Flexible high-resolution infrared chalcogenide glass optical fiber image transmission bundle and manufacturing method

A technology of optical fiber image transmission bundle and chalcogenide glass, which is applied in the direction of glass manufacturing equipment, optical fiber bundles, manufacturing tools, etc., can solve problems such as the difficulty in preparing flexible image transmission bundles, and achieve simple and easy-to-control manufacturing processes, high resolution, Effect of reducing wire breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

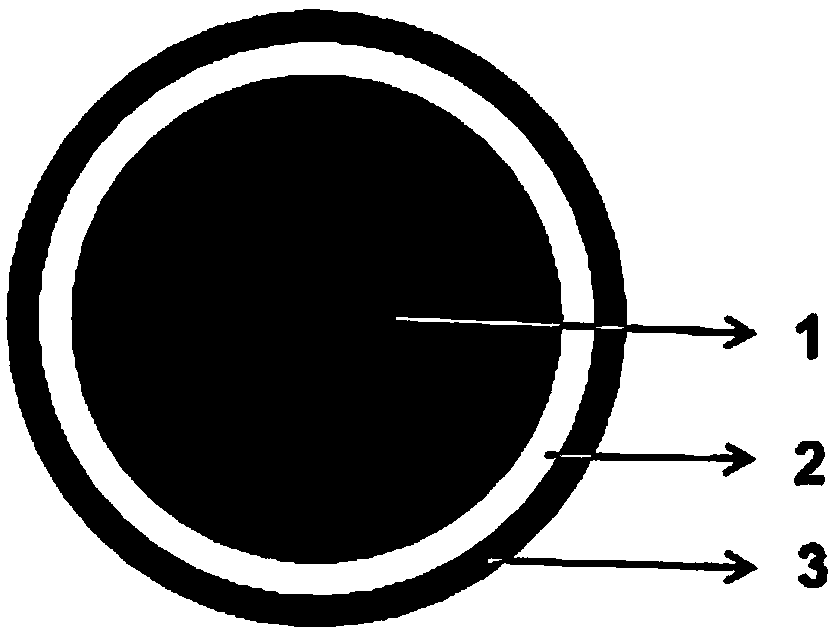

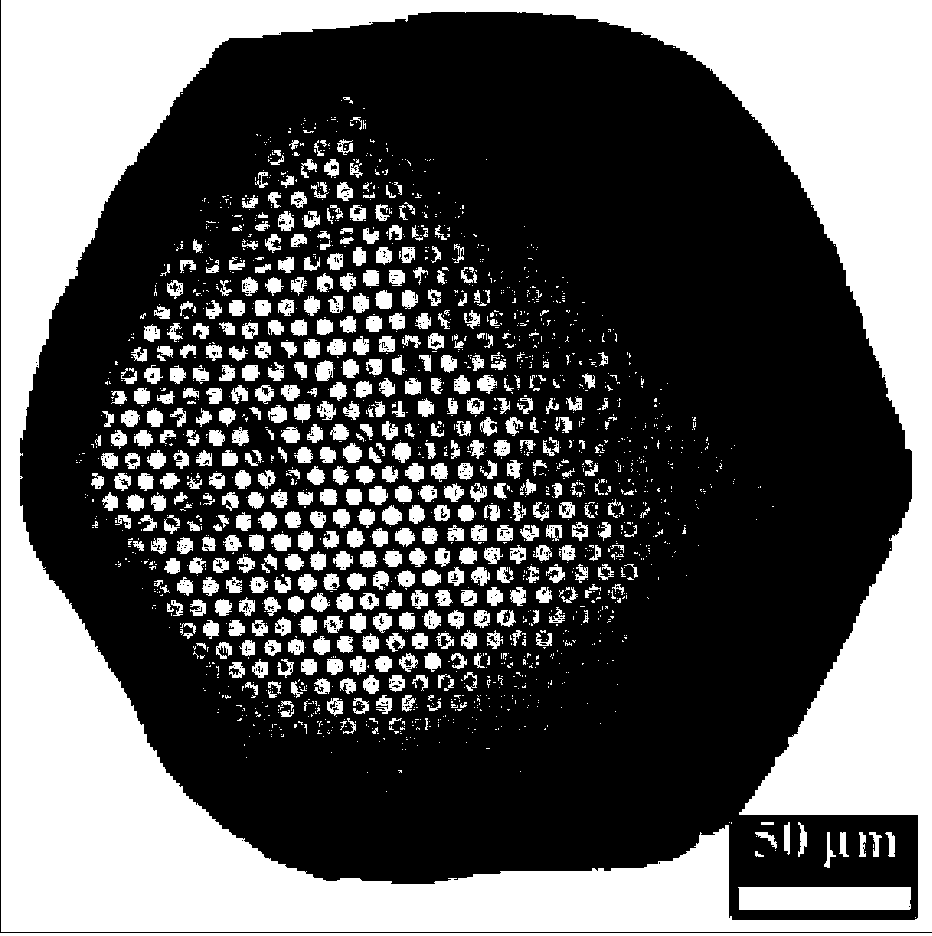

[0036] Embodiment 1: Preparation of high-resolution regular hexagonal As-S fiber optic bundle

[0037] (1) Preparation of optical fiber preform with three-layer coaxial structure

[0038] Separately prepare As by extrusion method 0.4 S 0.6 Chalcogenide glass core rod, As 0.38 S 0.62 Chalcogenide glass inner cladding casing and polyethersulfone resin outer cladding casing, the specific process is as follows:

[0039] The mixed raw materials of the chalcogenide glass core rod and the chalcogenide glass inner cladding sleeve were respectively placed in a vacuum quartz tube, the inner diameter and outer diameter of the quartz tube were 40mm and 44mm, respectively, and As 0.4 S 0.6 Chalcogenide glass rods and As 0.38 S 0.62 Chalcogenide glass rods. Will As 0.4 S 0.6 Chalcogenide glass rods and As 0.38 S 0.62 The chalcogenide glass rods were respectively put into the extruded rod and extruded pipe grinding tools of the extruder, and the chalcogenide glass core rod and th...

Embodiment 2

[0049] Embodiment 2: Preparation of high-resolution square Te-As-Se fiber optic bundle

[0050] (1) Preparation of optical fiber preform with three-layer coaxial structure:

[0051] Adopt the extrusion method described in embodiment 1 to prepare Te respectively 0.2 As 0.3 Se 0.5 Chalcogenide glass core rod, Te 0.16 As 0.30 Se 0.54 Chalcogenide glass inner-clad sleeve and polysulfone resin outer-clad sleeve, Te 0.2 As 0.3 Se 0.5 Chalcogenide glass mandrel diameter 16mm, Te 0.16 As 0.30 Se 0.54 The inner diameter and outer diameter of the chalcogenide glass inner cladding casing are 16.1mm and 19mm respectively, and the inner diameter and outer diameter of the polysulfone resin outer cladding casing are 19.1mm and 20mm respectively. Will Te 0.2 As 0.3 Se 0.5 Chalcogenide glass core rod, Te 0.16 As 0.30 Se 0.54 The chalcogenide glass inner cladding sleeve and the polysulfone resin outer cladding sleeve are assembled into a three-layer coaxial optical fiber prefab...

Embodiment 3

[0059] Example 3: Preparation of flexible high-resolution regular hexagonal Ge-Sb-Se fiber optic image bundle

[0060] (1) Preparation of optical fiber preform with three-layer coaxial structure:

[0061] Adopt the extrusion method described in embodiment 1 to prepare Ge respectively 0.13 Sb 0.17 Se 0.70 Chalcogenide glass core rod, Ge 0.15 Sb 0.15 Se 0.70 Chalcogenide Glass Inner Clad Sleeve and Polyetherimide Outer Clad Sleeve, Ge 0.13 Sb 0.17 Se 0.70 Chalcogenide glass mandrel diameter 16mm, Ge 0.15 Sb 0.15 Se 0.70 The inner diameter and outer diameter of the chalcogenide glass inner cladding sleeve are 16.1 mm and 19 mm, respectively, and the inner diameter and outer diameter of the polyetherimide outer cladding sleeve are 19.1 mm and 20 mm, respectively. Will Ge 0.13 Sb 0.17 Se 0.70 Chalcogenide glass core rod, Ge 0.15 Sb 0.15 Se 0.70 The chalcogenide glass inner cladding sleeve and the polyetherimide outer cladding sleeve are assembled into a three-layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com