Polarizer, display panel, display panel forming method and display device

A technology of display panels and polarizers, applied in optics, optical elements, polarizing elements, etc., can solve problems such as the inability to meet the mass production requirements of touch-type liquid crystal display panels, and the complicated attaching process of touch panels, so as to achieve simple and simplified lamination Fitting process, strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

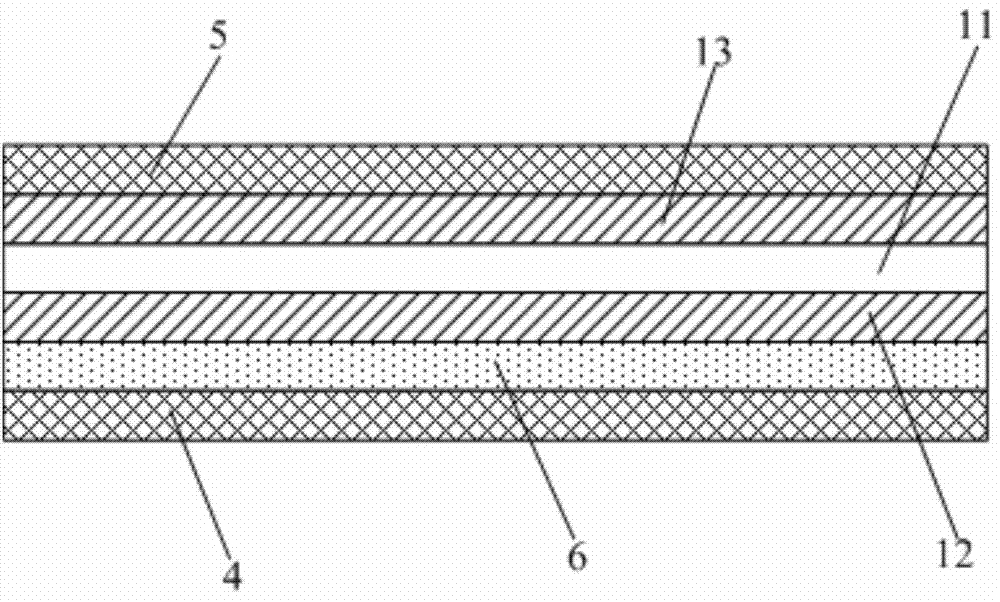

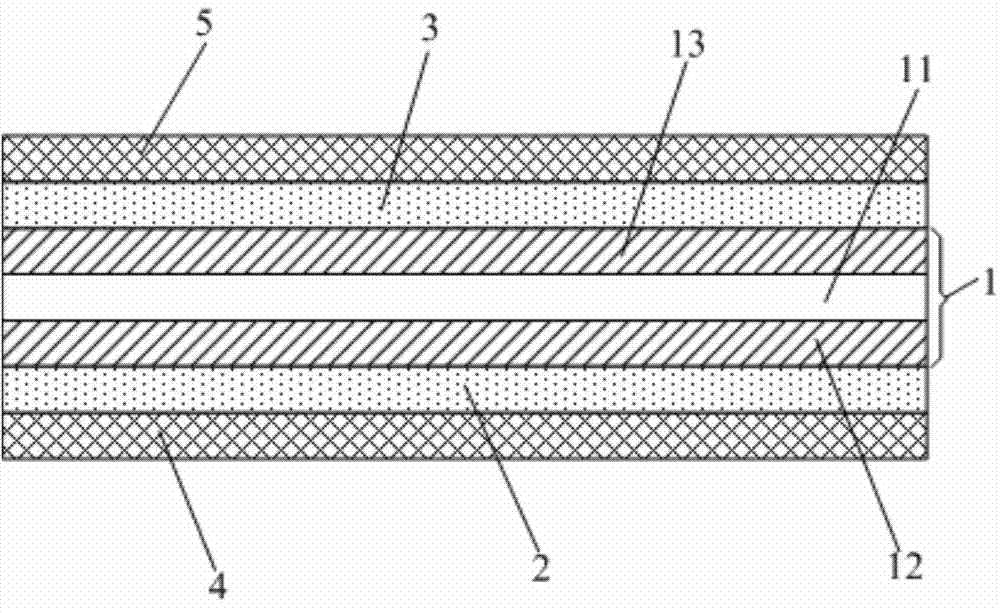

[0030] This embodiment provides a polarizer, such as figure 2 As shown, it includes a polarizing film layer 1 and a first adhesive layer 2 arranged on the lower surface of the polarizing film layer 1. The first adhesive layer 2 is used for bonding with the display substrate, and also includes a polarizing film layer 1 on the upper surface The second adhesive layer 3 and the second adhesive layer 3 are used for bonding with the first film layer.

[0031] Among them, the display substrate refers to the substrate formed after the array substrate and the color filter substrate are boxed together without a polarizer attached. The first film layer is a touch film layer (ie touch panel) or a protective film layer. The protective film layer can protect the display substrate.

[0032] The arrangement of the first adhesive layer 2 and the second adhesive layer 3 enables the polarizer to be attached to the display substrate and the first film layer on both sides of the polarizer easily, the...

Embodiment 2

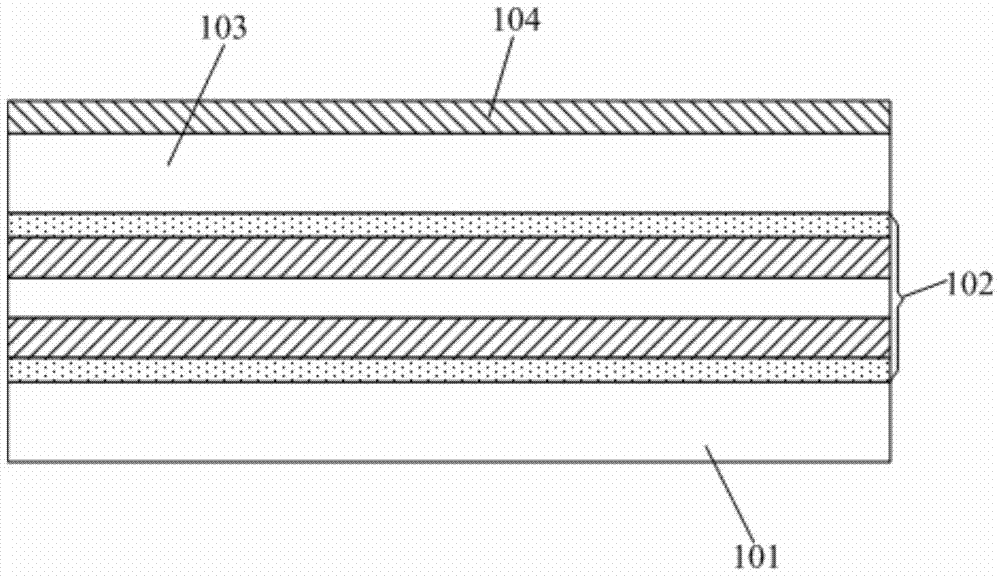

[0038] This embodiment provides a display panel, such as image 3 As shown, the display substrate 101 is included, and the polarizer 102 in embodiment 1 is also included. The polarizer 102 is attached to the light-emitting side of the display substrate 101, and the first polarizer 102 is attached to the side away from the display substrate 101. 膜层103。 Film layer 103.

[0039] Among them, the display substrate 101 refers to a substrate formed after the array substrate and the color filter substrate are assembled in a box without a polarizer attached. The first film layer 103 is a touch film layer (ie touch panel) or a protective film layer. The protective film layer can protect the light-emitting surface of the display substrate 101.

[0040] In this embodiment, a surface protection layer 104 is also attached to the side of the first film layer 103 away from the polarizer 102. The surface protection layer 104 can protect the first film layer 103 and prevent the first film layer 10...

Embodiment 3

[0050] This embodiment provides a display device, including the display panel in Embodiment 2.

[0051] By using the display panel in Embodiment 2, the manufacturing process of the display device is simplified, and the mass production efficiency of the display device is improved.

[0052] The display device provided by the present invention can be any product or component with a display function, such as a liquid crystal panel, a liquid crystal television, a display, a mobile phone, a navigator, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com