Conducting shoe material and manufacturing method thereof

A manufacturing method and technology for conductive shoes, applied in footwear, applications, apparel, etc., can solve the problems of reduced material fluidity, monotonous product color, waste of raw materials, etc., to reduce usage, improve large-scale production efficiency, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1), the conductive shoe material is made of the following raw materials in parts by weight: polyvinyl chloride 25, auxiliary agent 66, composite conductive component 9 (parts by weight without stearic acid and coupling agent pretreatment, the following examples Same as this), wherein the composite conductive component is metal fiber and conductive carbon powder, and the mass ratio of the two is 2:8.

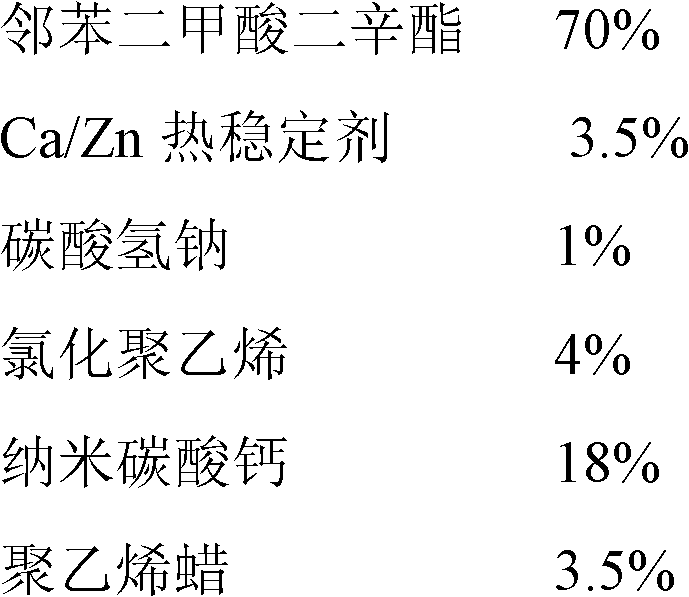

[0035] Wherein the percentage by weight of each component in the auxiliary agent is respectively:

[0036]

[0037] (2), the manufacturing method of conductive shoe material:

[0038] (1) Preprocessing:

[0039] A, stearic acid and coupling agent are added in the ethanol and obtain pretreatment solution by the weight ratio of 1:1;

[0040] B. Add the metal fiber and conductive carbon powder in the raw material to the above pretreatment solution and react at 70°C.

[0041] C. Put the reacted product into a vacuum drying oven to bake and dry to complete the pretreatme...

Embodiment 2

[0071] (1), the conductive shoe material is made of the following raw materials in parts by weight: polyvinyl chloride 60, auxiliary agent 20, composite conductive component 20, wherein the composite conductive component is conductive carbon fiber and conductive titanium dioxide, and the mass ratio of the two is 7: 3.

[0072] Wherein the percentage by weight of each component in the auxiliary agent is respectively:

[0073] Dioctyl phthalate 90%

[0074] Azodicarbonamide 5%

[0075] Ca / Zn heat stabilizer 5%

[0076] (1) Preprocessing:

[0077] A, stearic acid and coupling agent are added in the toluene by the weight ratio of 1: 2 and obtain pretreatment solution;

[0078] B. Add conductive carbon fiber and conductive titanium dioxide in the raw materials to the above pretreatment solution and reflux at 110°C;

[0079] C. Put the reacted product into a vacuum drying oven and bake it at 90° C. for 18 hours to complete the pretreatment.

[0080] (2) Mixing: Put the quantit...

Embodiment 3

[0083] (1), the conductive shoe material is made of the following raw materials in parts by weight: polyvinyl chloride 50, auxiliary agent 43, composite conductive component 7, wherein the composite conductive component is metal-plated fiber and conductive metal powder, and the mass ratio of the two is 5 : 5.

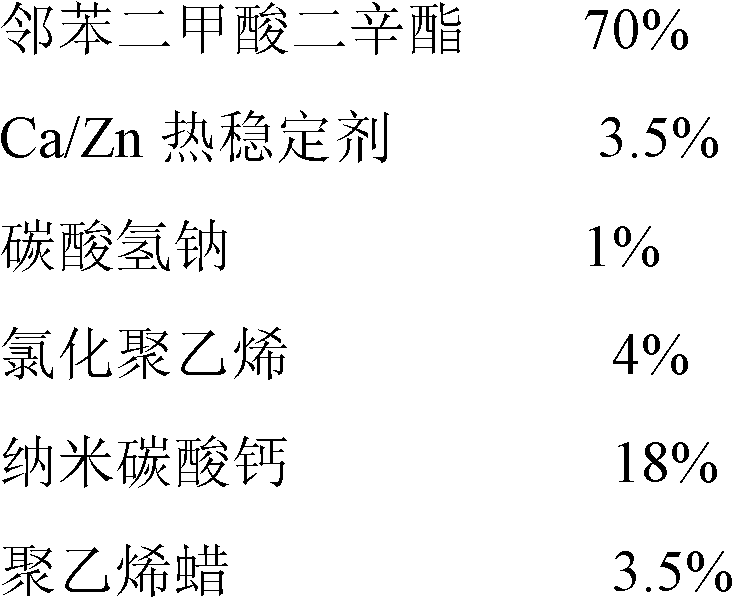

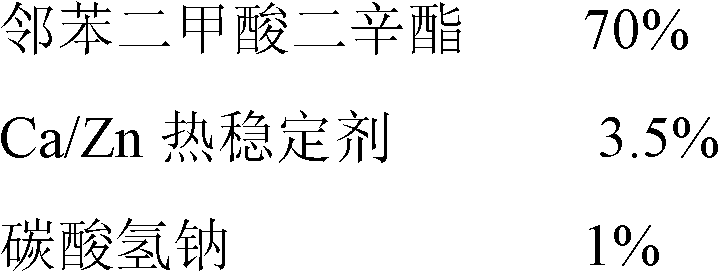

[0084] Wherein the percentage by weight of each component in the auxiliary agent is respectively:

[0085]

[0086] (2), the manufacturing method of conductive shoe material:

[0087] (1) Preprocessing:

[0088] A, stearic acid and coupling agent are added in chloroform by the weight ratio of 1: 2 and obtain pretreatment solution;

[0089] B. Add the metal-plated fiber and conductive metal powder in the raw material to the above-mentioned pretreatment solution and reflux at 60°C;

[0090] C. Put the reacted product into a vacuum oven and bake at 90°C for 18 hours.

[0091] (2) Mixing: Put the quantitatively proportioned raw materials into a high-speed mixer in ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com