Method for quickly detecting thickness of lower surface of blade in high-temperature thermal state

A blade and size technology is applied in the field of rapid detection of the thickness and size of the profile under the high temperature and thermal state of the blade, which can solve the problems of low detection efficiency, and achieve the effect of reducing detection time, convenient detection process, and safe and reliable detection environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, specifically describe the detection process of the inventive method:

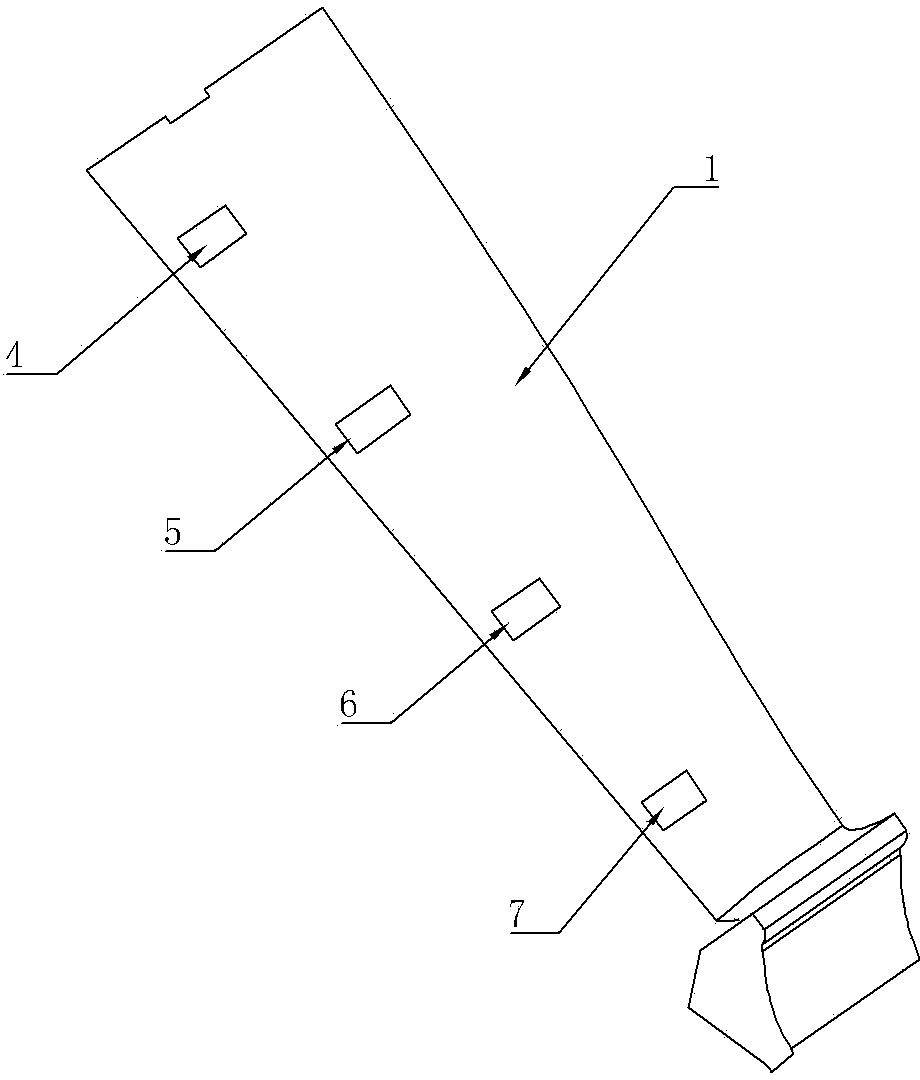

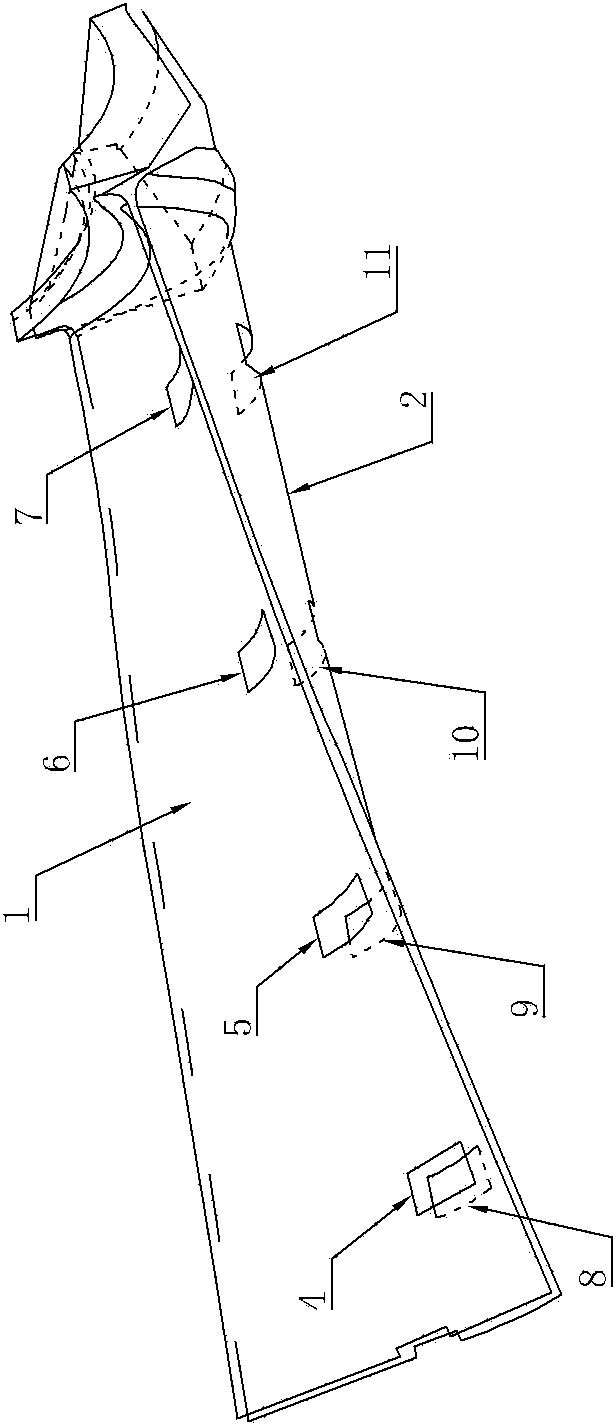

[0012] See figure 1 and figure 2 , according to the shape of the blade to be tested, respectively make the inner arc surface floating detection template 1 and the back arc surface floating detection template 2 that match the inner arc surface and the back arc surface of the blade to be tested, and according to the thickness dimension of the profile surface to be detected on the detection blade The position of the floating detection template on the inner arc surface and the floating detection template on the back arc surface are respectively cut to open the detection area holes 4, 5, 6, 7, 8, 9, 10, 11, and then the floating detection template 1 on the inner arc surface Floating detection template 2 with the back arc surface and the blade 3 to be detected (the blade 3 to be detected is in figure 1 , figure 2 not shown in ), the inner arc surface and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com