Construction method of existing railway tunnel overhaul polyurethane plugging agent high-pressure grouting

It is an existing railway and high-pressure grouting technology, which is applied to tunnels, tunnel linings, shaft linings, etc. It can solve the problems of reduced lining strength, tunnel structure cracks, impact on building structure durability, and hidden dangers of driving safety, so as to save product usage, The effect of shortening the construction period and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

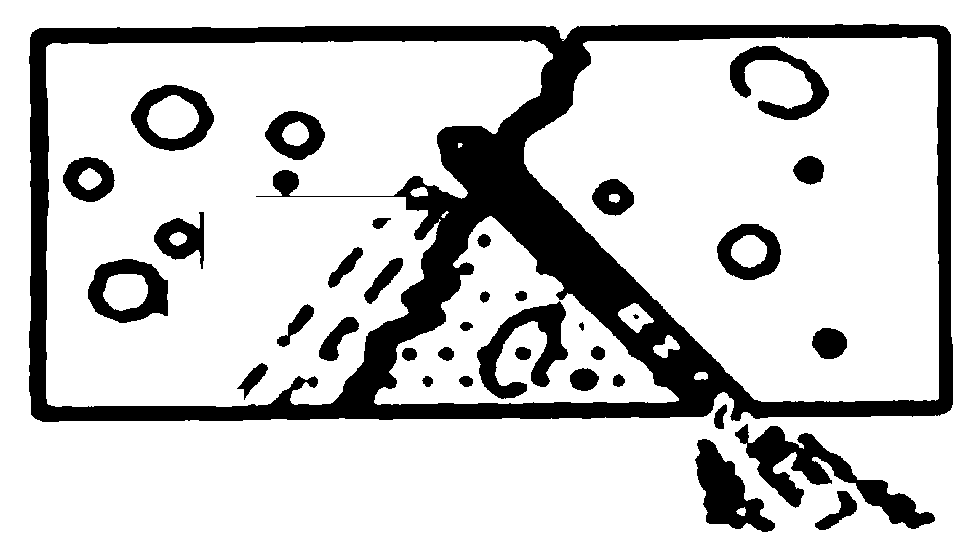

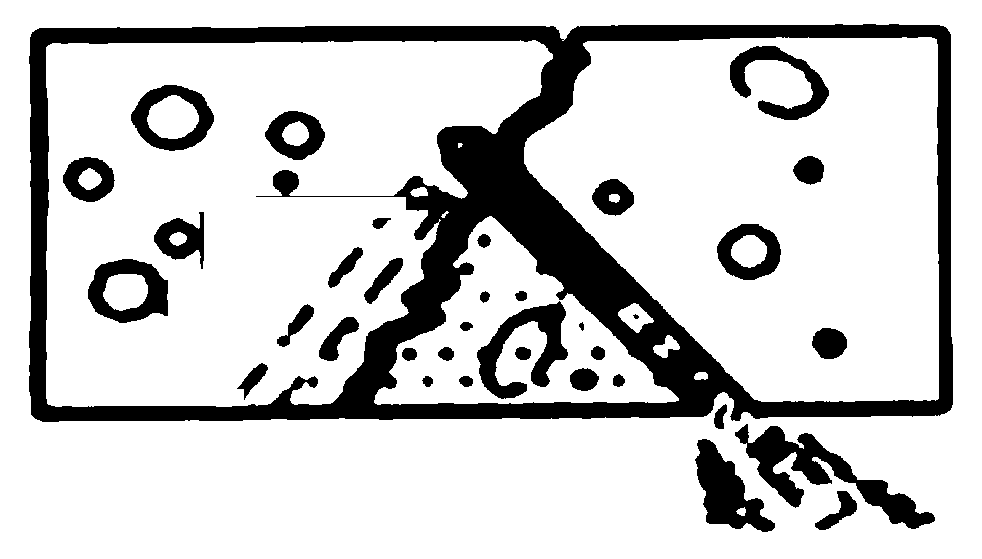

[0016] Such as figure 1 As shown, a method of high-pressure grouting with polyurethane plugging agent for the overhaul of existing railway tunnels, the steps are as follows: 1) Surface cleaning: clean the construction area, chisel and remove precipitates on the concrete surface to ensure that the surface is clean;

[0017] 2) Drilling: Use a drill bit to drill pressure relief holes around the hole, the drill bit diameter is 12mm, the drill bit angle is less than or equal to 45°, the drilling depth is less than or equal to two-thirds of the thickness of the structure, and the distance from the crack is 50-150mm, along the two sides of the crack direction Drill holes crosswise and dislocation in layers;

[0018] 3) Embedding needles: Observe the pressure of the main leakage hole. When the water flow is not urgent and the pressure is not high, the quick-drying leak plugging agent can be used to bury the grouting water-stop needles; Tighten with a special inner hexagonal wrench, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com