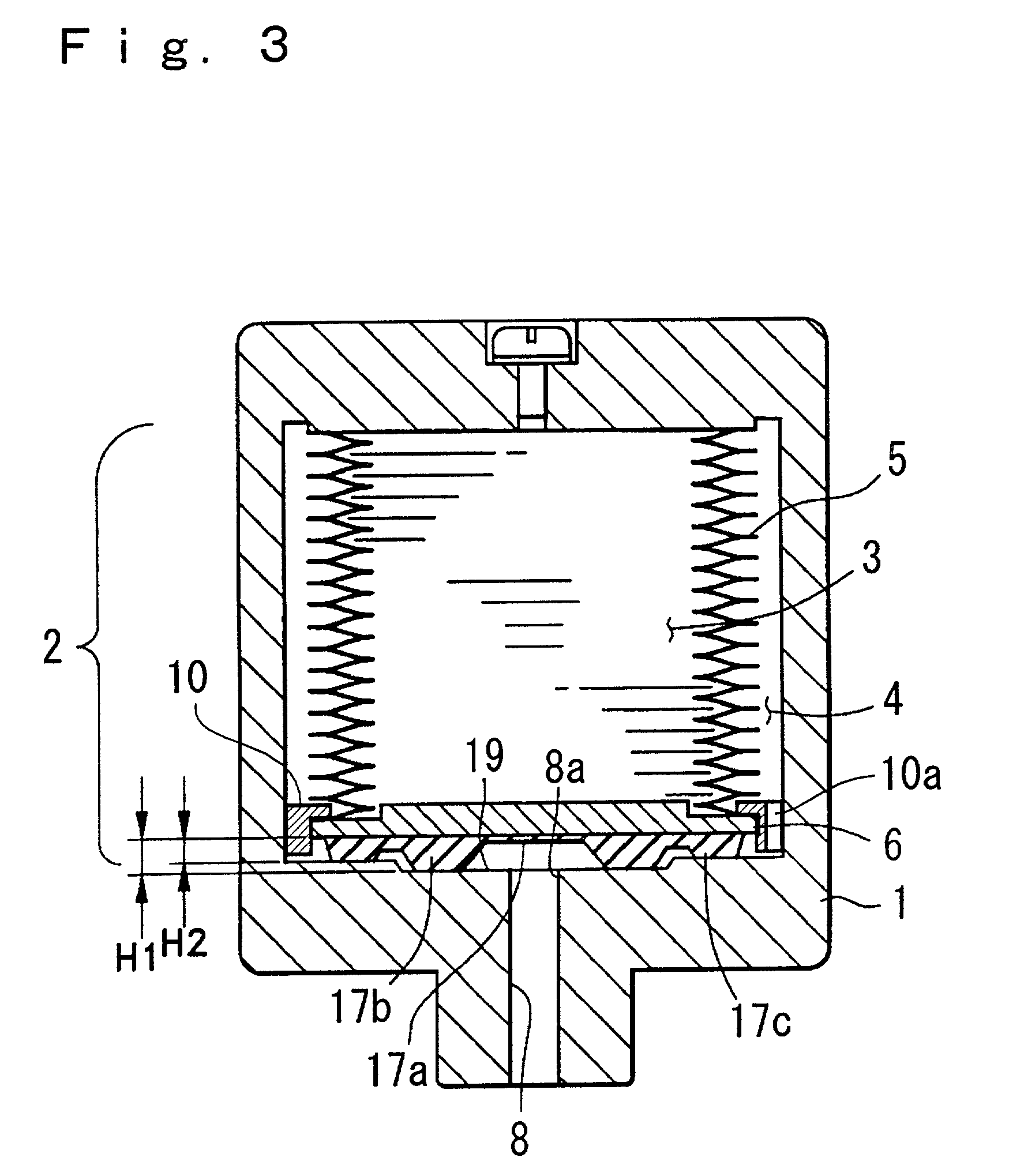

Accumulator and manufacturing process thereof

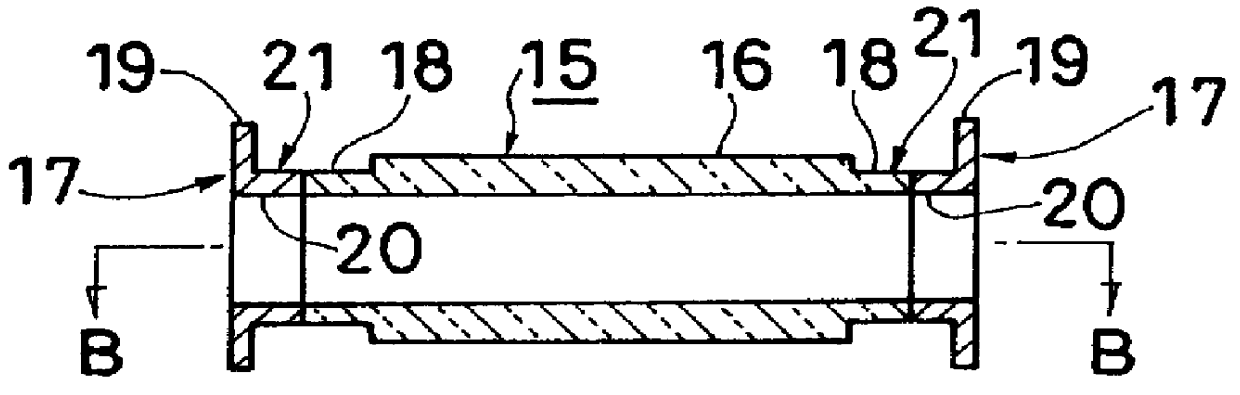

InactiveUS6286552B1Optimize timingImprove mass production efficiencyAccumulator installationsPipe elementsEngineeringGas chamber

Disclosed is an accumulator comprising: a pressure vessel; an elastic bellows in which a compressed gas is sealed, an end of the bellows being fixed to an interior of the pressure vessel; a flow path having an opening communicating with the interior and an exterior of the pressure vessel; a valve connected to a movable end of the bellows to operatively close the opening according to elastic motion of the bellows; and a hydraulic chamber partitioned from a gas chamber formed in an interior of the bellows containing the compressed gas. The valve comprises an upper surface which can cover the opening, and plural circular protrusions which surround the entire circumference of the opening and can closely contact the circumference of the opening.

Owner:NHK SPRING CO LTD

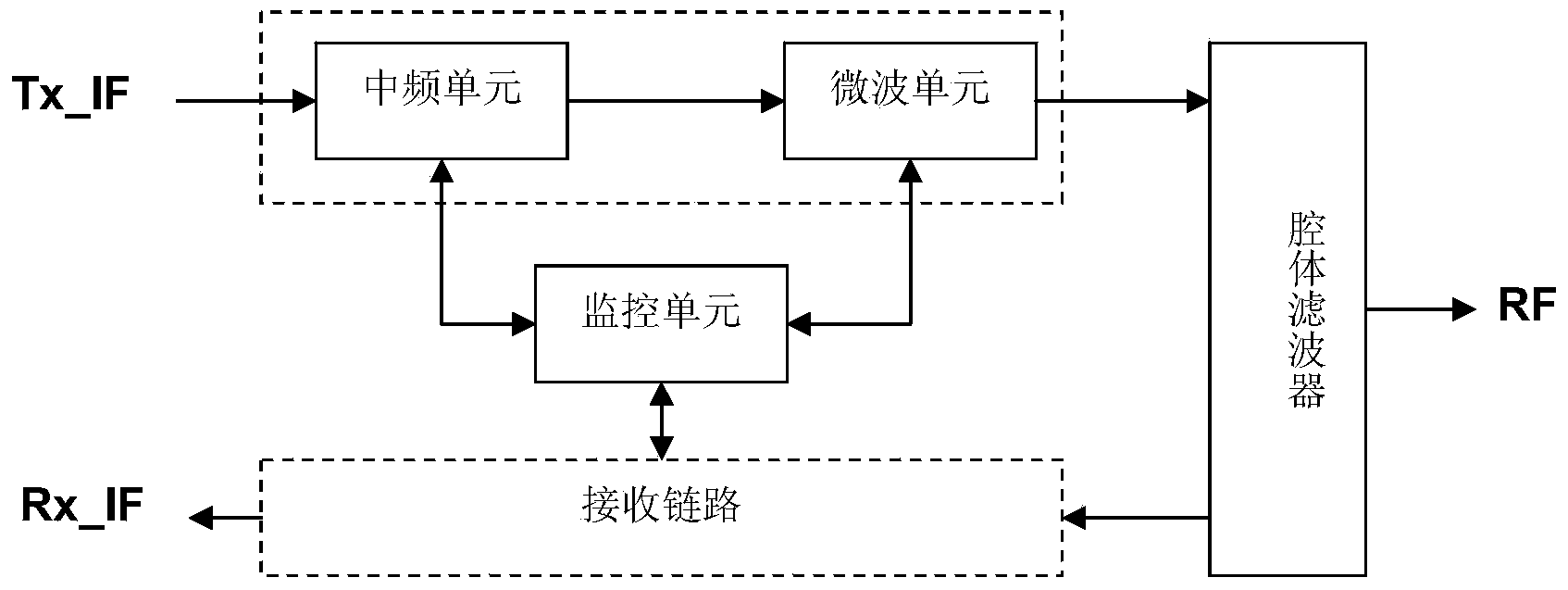

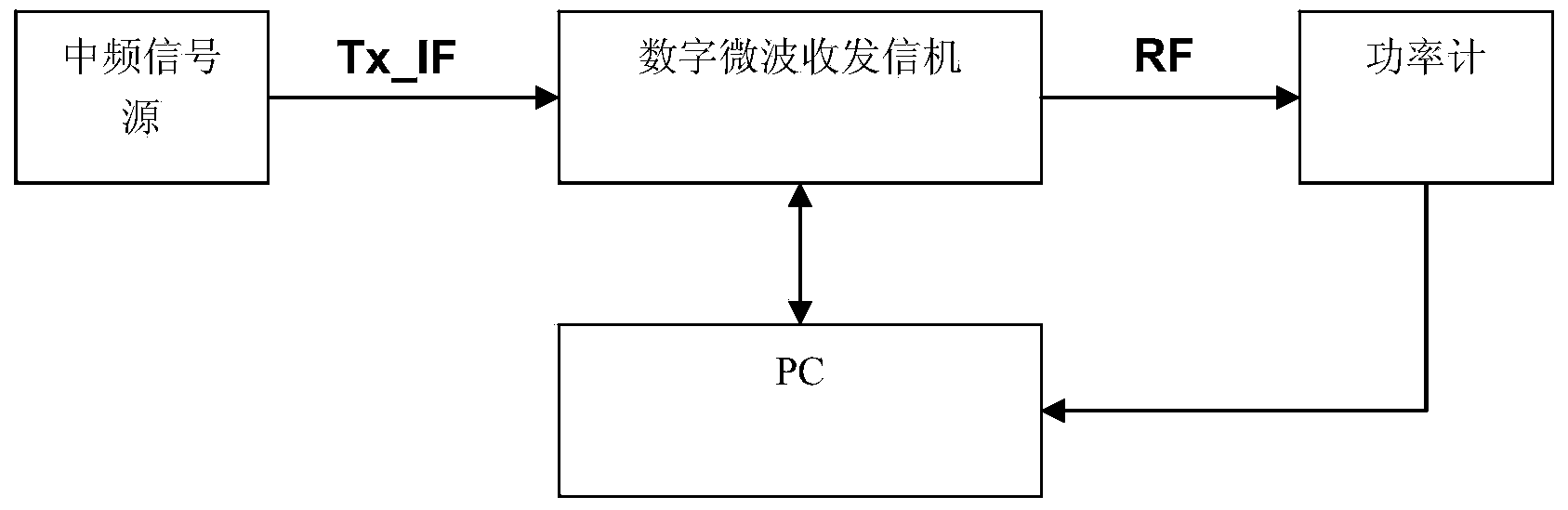

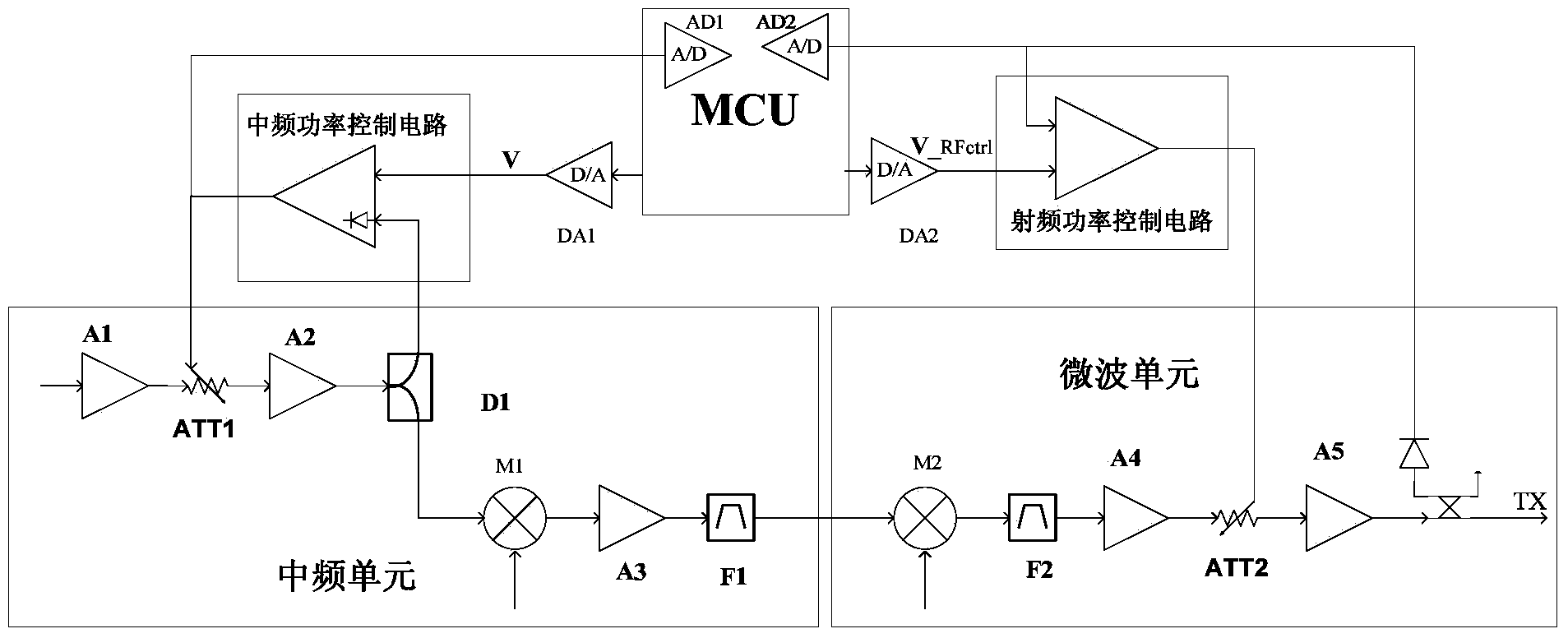

Calibration method and calibration circuit for transmitted power of digital microwave transceiver

ActiveCN103686968ASimple methodImprove mass production efficiencyPower managementTransceiverTransmitted power

The invention discloses a calibration method for the transmitted power of a digital microwave transceiver. The calibration method comprises the following steps of first generating a transmitted power calibration table according to transmitted power control voltages and actual radio frequency transmitted power which corresponds to the transmitted power control voltages and is transmitted by the microwave transceiver, second generating a channel calibration table, and thirdly correcting the transmitted power control voltage value in the transmitted power calibration table by using a channel correcting method. The invention further discloses a calibration circuit for achieving the calibration method for the transmitted power of the digital microwave transceiver. The calibration circuit comprises a microwave unit and a monitoring unit, and the microwave unit comprises a first power detection tube, a second power detection tube, a microwave amplifier and a microwave attenuator. The calibration circuit has the advantages of being high in batch production efficiency, high in calibration rate, high in transmitted power stability, simple in calibration method and the like.

Owner:波达通信设备(广州)有限公司

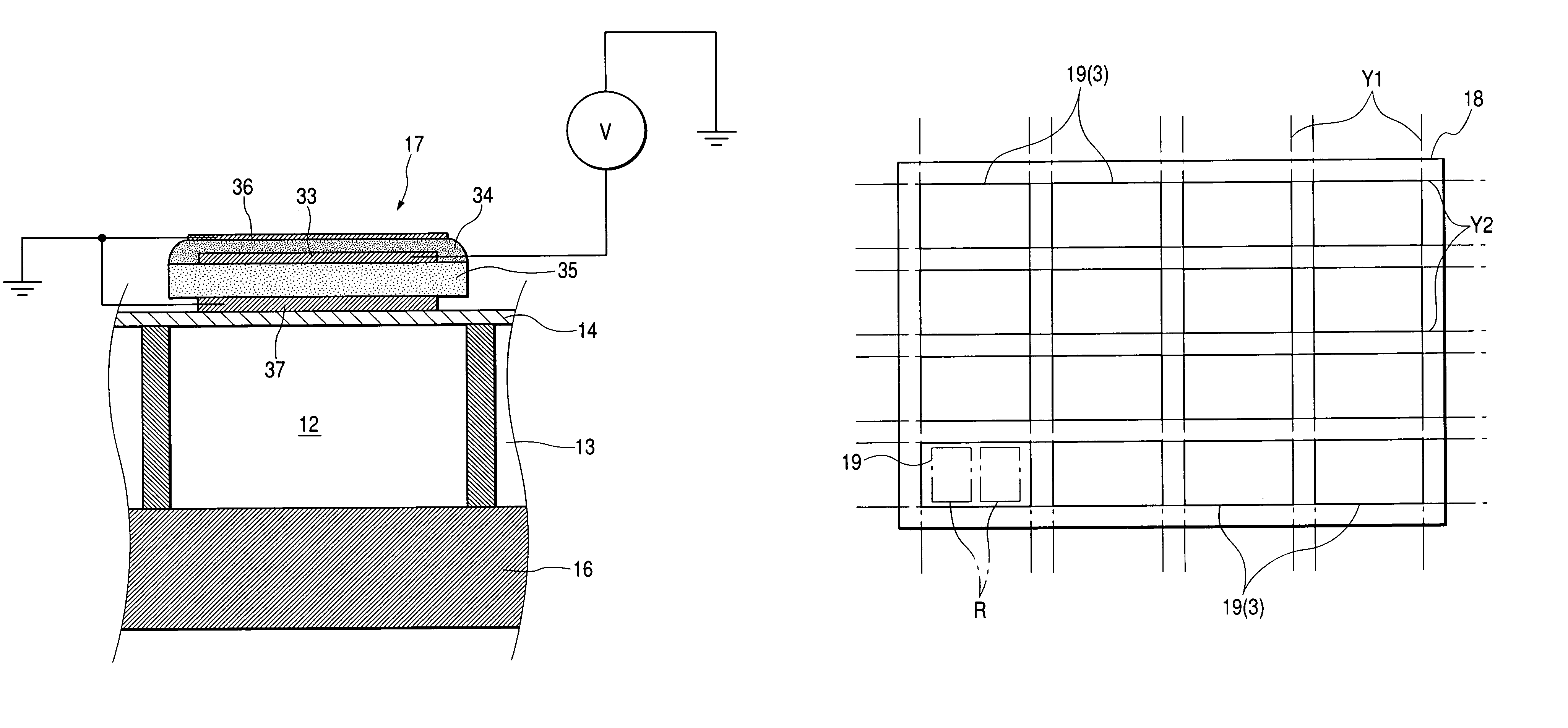

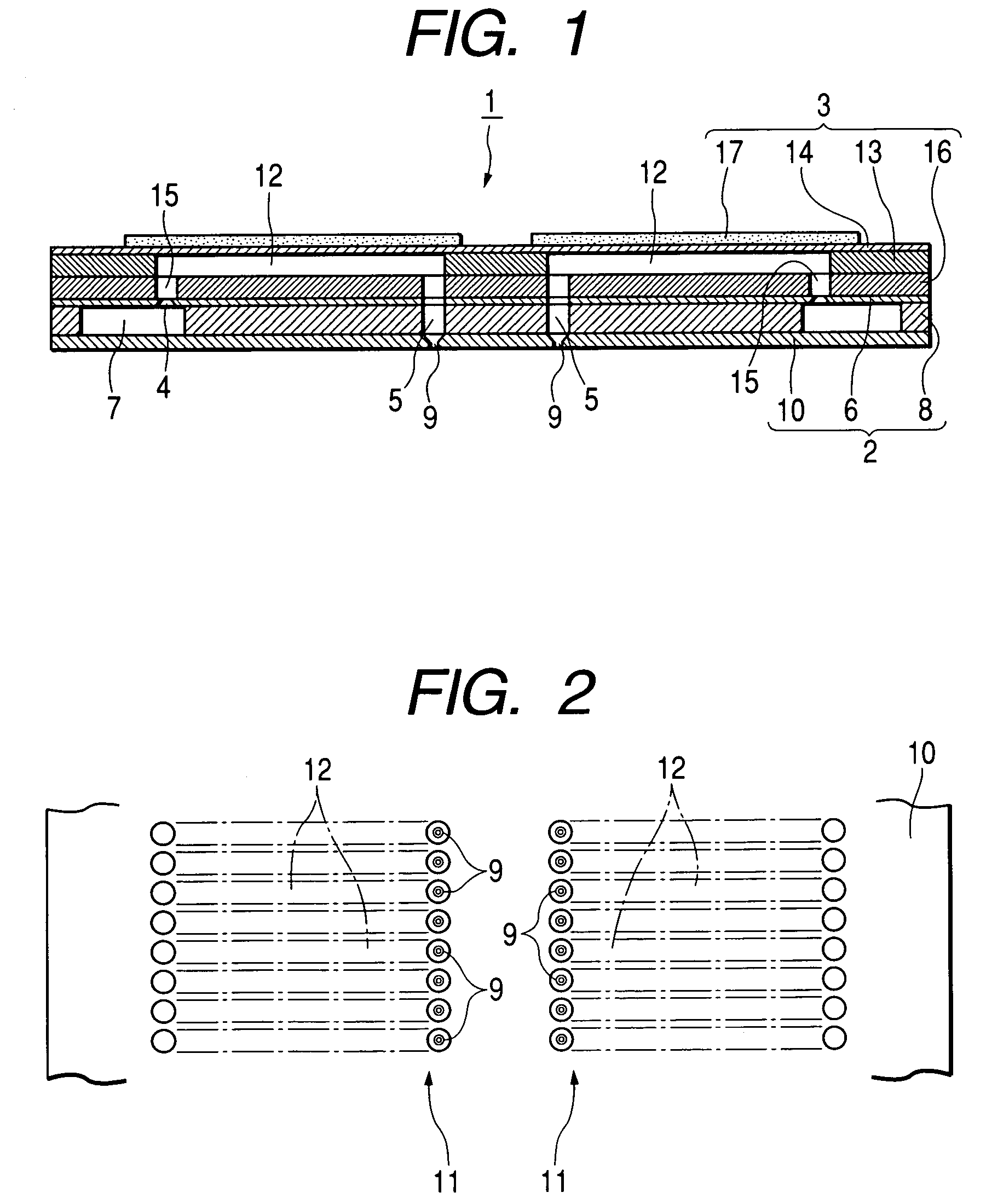

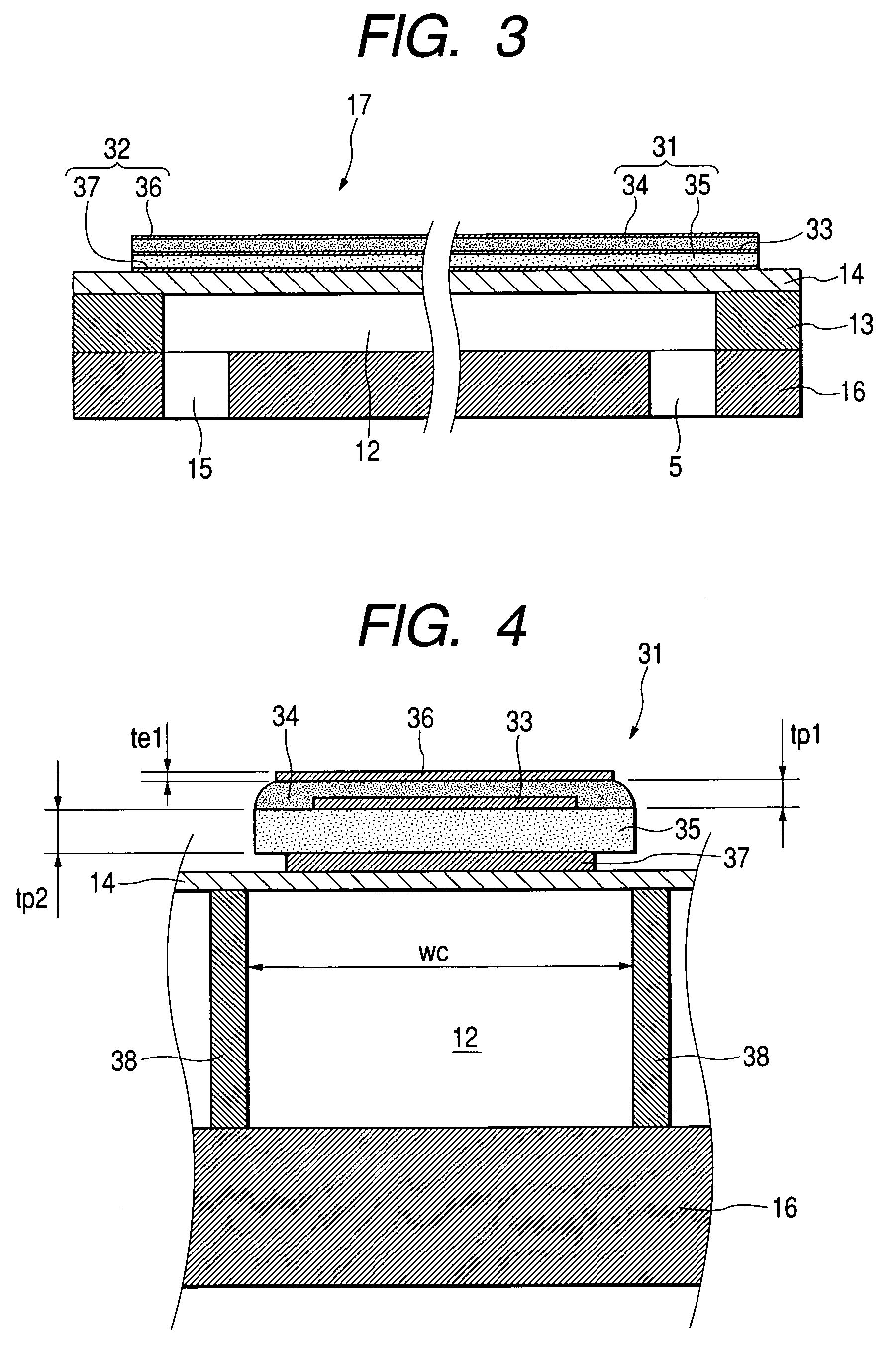

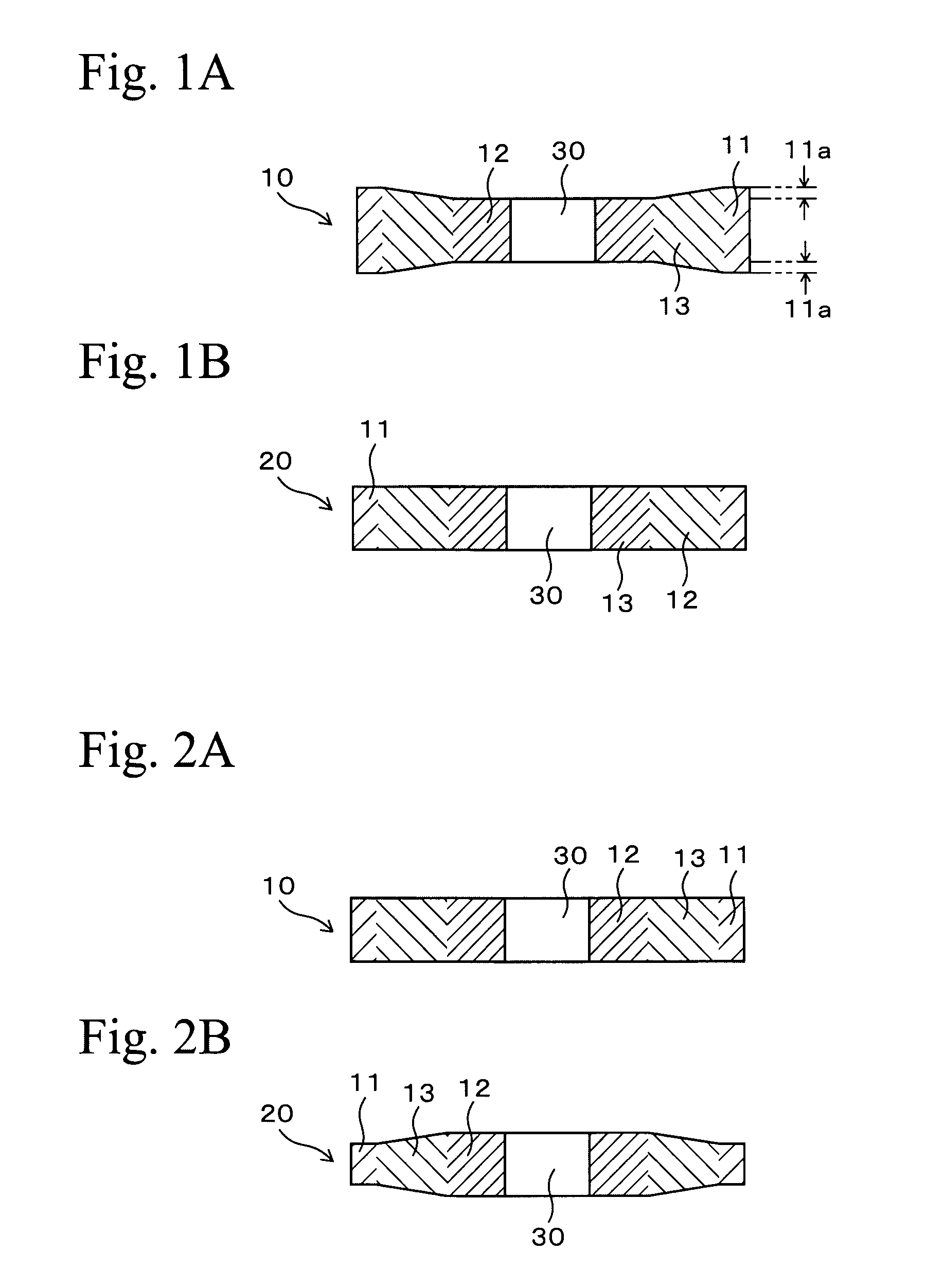

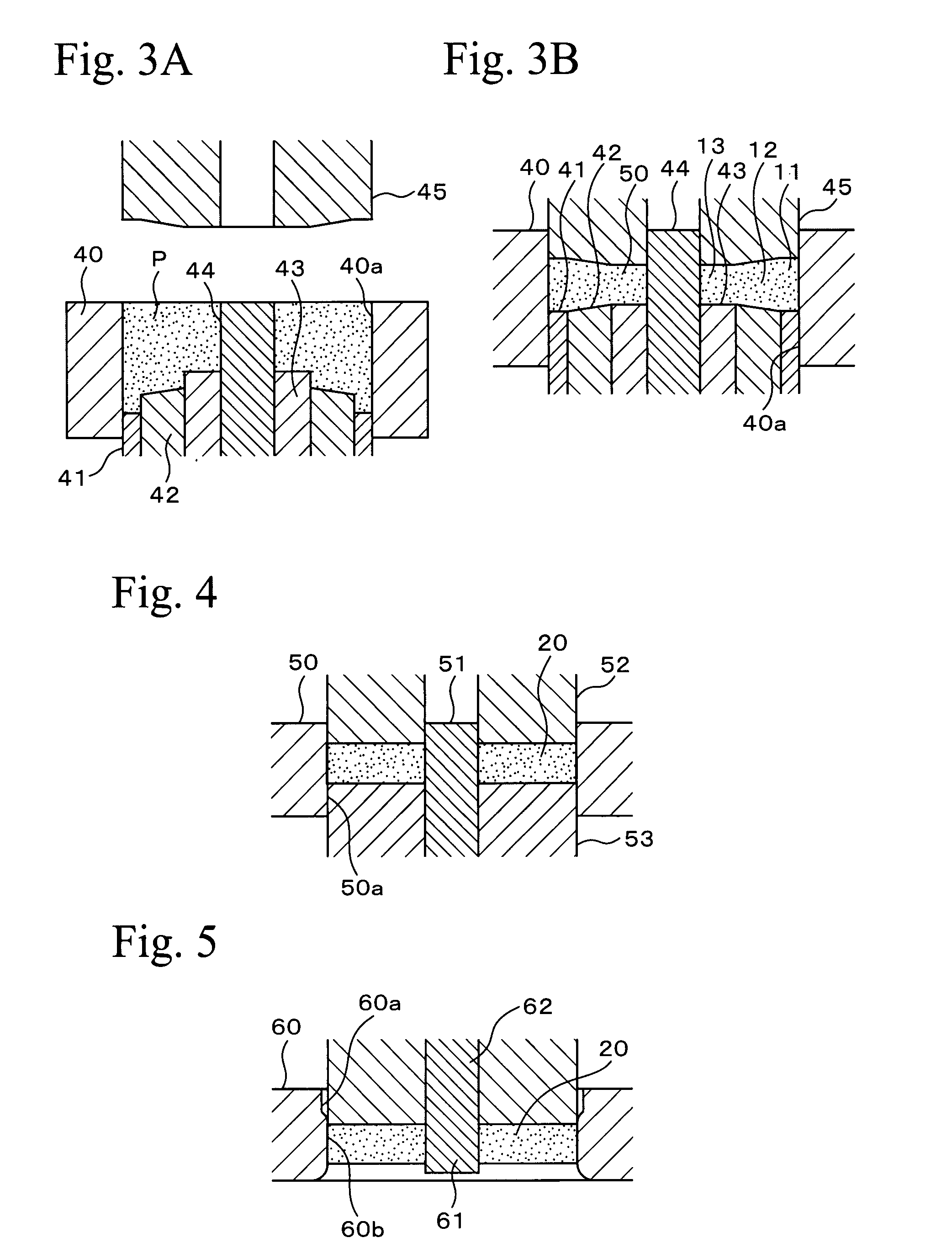

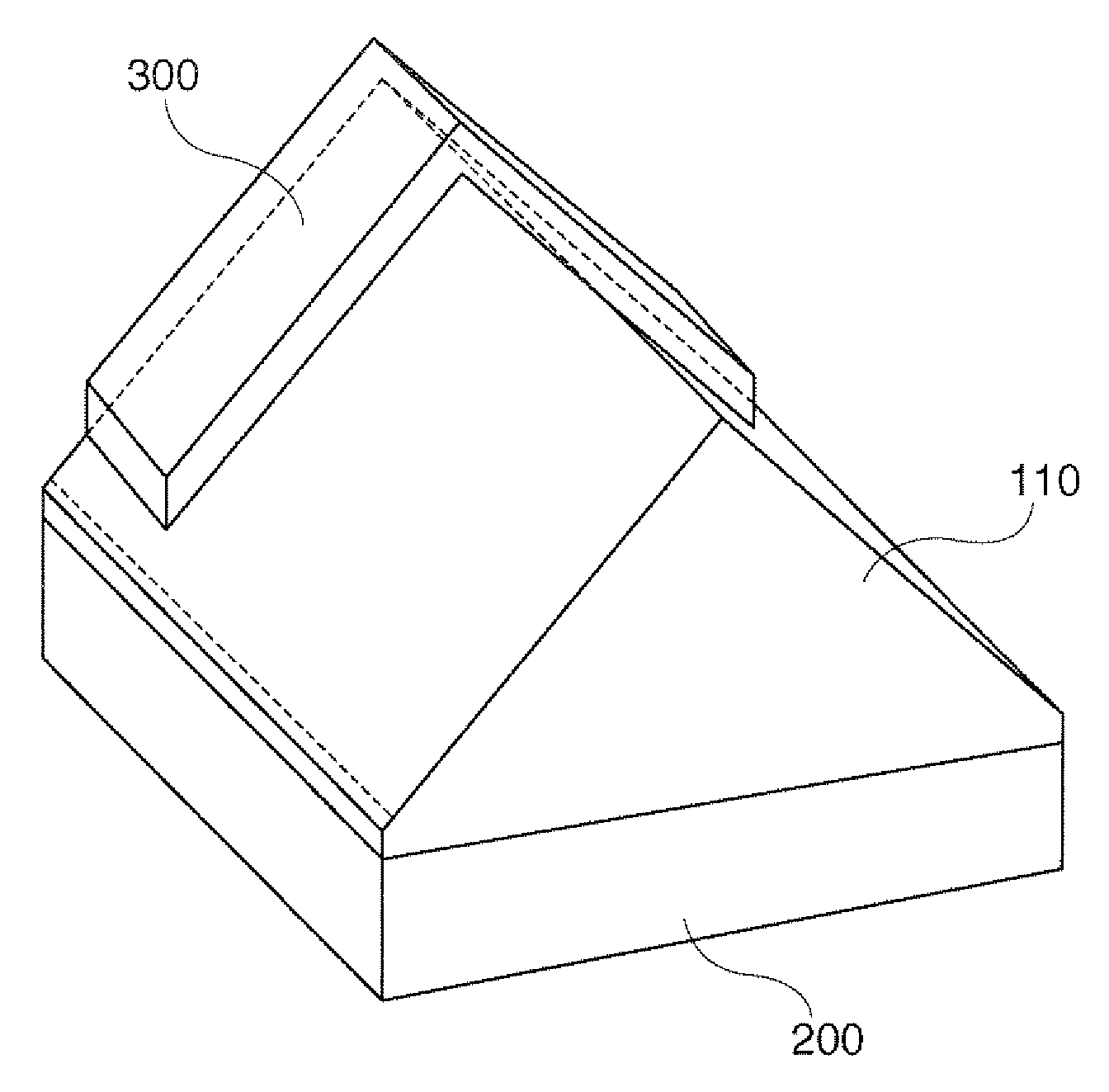

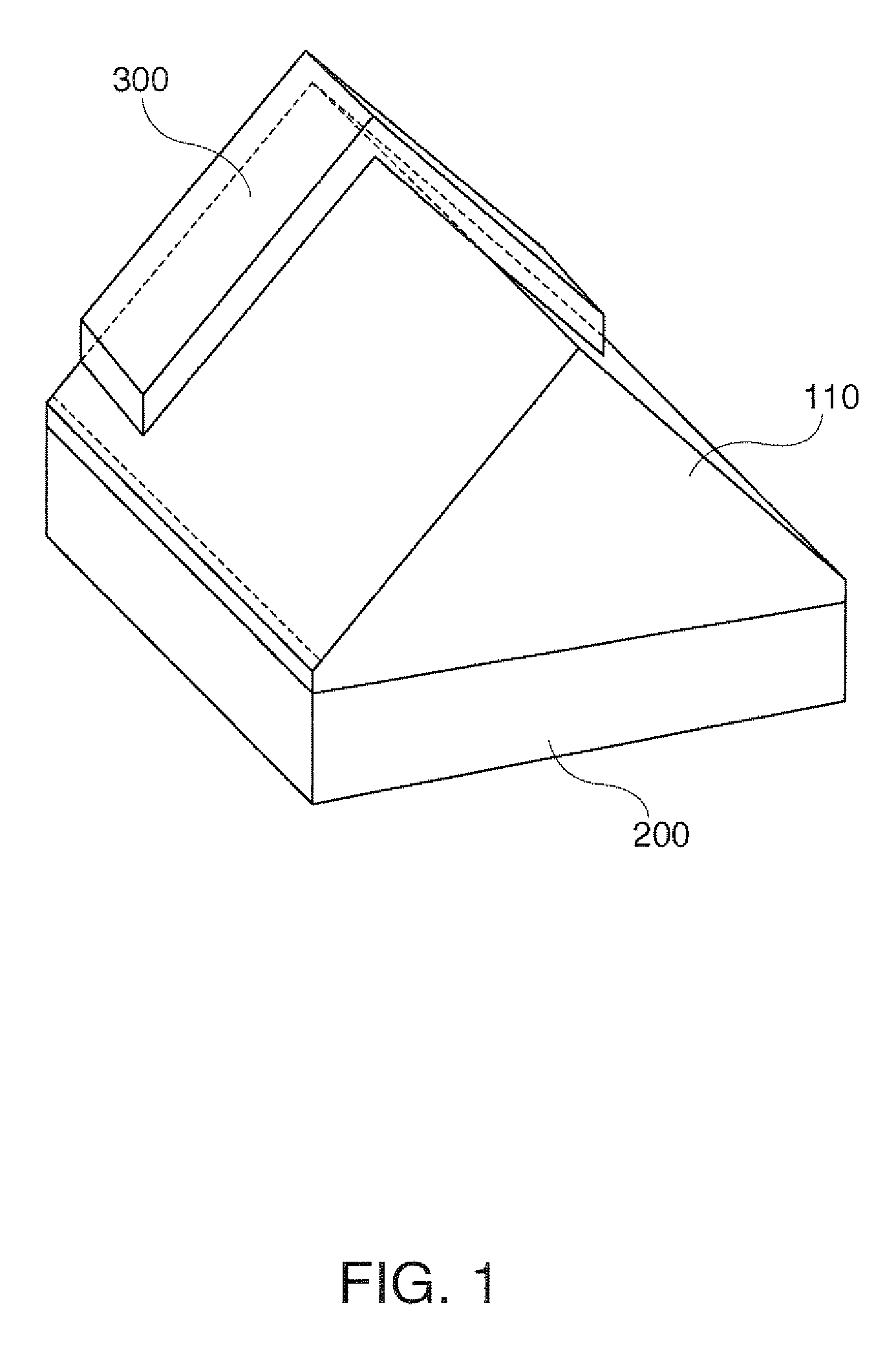

Methods of manufacturing a piezoelectric actuator and a liquid jetting head

InactiveUS7152290B2Improve production efficiencySuitable structurePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsEngineering

Methods for manufacturing a piezoelectric actuator and a liquid ejecting head. In particular, a substrate, which is to be a vibration plate actuated by a piezoelectric element is prepared. A plurality of chip regions are defined on the substrate. A first common electrode of the piezoelectric element is formed on the substrate. A first piezoelectric layer of the piezoelectric element is formed on the first common electrode. A drive electrode of the piezoelectric element is formed on the first piezoelectric layer. A second piezoelectric layer of the piezoelectric element is formed on the drive electrode. A second common electrode of the piezoelectric element is formed on the second piezoelectric layer. Then, the substrate is cut so as to divide the chip regions from one another. In the aforementioned aspects of the invention, the first and second common electrodes as well as the drive electrode are formed so as not to extend beyond the outline of each of the chip regions.

Owner:SEIKO EPSON CORP

Touch screen panel and method for manufacturing same

ActiveCN102402338AImprove clarityIn line with the development trendInput/output processes for data processingGlass coverAdhesive

The invention discloses a touch screen panel, which comprises a polyethylene glycol terephthalate tablet component and a glass cover plate component, wherein the polyethylene glycol terephthalate tablet component comprises polyethylene glycol terephthalate tablets; lower electrodes are formed on lower surfaces of the polyethylene glycol terephthalate tablets; the glass cover plate component comprises glass cover plates; anti-fingerprint films are coated on upper surfaces of the glass cover plates; printing-ink view windows are printed around the lower surfaces of the glass cover plates; anti-reflection layers are coated on the lower surfaces of the glass cover plates; upper electrodes are formed on the lower surfaces of the anti-reflection layers; and the upper surface of the polyethylene glycol terephthalate tablet component is adhered to the lower surface of the glass cover plate component by using an optical transparent adhesive. The invention also discloses a method for manufacturing the touch screen panel. By the invention, reflection can be reduced, the definition of a display screen is improved, and production cost is low.

Owner:天津美泰真空技术有限公司

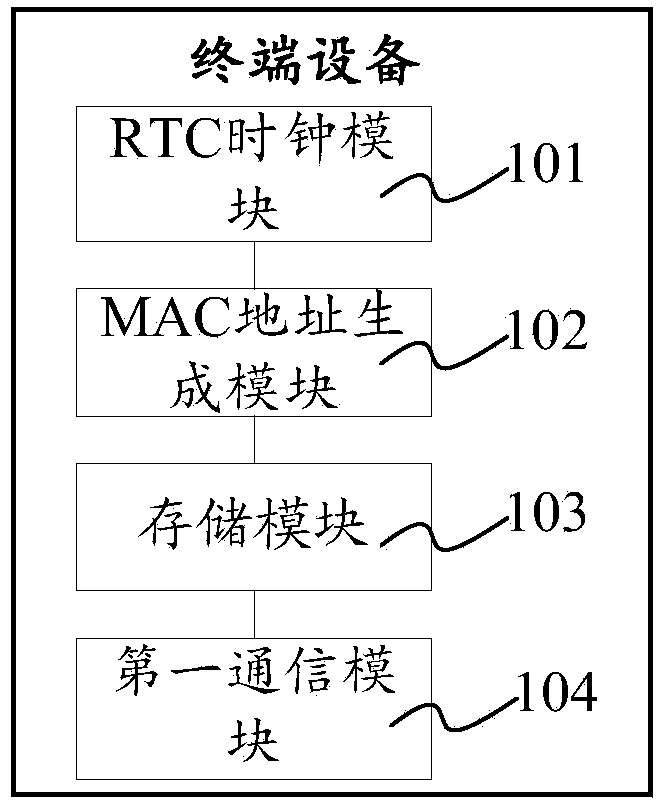

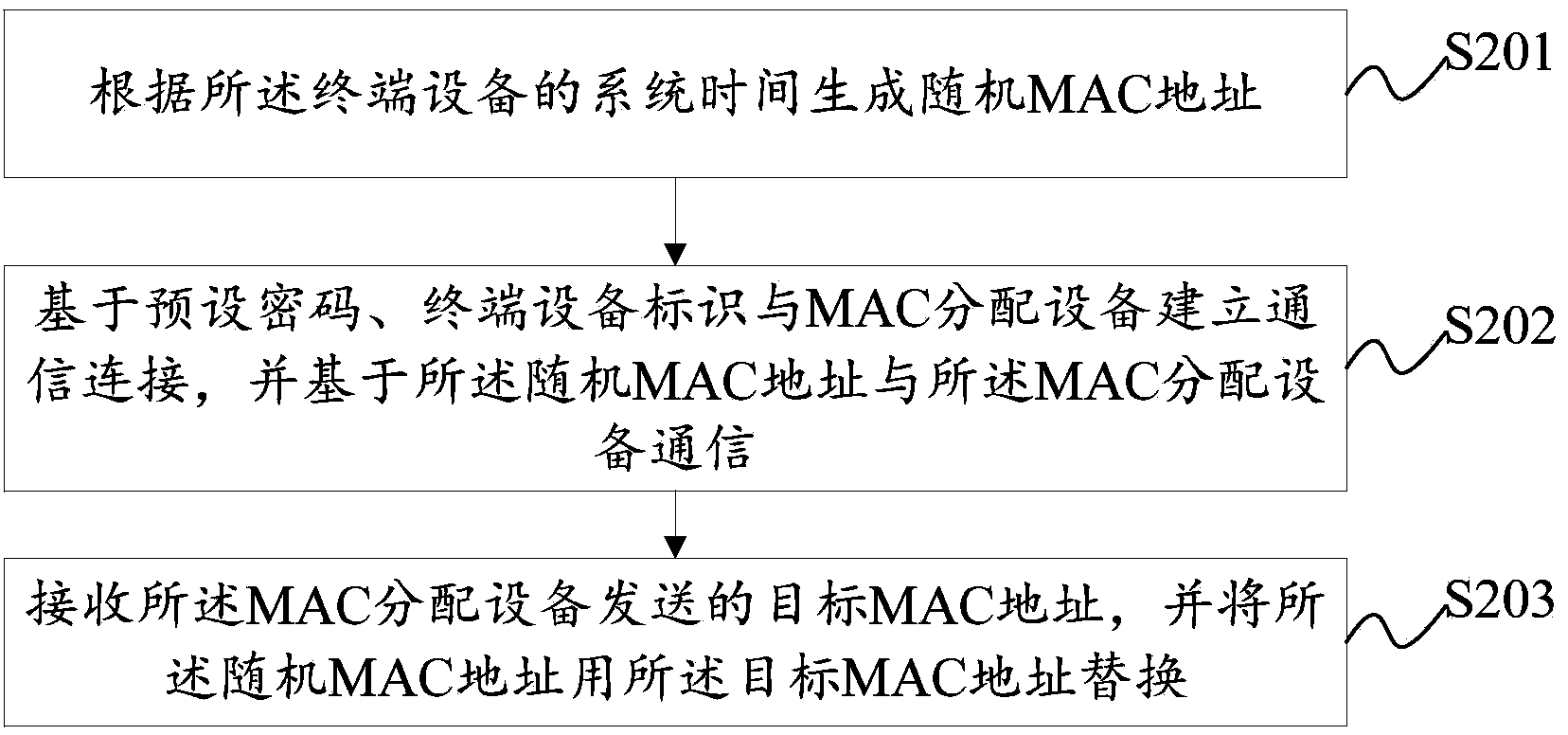

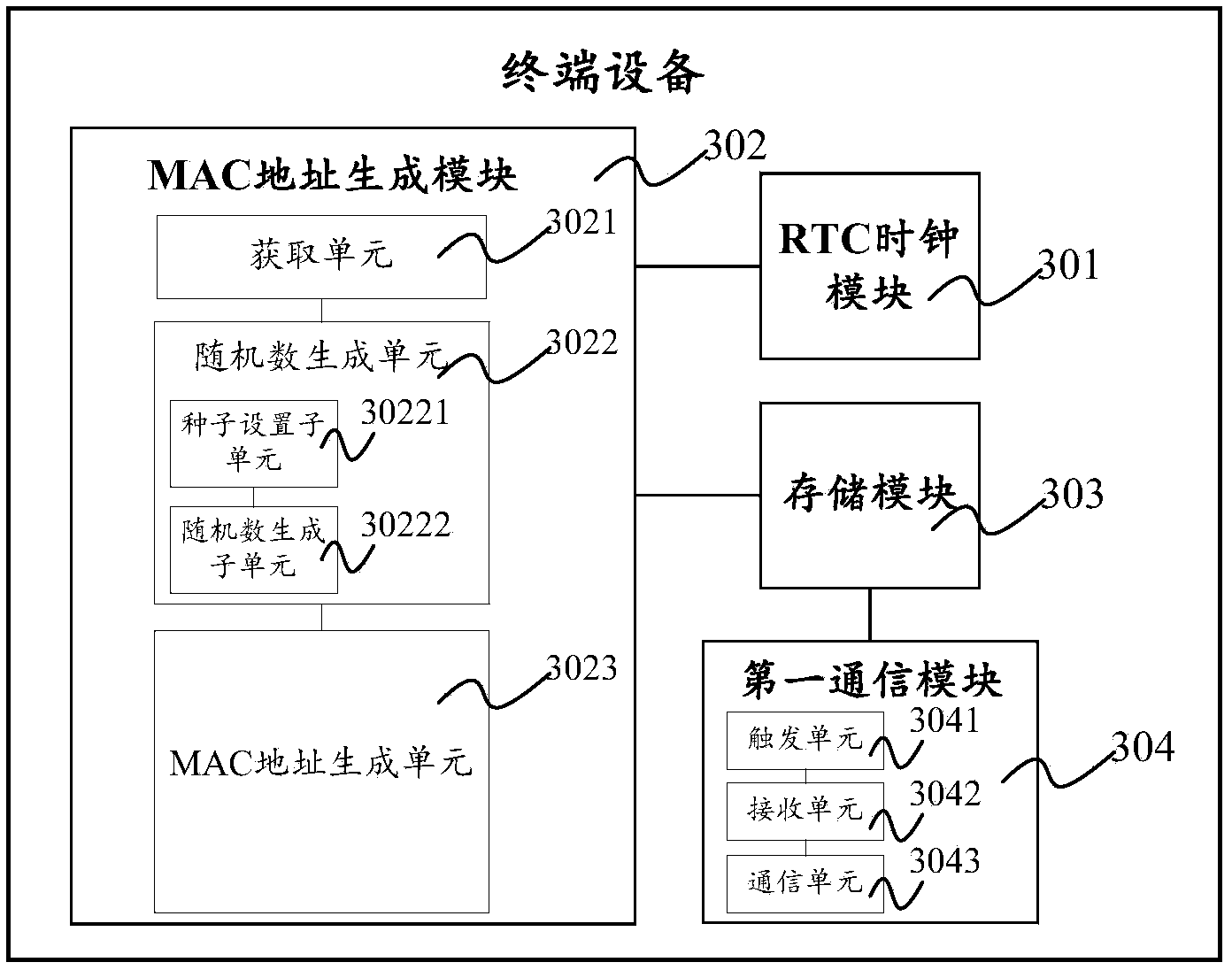

Setting method and distributing method for terminal equipment MAC address

ActiveCN104079686AImprove mass production efficiencyReduce labor costsTransmissionPasswordTerminal equipment

The invention discloses a setting method and a distributing method for a terminal equipment MAC address. The setting method includes the steps that a random MAC address is generated according to system time of terminal equipment; based on preset passwords, an MAC distributing equipment identification and MAC distributing equipment, communication connection is established, and communication with the MAC distributing equipment is achieved based on the random MAC address; the target MAC which is sent by the MAC distributing equipment is received, and the random MAC address is replaced with the target MAC address. According to the technical scheme, the terminal equipment can automatically obtain the target MAC address needing programming addition from the MAC distributing equipment, and the target MAC address is written into a storage module of the terminal equipment, so that efficiency of overall volume production is improved, and labor cost is reduced.

Owner:FUZHOU ROCKCHIP SEMICON

Accumulator and manufacturing process thereof

InactiveUS20010037834A1Optimize timingImprove mass production efficiencyAccumulator installationsElectrode supporting devicesEngineeringGas chamber

Disclosed is an accumulator comprising: a pressure vessel; an elastic bellows in which a compressed gas is sealed, an end of the bellows being fixed to an interior of the pressure vessel; a flow path having an opening communicating with the interior and an exterior of the pressure vessel; a valve connected to a movable end of the bellows to operatively close the opening according to elastic motion of the bellows; and a hydraulic chamber partitioned from a gas chamber formed in an interior of the bellows containing the compressed gas. The valve comprises an upper surface which can cover the opening, and plural circular protrusions which surround the entire circumference of the opening and can closely contact the circumference of the opening.

Owner:NHK SPRING CO LTD

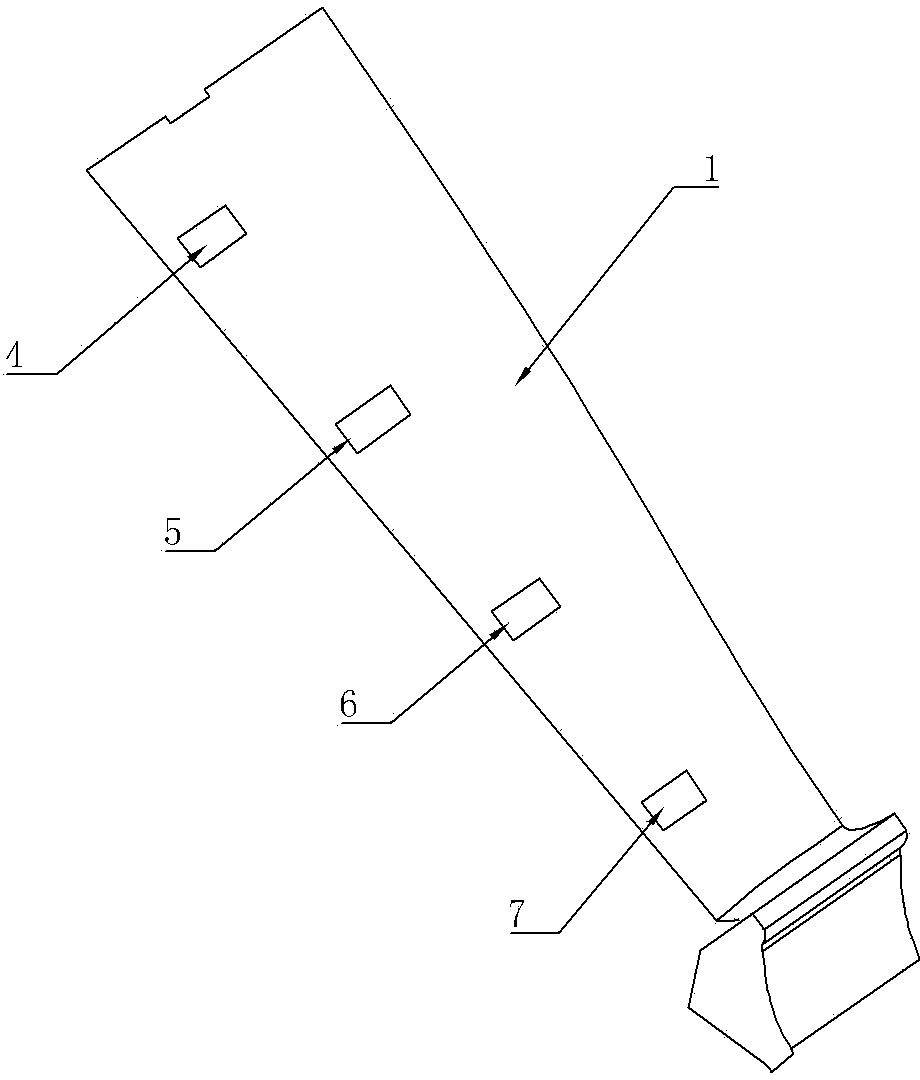

Atomic frequency acquiring apparatus and atomic clock

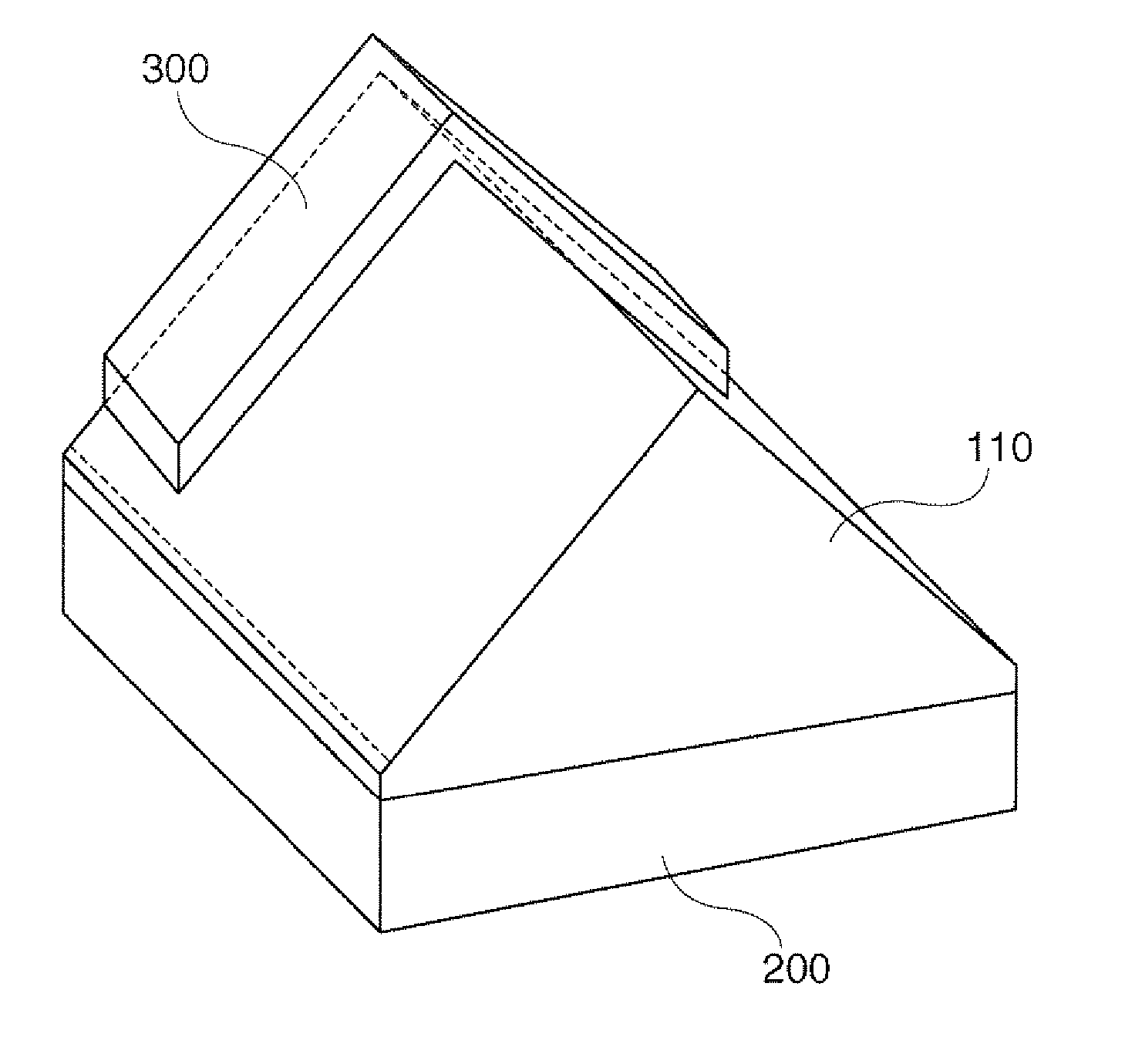

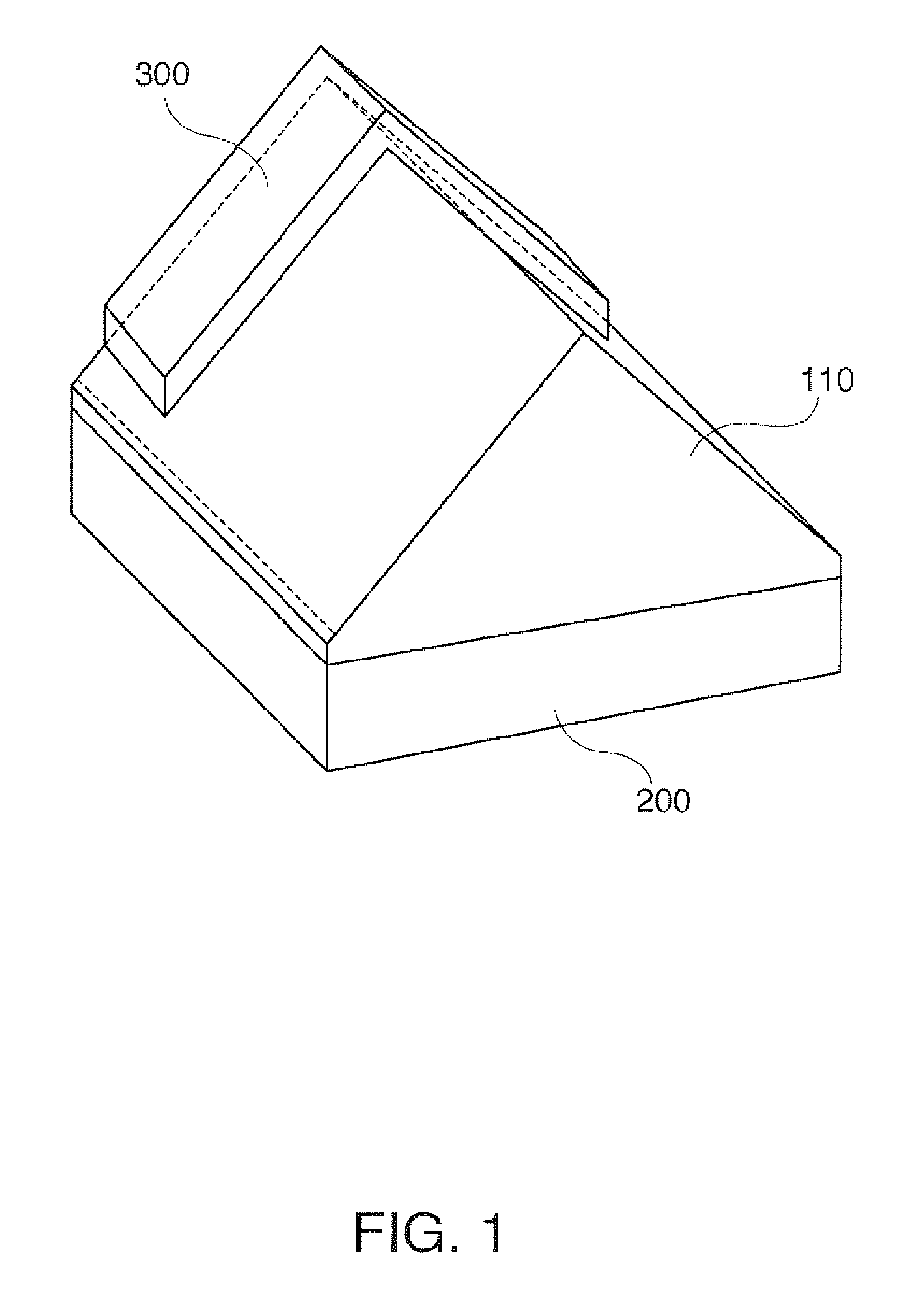

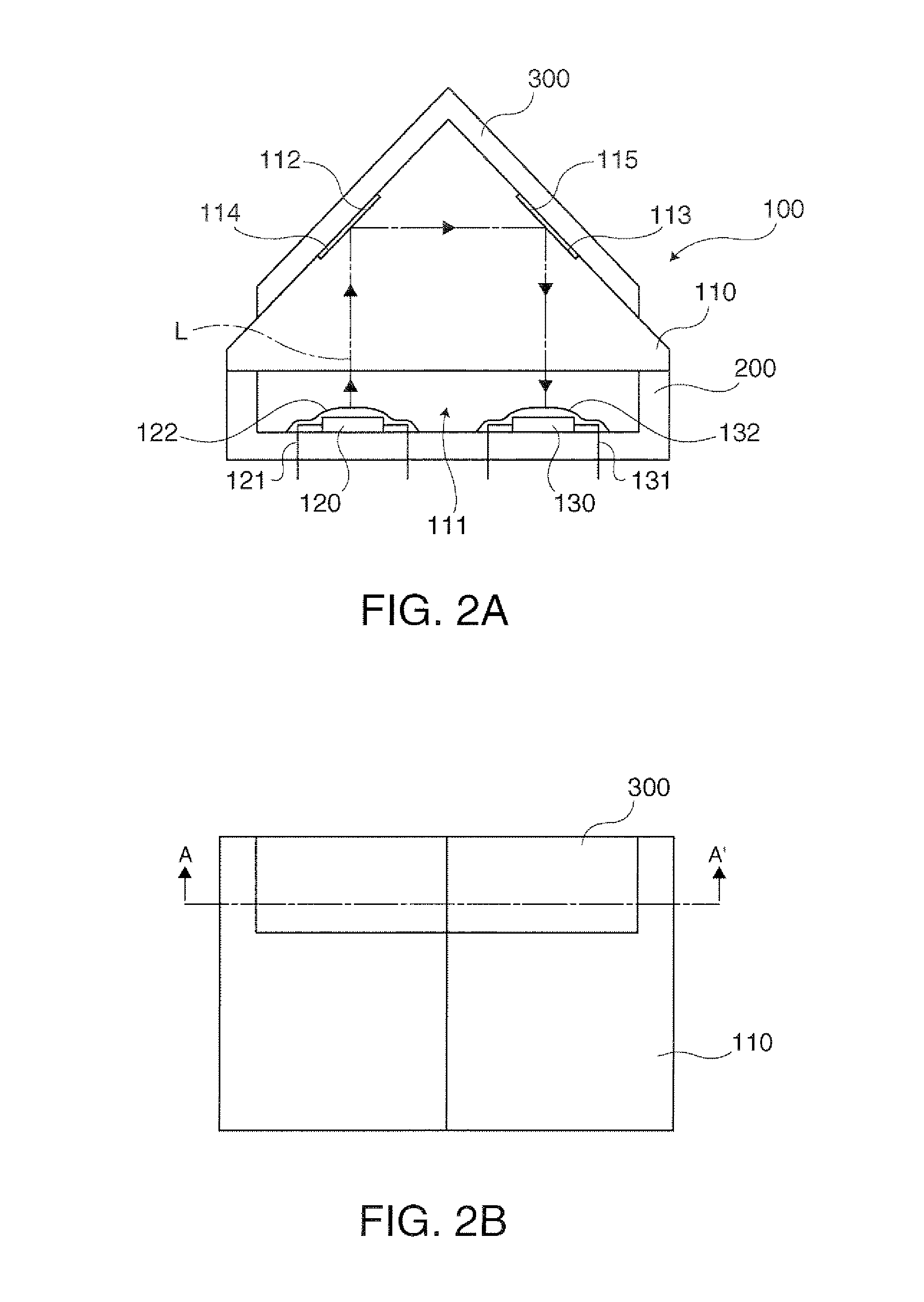

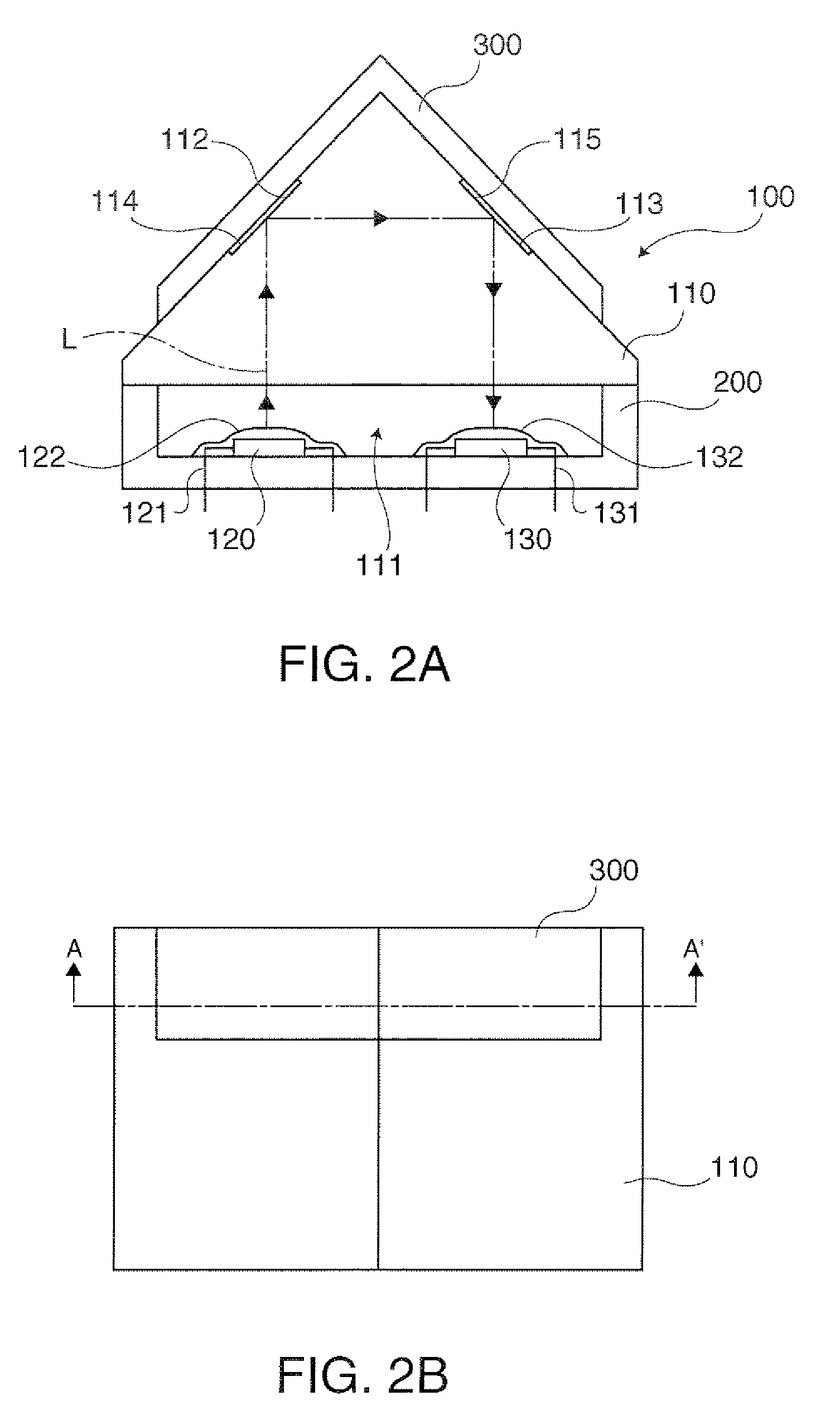

ActiveUS20070139128A1Improve mass production efficiencySmall sizeLaser detailsGaseous masersAcquisition apparatusOptoelectronics

An atomic frequency acquisition apparatus includes: a cell enclosing atomic gas therein; a laser light source that oscillates laser light that enters the cell and excites the atomic gas; and a photodetecting section that detects the laser light that has passed the cell, wherein the laser light source and the photodetecting section are attached to a common surface facing an interior of the cell, and the cell has a first reflection section on which the laser light oscillated from the laser light source is incident at an incident angle of 45 degrees, and a second reflection section on which the laser light reflected by the first reflection section is incident at an incident angle of 45 degrees.

Owner:MICROCHIP TECH INC

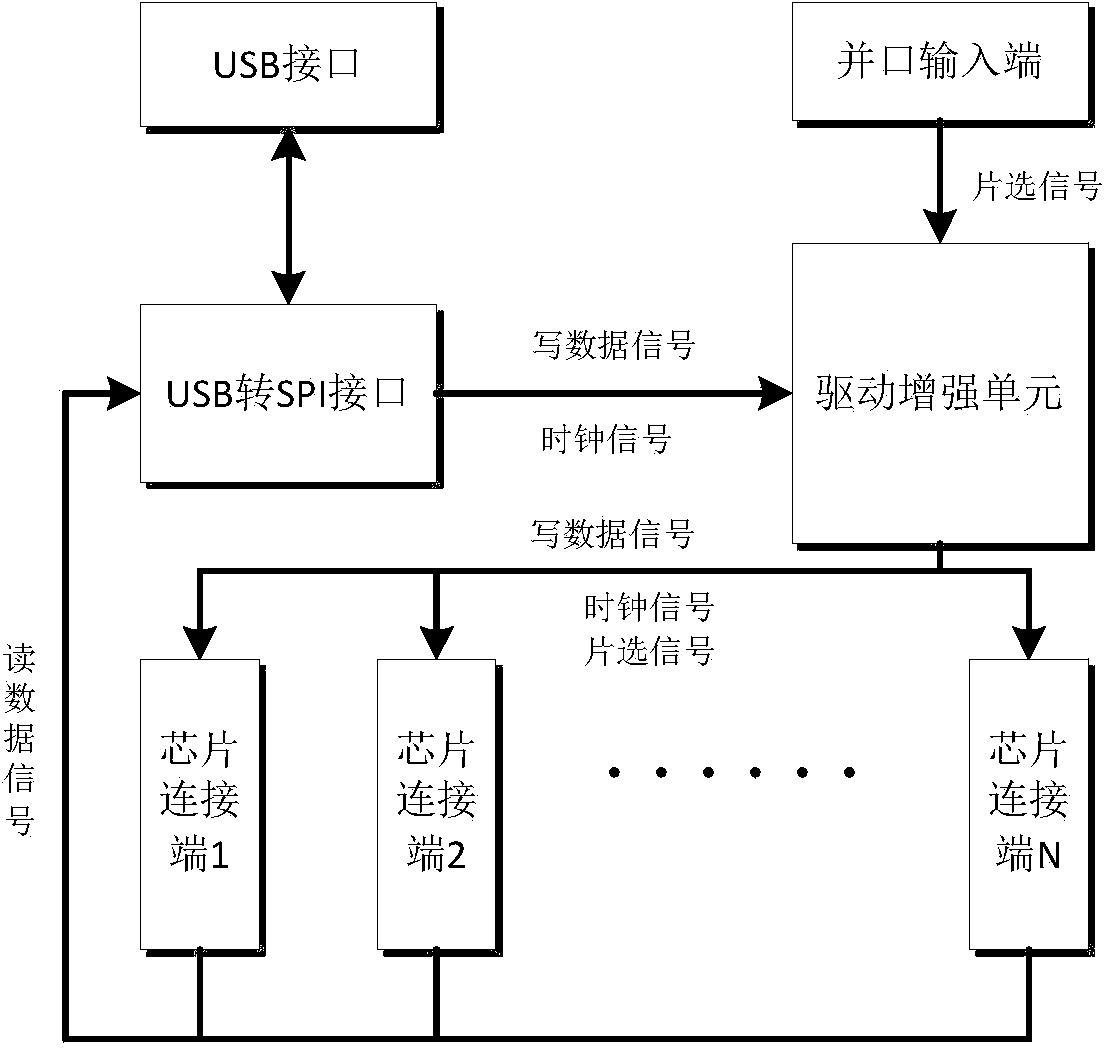

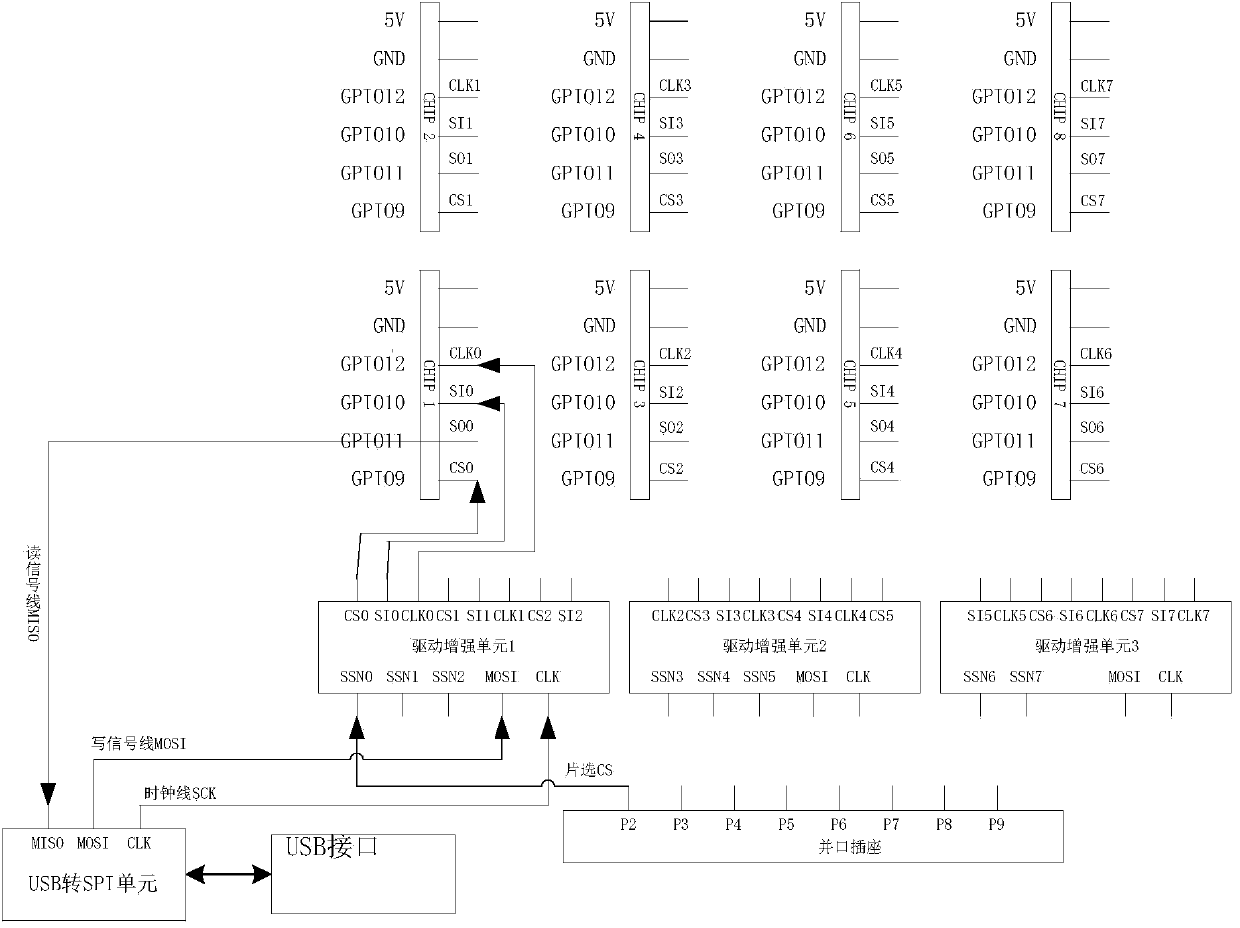

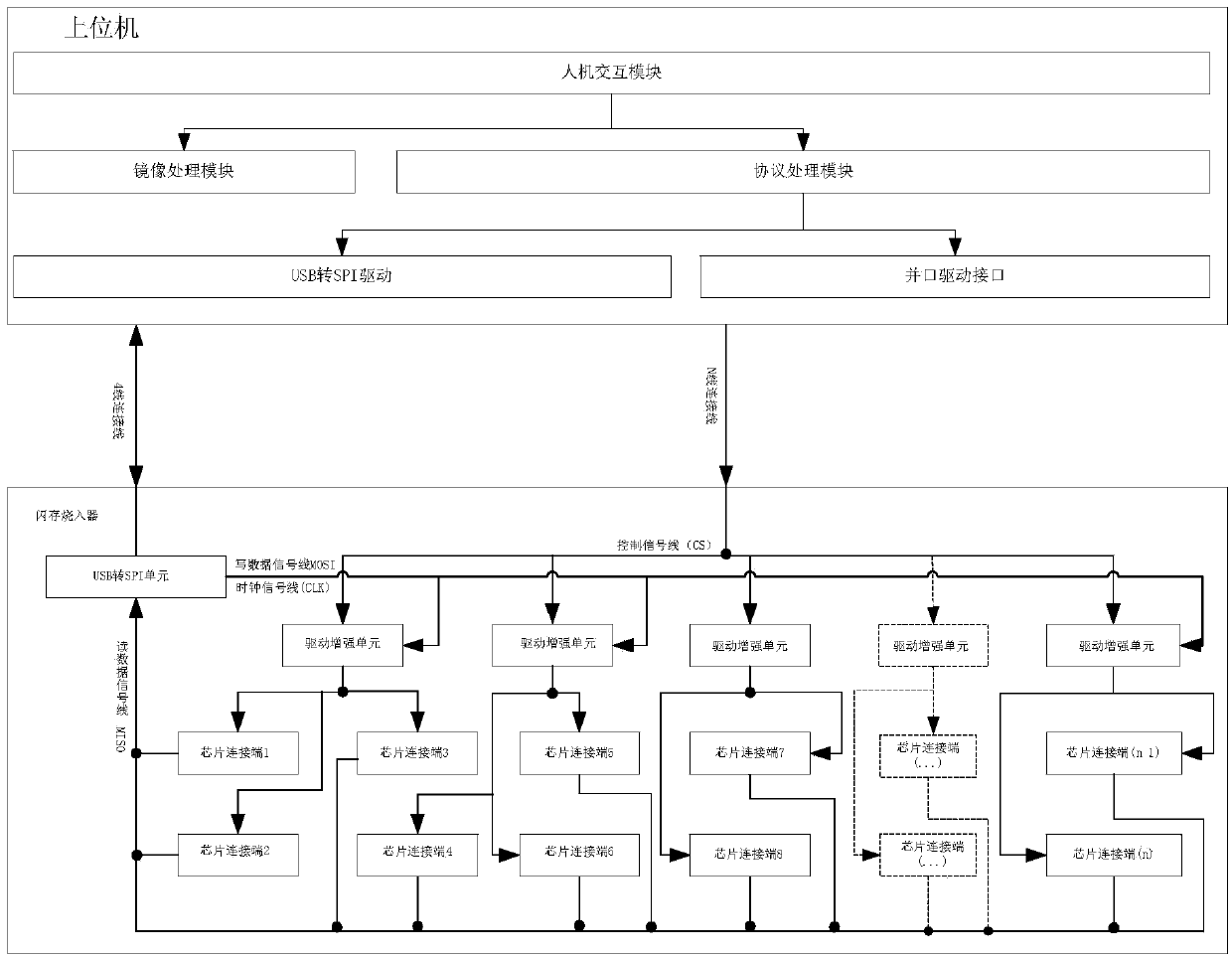

Flash memory burner, burning system and burning method

ActiveCN104200843AChange the burning processImprove mass production efficiencyRead-only memoriesControl flowChip select

The invention discloses a flash memory burner, a burning system and a burning method. Flash memories of a plurality of bluetooth chips can be simultaneously burnt, the number of the simultaneously burnt chips can be changed through the parallel transmission of chip select signals, the different requirements of one-step burning and one-to-one burning can be met, the operation is more flexible, and the application range is wider. Besides, as the memory positions of bluetooth addresses and equipment names are previously stored in an image file, the memory position information can be acquired when the image file is burnt, and corresponding to-be-burnt addresses in to-be-burnt chips can be found according to the memory position information. Therefore, the bluetooth addresses and the equipment names can be directly burnt after the image file is burnt, burning is no longer needed to be carried out after erasing like the prior art, the burning process of the flash memories of the bluetooth chips is essentially changed, the burning speed is raised, and the burning control procedures are simplified and more tend to automation.

Owner:WUXI ZGMICRO ELECTRONICS CO LTD

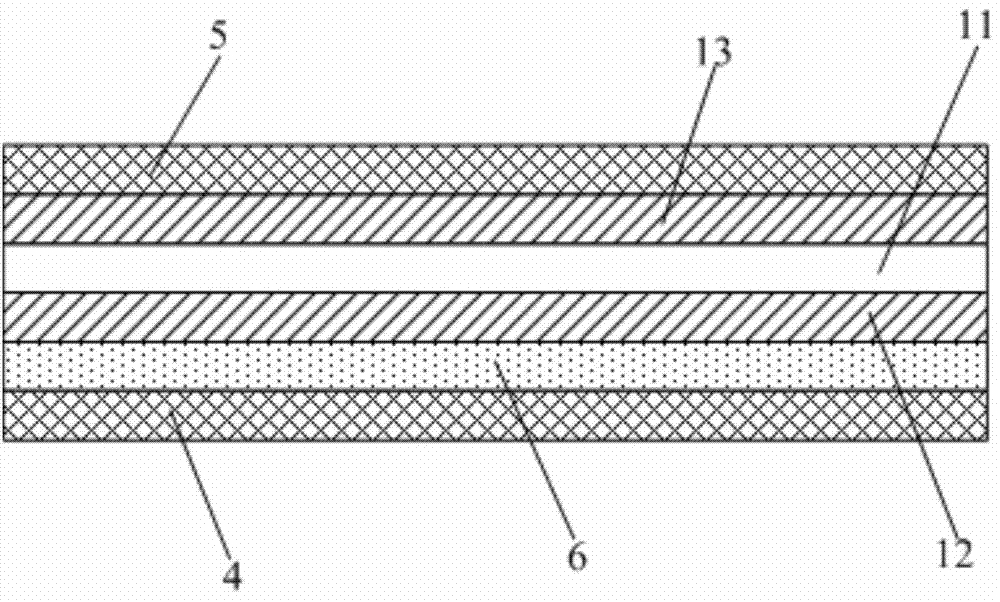

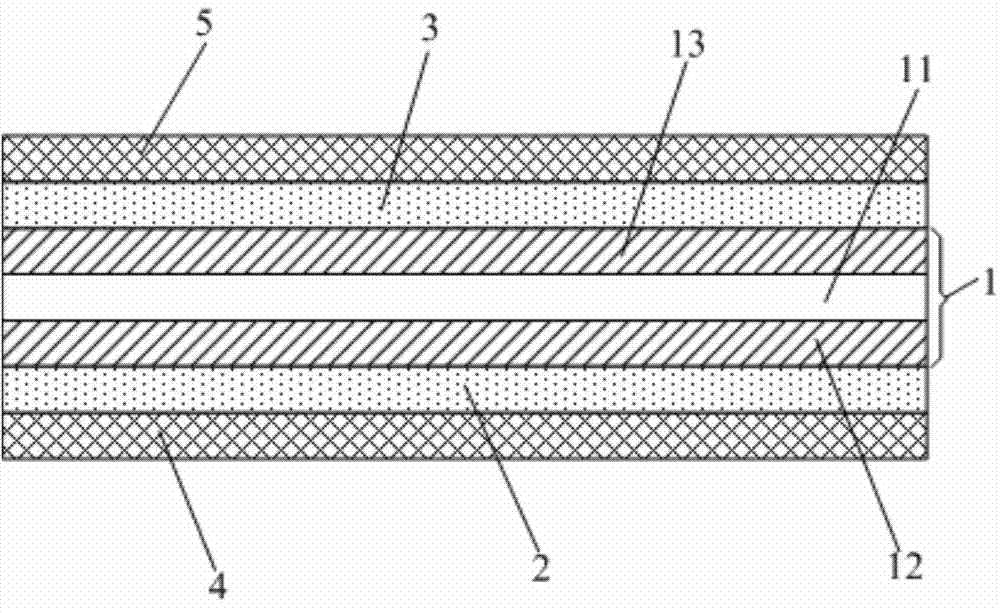

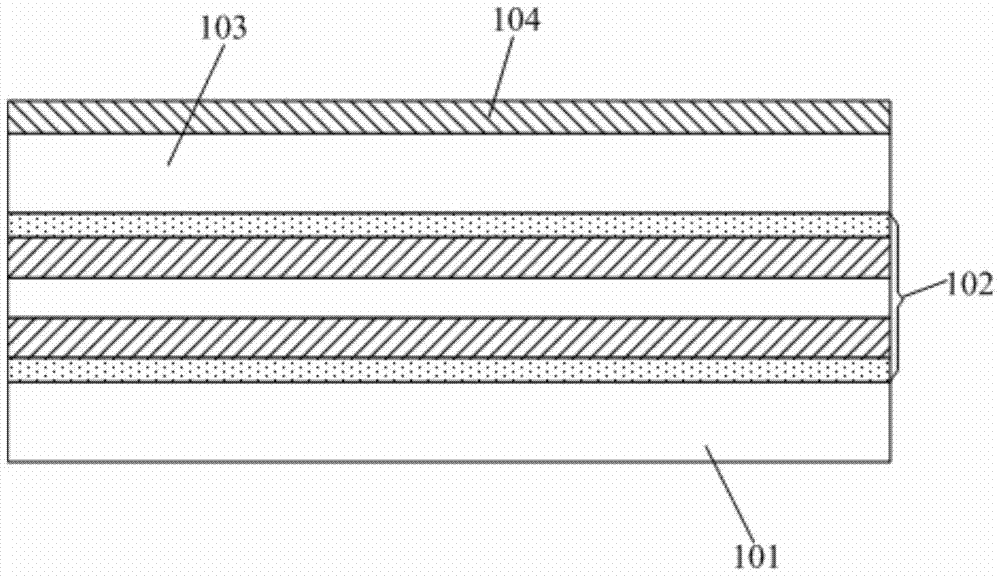

Polarizer, display panel, display panel forming method and display device

InactiveCN104267456ASimplify the bonding processImprove fitPolarising elementsNon-linear opticsDisplay devicePolarizer

The invention provides a polarizer, a display panel, a display panel forming method and a display device. The polarizer comprises a polarizing film layer and a first bonding layer arranged on the lower surface of the polarizing film layer. The first bonding layer is used for being bonded with a display substrate. The polarizer further comprises a second bonding layer arranged on the upper surface of the polarizing film layer. The second bonding layer is used for being bonded with a first film layer. The polarizer is formed by adding the second bonding layer to an existing polarizer, the two faces of the polarizer can be easily and conveniently attached to the display substrate and the first film layer, and therefore the attaching technology of the polarizer in the two-face attaching process is greatly simplified.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

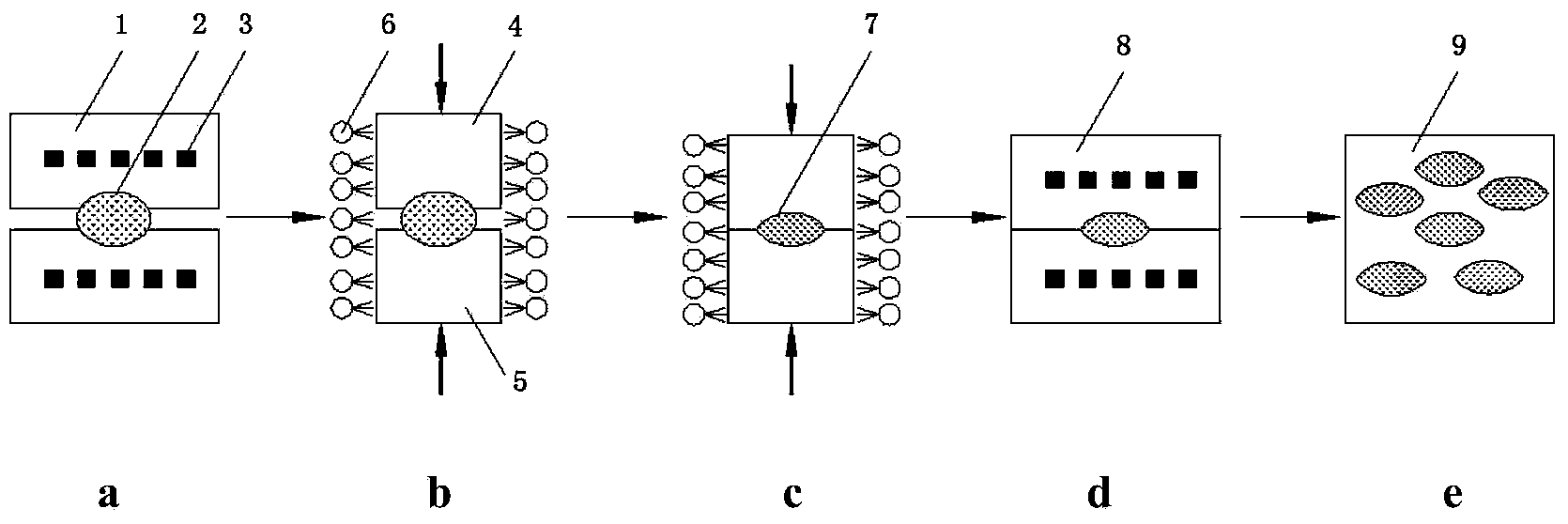

Forming method of chalcogenide glass aspherical lens

ActiveCN104310755AEfficient quality batch manufacturingEfficient batch manufacturingGlass pressing apparatusGlass press-moulding apparatusChalcogenide glassRoom temperature

A forming method of a chalcogenide glass aspherical lens is disclosed. The method includes: a) subjecting a chalcogenide glass prefabricated part to three times of heating in a preheating device to raise the temperature of the prefabricated part from room temperature to a temperature T1, with the temperature T1 being near the yield temperature At of the material; b) maintaining the temperature of a cavity and a core at T2 under the actions of heating elements, with the temperature T2 being 5-10 DEG C lower than the conversion temperature Tg of the material, transferring the prefabricated part having the temperature T1 into a mould pressing cavity formed by the cavity and the core; maintaining the temperature of the prefabricated part to be around the yield temperature At of the material, and applying a pressing force P1 on to the cavity and the core simultaneously for a time period of t1 to allow the prefabricated part to be turned into the chalcogenide glass aspherical lens by mould pressing; c) maintaining the pressing force P1 for a time period of t2, and cooling the temperature of the forming mould and the chalcogenide glass aspherical lens to a temperature T3; d) transferring the chalcogenide glass aspherical lens to a cooling bath, performing three times of cooling to cool the chalcogenide glass aspherical lens from the temperature T3 to room temperature, and taking the chalcogenide glass aspherical lens out; and e) putting the chalcogenide glass aspherical lens into a tempering device and tempering for 12-36 h.

Owner:沈奕芸

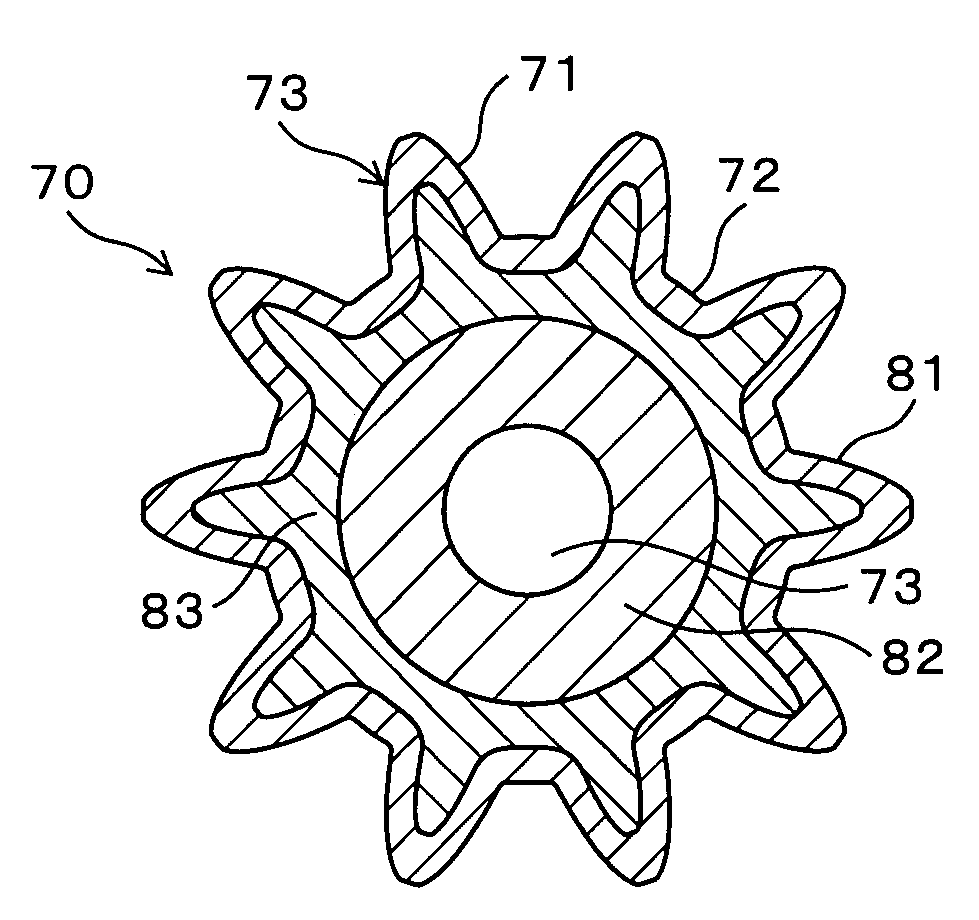

Sintered gear and production method therefor

ActiveUS20070283778A1Easy to produceEffectively densifiedMetal-working apparatusPortable liftingHigh densityVolumetric Mass Density

A sintered gear comprises: plural tooth portion having a tooth flank and a tooth bottom land; a high density area formed over entire surface of the tooth portion, the high density area having a density of 7.6 Mg / m3 or more and formed with a depth of 1 mm or more from the surface; a low density area formed in deeper area than the high density area, the low density area having a density of 7.3 Mg / m3 or less; and an intermediate area formed between the high density area and the low density area, the intermediate area having a density gradient in which the density is gradually decreased from the high density area to the low density area.

Owner:RESONAC CORP

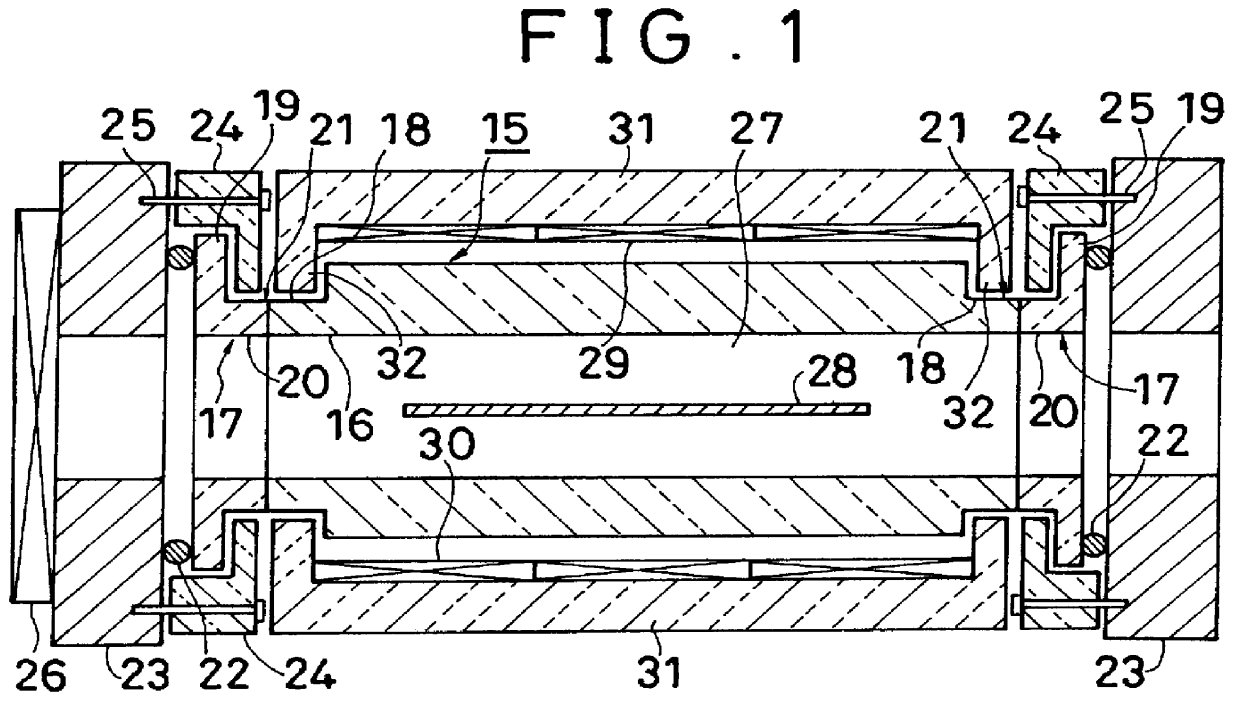

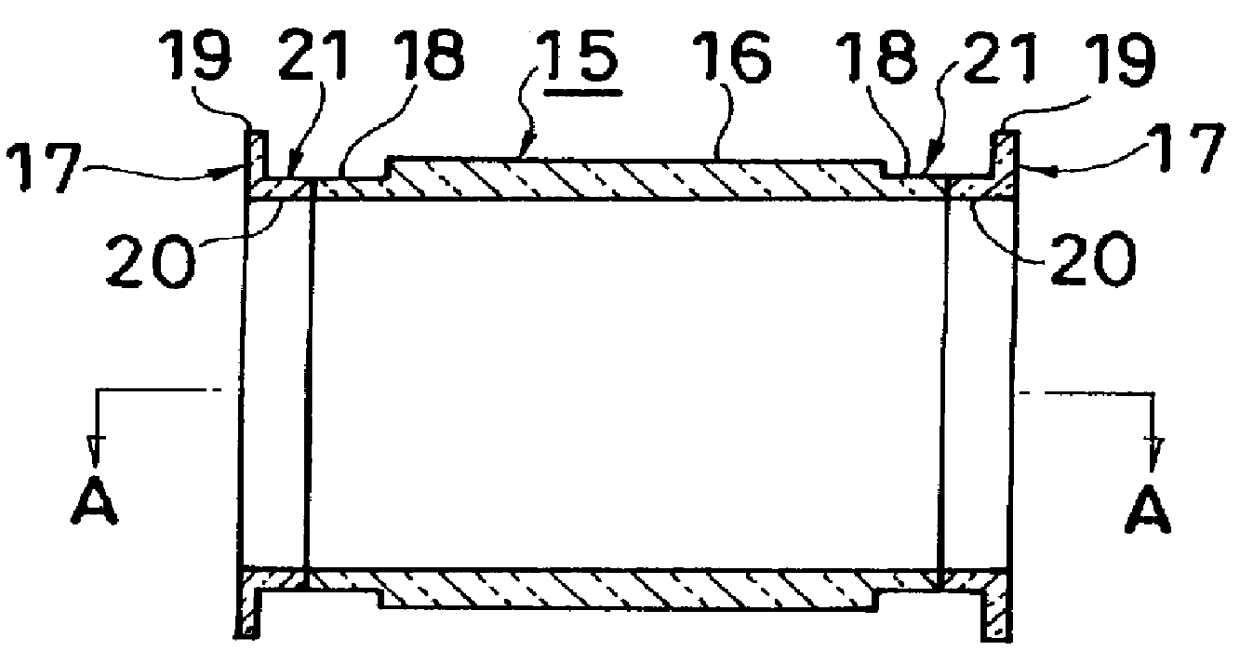

Substrate processing apparatus

InactiveUS6132553AImprove mass production efficiencyReduce material costsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingFlange

A substrate processing apparatus includes a reaction container for processing a substrate therein. The reaction container is provided with two open ends. The reaction container includes a central cylindrical body and two flanges respectively provided at the both open ends. The central cylindrical body includes at its both ends thin portion which are thinner than the central portion of the central cylindrical body, the flanges are respectively provided with flange connecting portions which are thinner than the central portion of the central cylindrical body, and the thin portions of the central cylindrical body and the flange connecting portions are welded together.

Owner:KOKUSA ELECTRIC CO LTD

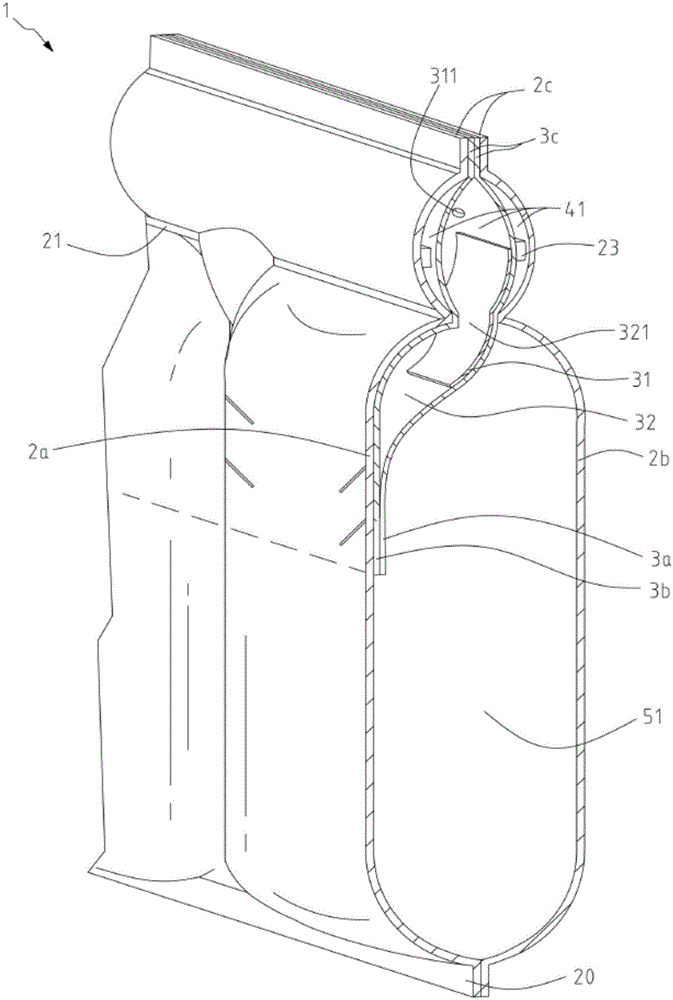

Air sealing body with air inlets capable of being opened quickly

ActiveCN104443794AEasy to manufactureReduce manufacturing costContainers to prevent mechanical damageInternal pressureManufacturing cost reduction

The invention discloses an air sealing body with air inlets capable of being opened quickly. The air sealing body comprises two outer films and two narrow inner films, wherein the two outer films and the two inner films are connected together in a heat-seal mode, and an inflation channel and a plurality of air columns are formed through a first heat-seal line. The two inner films extend to the two opposite inner sides and the upper edges of the two outer films respectively along the first heat-seal line, and the top edges of the two inner films and the upper edges of the two outer films are integrally connected in a heat-seal mode. The inner surface of at least one inner film is provided with a plurality of air guide portions. The air guide portions are arranged corresponding to the air columns and coated with heat-resisting materials. Each inner film is provided with a plurality of air guide holes which are formed between the air guide portions and the upper edge of the inner film. When inflation is conducted through the inflation channel, air enters the air guide holes, the air guide portions and the corresponding inner films form a flow guide channel, the air is quickly injected into the air columns to fill up the air columns, and internal pressure is generated to press the two inner films, so that the air is prevented from leaking outside. As a result, the air sealing body with the air inlets capable of being opened quickly can conduct inflation quickly, effectively simplify the manufacturing and connection process of the inner films and the outer films, and lower the manufacturing cost.

Owner:KUNSHAN AIRBAG PACKING CORP

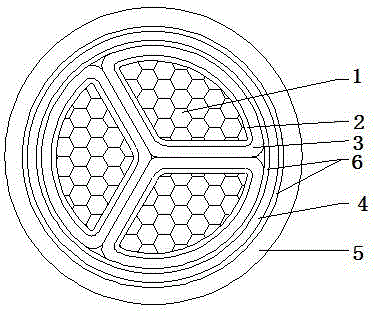

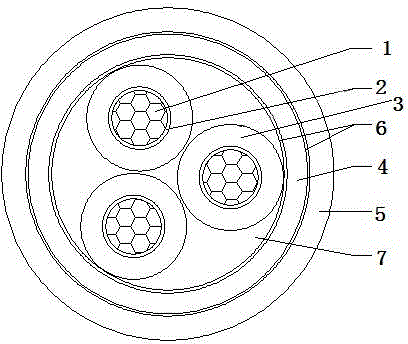

Flexible fireproof cable

ActiveCN104821195ALow costSimple processing technologyClimate change adaptationFlexible cablesElectrical conductorPolyolefin

A flexible fireproof cable belongs to the technical field of cables. The flexible fireproof cable comprises a cable core and a sheath. The cable core is formed by stranding a plurality of insulated wire cores. Each insulated wire core is composed of a conductor and a fireproof insulating layer. The flexible fireproof cable is characterized in that the fireproof insulating layers are of a composite double-layer insulating structure, a polymer composite ceramic polyolefin material is arranged in an extruding manner outside the cable core as a fireproof protective layer, and the sheath is arranged outside the fireproof protective layer. The materials of the flexible fireproof cable are halogen-free and environment-friendly materials which have no pollution to the environment and meet the requirement of modern people for environmental awareness. The fireproof layer of the cable is made of 'polymer composite ceramic polyolefin' which is a novel material, so that the outer diameter, manufacturing cost and production cycle of the cable are reduced and the production efficiency is improved under the condition of ensuring that the cable has the same fireproof performance. Moreover, the structure of the fireproof layer can form a hard shell after combusted at high temperature, so that a line can be protected from damage by stress, and the cable is enabled to work normally for a long period of time under the action of flame.

Owner:宝胜(宁夏)线缆科技有限公司

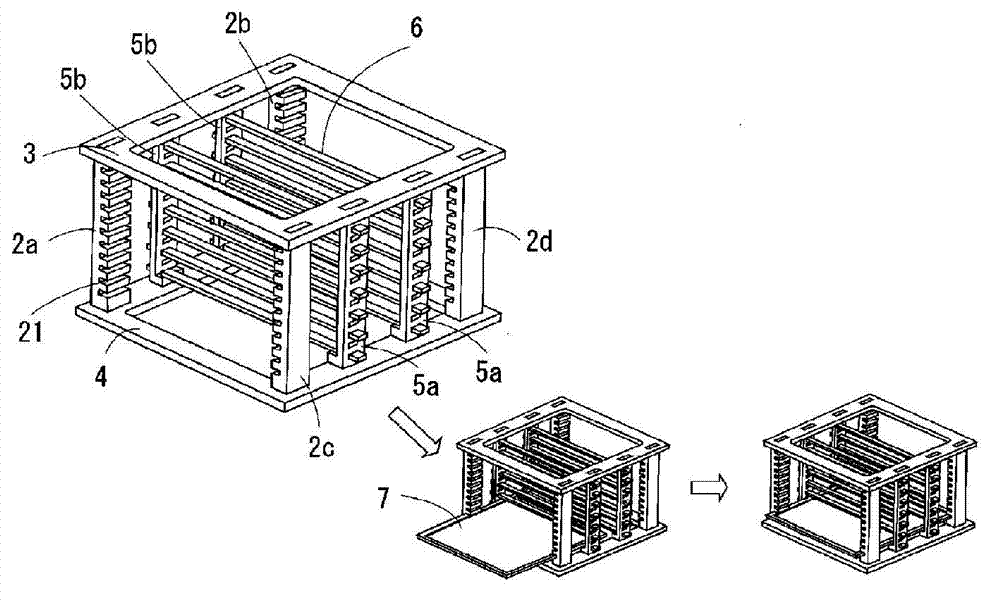

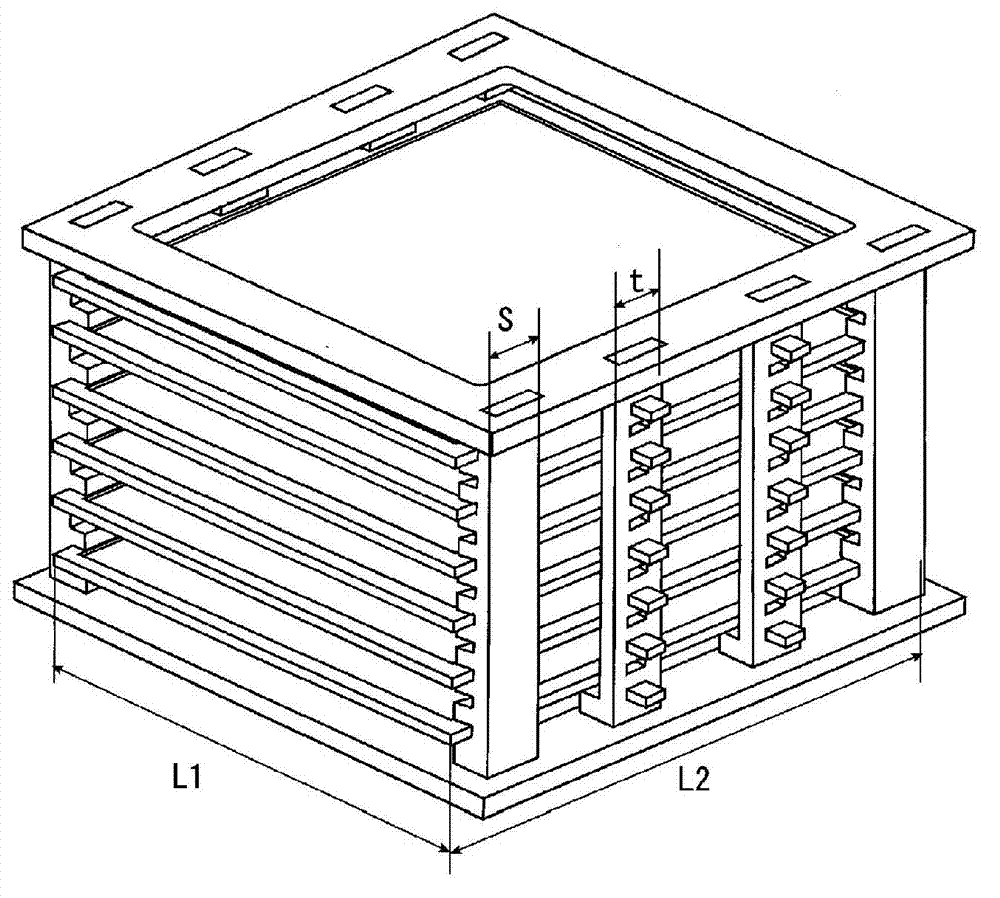

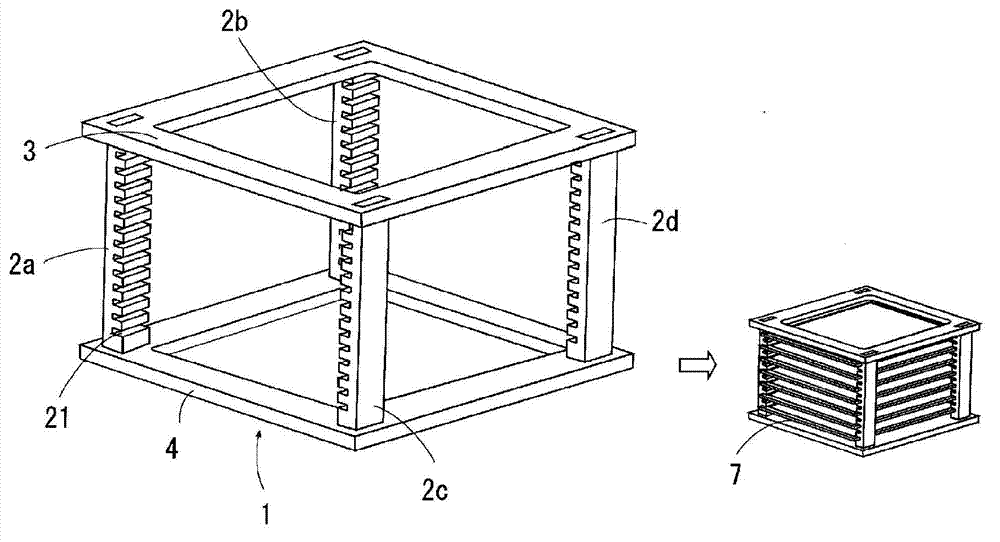

Rack for firing

ActiveCN103097845AEasy to passIncrease heat radiation rateCharge supportsCharge manipulationSetterEngineering

Provided is a rack for firing which holds a plurality of flat board-like setters at multiple levels in the perpendicular direction by means of a setter holding means, and fires electronic ceramic elements at multiple levels. The setter holding means is composed of a material composed of Si-SiC containing 0.01-30 % of Si or recrystallized SiC or Si3N4-SiC, and the setter holding means holds each of the flat board-like setters with 70-100 % of the outer circumferential side surface thereof exposed. Consequently, the rack has excellent energy efficiency, mass-production efficiency, and uniform heating characteristics at each of the multiple levels in the multiple-level firing.

Owner:NGK INSULATORS LTD +1

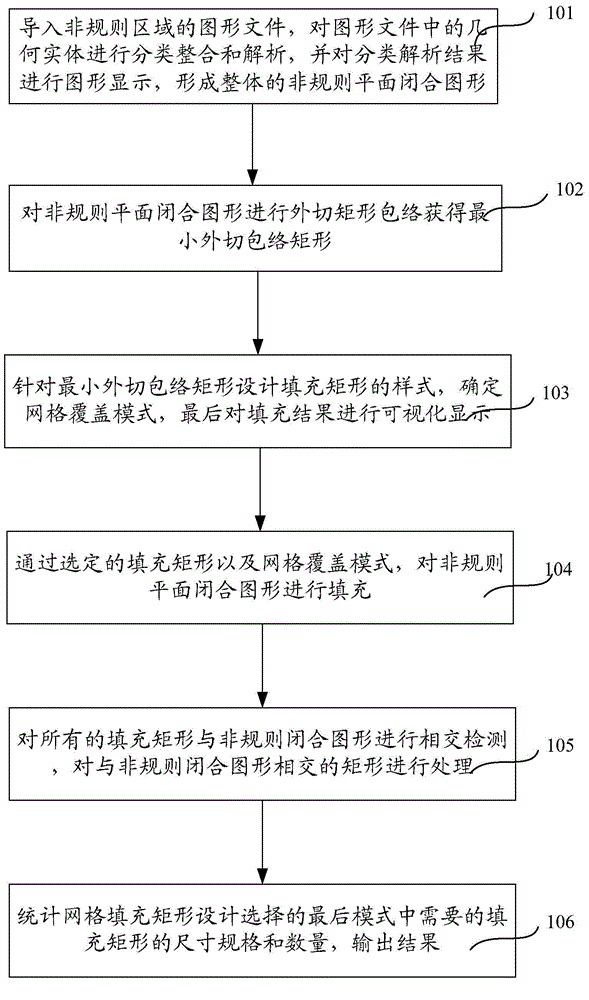

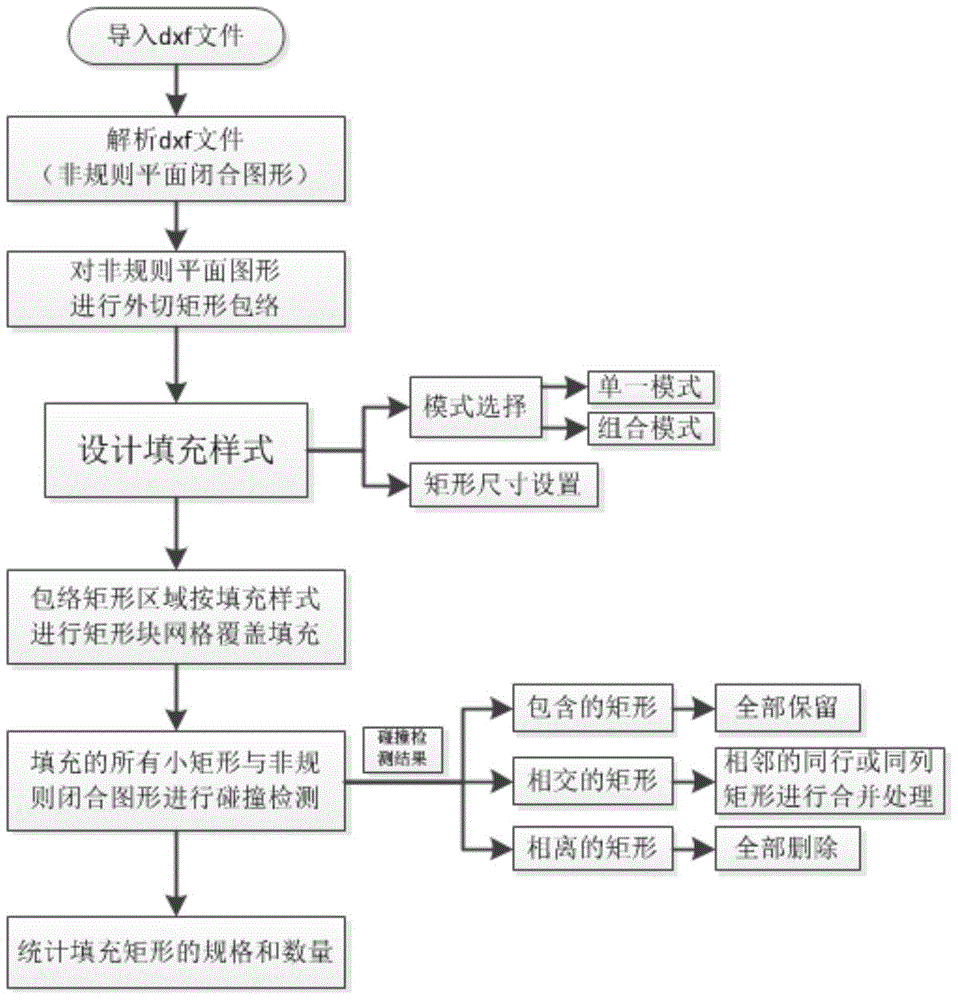

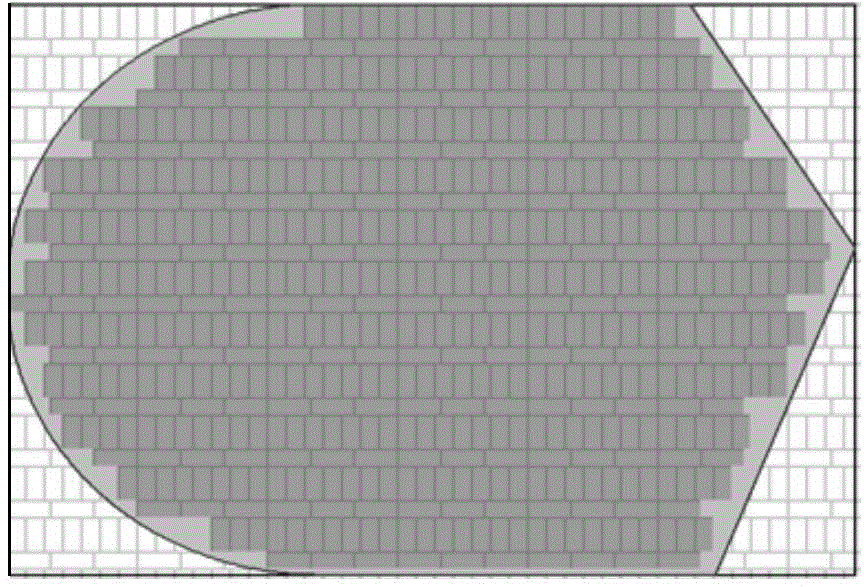

Rectangular block filling method for irregular area

ActiveCN104809752AProcessing developmentSolving the limitations of lineupsSpecial data processing applicationsFilling planer surface with attributesGraphicsComputer science

The invention discloses a rectangular block filling method for an irregular area, including the steps of: introducing a figure file of the irregular area, and integrating and analyzing geometry entities based on classification in the figure file to form a whole irregular planar closed figure; performing circumscribed rectangle envelope on the irregular planar closed figure to obtain a minimal circumscribed enveloped rectangle; designing the modes of filling rectangles with respect to the minimal circumscribed enveloped rectangle, and determining a grid covering mode; filling the irregular planar closed figure according to the selected filling rectangles and the grid covering mode; performing intersection detection on the all filling rectangles and the irregular closed figure, and processing rectangles intersecting with the irregular closed figure; making statistics on dimensions and quantity of the required filling rectangles in the final mode selected by the grid filling rectangle design; According to the rectangular block filling method, the irregular figure is subjected to the rectangle covering gridding process, and thereby optimization of the filling of the irregular figure is achieved.

Owner:GUANGDONG UNIV OF TECH

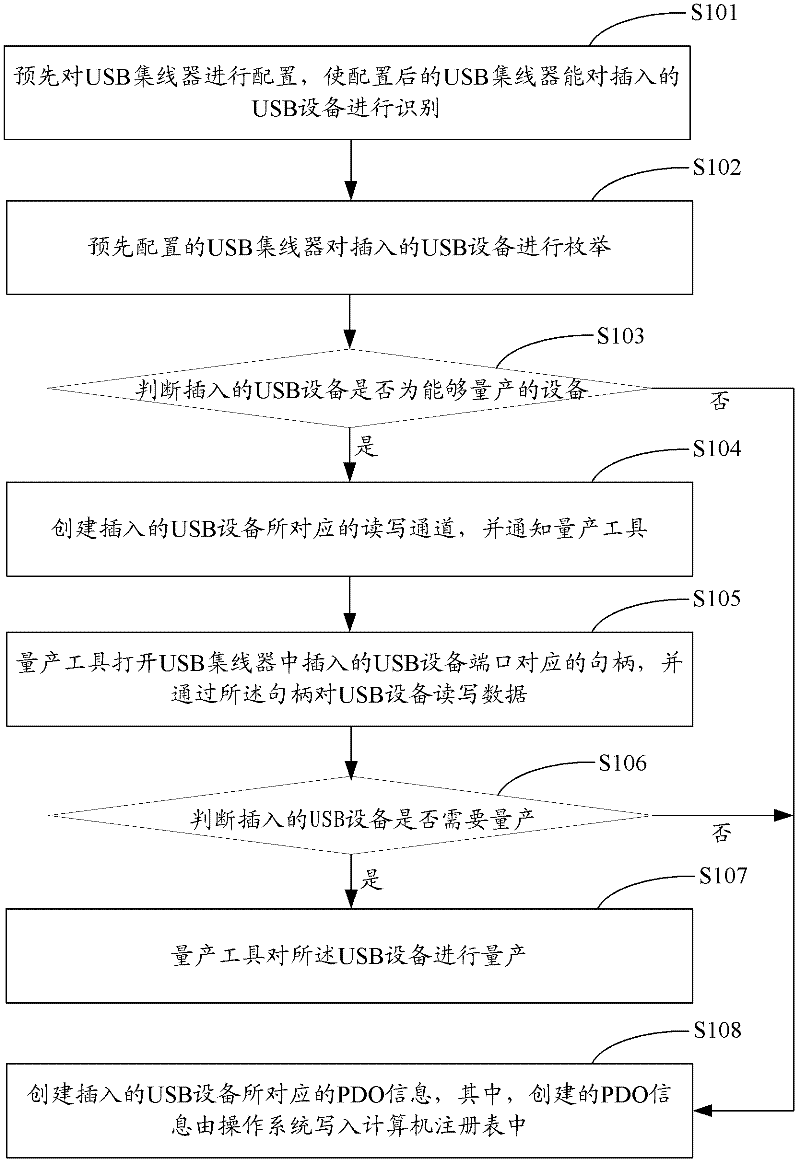

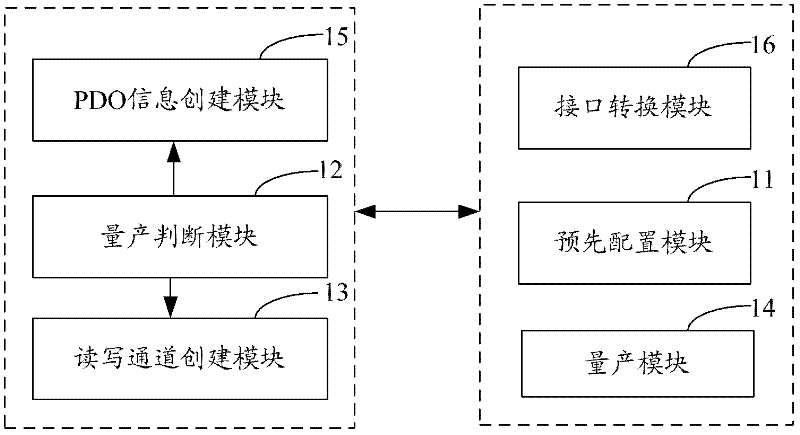

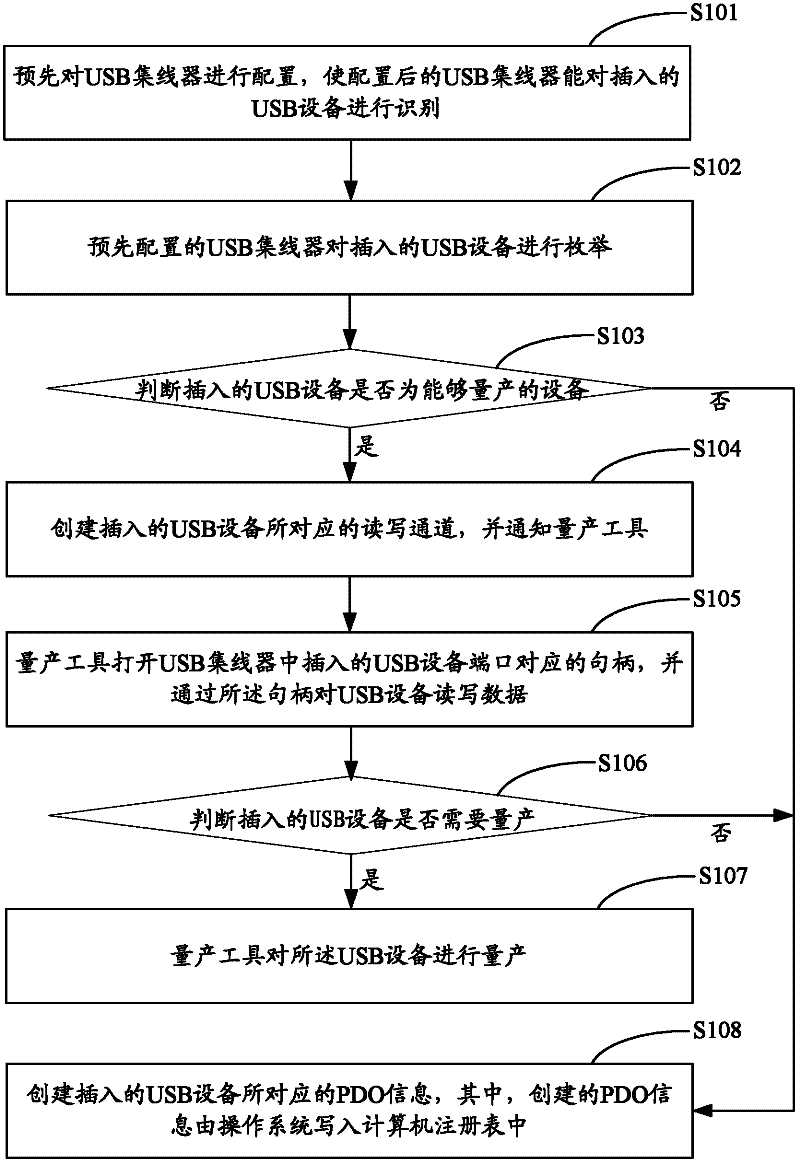

Mass production method and system thereof for USB (universal serial bus) devices

InactiveCN102236618AQuick identificationRapid mass productionElectric digital data processingUSB hubEngineering

The invention is suitable for the technical field of USB (universal serial bus) mass production, and provides a mass production method and a system thereof for USB devices. The method comprises the following steps of: pre-configuring a USB hub so as to enable the configured USB hub can identify the inserted USB devices; enumerating the inserted USB devices by the pre-configured USB hub to identify and judge whether the inserted USB devices are suitable for mass production; if so, creating a read / write channel corresponding to the inserted USB devices, and notifying a mass production tool; opening handles corresponding to ports of the USB devices inserted in the USB hub by the mass production tool, reading and writing data for the USB devices through the handles, and judging whether the inserted USB devices are needed to be produced massively, if so, performing mass production for the USB devices by the mass production tool. The embodiment of the invention implements that, in the mass production process of the USB devices, the USB devices are quickly identified, the handles of the USB devices are obtained in time, mass production speed is fast and mass production efficiency is improved.

Owner:SHENZHEN NETCOM ELECTRONICS CO LTD

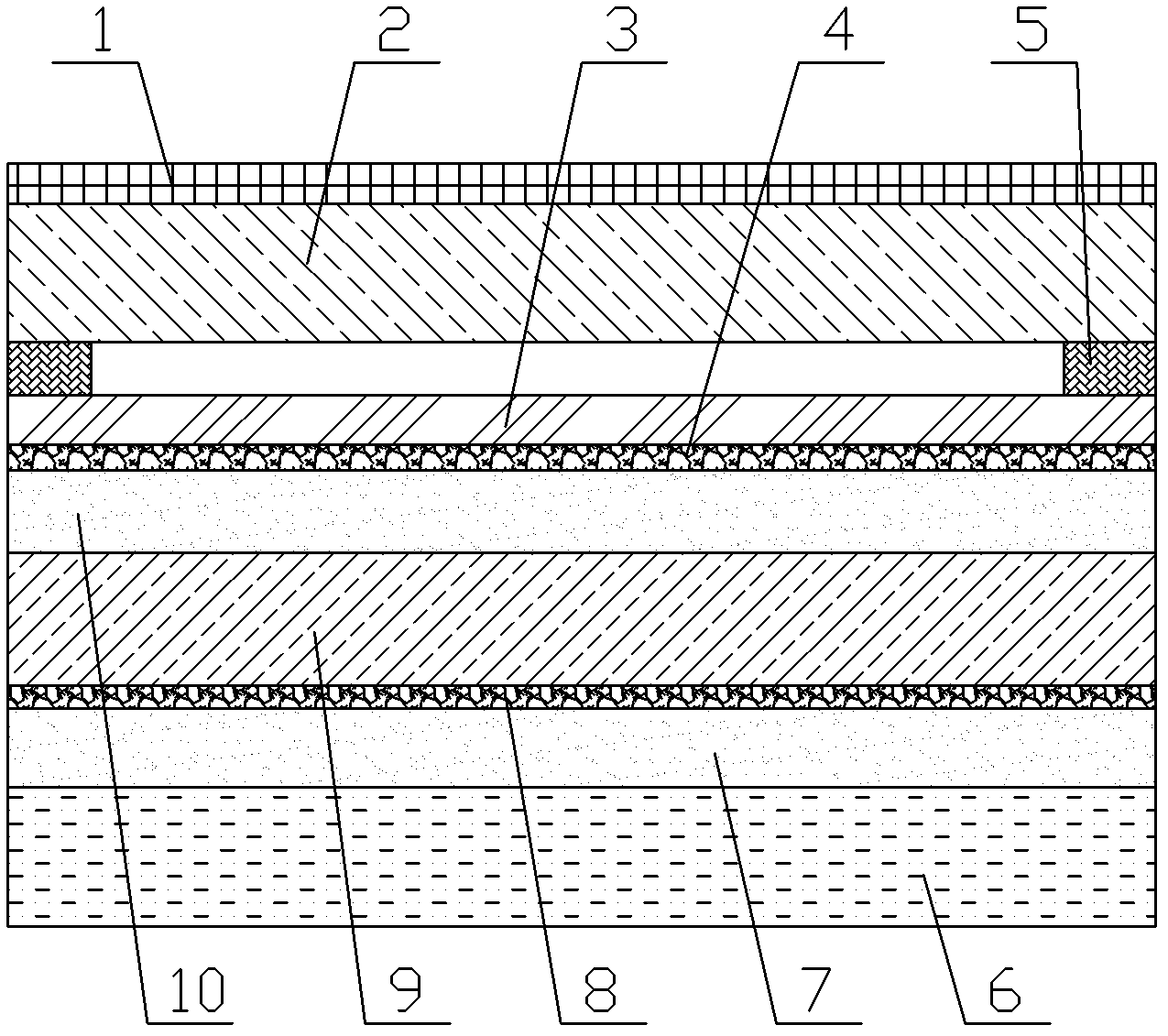

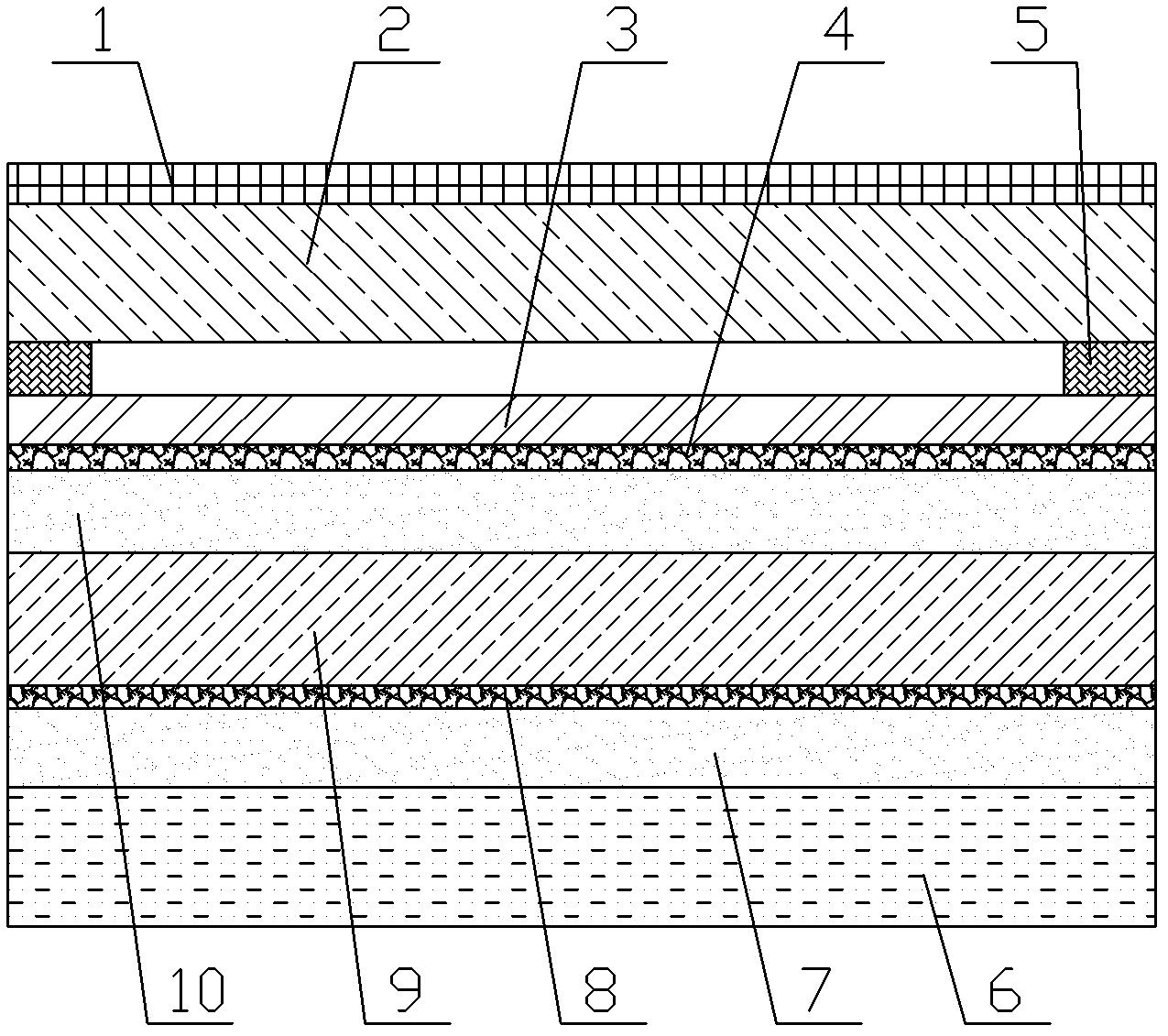

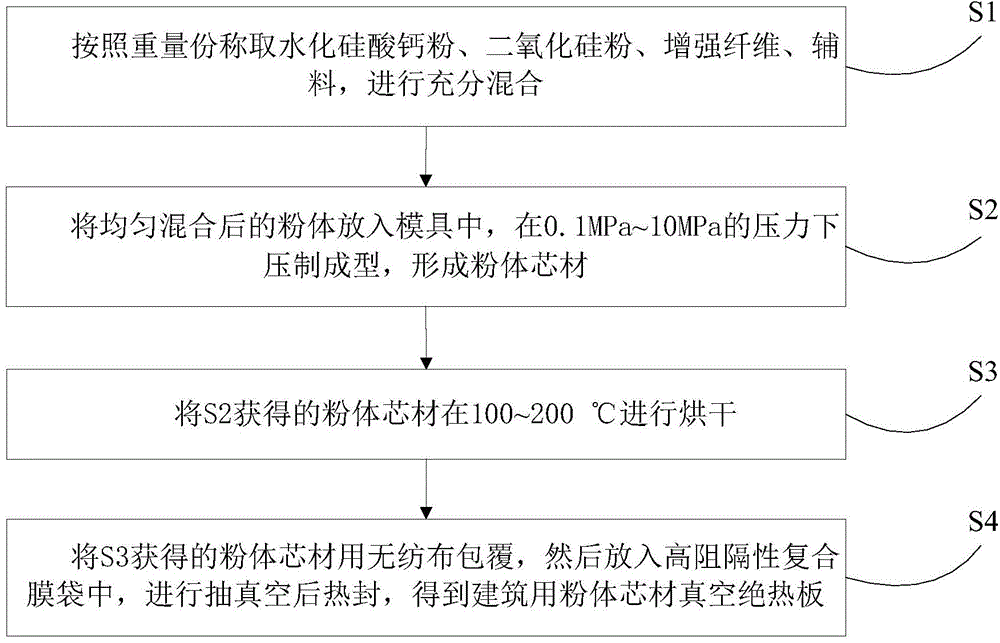

Powder core vacuum insulation panel for building and preparing method thereof

ActiveCN104631634AImprove mass production efficiencyHigh compressive strengthClimate change adaptationInsulation improvementCalcium in biologyFiber

The invention discloses a powder core vacuum insulation panel for a building and a preparing method of the powder core vacuum insulation panel. Calcium silicate hydrate powder, silicon dioxide powder, reinforced fibers and auxiliary materials are fully mixed, the mixed powder is pressed to be formed and dried, a dried powder core is wrapped by non-woven fabric and put into a high-barrier-property composite film bag, and the powder core is manufactured in a heat seal mode after vacuum pumping is conducted, wherein the calcium silicate hydrate powder is prepared by calcium raw materials and silica raw materials through a liquid chemistry reaction. According to the powder core vacuum insulation panel for the building, the calcium silicate hydrate powder serves as the main raw material of the powder core, weight is low, price is low, and the powder core is resistant to fires and flames, has good compression strength and a low heat conduction coefficient and can be applied to the field of building wall insulation. The invention further provides a preparing method of the powder core vacuum insulation panel for the building. The preparing method is simple and high in volume production efficiency.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

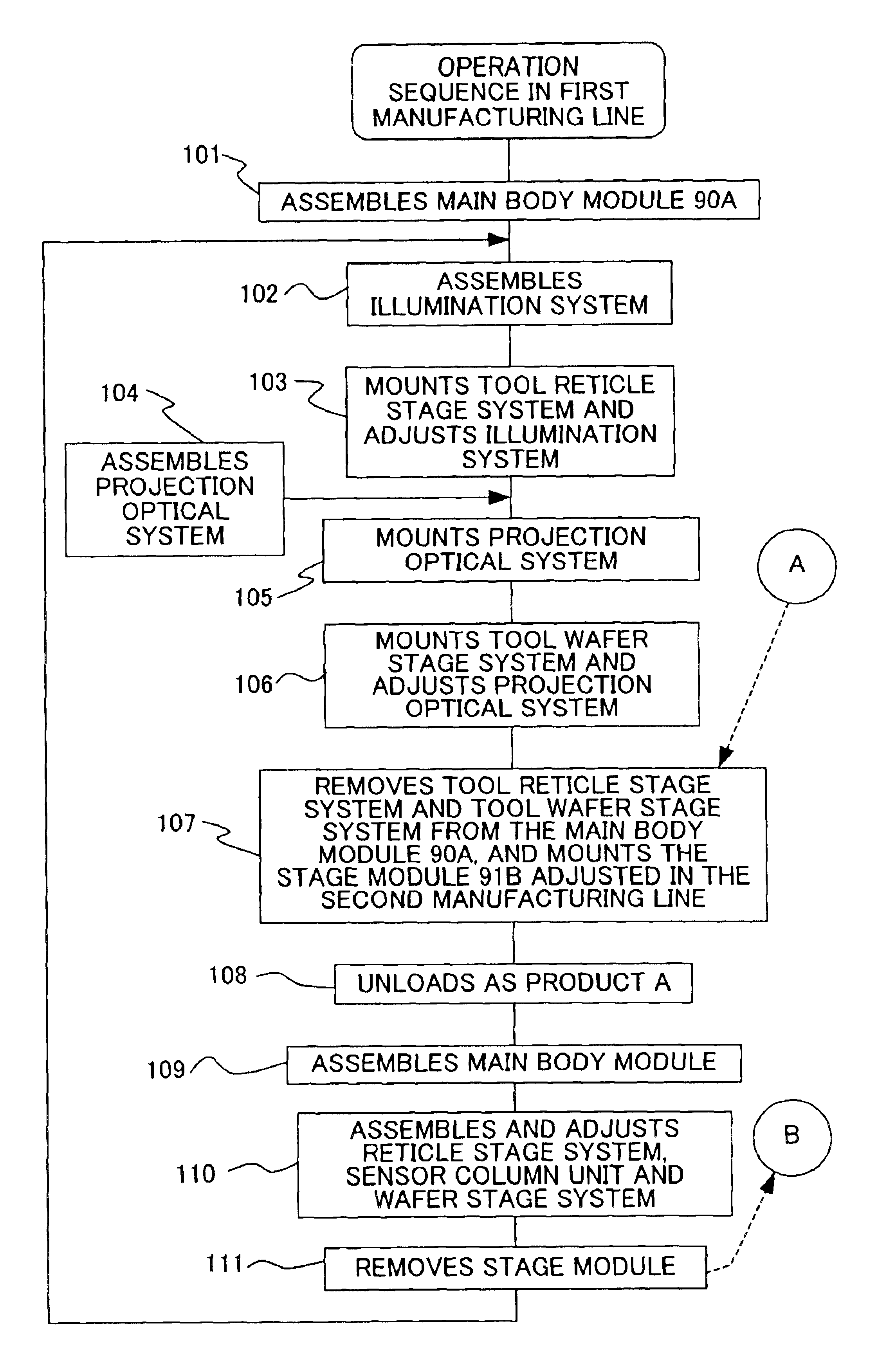

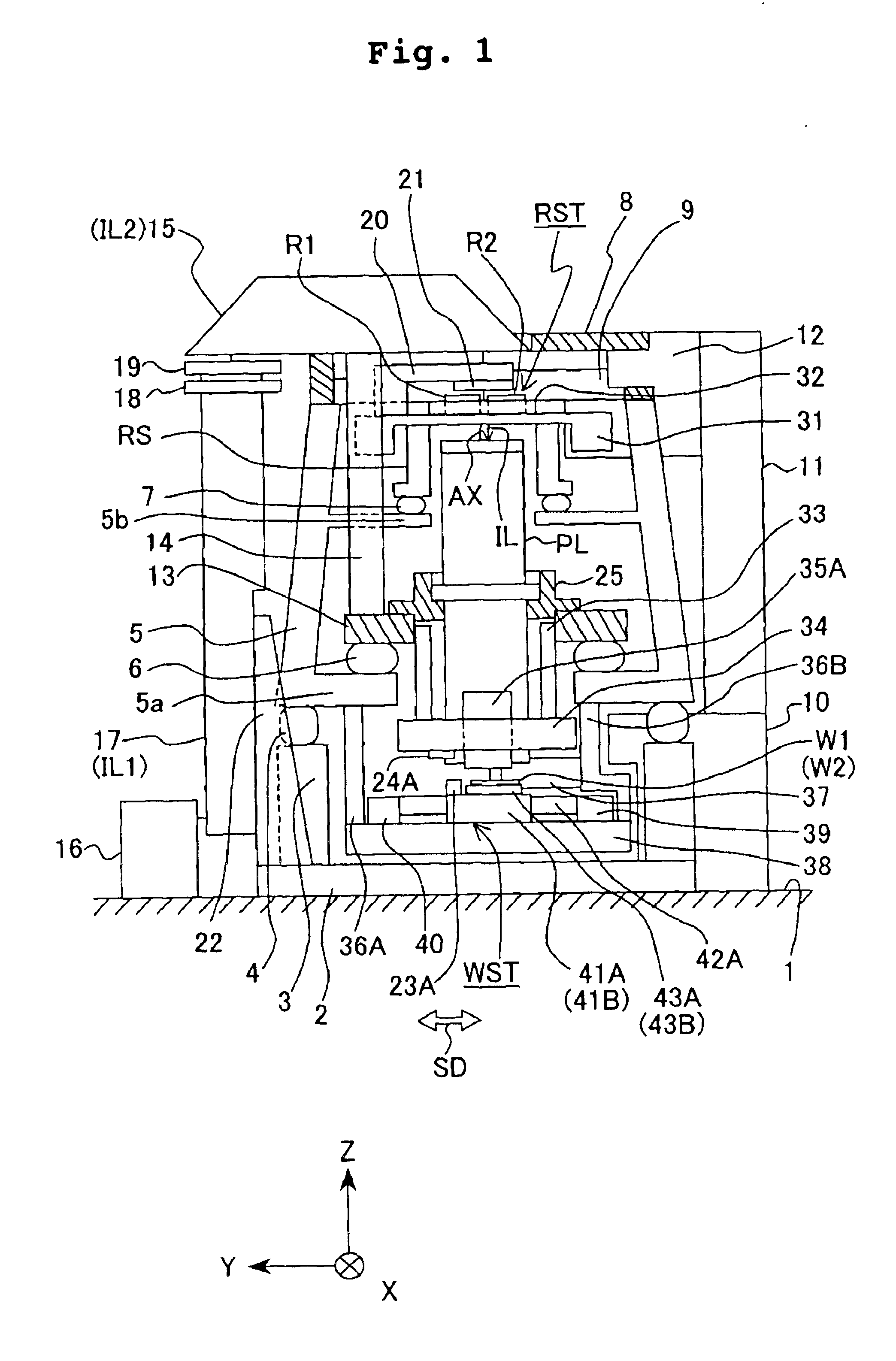

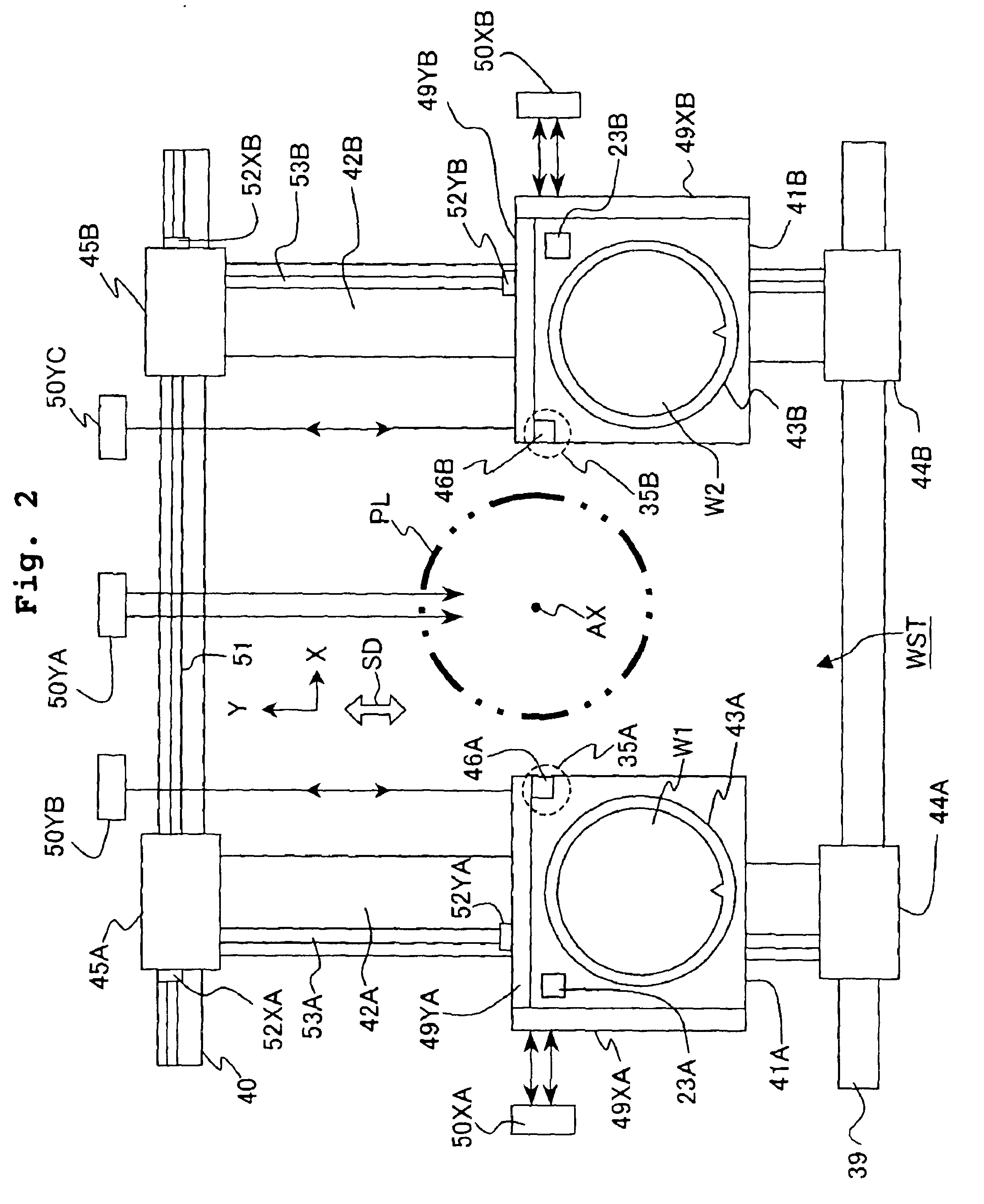

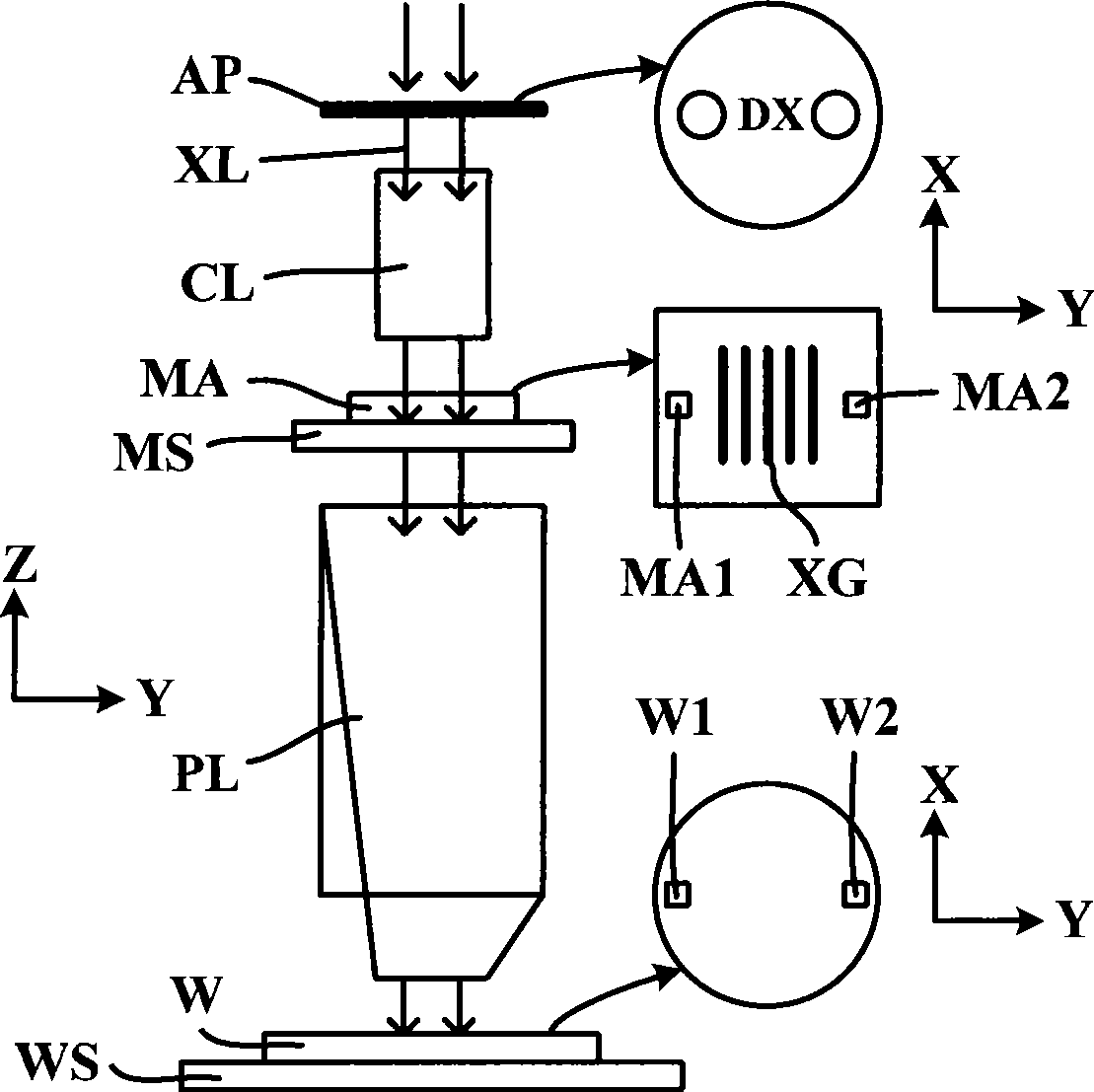

Manufacturing method in manufacturing line, manufacturing method for exposure apparatus, and exposure apparatus

InactiveUS6891603B2Easily removed/attachedLarge scaleAssembly machinesSemiconductor/solid-state device manufacturingEngineeringLighting system

A manufacturing method for exposure apparatuses is provided in which a reticle R1 held on a reticle stage system (RST) is illuminated by exposure light from an exposure light source (16) via the illumination systems (IL1) and (IL2). In a first manufacturing line, a main body module composed of a frame caster (2), a main body support section 3), and a main body column (5) is assembled, and an illumination system and the projection optical system PL are mounted on this main body module. Then a stage module, which is assembled and adjusted using another main body module in a second manufacturing line, is mounted on the main body module of the first manufacturing line. Therefore exposure apparatuses can be efficiently manufactured without using dedicated large scale adjustment jigs.

Owner:NIKON CORP

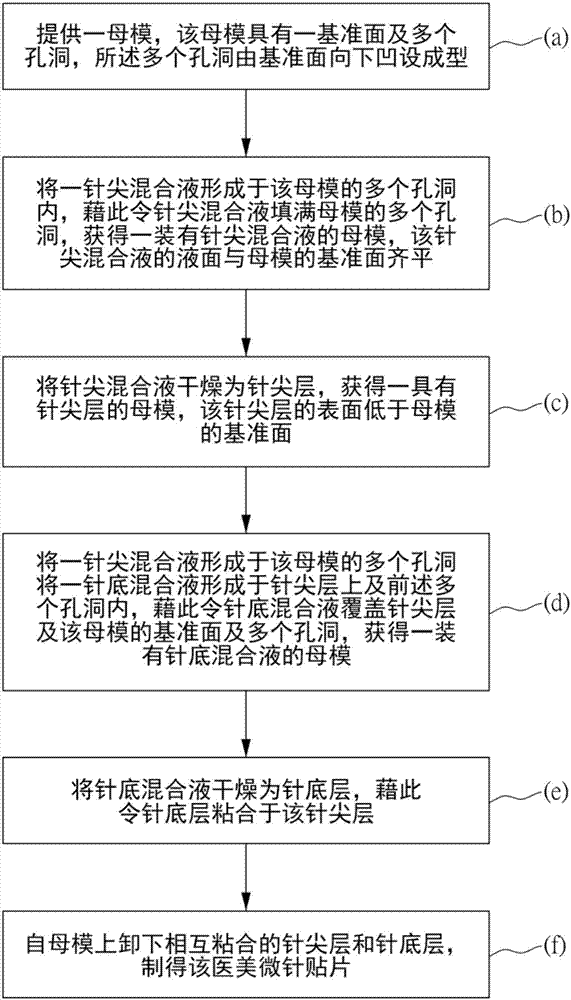

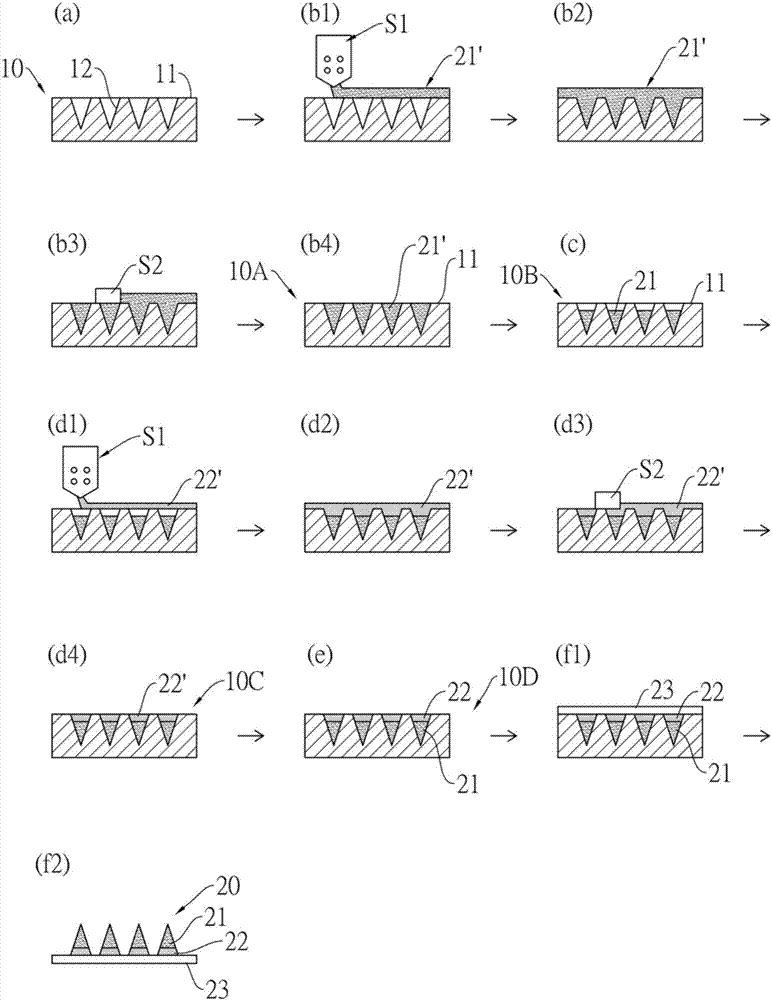

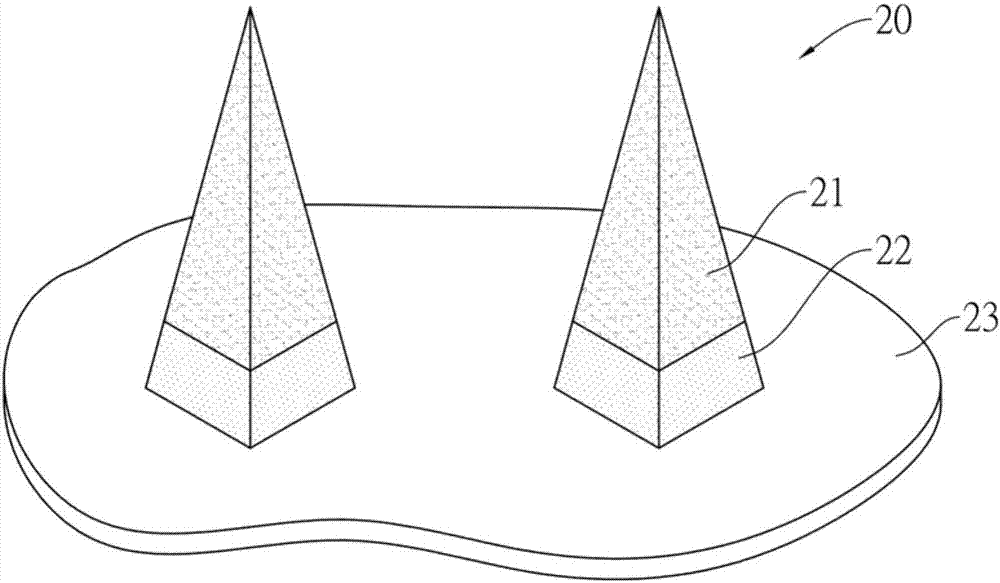

A preparing method of a cosmetic medical microneedle paster

ActiveCN107343984AOvercome bondingOvercoming machine alignmentMicroneedlesMedical devicesActive componentBiomedical engineering

The invention relates to a preparing method of a cosmetic medical microneedle paster. The method includes firstly forming a needle top liquid mixture containing a cosmetic medical active component in a plurality of holes of a female die; drying the mixture to form a needle top layer; then forming a needle bottom liquid mixture in the plurality of holes and on the needle top layer; then drying the needle bottom liquid mixture to form a needle bottom layer so that the needle bottom layer is adhered to the needle top layer; and finally dismounting the needle top and bottom layered which are adhered to each other from the female die to obtain the plaster. The method overcomes problems of adhesion, machine position aligning, and production costs in microneedle paster manufacturing in the prior art, saves process time, and increases the efficiency of mass production. The preparing method suitable for large-scale production of the cosmetic medical microneedle paster is provided.

Owner:WIN COAT CORP

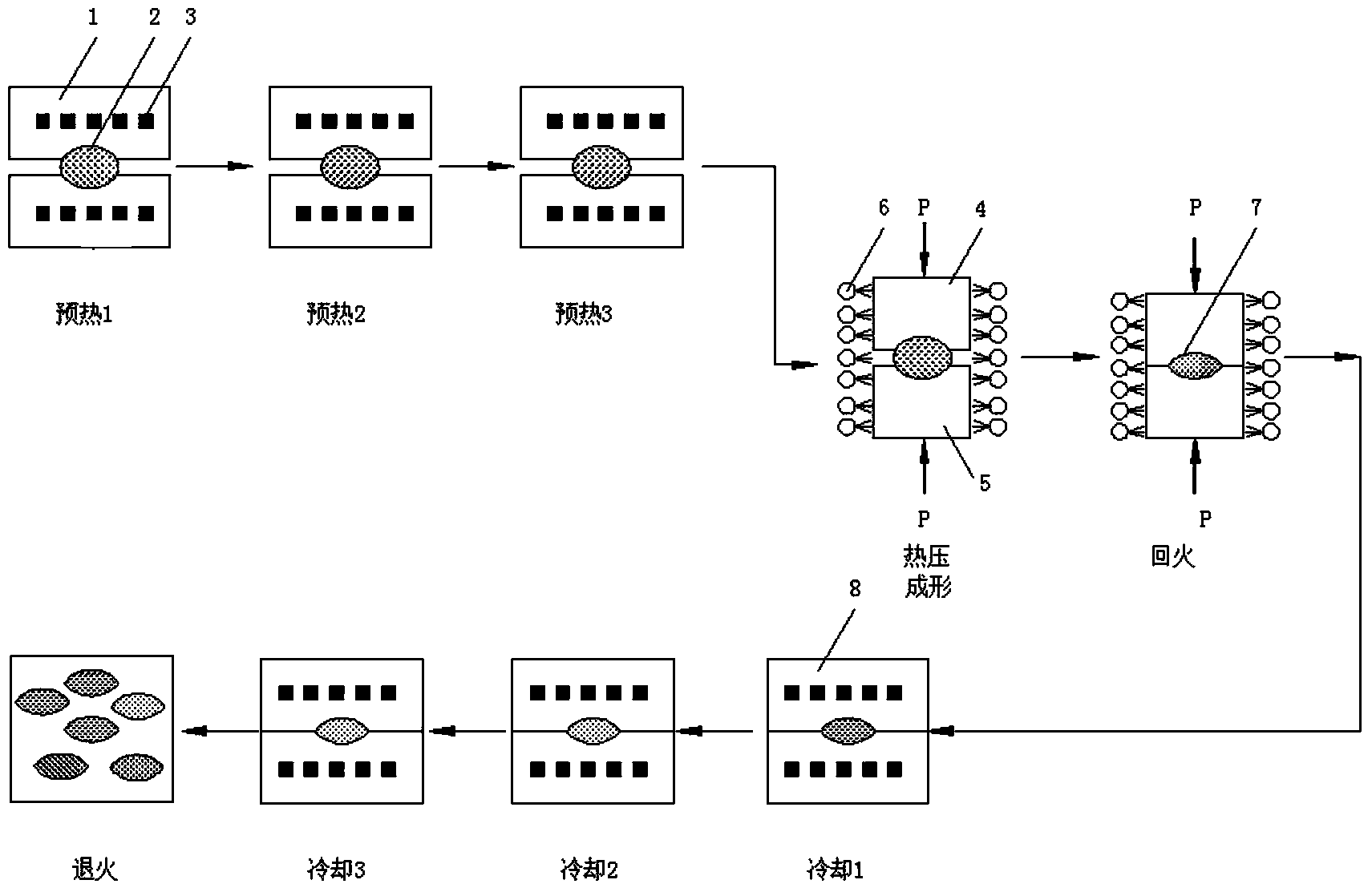

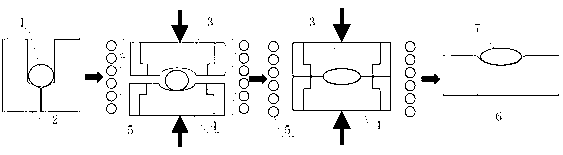

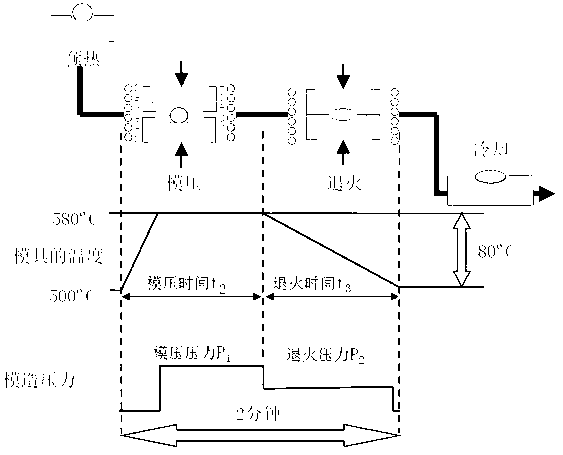

Non-isothermal mold pressing method for glass optical element

ActiveCN103214161AExtended service lifeImprove mass production efficiencyGlass pressing apparatusGlass productionComposite materialBatch production

The invention discloses a non-isothermal mold pressing method for a glass optical element. According to the method, the steps of glass preformed piece preheating, mold pressing shaping, optical element cooling and the like are performed in parallel in the mold pressing process, and the glass preformed piece preheating temperature and the mold pressing temperature are respectively controlled. The method mainly comprises the steps: preheating, namely heating a glass preformed piece to the temperature T1 in a preheating tank; pressurizing, namely maintaining the mold upper die and the mold lower die to the temperature T2 under the action of the heating device, wherein T1 is more than T2, arranging the preformed piece in a mold pressing cavity, applying pressure to the upper die and the lower die, heating the mold to be T3, maintaining for a certain period of time, and performing die forming on the preformed piece to form an optical element; annealing, namely slowly reducing the temperature of the optical element to be T2 in the mold pressing cavity; and cooling, taking the glass optical element from a die cavity, and cooling the optical element to be room temperature on a cooling plate. The method has the advantages of prolonging the service life of the mold pressing die and improving the batch production efficiency of the glass optical element.

Owner:吴佑林

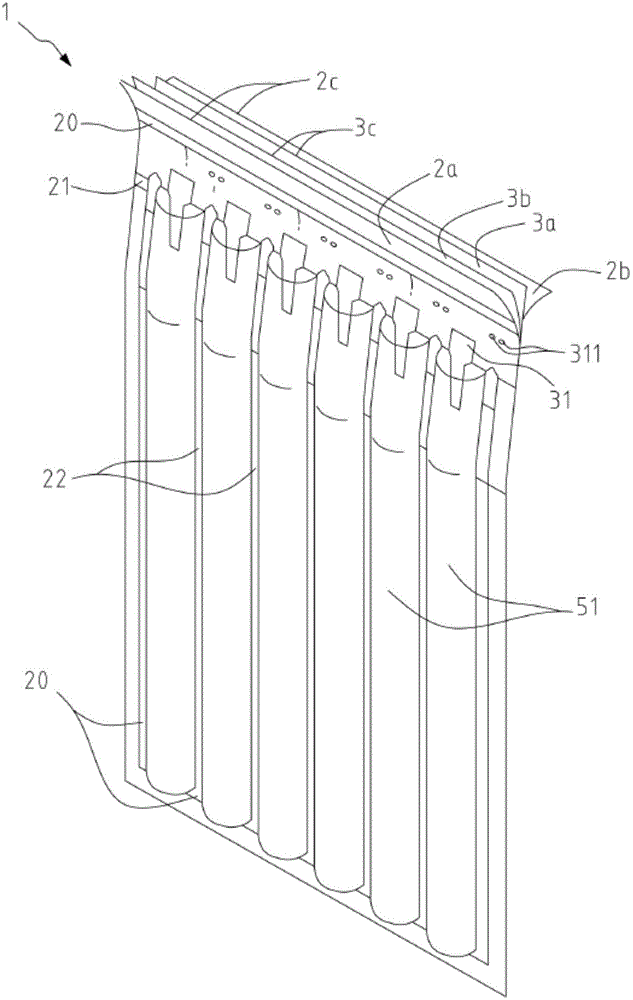

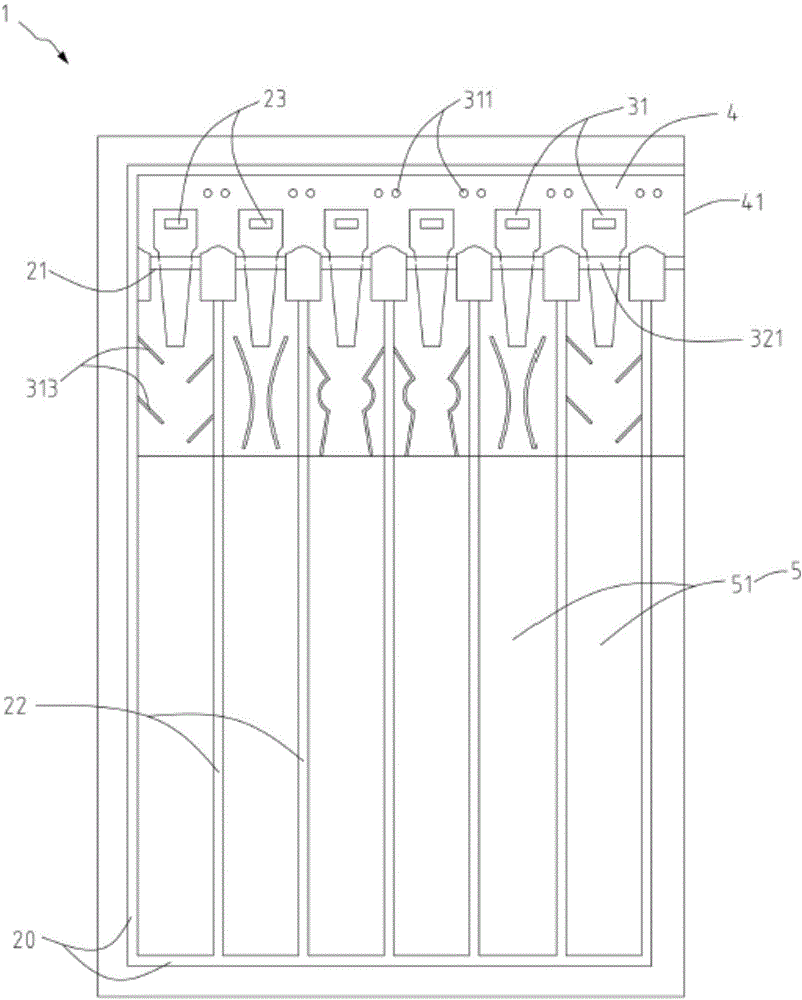

Battery pack

InactiveUS7597994B2Mass-productivity is degradedPoor moldabilitySmall-sized cells cases/jacketsVent arrangementsRechargeable cellBattery pack

Owner:PANASONIC CORP

Method for quickly detecting thickness of lower surface of blade in high-temperature thermal state

InactiveCN103673829AShorten detection timeSimple structureMechanical thickness measurementsThermal stateEngineering

The invention provides a method for quickly detecting the thickness of the lower surface of a blade in a high-temperature thermal state and aims at solving the problem of low detection efficiency of a traditional method. The method is characterized in that an inner cambered surface floating detection sample plate and a back cambered surface floating detection sample plate which are matched with the inner cambered surface and the back cambered surface of the blade to be detected are respectively manufactured according to the shape of the blade to be detected, detection regional holes are respectively and correspondingly cut and formed in the inner cambered surface floating detection sample plate and the back cambered surface floating detection sample plate according to the position of the thickness of the surface to be detected on the blade to be detected, then the inner cambered surface floating detection sample plate and the back cambered surface floating detection sample plate tightly adhere to the inner cambered surface and the back cambered surface of the blade to be detected, and then a pair of outside calipers is utilized to detect the thickness of a blade forge piece between the detection regional holes in the inner cambered surface floating detection sample plate and the back cambered surface floating detection sample plate of the blade to be detected.

Owner:WUXI TURBINE BLADE

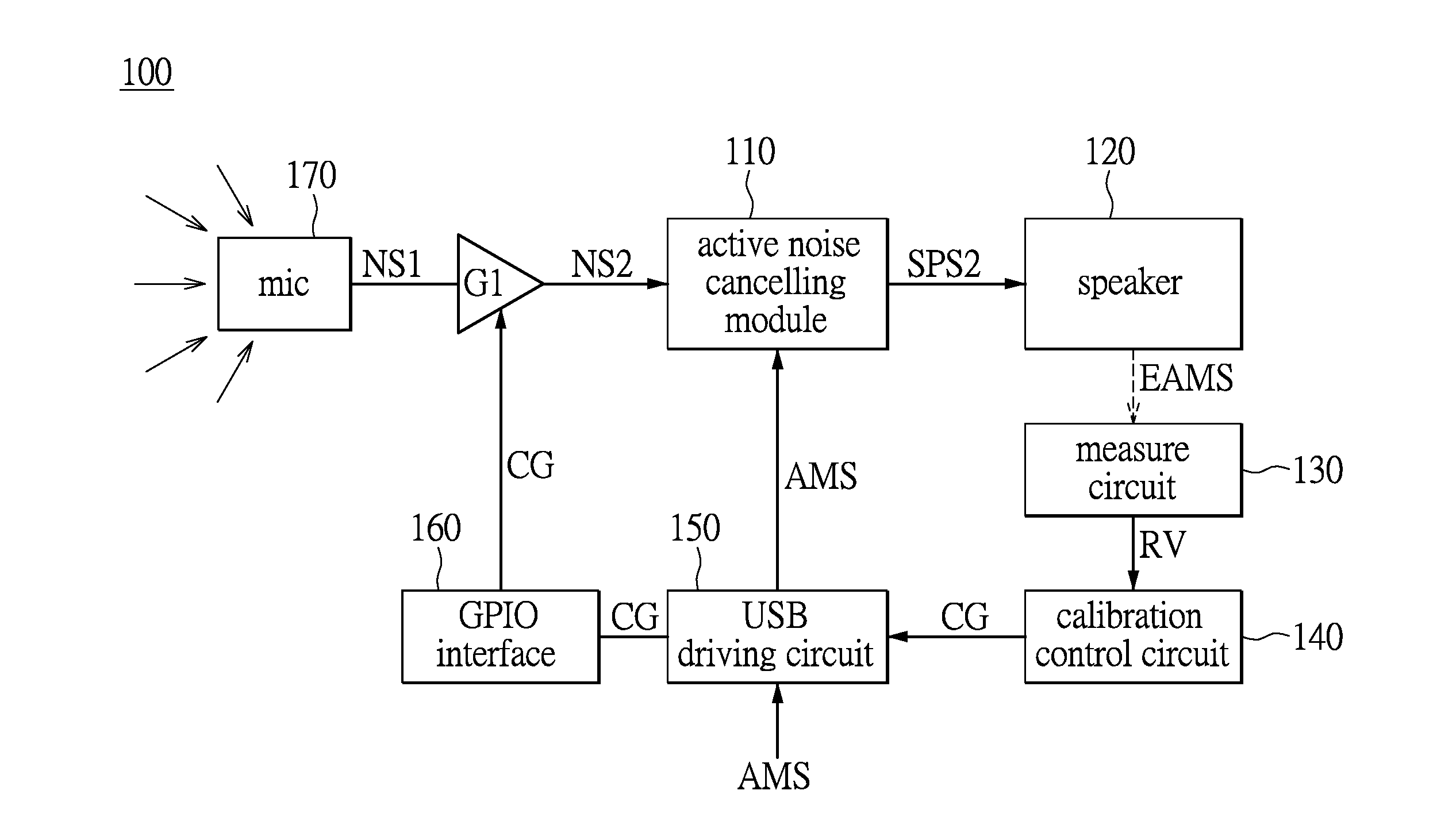

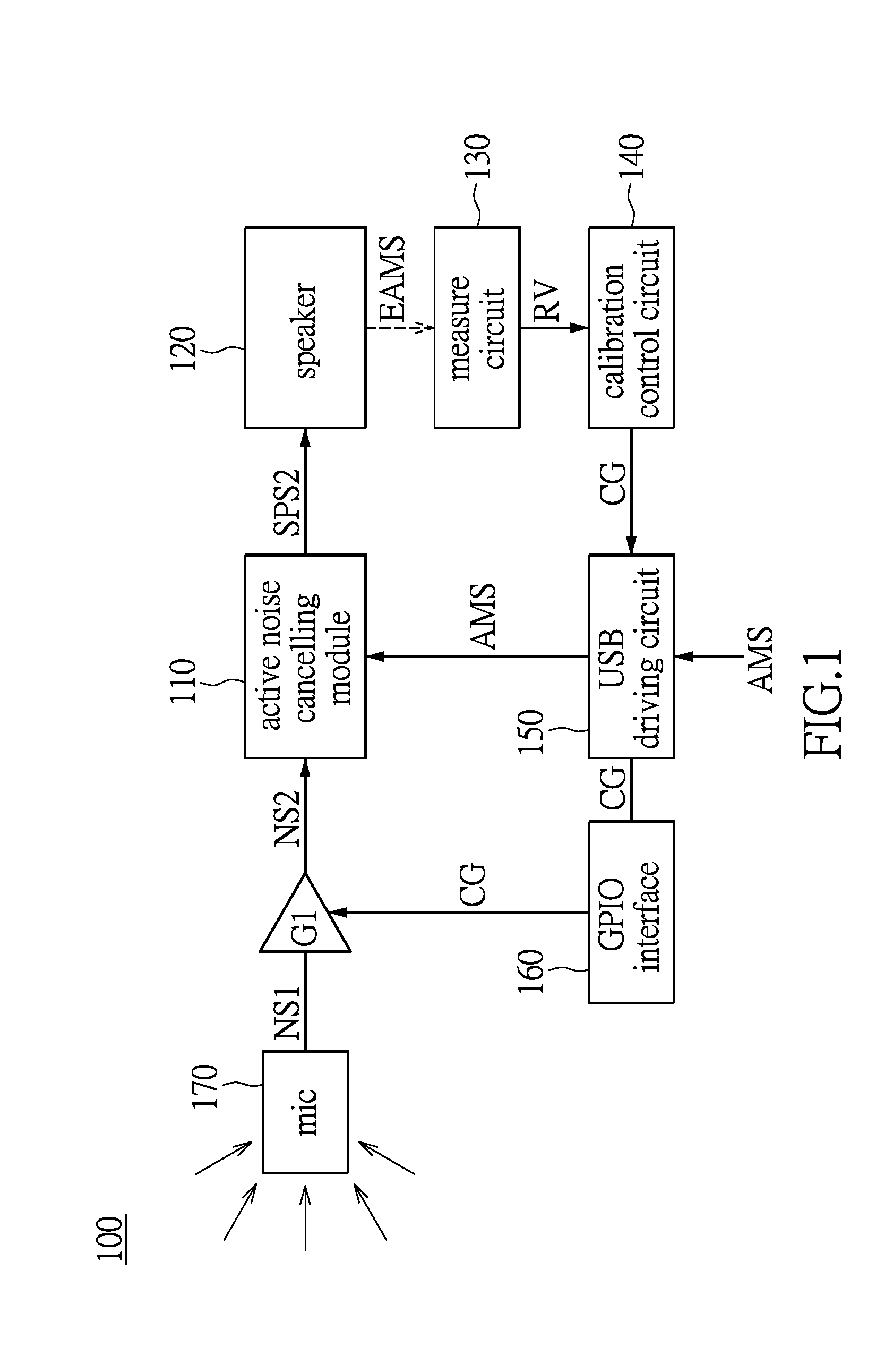

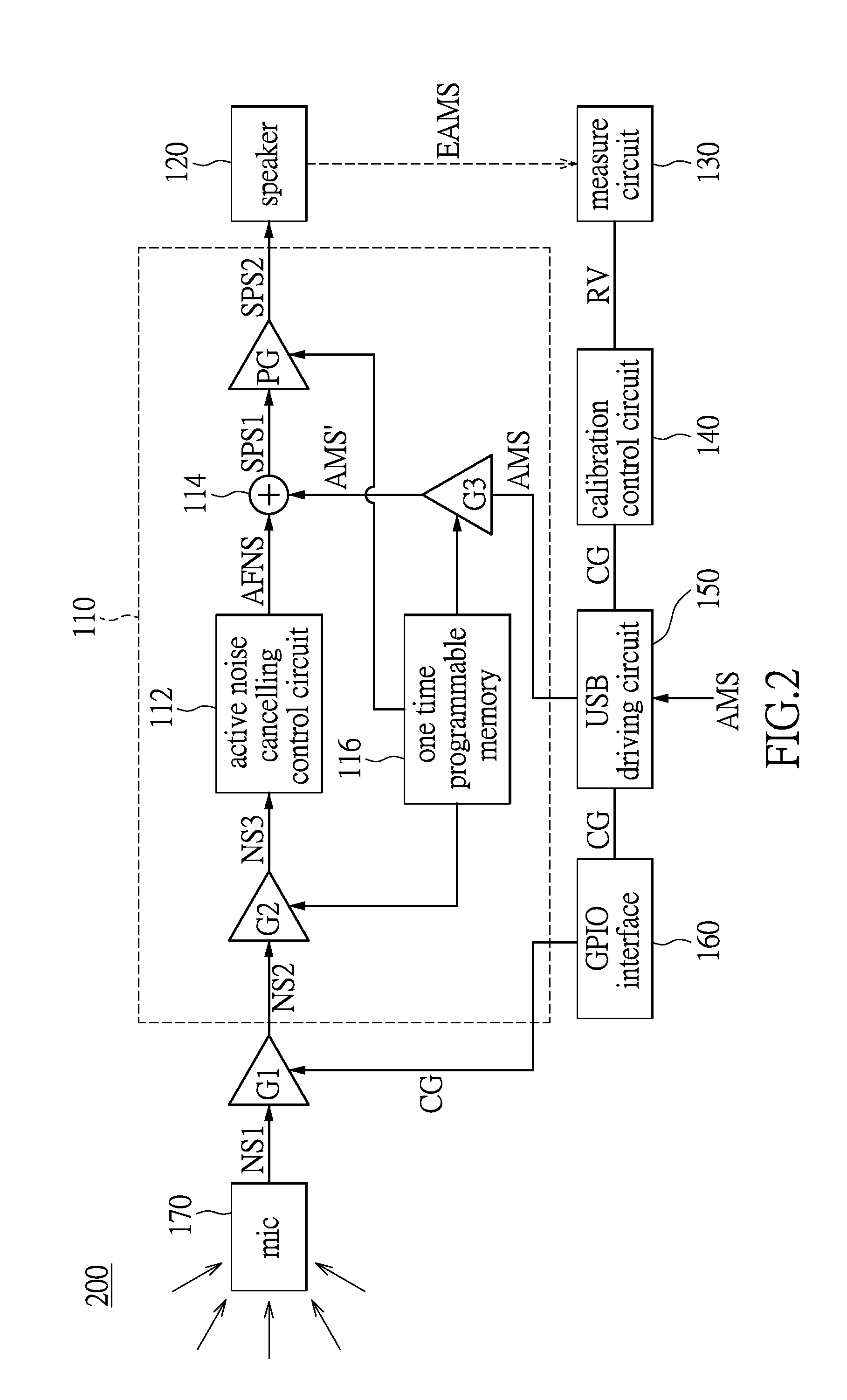

Headphone with active noise cancelling and auto-calibration method thereof

ActiveUS20150092951A1Improve mass production efficiencyReduce calibration timeEar treatmentHearing device active noise cancellationAudio power amplifierEngineering

A headphone with active noise cancelling and auto-calibration method thereof is disclosed. The headphone includes a first gain-amplifier, an active noise cancelling module, a speaker, a measurement circuit, a calibration control circuit and USB driving circuit. Auto-calibration of the headphone is by means of a USB interface in the instant disclosure, so as to significantly reduce calibration time and then improve production efficiency.

Owner:C-MEDIA ELECTRONICS INC

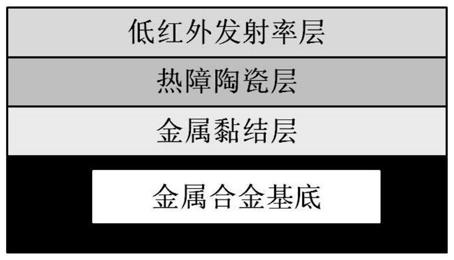

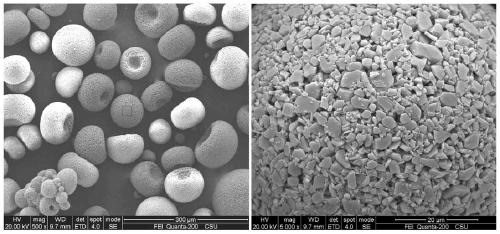

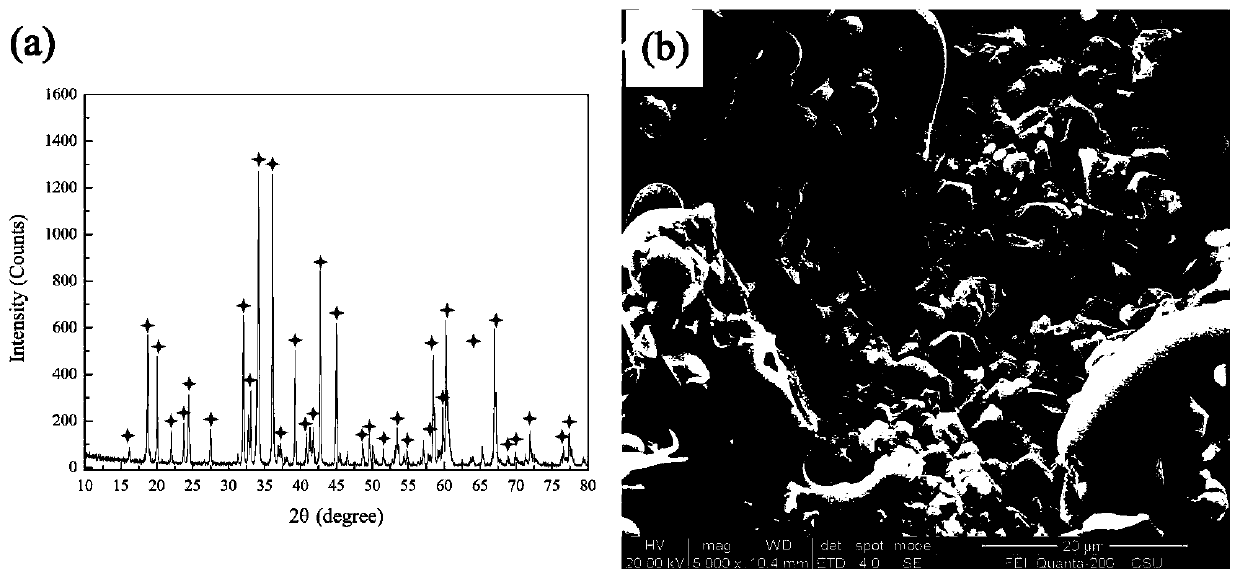

Thermal barrier/high-temperature low infrared emissivity integrated coating, metal composite material with coating and preparation method thereof

ActiveCN110117764AImprove temperature resistanceImprove thermal insulation performance and bond strengthMolten spray coatingBonding strengthMetal

The invention discloses a thermal barrier / high-temperature low infrared emissivity integrated coating. The coating is of a multilayer stacked structure. The multilayer stacked structure successively comprises a metal bonding layer, a thermal barrier ceramic layer and a low infrared emissivity layer from inside to outside. The thermal barrier ceramic layer is a rare earth hexaaluminate layer, and the low infrared emissivity layer is a Bi2O3-MgO-Al2O3-Li2O-SiO2 serial glass coating containing a conductive phase Pd powder. The integrated coating has the advantages of heat-insulating property, high-temperature low infrared emissivity, high bonding strength and the like. The metal composite material with the coating is simple and manure in process, relatively low in cost and easy for scaled production and application.

Owner:NAT UNIV OF DEFENSE TECH

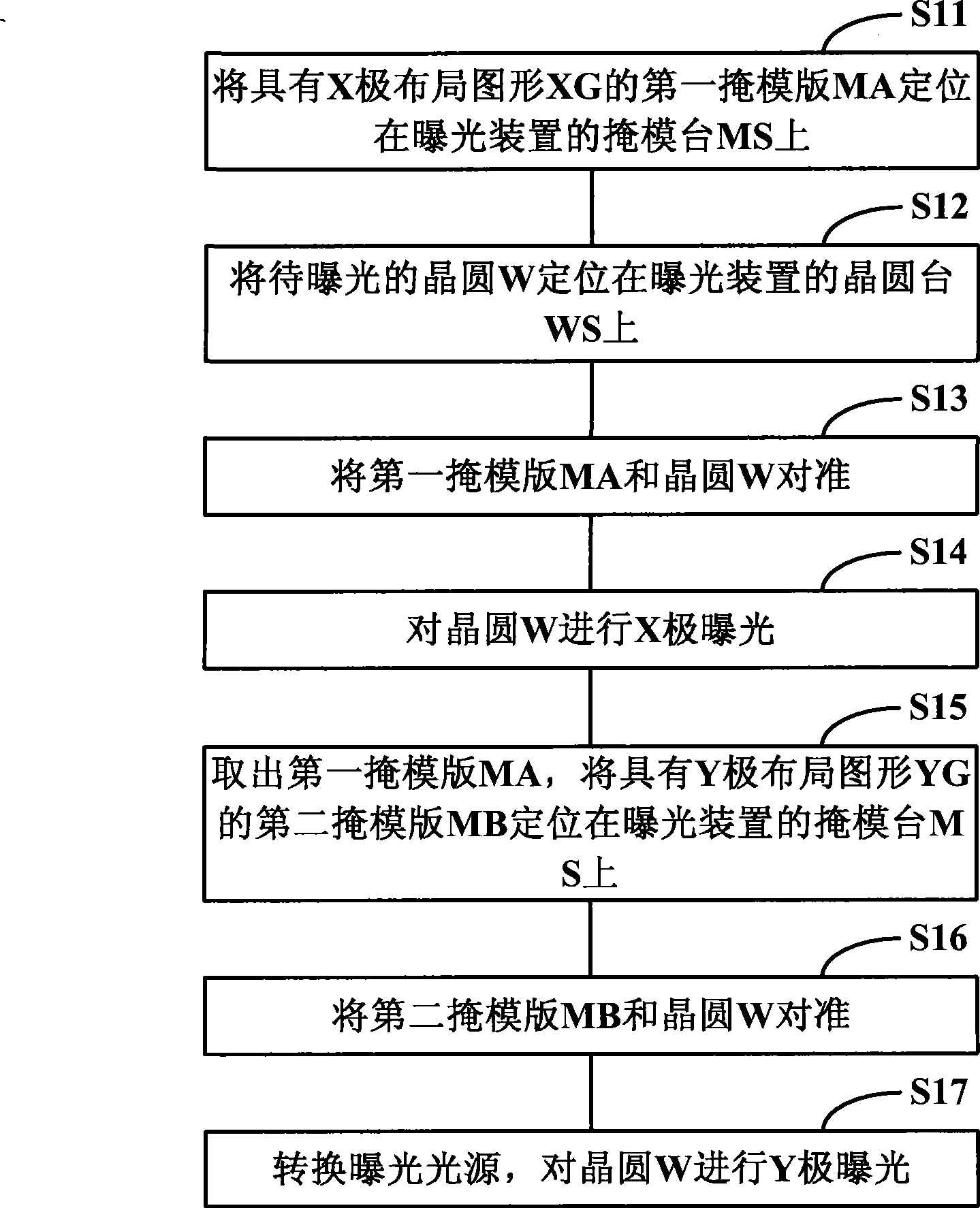

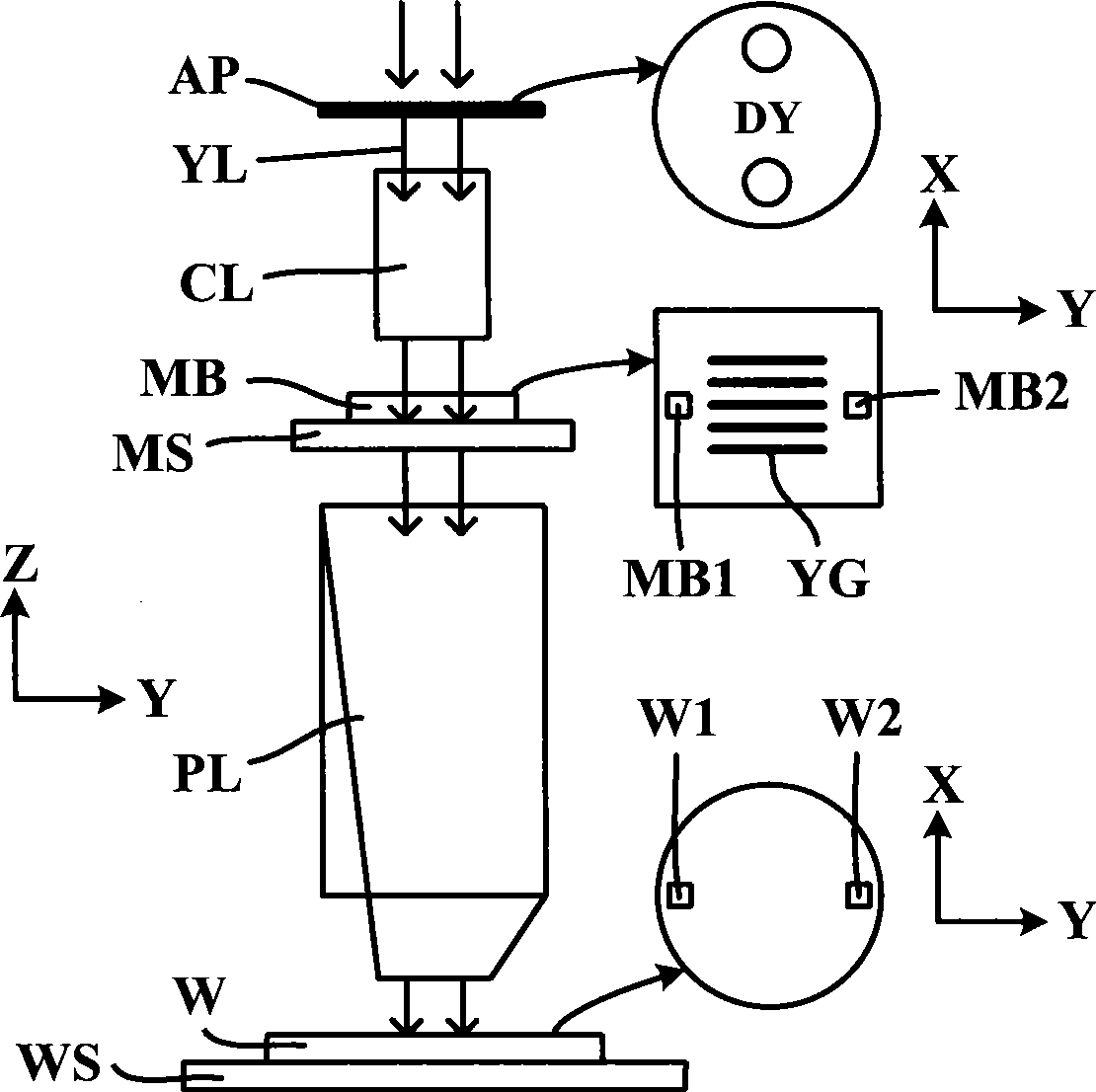

Exposure device and method

InactiveCN101458455ATimely processing stepsEliminates alignment stepsPhotomechanical exposure apparatusMicrolithography exposure apparatusElectrical and Electronics engineering

The invention relates to an exposure device and a method thereof. The exposure method comprises: positioning a first mask plate provided with a first direction layout pattern and a second mask plate provided with a second direction layout pattern on a mask table which has an area for supporting the first mask plate and the second mask plate; positioning a wafer to be exposed on a wafer table; aligning the first mask plate with the wafer to be exposed; exposing the wafer in the first direction; aligning the second mask plate with the wafer to be exposed; and exposing the wafer in the second direction. The exposure device and the method thereof save the steps of converting the mask plates and aligning the mask plates with the mask table, so as to shorten exposure time, and improve production efficiency and performance of products.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Atomic frequency acquiring apparatus and atomic clock

ActiveUS7446618B2Improve mass production efficiencySmall sizeLaser detailsGaseous masersAcquisition apparatusLaser light

An atomic frequency acquisition apparatus includes: a cell enclosing atomic gas therein; a laser light source that oscillates laser light that enters the cell and excites the atomic gas; and a photodetecting section that detects the laser light that has passed the cell, wherein the laser light source and the photodetecting section are attached to a common surface facing an interior of the cell, and the cell has a first reflection section on which the laser light oscillated from the laser light source is incident at an incident angle of 45 degrees, and a second reflection section on which the laser light reflected by the first reflection section is incident at an incident angle of 45 degrees.

Owner:MICROCHIP TECH INC

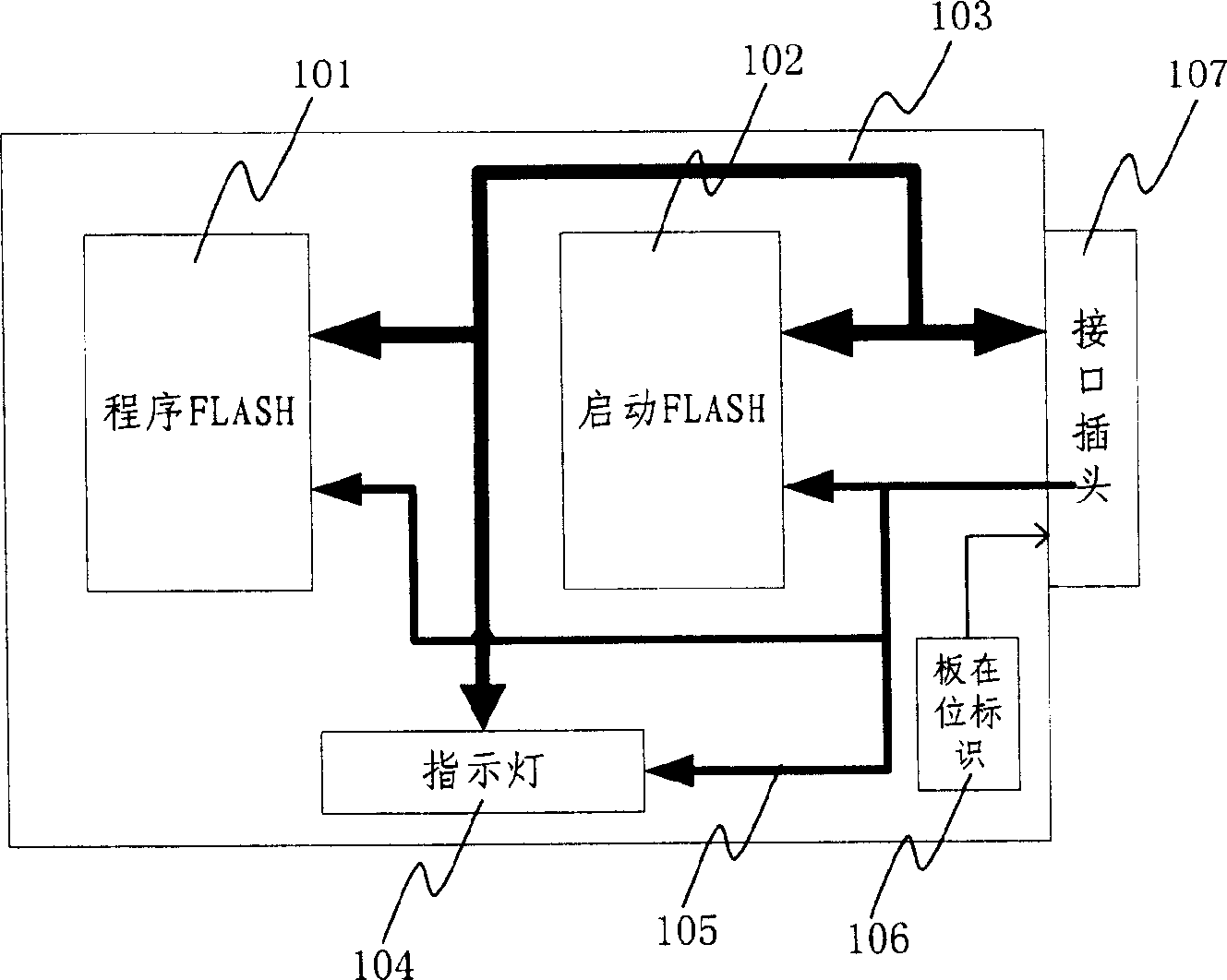

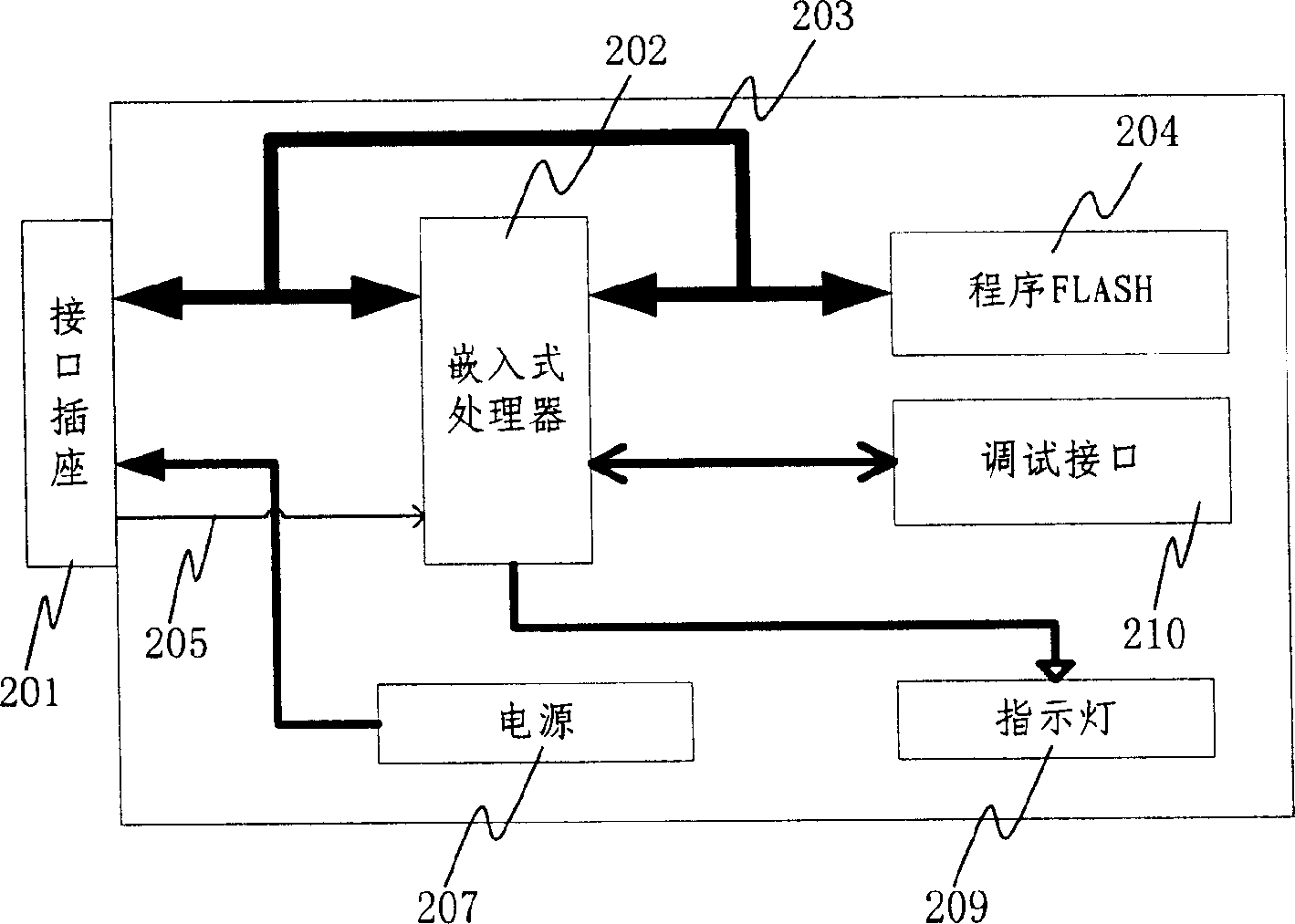

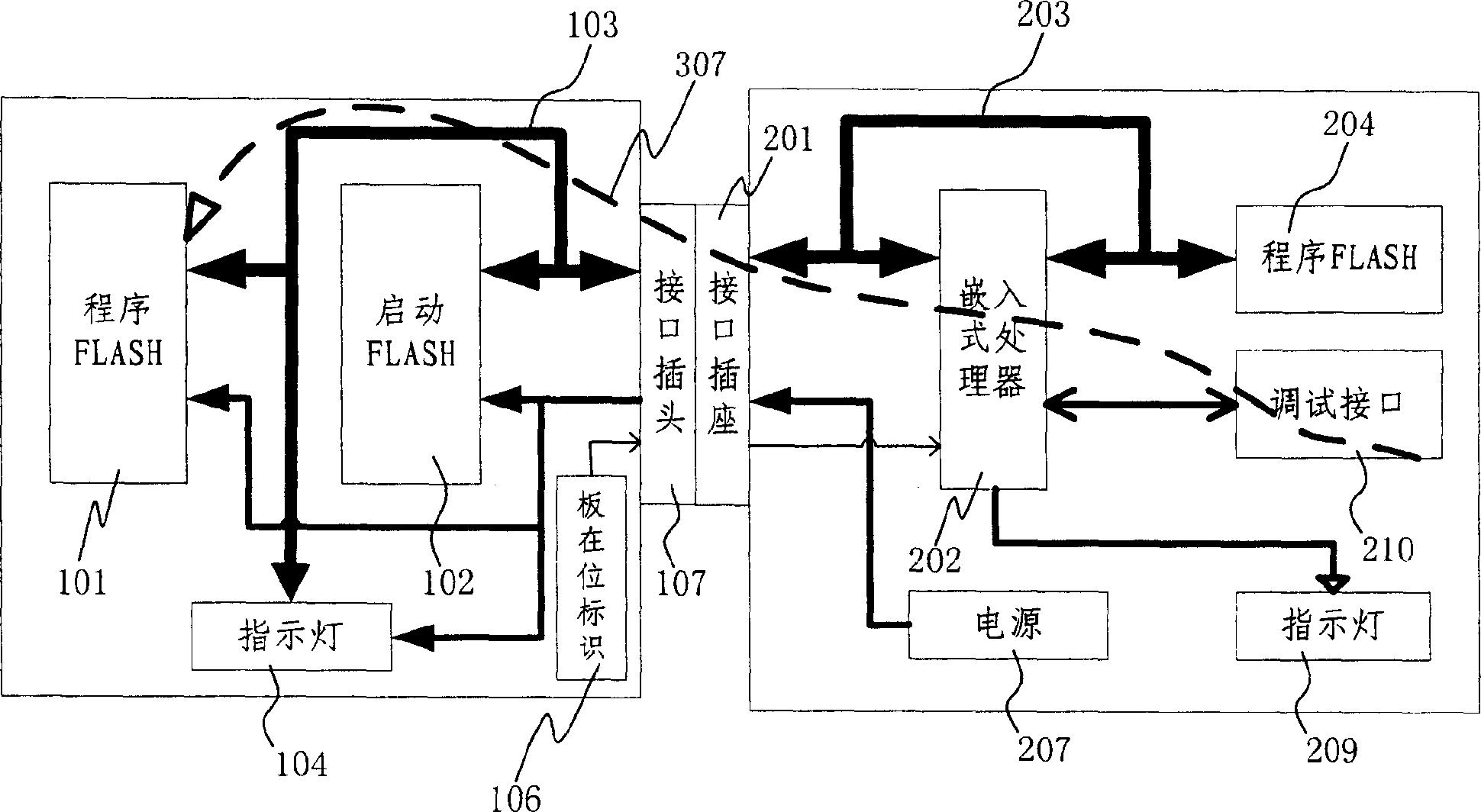

Single board software downloading method and apparatus

ActiveCN1790264ALow costNo impact on reliabilityProgram loading/initiatingMemory interfaceProgram code

The invention discloses one-board software loading method and device, which is characterized by the following: preforming the loading interface on the one-board; adapting the interface as the exterior storage interface of embedded disposer; articulating the loading plate as the auxiliary single-board on the interface; naming the loading software single-board as the object board; storing the program code of object board in the loading board; plugging the loading board in the object board; guiding the embedded disposer to start the beginning program; writing the program code of object board on the loading board in the object flash memory of object board. The invention simplifies the loading operation without other equipment and trained operator, which improves the production efficiency of single-board greatly.

Owner:ZTE CORP

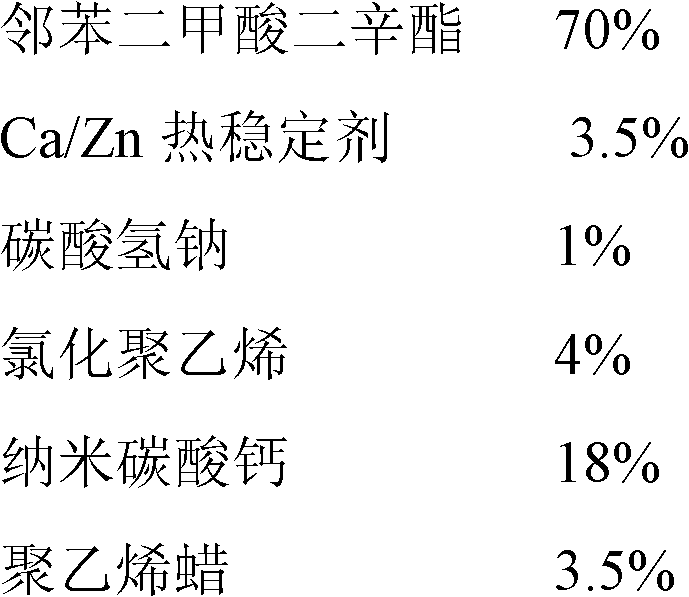

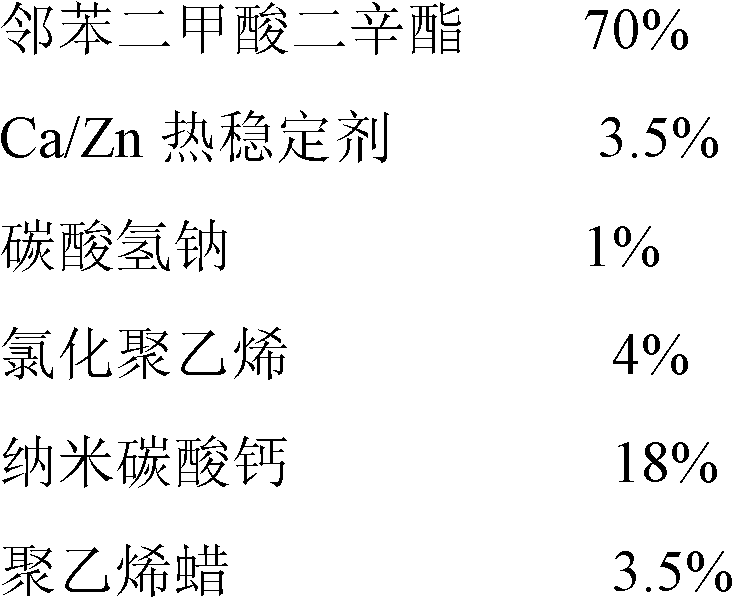

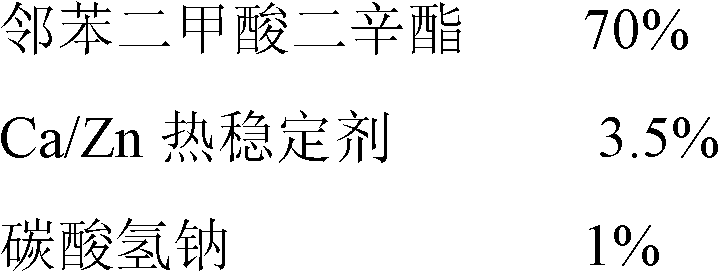

Conducting shoe material and manufacturing method thereof

The invention discloses a conducting shoe material and a manufacturing method thereof. The conducting shoe material is prepared from polyvinyl chloride, a composite conducting component consisting of conducting fiber and conducting powder, and an aid, wherein the composite conducting component is pretreated with a stearic acid-coupling agent treating liquid. The manufacturing method comprises the following steps of: (1) pretreating: pretreating the conducting fiber and the conducting powder through the stearic acid-coupling agent treating liquid; (2) mixing: mixing the polyvinyl chloride, a plasticizer and a stabilizer at a high speed, adding a foaming agent, a solubilizer and the composite conducting component pretreated with the stearic acid-coupling agent treating liquid for mixing; (3) extruding: plasticizing and extruding a mixed material, and cutting to obtain particles; and (4) injection molding: performing injection molding on the particles through an injection molding machine at the temperature of 160 DEG C to obtain a finished shoe material. In the conducting shoe material disclosed by the invention, the conducting component is uniformly dispersed, an effective conducting network can be formed, and cost is low. The manufacturing method has a simple structure and low cost, and can be applied to large-scale production.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com