Forming method of chalcogenide glass aspherical lens

An aspheric lens, chalcogenide glass technology, applied in glass molding, glass production, glass pressing, etc., can solve the problems of large temperature change during molding cycle, influence of mold service life and accuracy, etc., to reduce the temperature change range, The effect of improving surface accuracy and surface roughness and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

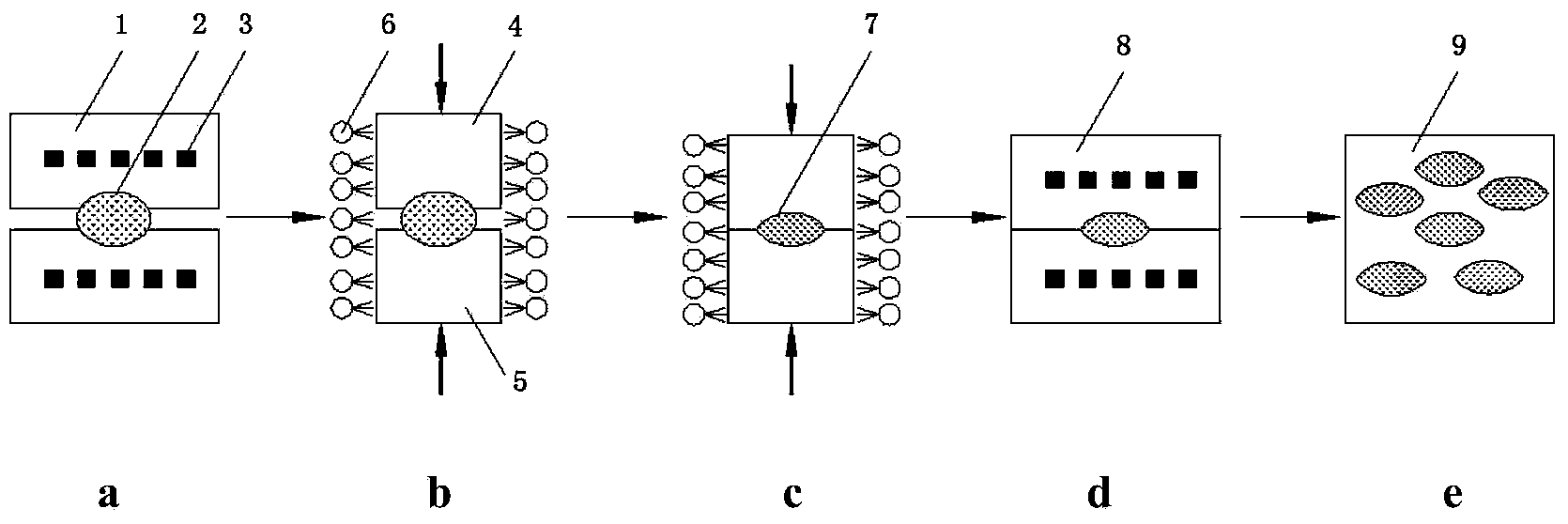

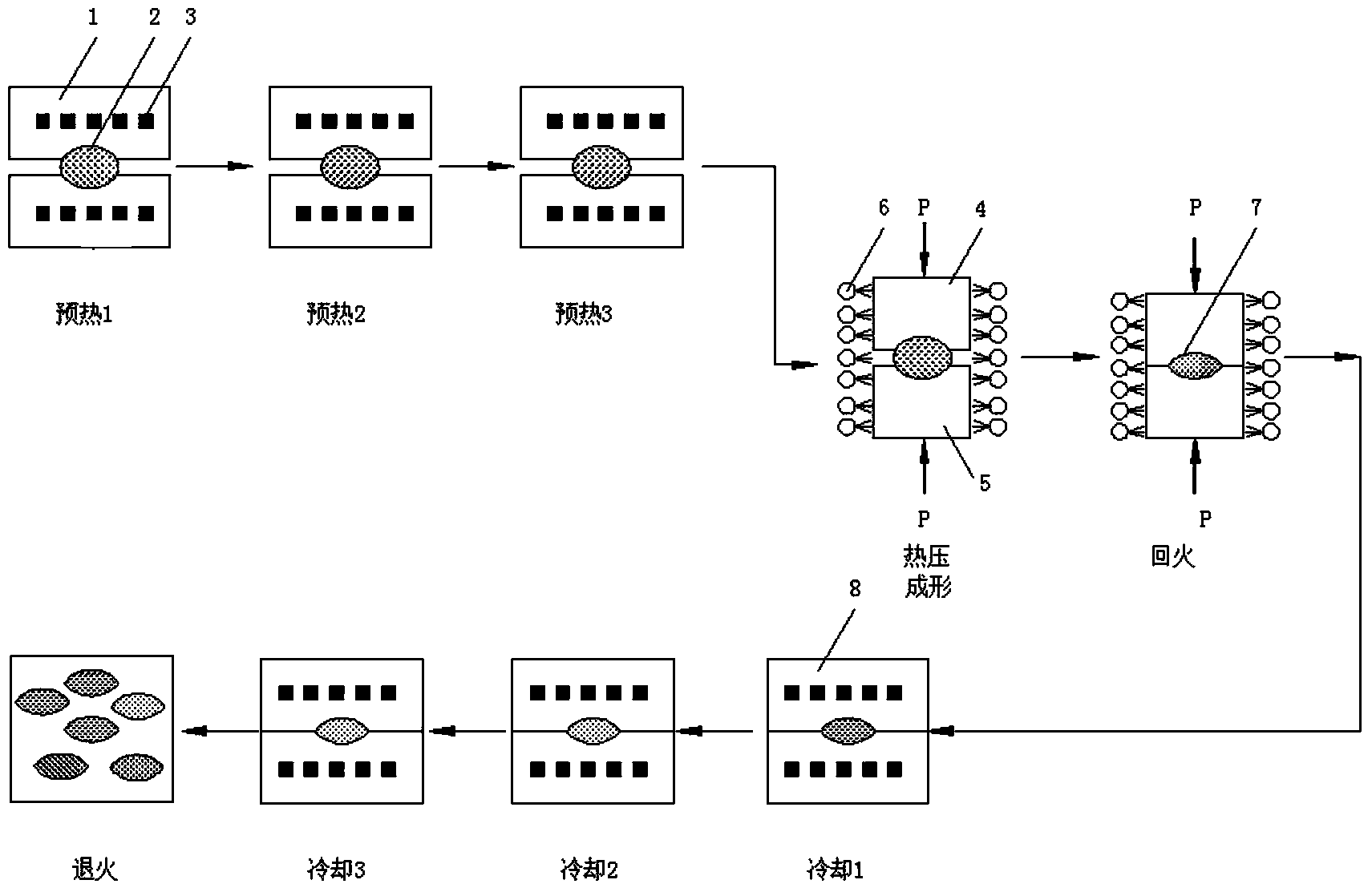

[0026] see figure 1 , 2 , the present embodiment chalcogenide glass aspherical lens forming method, the method steps are as follows:

[0027] a. The preform is preheated three times (preheating 1, preheating 2, preheating 3), the temperature of the preheating device (1) is controlled separately, and the chalcogenide glass preform (3) passes through the preheating device (1) three times Heating from 20° to a temperature T1 (about 340°), the temperature T1 is higher than the transformation temperature Tg (about 325°) of the material, and the temperature T1 is near the yield temperature At of the material. Preheating 1 heats the preform from 20° to 120°, preheating 2 heats the preform from 120° to 230°, preheating 3 heats the preform from 230° to 340°. Preheating 1, preheating 2, and preheating 3 have the same time, and each time is about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com