Air sealing body with air inlets capable of being opened quickly

A technology of air sealing body and air inlet, which is applied in the direction of preventing mechanical damage, container, transportation and packaging, etc. It can solve the problems that hinder the mass production efficiency of inflatable structures, increase the manufacturing process, and increase the manufacturing cost of packaging materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

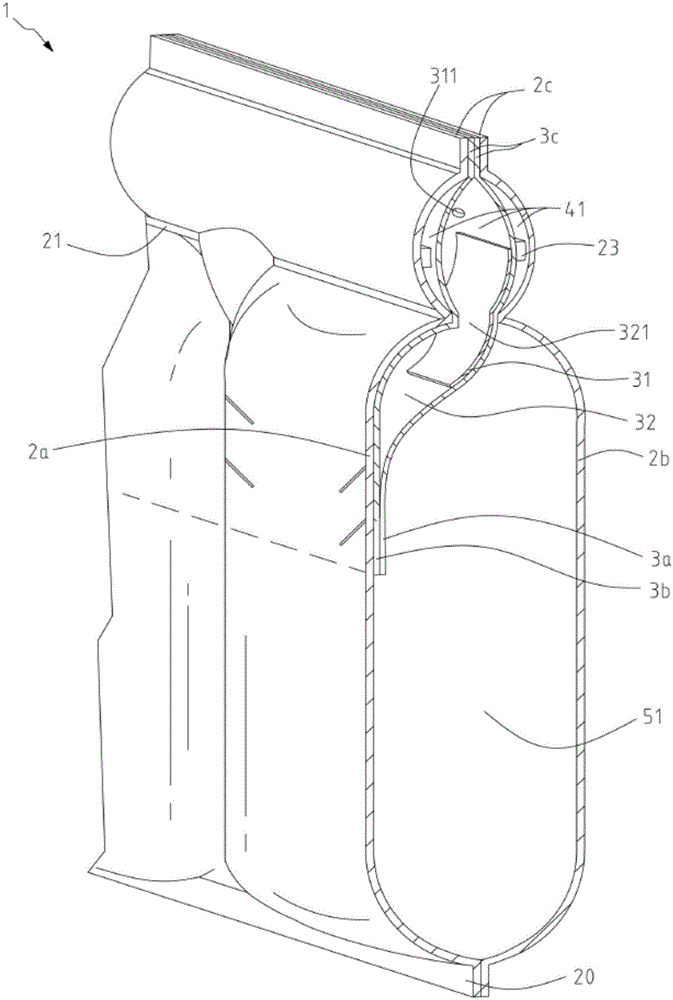

[0073] The air sealing body of the quick opening air inlet of the present invention uses air to quickly fill to form a cushioning and shockproof structure, which can automatically open the drainage channel and automatically lock the drainage channel after inflation. The air sealing body of the quick opening air inlet can be a single row Columnar shape, or can be bent to form a containing space, which is used to provide cushioning and shockproof structure for objects.

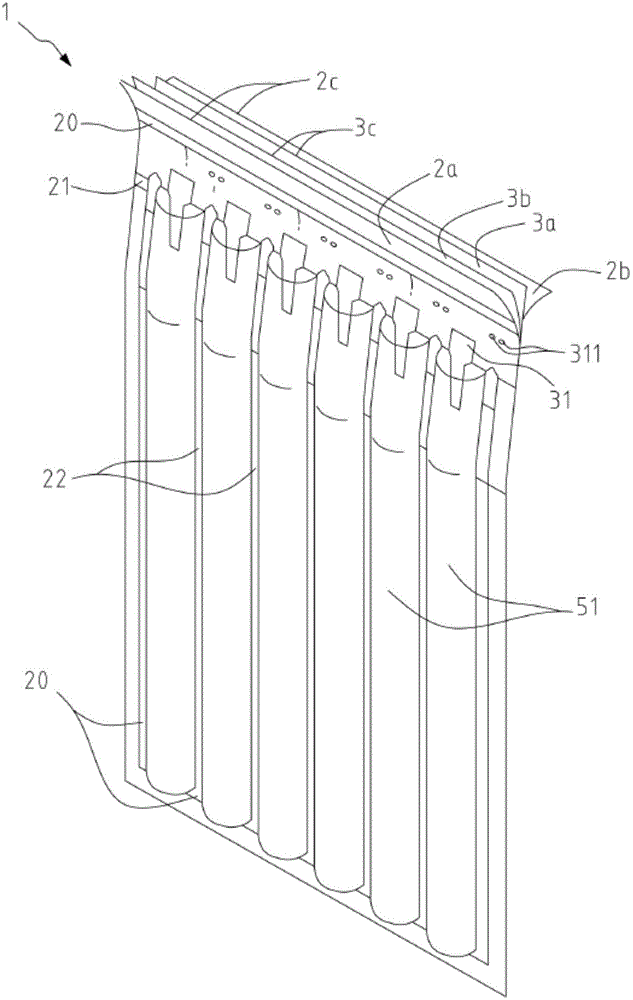

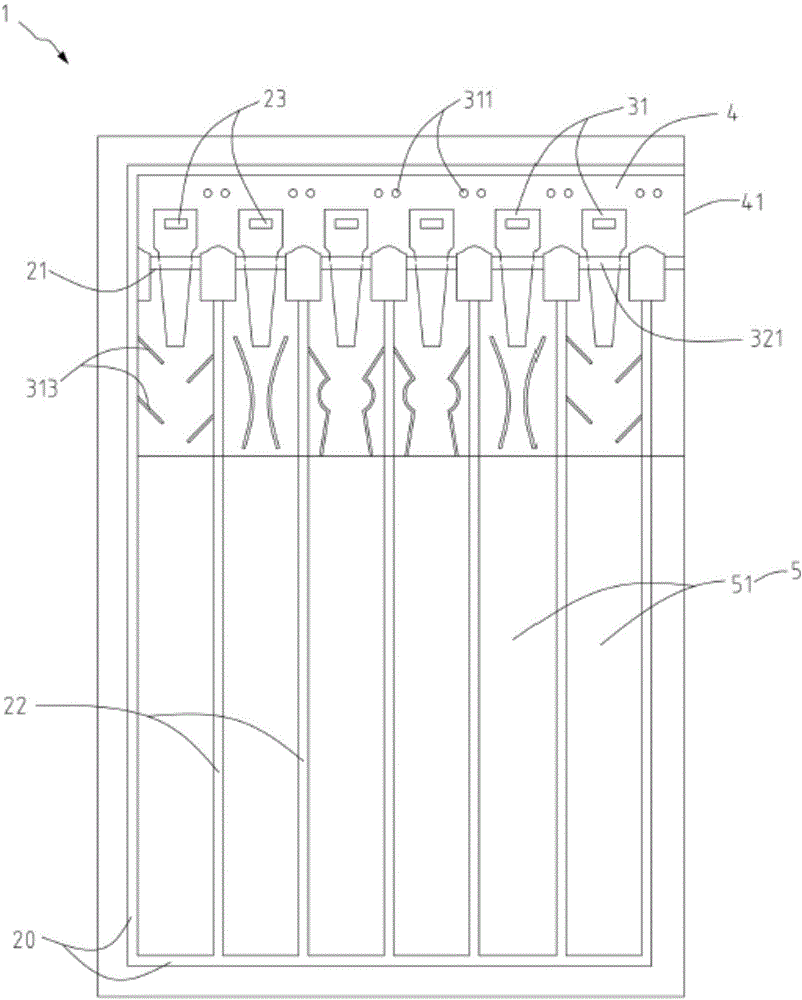

[0074] see Figure 1 to Figure 3 It is one of the preferred embodiments of the air-tight body 1 of the present invention. In this embodiment, the air-tight body 1 of the present invention is a single row of columns, which includes two outer membranes 2a, 2b and two inner membranes 3a, 3b, They can be transparent or opaque respectively. The two outer films 2a and 2b are arranged correspondingly and have the same size. A heat-sealed edge 20 is respectively arranged around them, and they are joined together by mean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com