Touch screen panel and method for manufacturing same

A technology of touch screen and panel, which is applied in the direction of instruments, electrical digital data processing, and input/output process of data processing, etc. It can solve the problems of large reflection on the surface of the touch screen, affecting visual effects, and low transmittance, so as to save etching and tempering Equal costs, improved safety, and good explosion-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

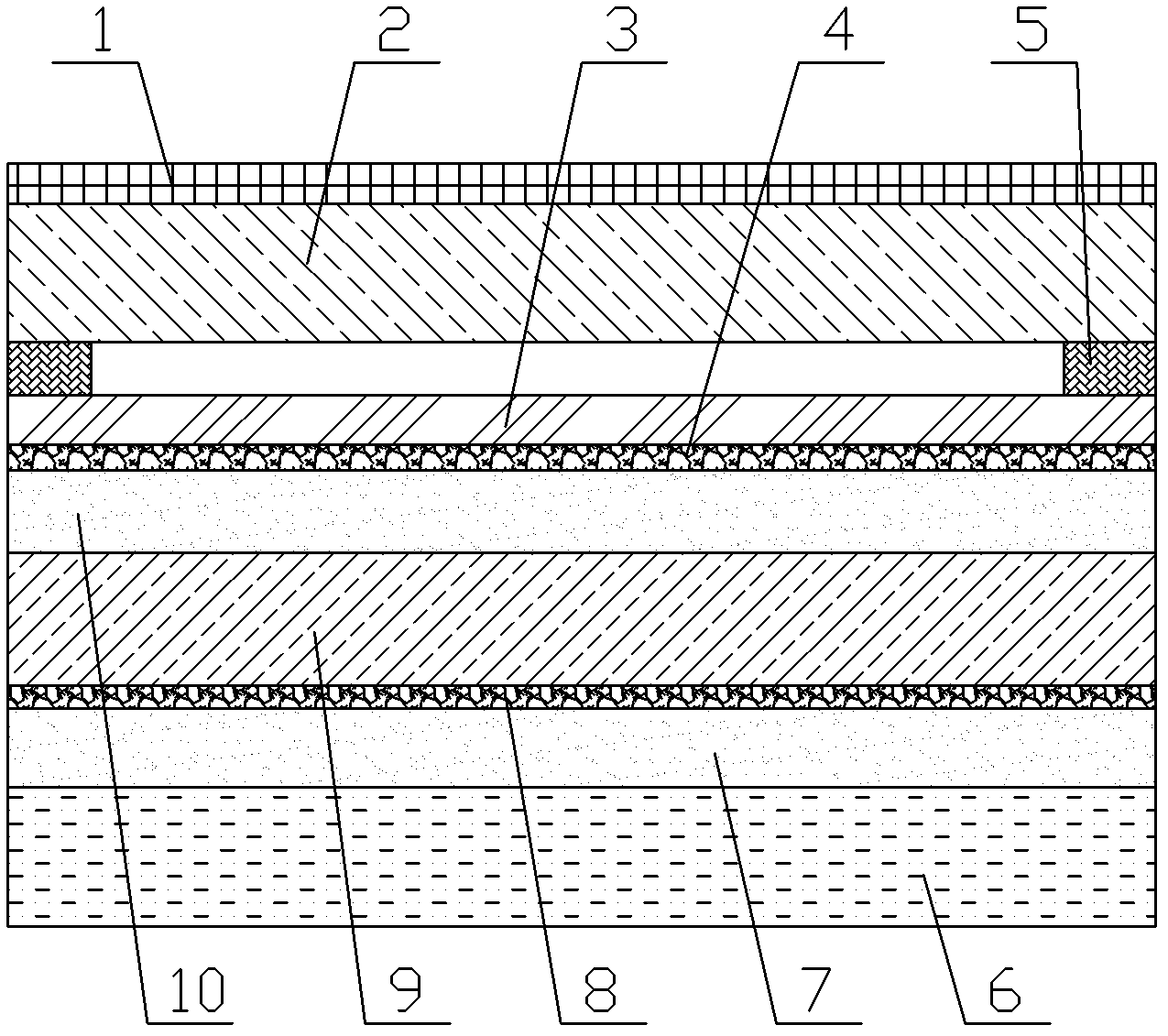

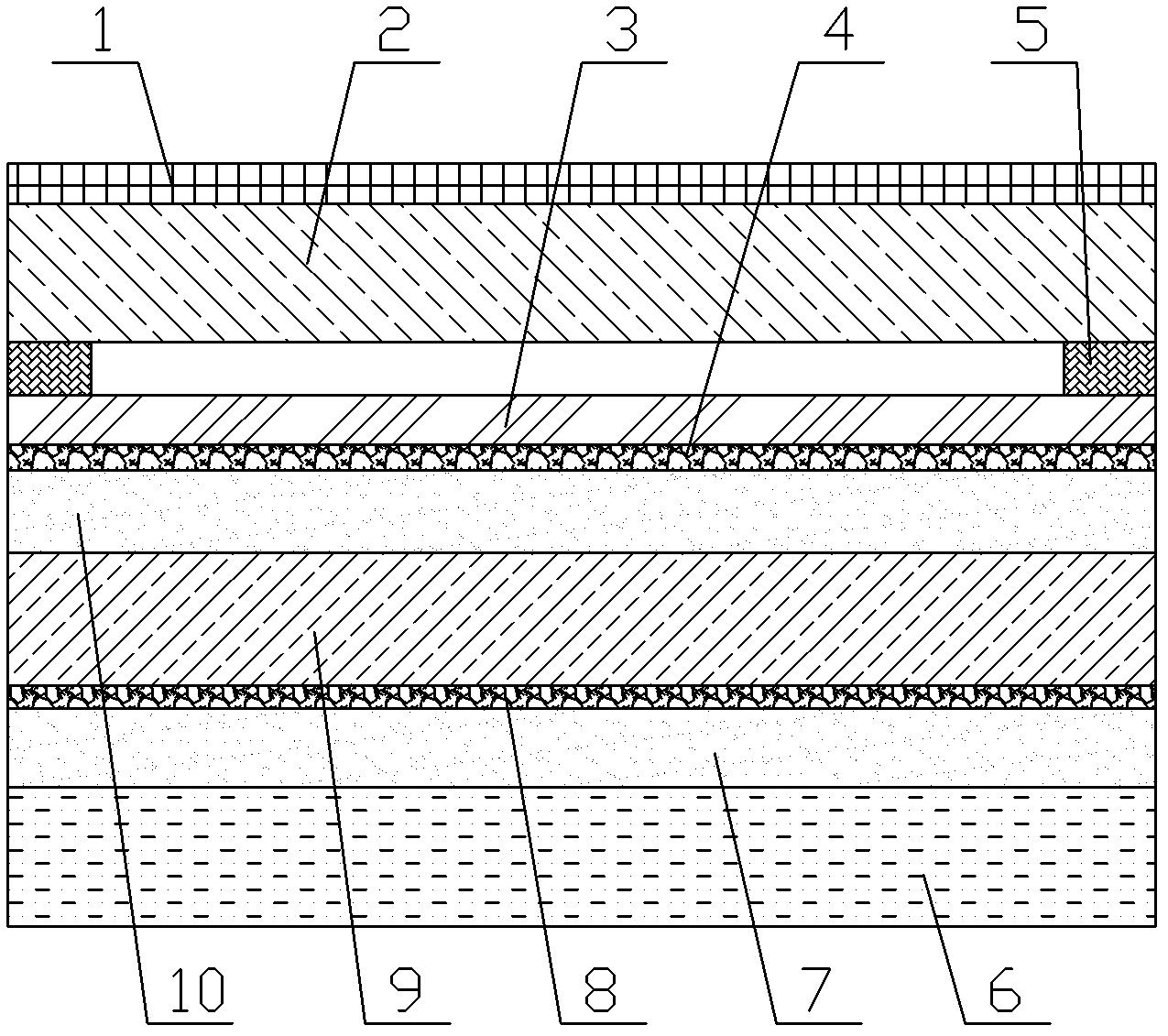

[0028] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0029] see figure 1 , a touch screen panel comprising a polyethylene terephthalate sheet assembly and a glass cover assembly;

[0030] The polyethylene terephthalate sheet assembly includes a polyethylene terephthalate sheet 9, and a lower electrode 8 is formed on the lower surface of the polyethylene terephthalate sheet 9;

[0031] The glass cover plate assembly includes a glass cover plate 2, an anti-fingerprint film 1 is coated on the upper surface of the glass cover plate 2, and ink window windows 5 are printed around the lower surface of the glass cover plate 2, and on the lower surface of the glass cover plate 2 An anti-reflection layer 3 is coated, and an upper electrode 4 is formed on the lower surface of the anti-reflection layer 3;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com